DA9155M Getting Started with Evaluation Board

© 2015 Dialog Semiconductor

Contents

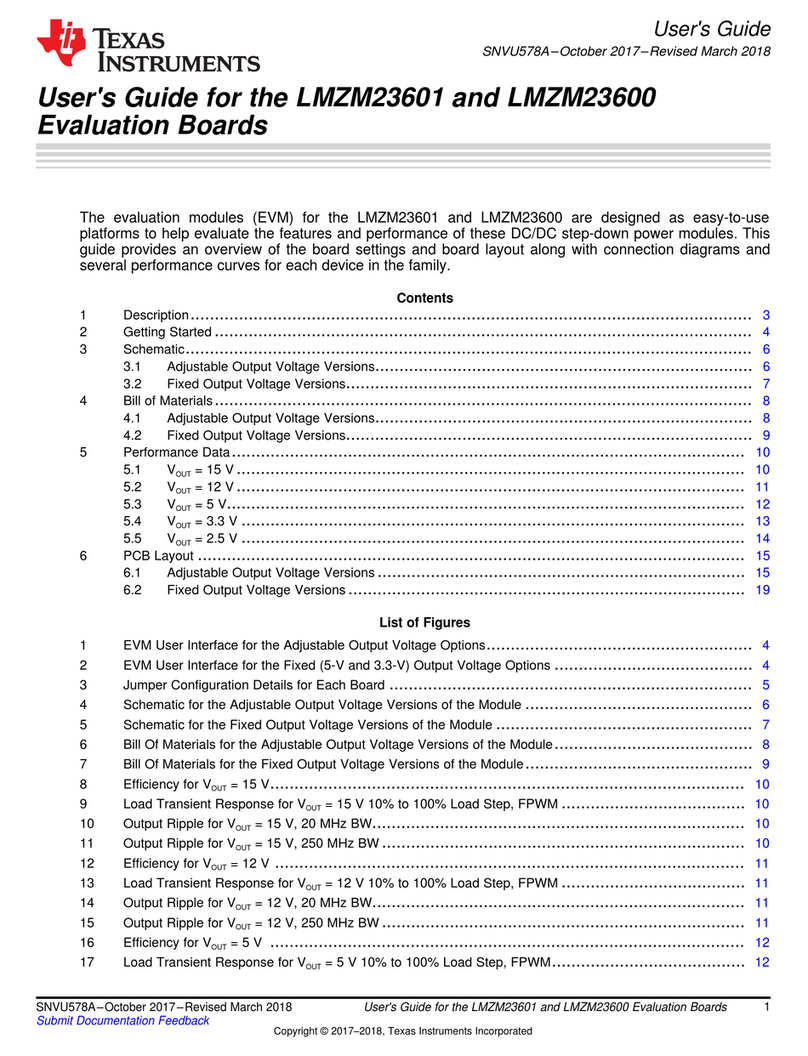

Abstract................................................................................................................................................ 1

Contents............................................................................................................................................... 2

Figures.................................................................................................................................................. 2

Tables ................................................................................................................................................... 3

1Terms and definitions................................................................................................................... 3

2References..................................................................................................................................... 3

3Introduction.................................................................................................................................... 4

4Board recommended operating conditions................................................................................ 5

