Model

Maximumrotatingspeedatthecuttingtool

Maximumallowablemotorspeedforthespindle

AppropriateMotor

Reduction Ratio

StandardColletChuck(CHS-3.0)

Weight

RA-200

13,330min−1

20,000min−1

AM-300(R)(L)(RA)(LA)

AM-310(R)(L)(RA)(LA)

EM-250EM-255

1/1.5

φ3.0㎜

150g

The maximum allowable motor speed for RA-200 is less than 20,000 min-1 for continuous

use. Always use the reducer between the air motor(A -300

・

A -310) and RA-200.

!

CAUTION

+0

−0.01

1

Cautions for handling and operation

■Readthesecautionscarefullyandonlyuseinthemannerintended.

■Safetyinstructionsareintendedtoavoidpotentialhazardsthatcouldresultinpersonalinjuryor

damage to the device. Safety instructions are classified as follows in accordance with the

seriousnessoftherisk.

①

RA-200 is not a hand tool. It is designed to be installed in a machine.

②

Do not touch the tools , motor,or spindle when in operation.

③

Always wear safety glasses. Everyday eyeglasses only have impact resistant

lenses, they are not safety glasses. Also use a dust or face mask whenever the

motor is running.

④

Do not apply excessive force(such as deep single pass cuts or high feed rates) .

This may cause tool slippage or spindle damage.

⑤

Fasten the tool in the chuck firmly before working.

Thankyouforpurchasing90°AngleSpindle,RA-200.RA-200isdesignedfordrillingonsidefaces,

orworkingoncornersdifficulttoworkorunfitforworkingwithstraighttypespindles.

ElectricMotororAir MotorandAir LineKit with Lubricatorcombinationare used todrive

RA-200.

PleasereadthisOperationManualcarefullypriortouse.

A hazard that could result in bodily injury or damage to the device if the

safety instructions are not followed.

Degree of Risk

A hazard that could result in light or moderate bodily injury or damage to

the device if the safety instructions are not followed

Class

!

!

!

WARNING

CAUTION

WARNING

!

CAUTION

①

The maximum allowable motor speed for the spindle is less than 20,000min-1.Donot

exceed the specified motor speed by the manufacturer.

②

The speed reducer is always used to connect between the air motor A -300

・

A -310 and RA-200.

③

Do not drop or hit RA-200, the shock can damage internal components.

④

Always clean the chuck. If ground particles or metal chips stick to the inside of

spindle or the chuck, this will cause damage to the chuck or spindle and loss of

precision.

⑤

Do not over-tighten the chuck ,this will cause the spindleÕs damage.

⑥

Use tools with high shank tolerance to

㎜

or better.

⑦

Do not use the unbalanced or low quality tools.

⑧

Select suitable products or tools for the application. Do not exceed the capabilities

of the spindle or cutting tools.

⑨

Stop working immediately if rough rotation or unusual vibration occur.

⑩

If the spindle has not been used for a long period of time, in excess of one month ,

start at a low air pressure and run the spindle as slowly as possible. Over a period of

15-20 minutes , raise the air pressure and spindle speed incrementally until you

reach the maximum allowable speed. Check for abnormal noises, vibration or heat.

⑪

Check if tools or chucks are damaged before working.

①TheRA-200isdesignedfordrillingonsidefaces,orworkingoncornersdifficulttoworkorunfitfor

workingwithstraighttypespindles.

②Thespindlehousingsmadeofprecision-groundstainlesssteel(SUS-416).Thisiseasilyattached

onspecialpurposemachines.

③Awideselectionofcolletchucksareavailabledependingonapplicationrequirements.

