Di-soric ID-06 User manual

Step 1 — Check Hardware

Item Description Part Number

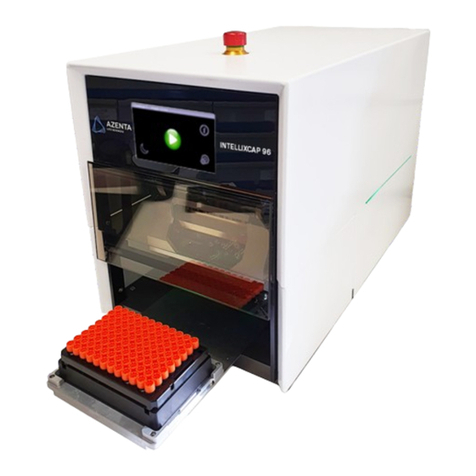

1

ID-06 C-Mount Industrial Imager

ID-06-IXX-00-ES

2

Interface Device

VSID-IB-ES

Note: Additional cordsets and accessories are available in the di-soric Product Catalog.

Caution: Be sure that all connections are secure BEFORE

applying power. Power down BEFORE disconnecting any cables.

Ethernet Standalone

1

2

Quick Start Guide

ID-06 C-Mount

Industrial Imager

P/N 83-116801 Rev A

Step 2 — Connect the System

Important: When connecting cordsets to the ID-06 C-Mount

and VSID-IB-ES, align the pins first and then push the connec-

tor into place. Do not twist the connectors, as this will bend the

pins.

Important: Do not attempt to power more than four imagers

with a single power supply in a daisy chain configuration. Add a

VSID-IB-ES and one power supply for every four additional

imagers in the daisy chain.

RS-232

1. Connect the Serial Communication Cable from “A” on the

ID-06 C-Mount to “2” on the VSID-IB-ES.

2. Connect the host cable from “1” on the VSID-IB-ES to the

host computer.

3. Connect the photo sensor to “T” on the VSID-IB-ES.

4. Connect the power supply to “3” on the VSID-IB-ES.

5. Plug in the power supply.

Ethernet

1. Connect the Ethernet Cable from “B” on the ID-06 C-

Mount to the network.

2. Connect the power supply to “A” on the ID-06 C-

Mount.

3. Connect the photo sensor to “T” on the VSID-IB-ES.

4. Plug in the power supply.

Step 3 — Position the Imager

1. Position the imager at a focal distance of one inch or more from

a test symbol.

2. Tip the imager relative to the symbol to avoid the glare of direct

(specular) reflection. The case parting line should be perpendicular

to the plane of the symbol by either pitching the symbol or the

imager as shown.

3. Symbols can be rotated (tilted) at any angle; however, for best

results symbols should be aligned with the field of view. In the

case of linear symbols, aligning the bars in the direction of their

movement (ladder orientation) will minimize the chances of

blurring and will result in more consistent decodes.

Important: Avoid excessive skew or pitch. Maximum skew is

±30°; maximum pitch is ±30°.

Step 4 —

Install di-soric ID

di-soric ID Software can be found on the di-soric USB-Stick

that is packaged with the ID-06 C-Mount.

1. Follow the prompts to install di-soric ID from the Tools

Drive.

2. Click on the di-soric ID icon to run the program.

Note: di-soric ID can also be installed from the Down-

load Center at www.di-soric.com.

Minimum System Requirements

• 233 MHz Pentium processor

• Windows 7 (32-bit or 64-bit), Vista (32-bit or 64-bit), XP, or

2000 operating system

• Internet Explorer 6.0 or higher

• 128 MB RAM or greater

• 80 MB hard drive space

• 800 x 600 minimum 256 color display (1024 x 768 32-bit color

recommended)

Refer to the ID-06 Industrial Imager User’s Manual for detailed

information about using di-soric ID to configure the ID-06 C-

Mount.

Step 5 — Select Model

When you start di-soric ID, the model menu will appear:

1. Click the button showing the ID-06 C-Mount.

2. Click OK.

Note: You can also simply double-click the button showing

your imager to make your selection.

3. Click Yes when the following dialog appears:

Note: If you need to select another model later, click the

Switch Model button near the top of the screen or use

Model > New Model in the menu toolbar.

Step 8 — Calibrate

Imager settings can be adjusted automatically for optimum

performance by either the EZ Button or by di-soric ID.

During the calibration routine, the imager will flash its Read

Rate percent LEDs and illumination LEDs while searching

camera settings and determining the best configuration for

decoding symbol data. If unsuccessful, the imager will emit 5

short beeps and stop searching.

Calibrate by di-soric ID

1. Click the Calibrate button.

2. The imager will search camera settings to determine the

best configuration for decoding symbol data.

A successful calibration will display a green frame around

the symbol in di-soric ID, and the following message will

appear: “Uploading all reader parameters.” After a moment

the symbol data will be presented in the field below the

image display window.

