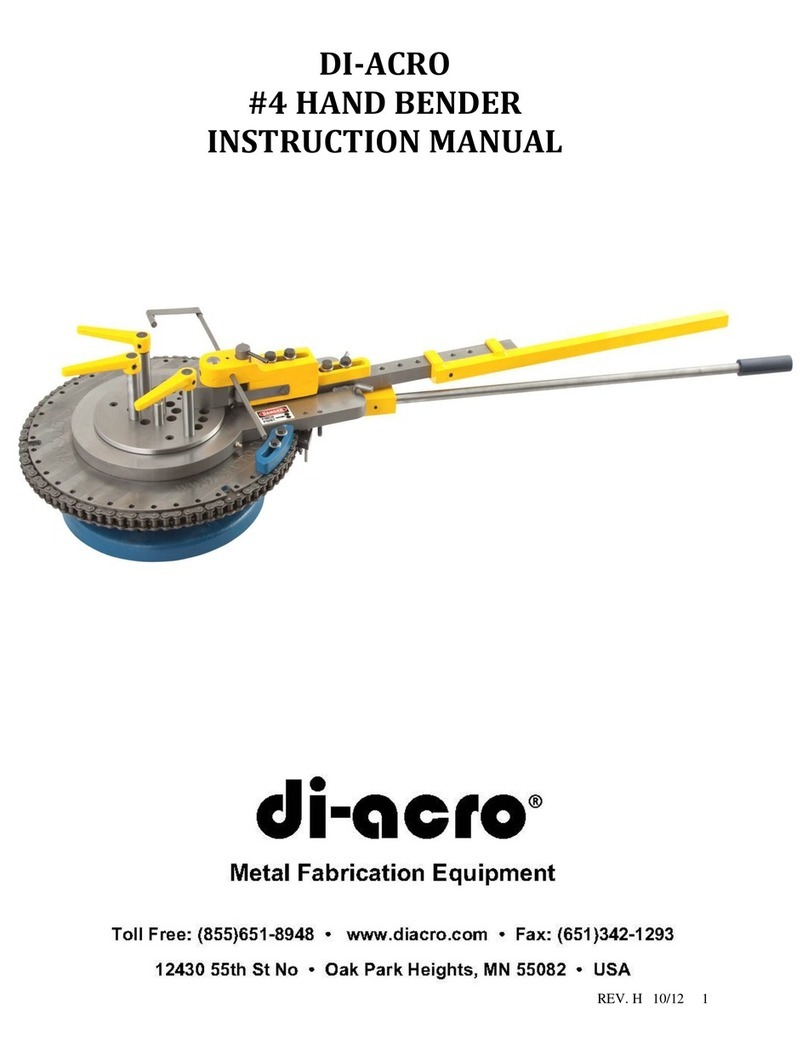

Di-Acro 2 TAB Guide

12430 55th St N · Oak Park Heights, MN 55082

Phone: 651.342.1756 · Fax: 651.342.1293

Email: info@diacro.com

© Copyright 2014 REV. 9-MAY-2014

2

SAFETY INFORMATION PG. 3

TECHNICAL DATA PG. 3

SET-UP PROCEDURE PG. 4-6

MAINTENANCE & BLADE SHARPENING PG. 7

#2 TAB NOTCHER BREAKDOWN AND PARTS LIST PG. 8-10

OPTIONAL STAND PG. 11

WARRANTY PG. 12

© Copyright 2014 REV. 9-MAY-2014

3

Before Notcher is set up for operation, mount on work bench or

stand.

*IF NOTCHER IS MOUNTED ON ITS OWN STAND, SECURE

STAND TO FLOOR.

SPECIFICATIONS

Model #2 Tab Notcher in. mm

Max. 90° Notch 6 x 6 152 x 152

Max. Tab 1 25.4

Max Material Cap. m.s. 16 ga. 1.5

Tonnage 4 3.6

Stroke of Ram 5/8 16.9

Shipping Weight 265 lbs. 120 kg.

© Copyright 2014 REV. 9-MAY-2014

4

CHANGING SIZE OF TAB:

1. Loosen bolts (A) holding lower blade to blade carrier (DO NOT REMOVE).

2. Slide blades forward or back, holding them against shoulder machined in

blade carrier to obtain desired tab.

3. Tighten bolts (A).

4. Loosen bolts (B).

5. Lower ram until upper blades pass by lower blades (it may be necessary

to slide one upper blade back).