2

Features

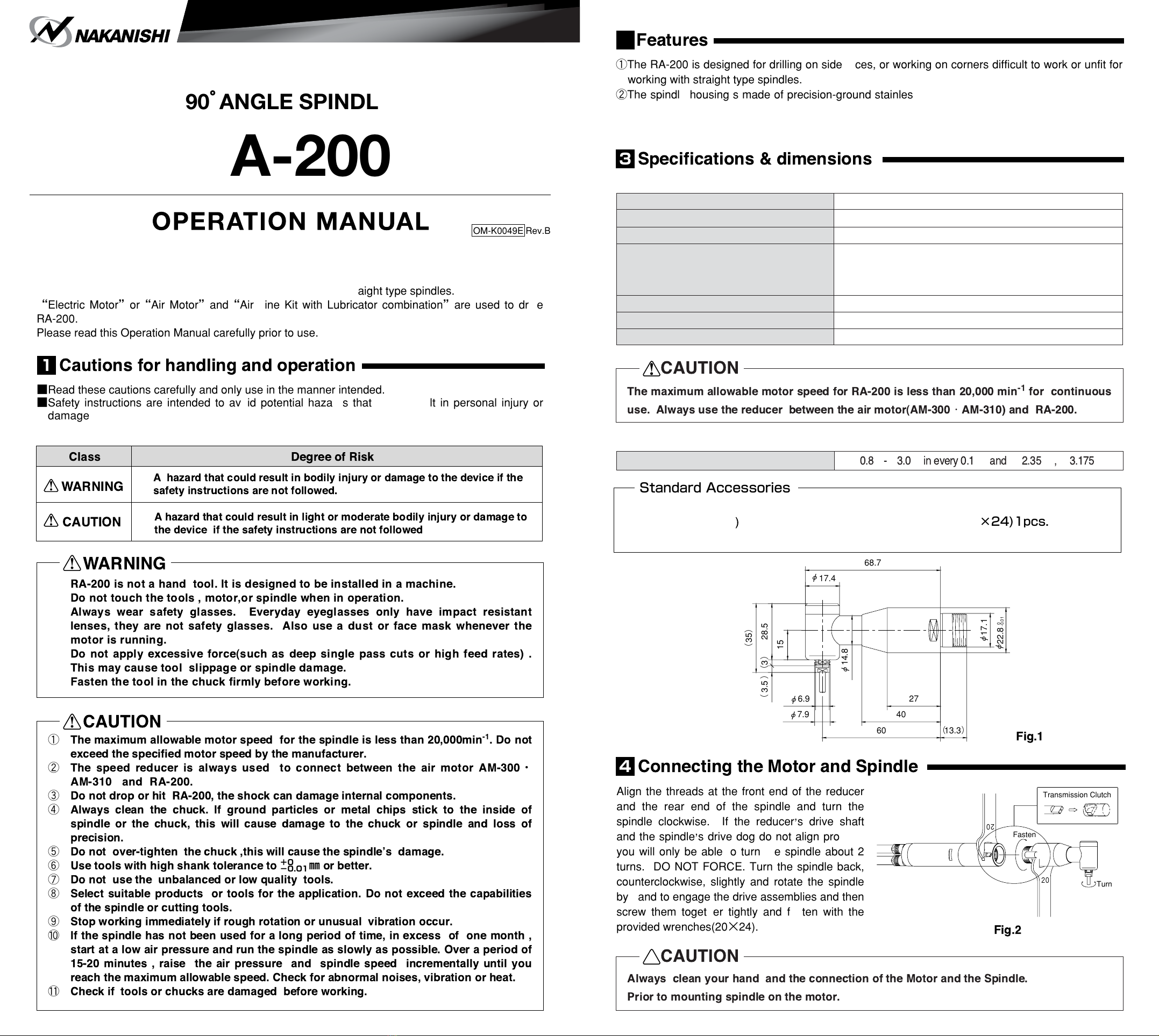

3-2Dimensions

3-1Specifications

Always clean your hand and the connection of the otor and the Spindle.

Prior to mounting spindle on the motor.

!

CAUTION

Colletchuck(CHS-□□)

φ

㎜

φ

㎜

㎜

φ

㎜

φ

㎜

〈Option〉

・ColletChuckφ3.0mm(provided)1pcs.

・Wrench(7×5.1

1pcs.

・Operationmanual

・Wrench(8×5)1pcs.

・Wrench(20×24)1pcs.