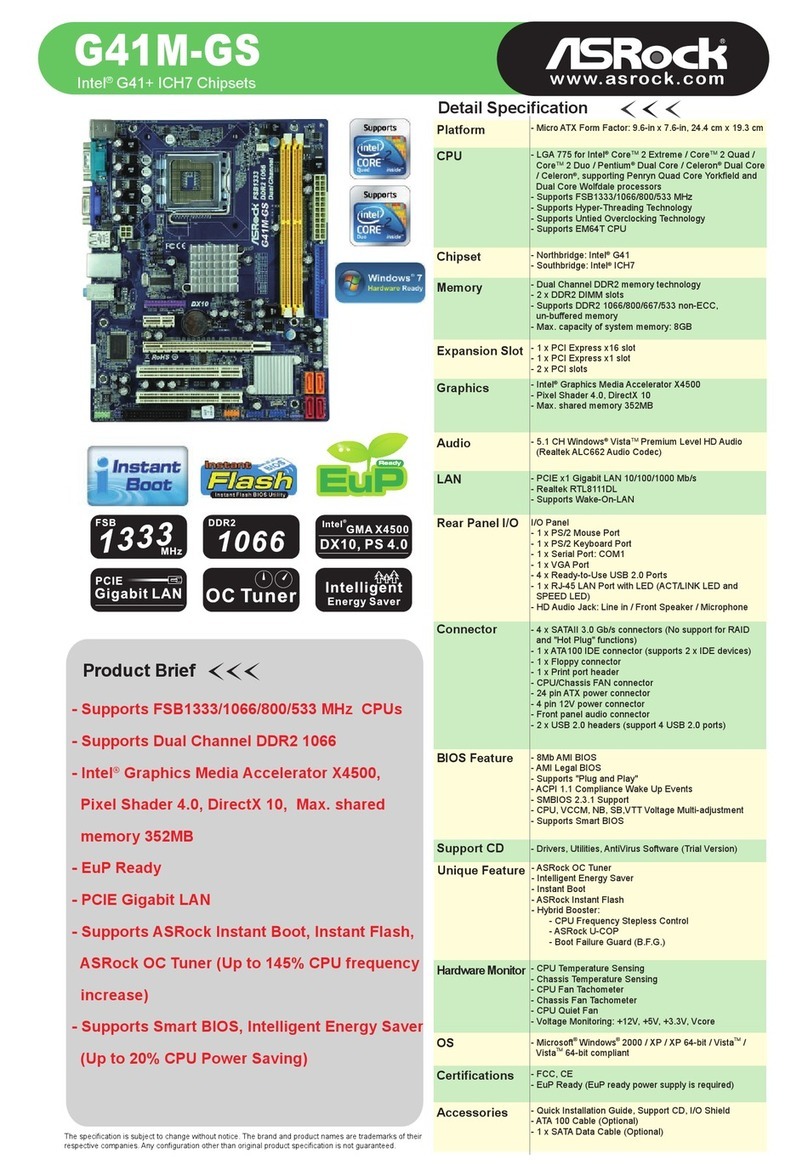

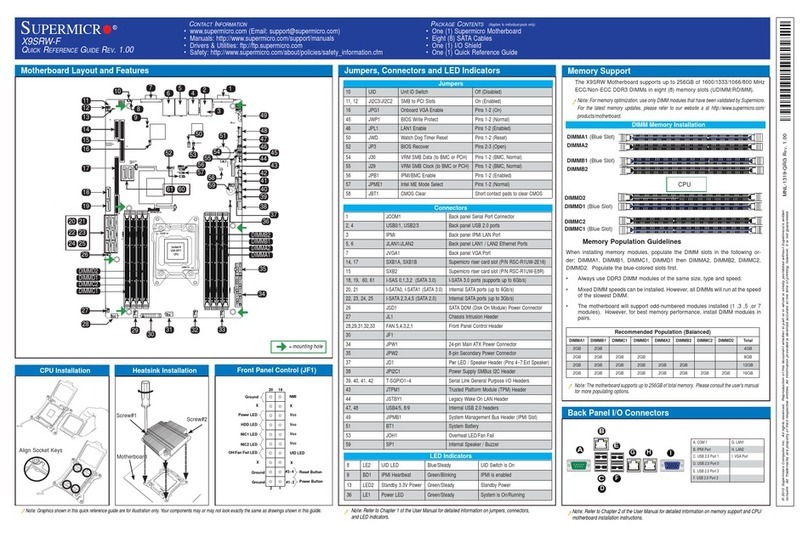

5DA9155M Performance Board Hardware .................................................................................... 6