6. Slide blade (C) forward into notch in lower blade. Tighten bolts.

7. Slide blade (D) forward until it contacts blade (C). Tighten bolts.

Note: A slight opening at (H) is normal to insure contact at cutting edge.

© Copyright 2014 REV. 9-MAY-2014

5

SETTING SIZE OF NOTCH:

1. Loosen screws (G) and set to required notch depth, reading scale along

edge (E).

Note: Scale is set to read from the edge of the notch so tab size must be

subtracted to obtain a corner notch of equal depth.

2. To notch along the side of a sheet, remove gauges and turn them upside

down. Screws will fit in outside slot when gauges are set parallel to each

other.

SHEARING LONG STRIPS FULL WIDTH:

Remove lower left blade and adjust right blade to maximum tab size.

SETTING DEPTH OF STROKE:

Adjust screw on cam until upper blade passes slightly by lower blade at

bottom of stroke.

© Copyright 2014 REV. 9-MAY-2014

6

ADJUSTING BLADE CLEARANCE:

1. Remove table.

2. Loosen blade mounting bolts (A) and (B).

3. Loosen blade carrier bolts (J).

4. Adjust lower blades to required tab (per instructions, B “changing size of

tab” 1, 2 and 3).

5. Set upper blades for no tab smaller than set in lower blades.

6. Back off screws (K) and pull blade carrier away from top blade.

7. Move ram to bottom of stroke.

8. Turn in screws (K) by hand pushing blade in until it contacts upper blade.

Placing a shim or piece of paper between blades will provide clearance to

prevent rubbing of blades. Too much clearance will cause a burr on work

piece. Excessive rubbing of blade will reduce blade life.

9. Tighten bolts (J).

10. Set upper blade to tab notch in lower blade and tighten.

ADJUST RAM CLEARANCE:

1. Remove ram cap (M) and remove a shim from both sides. Color of shim

indicates the thickness: Purple .0015; Red .002; Green .003; Blue .005.

2. Replace cap (M).

© Copyright 2014 REV. 9-MAY-2014

7

Lubricate cam roller and ram occasionally with a few drops of heavy

machine oil.

SHARPENING BLADES:

1. Blades have two cutting edges. A new cutting edge is obtained by

changing right blade to the left side and vice versa.

2. If only a slight amount of sharpening is required, grind wide edge only, as

this will eliminate necessity of resetting clearance.

3. When grinding ends, be sure to maintain angle presently on blade.

4. Reset scale to zero, lining up zero on scale with straight edge along blade

cutting edge.

© Copyright 2014 REV. 9-MAY-2014

8

© Copyright 2014 REV. 9-MAY-2014

9

ITEM

PART NUMBER

DESCRIPTION

QTY

1

8905350-000

T-NUT

4

2

8031110-101

BLADE CARRIER

1

3

21A0308C1102

SCREW-HHCS 3/8-16X1-1/2

4

4

61X0308

WASHER-3/8

4

4A

0102WILLIAMS WASHER

WASHER-1/2 WILLIAMS (NOT

SHOWN GOES UNDER 3/8

WASHER)

