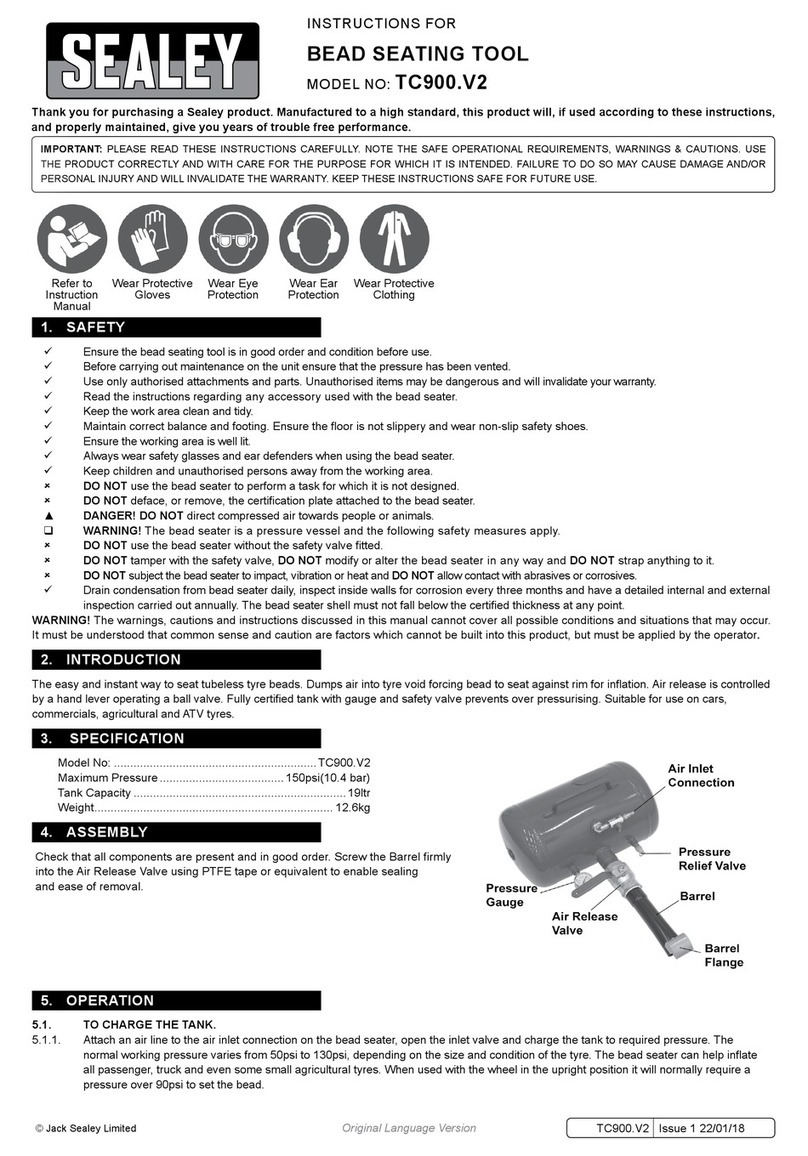

5. OPERATION

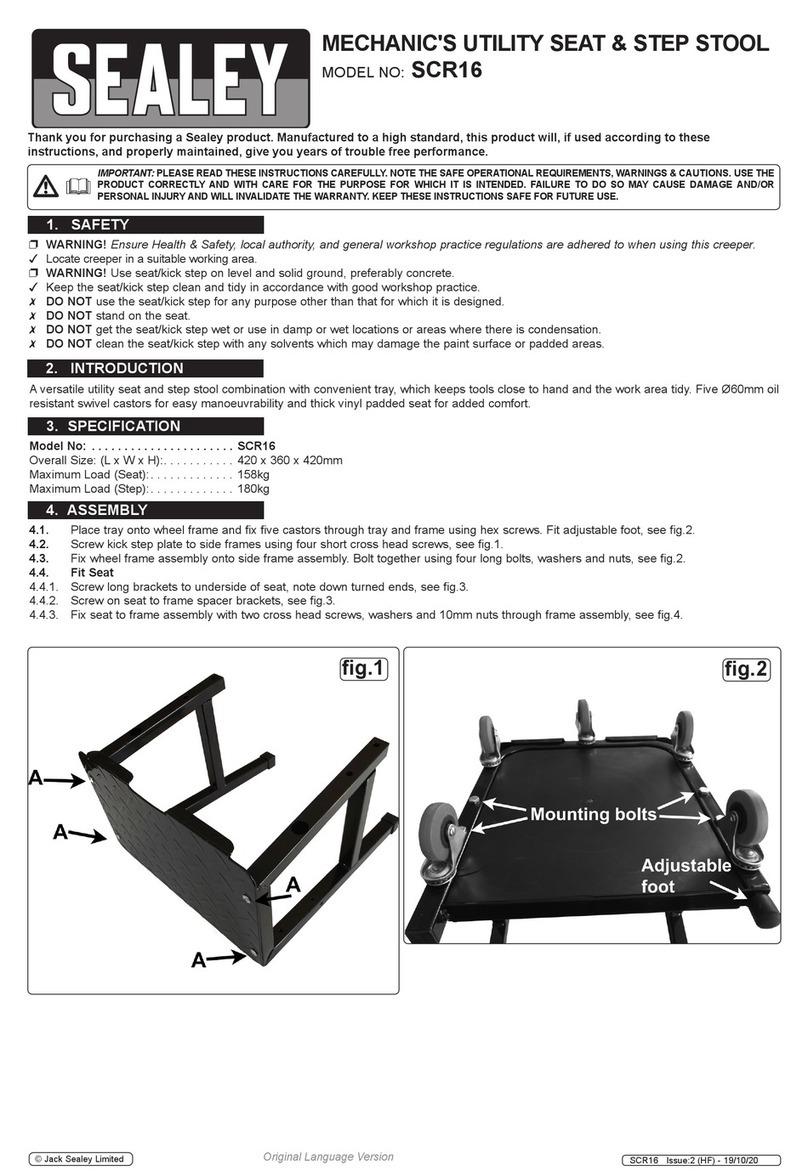

Numberswithinthebracketsrefertoitemsing.1

5.1. NOTE: To minimise the possibility of damage to the engine, it is advisable to remove the cylinder head from the engine to work on it.

Alternatively, remove the relevant injector and connect an air line via an appropriate adaptor to the aperture to ensure dirt and swarf do

not enter the combustion chamber as the procedure is carried out. Wear eye protection.

5.2. PushtStarSocket(6)ontothetopoftheglowplug;itmayneedtobetappedonlightly.Then,usinga⅜”ratchet,remove/breakoff

the top part of the glow plug.