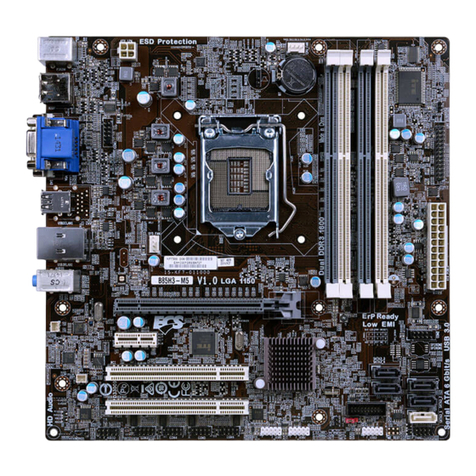

5.1 DA9155M Slave charger layout ............................................................................................ 7

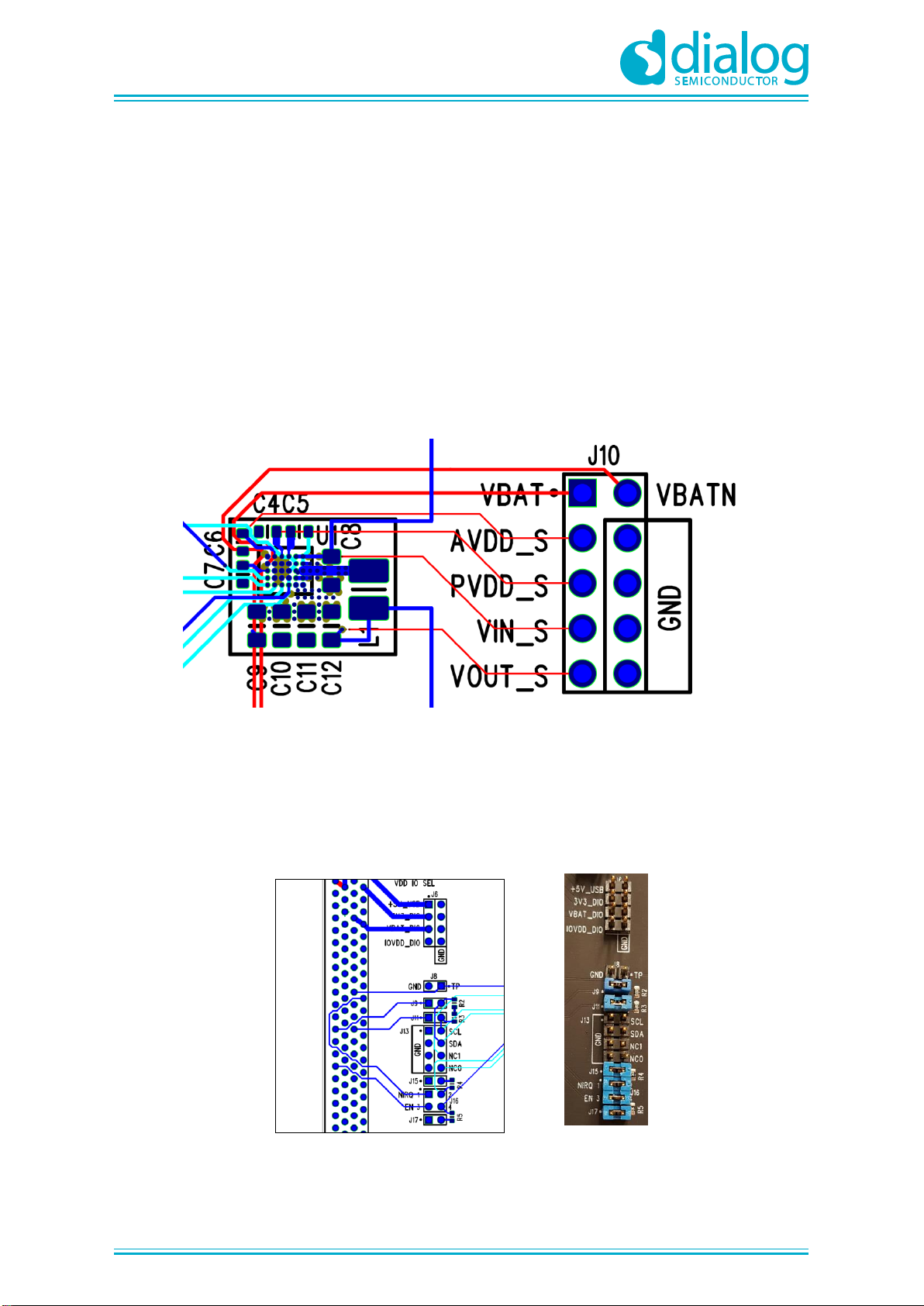

5.2 Slave charger multi-test point J10 connector........................................................................ 8

5.3 Digital I/O board connectivity headers .................................................................................. 8

5.4 Transient injection points ...................................................................................................... 9