4

5

8031160-101

RULE

2

6

20C0104C0508

SCREW-FHSCS 1/4-20X5/8

3

7

8000110-501

TABLE

1

8

8031140-571

PROTRACTOR GAUGE-LH

1

8

8031140-572

PROTRACTOR GAUGE-RH

1

9

20B0X06C0108

SCREW-BHSCS #6-32X1/8

4

10

21A0104C0308

SCREW-HHCS 1/4-20X3/8

4

11

61X0104

WASHER-FLAT 1/4

4

12

8031120-901

LOWER BLADE

2

13

20C0516C2000

SCREW-FHSCS 5/16-18X2

4

14

8031120-900

UPPER BLADE

2

15

8031121-300

RAM WELDMENT

1

16

21A0516C1308

SCREW-HHCS 5/16-18X1-3/8

4

17

61X0516

WASHER-FLAT 5/16

4

18

20A0516C1102

SCREW-SHCS 5/16-18X1-1/2

4

19

8031110-609

GUARD WLDMT

1

20

21A0516C0102

SCREW-HHCS 5/16-18X1/2

4

21

61X0516

WASHER-FLAT 5/16

4

22

18A0516X1102

PIN-DOWEL 5/16X1-1/2

4

23

8040110-800

CAP

1

24

8690100-200

DRIVE FITTING

1

25

8470510-100

RETAINING RING

4

26

8060120-300

CAM ROLLER PIN

1

27

20B0516C0508

SCREW-BHSCS 5/16-18X5/8

1

28

8030120-800

LONG HANDLE ARM

1

29

8030120-302

CAM PIN

1

30

23C0516C2000

SCREW-SQHSS 5/16-18X2

1

31

31X0516C

NUT-JAM 5/16-18

1

32

8156111-300

ROLLER

1

33

8030120-200

CAM

1

34

8310410-100

BEARING

1

© Copyright 2014 REV. 9-MAY-2014

10

ITEM

PART NUMBER

DESCRIPTION

QTY

35

8030570-101

SHIM .0015” - PURPLE

VARIES

36

8930570-101

SHIM .0020” - RED

VARIES

37

8940570-101

SHIM .0030” - GREEN

VARIES

38

8030570-102

SHIM .0050” - BLUE

VARIES

39

8040110-200

UPPER CASTING

1

40

20A0102C1304

SCREW-SHCS 1/2-13X1-3/4

4

42

8150650-110

NAMEPLATE

1

45

030-6503001

CAUTION TAG

1

47

8031110-100

BASE

1

48

21A0308C1000

SCREW-HHCS 3/8-16X1

4

49

31X0308C

NUT-JAM 3/8-16

4

50

031-1105011

BACKUP PLATE

4

51

21A0308C1104

SCREW-HHCS 3/8-16X1-1/4

4

52

19A0108X0102

PIN-DOWEL 1/8X1/2

4

53

8030120-801

HANDLE GRIP

1

8030650-301

LABEL –PINCH POINT (NOT SHOWN)

1

© Copyright 2014 REV. 9-MAY-2014

11

Part Number: 8031110-900

Stand Dimensions: 28” WIDE, 15” DEEP, 33-1/4” HIGH

Fasteners needed to attach Punch to the stand are the following:

(Fasteners to attach stand to floor are not included.)

PART NUMBER

DESCRIPTION

QTY

21A0102C2102

SCREW-HHCS 1/2-13X2-1/2

4

61X0102

WASHER-FLAT 1/2

4

30X0102C

NUT-FULL 1/2-13

4

© Copyright 2014 REV. 9-MAY-2014

12

Defective parts, of a product manufactured by DI-ACRO, will be replaced or repaired at

no charge for twelve (12) months following delivery to the original purchaser. Labor is

included for the first 90 days. This warranty becomes void when products have not

been used according to instructions furnished by DI-ACRO, nor does it cover any

altered parts or unauthorized repairs. We cannot be responsible for the cost of repairs

made or attempted outside of our factory. All other warranty claims are made FOB our

plant, providing such items(s) is returned freight prepaid to our plant for examination.

This warranty does not apply to parts, components or systems not manufactured by DI-

ACRO. These products are covered instead by the existing warranties, if any, of their

manufacturers. Normal service items with a reasonable life expectancy of less than one

year are warranted only to the extent of the reasonable life under normal use and

service.

Authorization must be obtained from DI-ACRO before returning parts or equipment to

the factory. DI-ACRO will satisfy this warranty by replacing the product or refunding the

purchase price upon receipt, inspection and defect identification.

DI-ACRO’s liability under this warranty shall not exceed the amount paid for the product.

THIS IS DI-ACRO’S SOLE WARRANTY IN LIEU OF ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED, WHICH ARE HEREBY EXCLUDED, INCLUDING IN

PARTICULAR ALL WARRANTIES OF MERCHANTABILITY, FITNESS OR ANY

LOSS, DAMAGE OR EXPENSES DIRECTLY OR INDIRECTLY RELATED TO THE

USE OF ITS PRODUCT OR FROM ANY OTHER CAUSE OR FOR CONSEQUENTIAL

DAMAGES INCLUDING, WITHOUT LIMITATION, LOSS OF TIME AND LOSS OF

PRODUCTION.

IT IS EXPRESSLY UNDERSTOOD THAT DI-ACRO IS NOT RESPONSIBLE FOR

DAMAGE OR INJURY CAUSED TO OTHER PRODUCTS, MACHINERY, PROPERTY

OR PERSONS BY REASON OF THE USE OF ITS PRODUCTS.

12430 55th St N · Oak Park Heights, MN 55082

Phone: 651.342.1756 · Fax: 651.342.1293

Email: info@diacro.com

Other manuals for 2 TAB

1

This manual suits for next models

2

Table of contents

Other Di-Acro Tools manuals