StandardAccessories

Fig.1

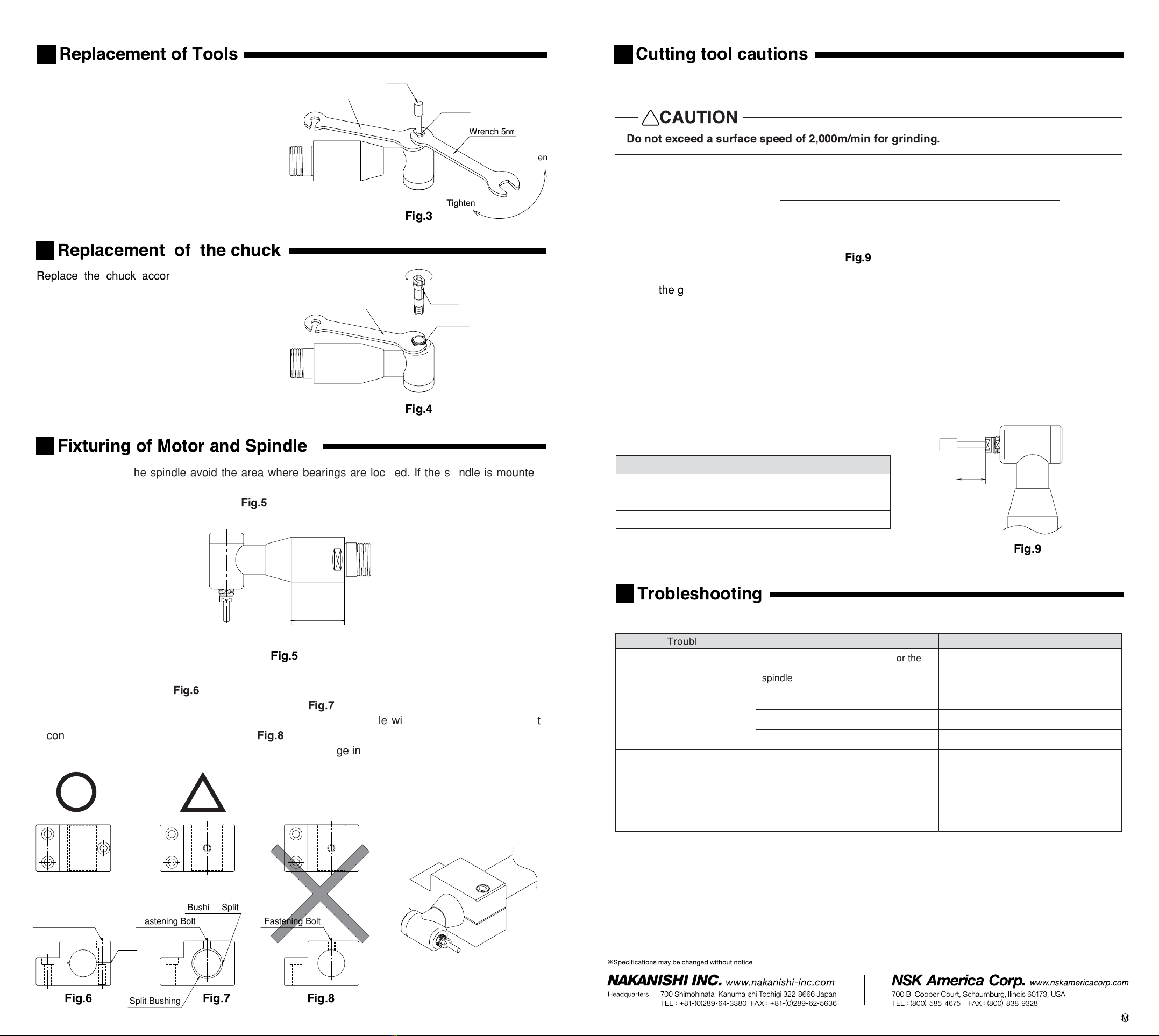

Alignthethreadsatthefrontendofthereducer

and the rear end of the spindle and turn the

spindle clockwise. If the reducer,s drive shaft

andthespindle,sdrivedogdonotalignproperly

youwillonlybeabletoturnthespindleabout2

turns.DONOTFORCE.Turnthespindleback,

counterclockwise, slightly and rotate the spindle

byhandtoengagethedriveassembliesandthen

screw them together tightly and fasten with the

providedwrenches(20×24).

4

Connecting the otor and Spindle

Fig.2

3

Specifications & dimensions

90°ANGLE SPINDLE

RA-200

OM-K0049E Rev.B

68.7

)35(

7.9φ 40

27

15

17.4

φ

14.8

φ

6.9φ

60 (13.3)

28.5)3()3.5(

-0.01

0

22.8

φ

17.1

φ

20

20

Turn

Fasten

TransmissionClutch