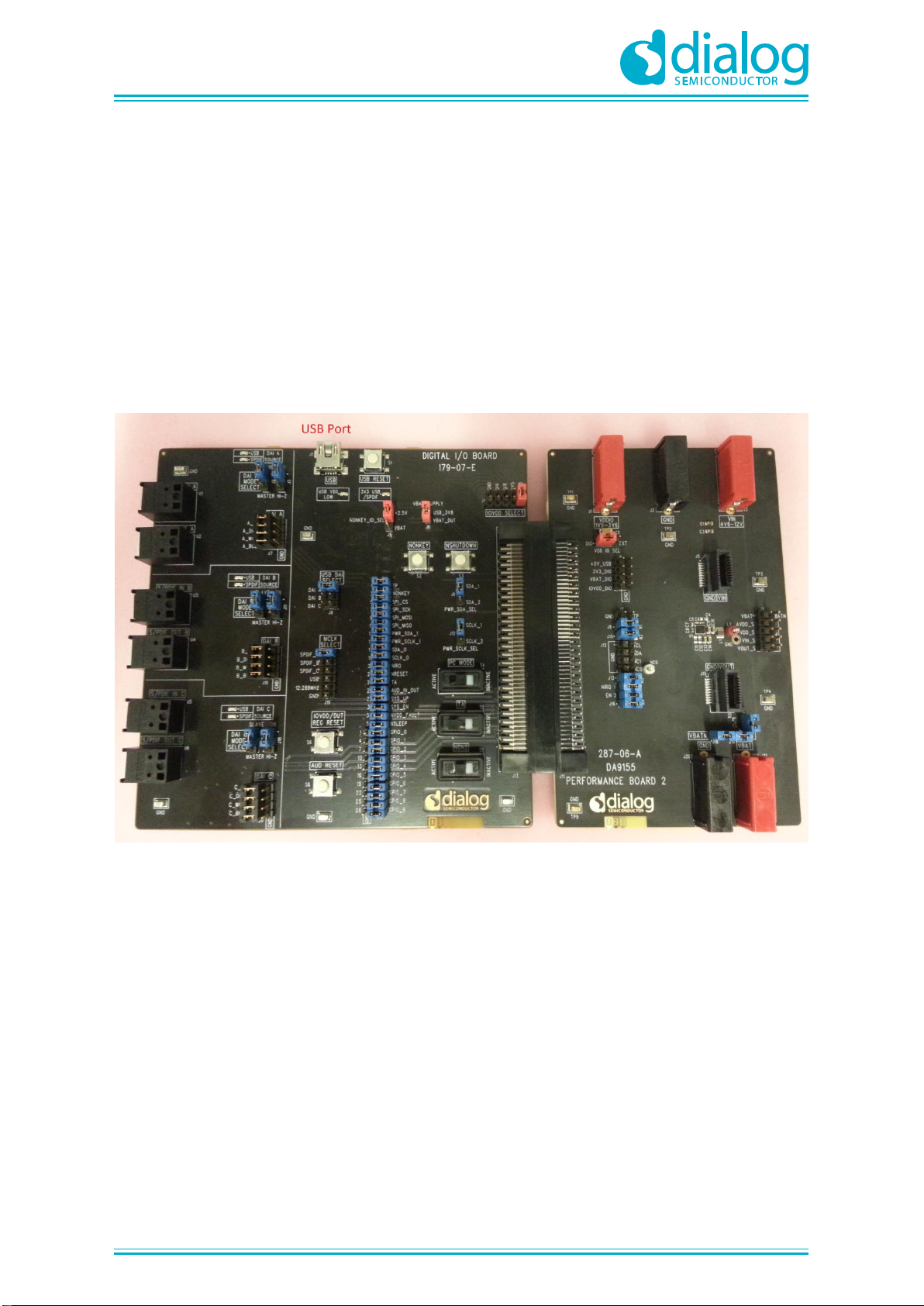

5.5 Connectivity........................................................................................................................... 9

6Hardware requirements .............................................................................................................. 10

6.1 Input voltage supply............................................................................................................ 10

6.2 Battery voltage .................................................................................................................... 10

7DA9155M Performance Board Graphical User Interface......................................................... 11

7.1 Software installation............................................................................................................ 11

7.2 GUI overview....................................................................................................................... 12

8Quick start tutorial guide............................................................................................................ 16

Revision history................................................................................................................................. 18

Figures

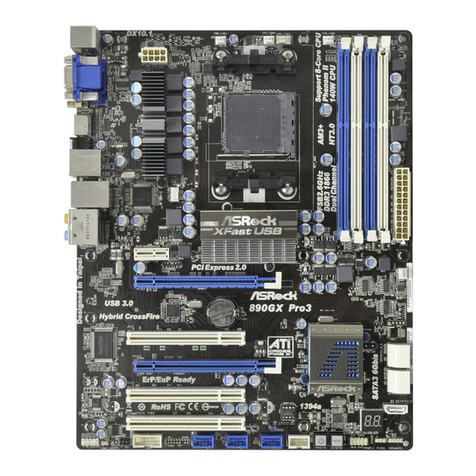