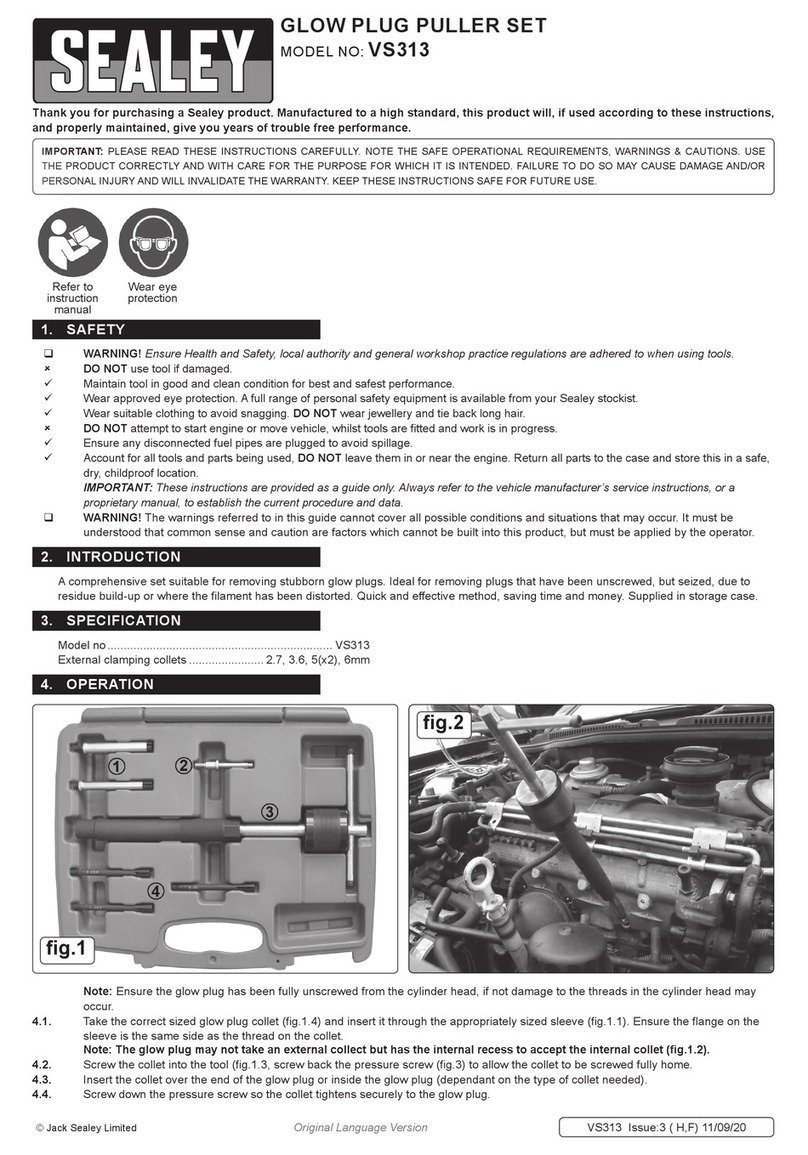

(Seeg.2)InsertCentringSleeve(4)intotherecessinthetopoftheglowplug.FitPilotDrill(10)toanelectricdrillandinsertpilot

drill into centering sleeve, drill a pilot hole in the centre of the glow plug remains. Ensure that pilot drilling is at least 15mm deep. Clean

away the swarf using an air line. Note: If the electrode can be withdrawn in one piece, the aperture created may be used as a pilot.

If this is the case, proceed to 5.4.

5.3. Fit either 7mm (7) or 9mm (8) Drill Bit into the Drill Holding Adaptor (2) and lock in place with the grub screw, using the hex key (5).

Makesurethatthegrubscrewbearsontheat,machinedintotheshankofthedrillbit.Carefullydrilloutthecentreoftheglowplug

and threaded portion of glow plug body. Take care not to damage the female threads in the cylinder head.

Clean out the swarf using an air line.

5.4. Fit the ¼” tap provided into the ratchet T-bar. Cut a thread with this in the remains of the glow plug body, cutting at least 15mm of

thread.

5.5. Screw a Puller Adaptor Mandrel (3) into the thread that has just been cut into the glow plug. Remove the nut from the force screw in

the Puller Housing (1) and thread the force screw onto the mandrel. Slide the outer sleeve of the puller housing over the force screw.

5.6. Re-tthenuttotheforcescrewwiththecollarfacingtheoutersleeve.Holdtheheadoftheforcescrewwitha12mmwrenchorsocket

and wind the nut down using a 30mm wrench.This will draw the remaining lower part of the glow plug free from the cylinder head.

5.7. Fit either M8 (12) or M10 (11) Tap into Ratchet T-Bar (9). Run the tap down to clean/restore the threads in the cylinder head. An

application of grease to the tap will both lubricate and help contain the swarf.

5.8. Clean thoroughly the thread and surrounding area and make sure that the combustion chamber (if head is in-situ) is free from debris

beforettingareplacementglowplug.