Calibrate by EZ Button

1. Hold down the EZ Button for about two seconds and

release when you hear two short beeps. The 20% and

40% LEDs will illuminate.

2. The imager will search camera settings to determine the

best configuration for decoding symbol data.

Note: To end all EZ Button functions, press the EZ Button

once and quickly release.

Calibrate by Serial Command

Send <@CAL> from a terminal program to begin auto-calibration.

Step 6 — Connect

To connect using the Connection Wizard:

• Click Connect on the menu toolbar, and then select Connection Wizard.

• Select RS-232 or Ethernet to activate the appropriate display.

•

Configure settings as required by the application, and click Connect.

• When a connection is established, the green indicator in the status

bar at the bottom right of the screen will be visible:

Important: The imager is in Continuous Read Mode by default. For

best connection results, be sure that no decodable symbols are

within the imager’s field of view while attempting to connect.

Step 9 — Test Read Rate

Read Rate indicates the number of successful decodes per second

achieved by the imager.

Test Read Rate by di-soric ID

1. Click the Test button to start the Read Rate test.

If a symbol has been successfully decoded, its data and related

information will be presented in the field below the image display

window. While the symbol is being decoded,

the Read Rate

LEDs will indicate the read rate percentage

on the top of the unit.

2. Click the Stop button to end the Read Rate test.

Note: Read rate can also be tested using the Read Rate interface

in Utilities.

Test Read Rate by EZ Button

1. To start the Read Rate test, hold down the EZ Button about

three seconds until you hear three short beeps. The

20%, 40%,

and 60% LEDs on the top of the unit will illuminate.

While the symbol is being decoded, the Read Rate LEDs will

indicate the read rate percentage on the top of the unit.

2. To end the Read Rate test, press the EZ Button and quickly

release.

Test Read Rate by Serial Command

You can also start a test with the <C> or <Cp> command and end it

with the <J> command.

Step 7 — Locate Symbol

Locate by di-soric ID

• In di-soric ID’s EZ Mode, click the Locate button.

The symbol in the field of view will appear in the video view

beneath the Locate and Calibrate buttons.

• Center the symbol in the imager’s field of view.

Important: The entire symbol should fall within the field of

view (FOV) of the imager. The field of view is what appears in

di-soric ID’s Locate/Calibrate window in EZ Mode.

• Click the Stop button to end the Locate function.

Locate by EZ Button

If you are not connected to a host computer, the EZ Button

allows you to locate the symbol in the imager’s field of view.

• Hold down the EZ Button for about one second and release

when you hear one short beep. The amber 20% LED will

illuminate when the symbol is located.

Note: To end all EZ Button functions, press the EZ Button

once and quickly release.

Step 10 — Configure and Save

Click the App Mode button to make configuration changes.

The following modes are accessible by clicking the buttons at

the top of the screen:

• Click the EZ Mode button to return to EZ Mode.

• Click the Autoconnect button to establish communication.

• Click the Send/Recv button to send or receive commands.

• Click the Switch Model button to open the model menu.

• Click the Parameters button to show the tree controls for

Communication, Read Cycle, Symbologies, I/O Parameters,

Symbol Quality, Matchcode, and Diagnostics.

• Click the Setup button to access the Camera Setup tree

and

the interfaces for Video, Evaluation, Calibration, Window

of

Interest (WOI), Configuration Database, Ordered Output, Output

Format, and Dynamic Setup.

• Click the Terminal button to display decoded symbol data,

and to send serial commands to the imager using text or macros.

•

Click the Utilities button to show the tabbed interfaces for Read

Rate, Counters, Device Control, Differences from Default, Master

Database, and Firmware

.

Saving Options

•Send, No Save. Changes will be lost when power is re-applied

to the imager.

•Send and Save. This activates all changes in current memory

and saves to the imager for power-on.