Figure 1: DA9155M Performance Board (top view) .............................................................................. 4

Figure 2: Functional overview ............................................................................................................... 6

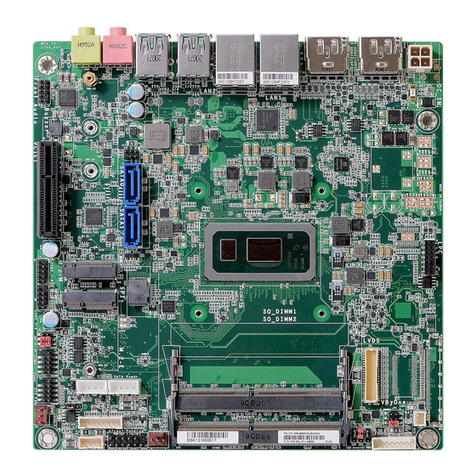

Figure 3: PCB Layout for DA9155M...................................................................................................... 7

Figure 4: DA9155M Performance Board Layout................................................................................... 7

Figure 5: Test point J10 header ............................................................................................................ 8

Figure 6: DIO connectivity headers (a) Layout view (b) Default jumper settings.................................. 8

Figure 7: DIO and DA9155M Performance board................................................................................. 9

Figure 8: DA9155M Evaluation GUI Installation File........................................................................... 11

Figure 9: DA9155M GUI Software Licensing and Installation............................................................. 11

Figure 10: DA9155M GUI Installation Path......................................................................................... 11