5.9. Ensure all tools are removed from the engine bay and returned to the tool tray, and store this in a safe, dry, childproof location.

g.2

© Jack Sealey Limited Original Language Version

Sealey Group, Kempson Way, Suffolk Business Park, Bury St Edmunds, Suffolk. IP32 7AR

01284 757500 sales@sealey.co.uk www.sealey.co.uk

SX0408.V2 Issue: 2 (H,F) 27/07/23

Note: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior

notice. Please note that other versions of this product are available. If you require documentation for alternative versions, please email or call

our technical team on technical@sealey.co.uk or 01284 757505.

Important: No Liability is accepted for incorrect use of this product.

Warranty: Guarantee is 12 months from purchase date, proof of which is required for any claim.

ENVIRONMENT PROTECTION

Recycle unwanted materials instead of disposing of them as waste.All tools, accessories and packaging should be sorted,

taken to a recycling centre and disposed of in a manner which is compatible with the environment. When the product

becomes completely unserviceable and requires disposal, drain any fluids (if applicable) into approved containers and

dispose of the product and fluids according to local regulations.

REGISTER YOUR

PURCHASE HERE

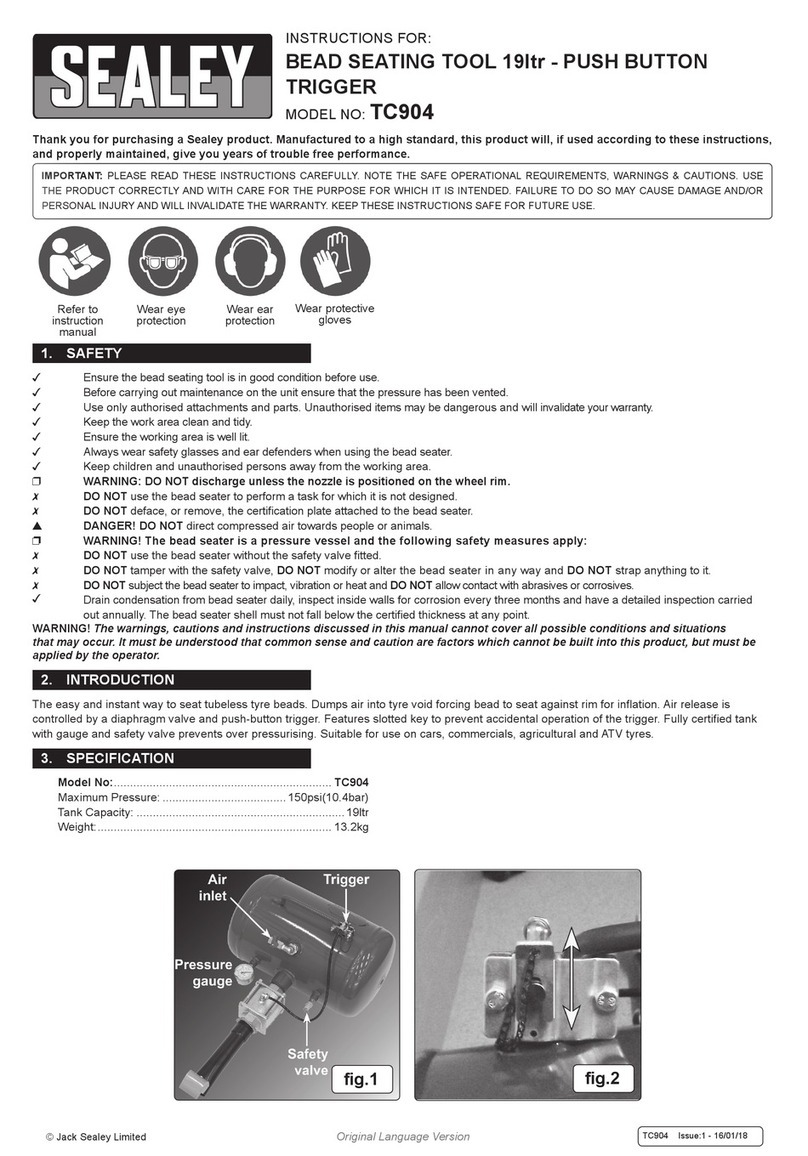

Glow plug with electrode

withdrawn

Glow plug

construction