Other Di-soric Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Dickey-John

Dickey-John Instalab 600 Series Operator's manual

Endress+Hauser

Endress+Hauser Liquistation CSF48 operating instructions

Agilent Technologies

Agilent Technologies 6850 Series Service information

Beckman Coulter

Beckman Coulter Avanti J-26S XPI Instructions for use

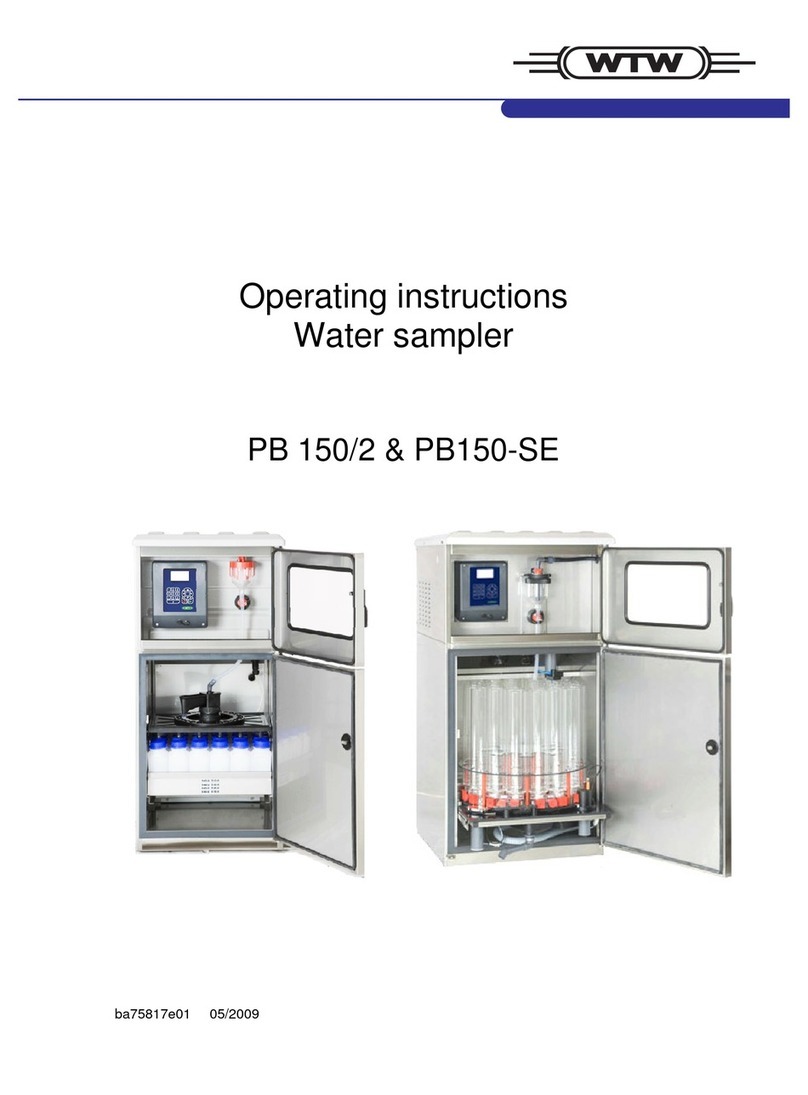

wtw

wtw PB 150/2 operating instructions

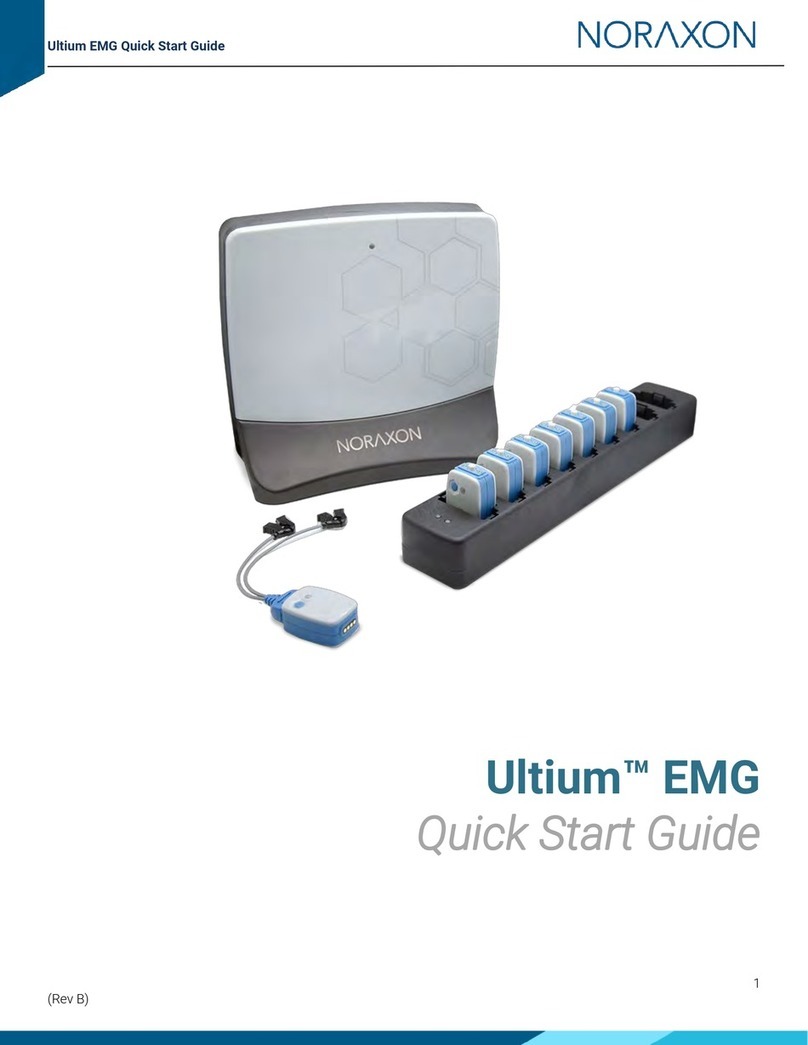

Noraxon

Noraxon Ultium EMG System quick start guide