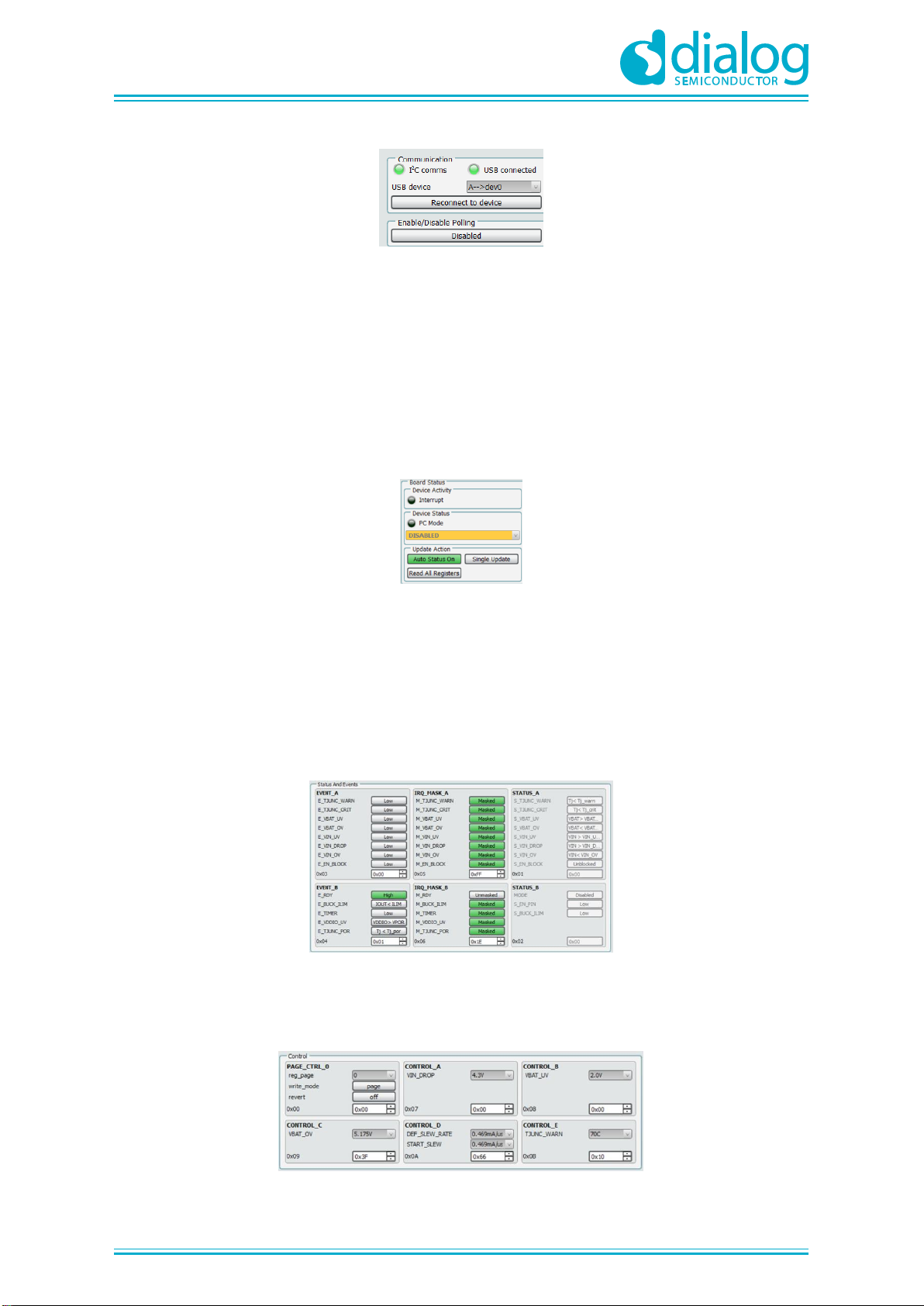

Figure 11: GUI Overview Screen ........................................................................................................ 12

Figure 12: Active Communication Indicator......................................................................................... 13

Figure 13: Board Status Indicator........................................................................................................ 13

Figure 14: Status and Events shown in GUI ....................................................................................... 13

Figure 15: Control Registers in GUI .................................................................................................... 13

Figure 16: Buck converter control registers......................................................................................... 14

Figure 17: Raw I/O and File I/O GUI Controls..................................................................................... 14

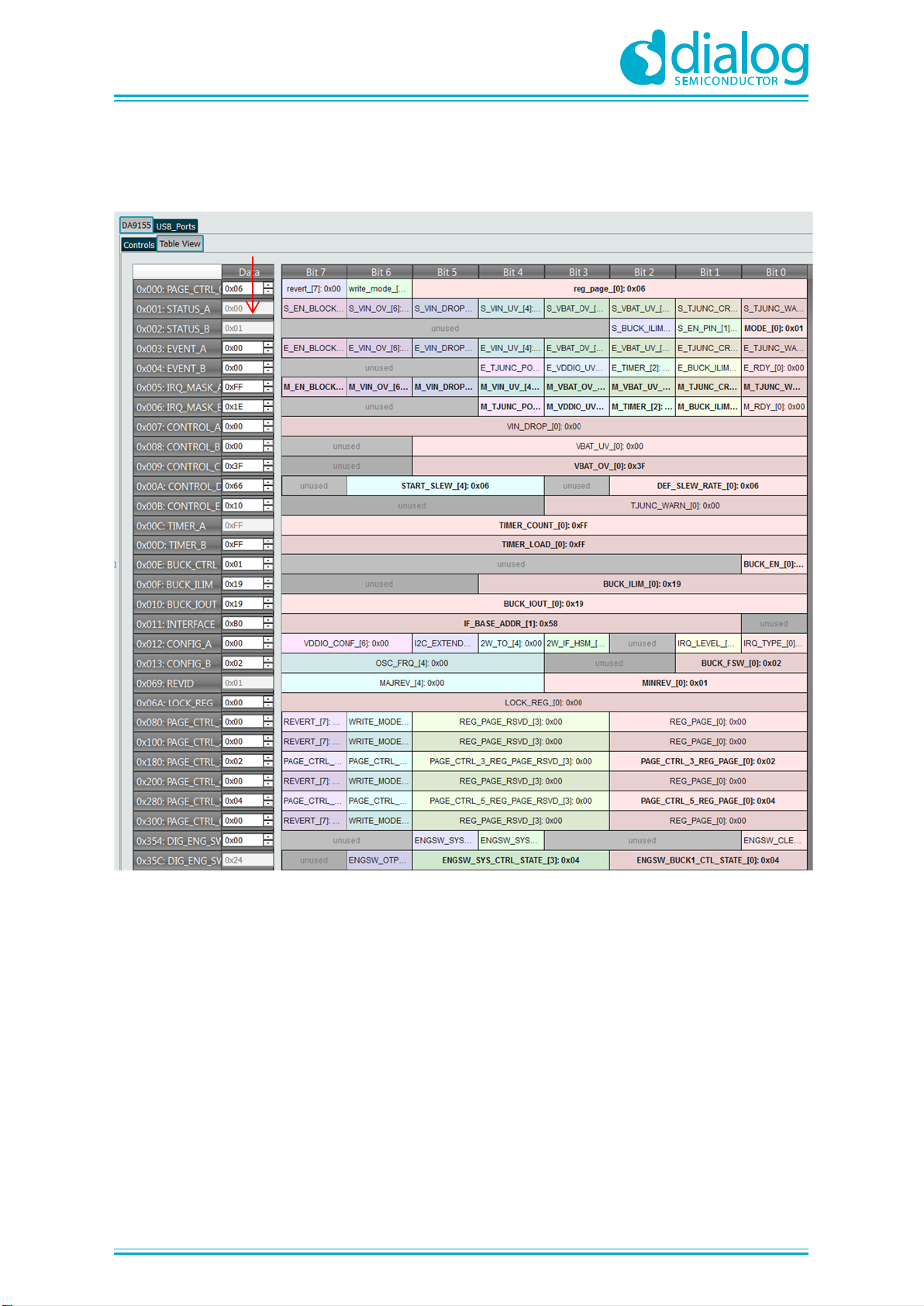

Figure 18: DA9155M GUI using the Table View ................................................................................. 15

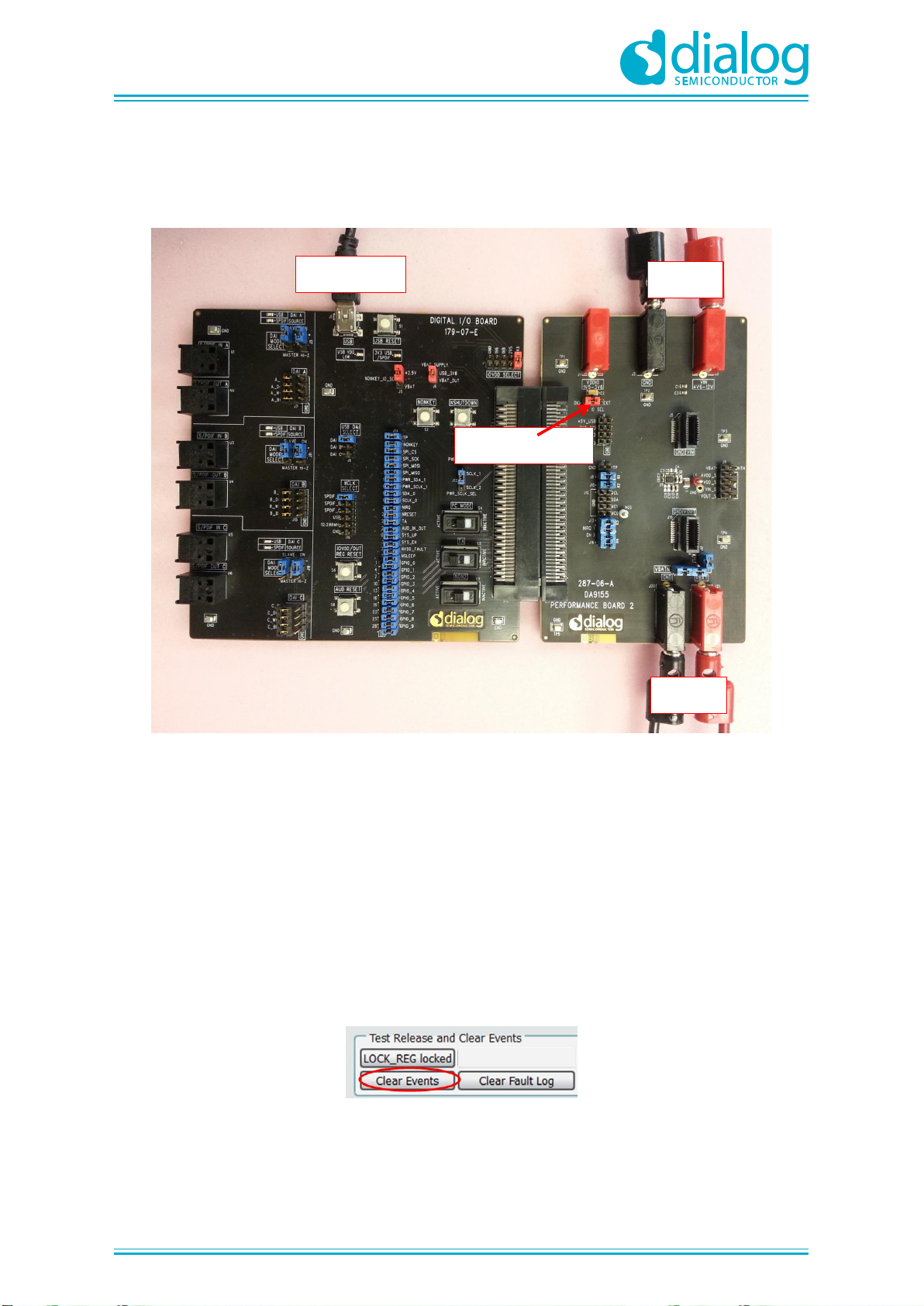

Figure 19: DA9155M Performance Board Full Setup.......................................................................... 16

Figure 20: Clear Events button............................................................................................................ 16

Figure 21: Configure the output current .............................................................................................. 17

Figure 22: Enable Buck converter button............................................................................................ 17