diamond mowers Drum Mulcher OD Pro X User manual

DIAMONDMOWERS.COM

OPERATOR’S MANUAL

PRODUCT INFORMATION

Record the model and serial number of your unit here. When calling for

warranty, service or parts, you may be asked to provide this information,

in order to ensure fast, accurate service.

MODEL: Drum Mulcher OD Pro X SIZE: 60”(1524mm) 72”(1829mm)

SERIAL NUMBER:___________________________________________________

© Diamond Mowers®, LLC

All rights reserved.

Any failure to read, understand and follow the instructions found in this operator’s

manual could lead to serious injury. Operators who choose to operate this equipment

without following instructions, or who choose to operate this equipment in a manner

inconsistent with the recommendations set forth in this manual, do so at their own

risk and assume the risk of injury. Diamond Mowers will not be liable for an owner

or operator’s loss, damage, or injury due to the misuse of the equipment, failure to

understand the inherent risks, or inability to properly operate the equipment.

(circle one)

2

WELCOME!

Thank you for choosing Diamond Mowers®, and welcome to your Drum

Mulcher OD Pro X. Before you begin operating, we encourage you to look

through this manual to review the proper maintenance and operating

techniques that will keep you, and your equipment, safe — while ensuring you

the most productive Drum Mulcher in the market.

We have nothing but respect and admiration for you. Our job at Diamond® is

to provide you with the toughest, most reliable and safest equipment that

will allow you to do your job better. That also means being there when you

need us.

CONTACT US:

Parts: 888.960.0361 | [email protected]

Main Office:800.658.5561 | 605.977.3300

Website: www.diamondmowers.com |Email: inf[email protected]

Your time is important to us.

We guarantee that Genuine Diamond Parts will ship within 72-hours of the

order being placed or the parts and shipping are free.

Thanks again for choosing Diamond.

If at any time your needs are not being met, please feel free to contact

anyone in our executive team.

OWNER REGISTRATION

In your welcome packet you should have received a warranty registration

form. Complete and return this form to our main office. It’s a self-mailer,

so no postage is required.

If you’d rather complete this info online, go to:

http://info.diamondmowers.com/register-my-product

Returning your registration information to Diamond will help us process any

warranty claims quickly and efficiently – so you can get back to work, fast.

TRANSFERRED OWNERSHIP

If you have acquired this Drum Mulcher OD Pro X from a previous owner,

we encourage you to register your equipment online. By registering your

Diamond Mowers unit, you’ll stay informed on product advancements,

offers and service alerts.

Register by going to: http://info.diamondmowers.com/register-my-product

We honor our equipment’s warranty from the date it was put into service,

no matter who’s in charge of running it.

For any questions, contact our Warranty / Service team at:

888.960.0364 or 605.977.3300

warran[email protected]

PRODUCT REGISTRATION

4

INTENDED USE 6

TAKE A LOOK AROUND 7

GETTING STARTED 8

OPERATING YOUR DRUM MULCHER 12

MAINTENANCE 19

TROUBLESHOOTING 37

INDEX 41

TABLE OF CONTENTS

INTENDED USE

This attachment is designed to be used for mowing and brush

management applications.

This includes:

•Mulching brush.

•Cutting small trees up to 9" (229mm) in diameter to ground level.

This attachment should only be used in an area free of obstructions and

bystanders. Any use on non-vegetative material, or in an area that is not

clear of persons and property, is strictly prohibited. Any use outside of the

aforementioned application is considered contrary to its intended use. Any

damage that may occur as a result of misuse will void warranty as stated in

Diamond Mowers’ warranty policy.

Do not operate this unit without first reading the safety precautions

and operating instructions in this manual.

Do not operate this unit without first reading the safety precautions

and operating instructions in this manual.

6

v

TAKE A LOOK AROUNDTAKE A LOOK AROUND

TEETH

Multiple tooth options are offered,

allowing the operator to tailor the

attachment for optimum cutting

efficiency and tooth life.

CHAIN GUARD

A chain curtain is provided to catch

debris and assist in protection of

the carrier vehicle.

PUSH BAR

The two-position push bar helps to

guide material away from

the loader.

DRUM LINER

Replaceable drum liner to protect

the frame from premature wear,

extending the life of the machine.

HOSES

Shipped with quick couplers and a

case drain line with both male and

female ends.

SKID SHOES

Skid shoes provide extra frame

protection, and are easily replaced.

77

© Diamond Mowers®, LLC

INSTALLATION

The Drum Mulcher OD Pro X will mount(1)

onto the front of the skid-steer /

compact track loader quick attach

plate in place of a bucket or other

implements.

QUICK ATTACH

PUSH BAR

The push bar has two positions(2)

to allow the operator to adjust the

attachment to the conditions.

•Loosen the hardware(4) on the push

bar front and rear supports(1)(3).

•Unbolt the push bar rear supports(1)

and reposition them in the adjacent

mounting location(2) on the rear

support brackets and secure them

in place.

•Tighten down all hardware(4) on

the rear and front / outer push bar

supports(1)(3).

A minimum ⁄” (13mm) safety door is

REQUIRED! This product must not be

used without a minimum ⁄” (13mm)

safety door. Debris can fly back at the

cab and cause injury.

SAFETY POLYCARBONATE

(1)

(1)

(3)

(2)

(4)

8

© Diamond Mowers®, LLC

The case drain line must be properly

connected or you will damage your

hydraulic motor. The case drain line

will come equipped with both male and

female QD couplers.

•Install the QD coupler(s) that

matches the machine.

◦NOTE: The pressure hose will

have a red ID band attached.

•Attachment is shipped with ⁄”

flat face connectors, which are a

common size for most skid-steer /

compact track loaders.

◦Larger couplers are available to

purchase at

DiamondMowers.com.

•Clean connections before

attaching(1) to prevent

contamination.

◦NOTE: The pressure(1) hose will

have a red ID band attached.

•Make sure hoses are positioned

so they do not pinch between the

mulcher and the carrier.

•Start machine at low idle and verify

that the drum is spinning in the

correct direction - teeth are cutting.

◦If the pressure and return hoses

are reversed, the drum will

NOT spin.

•If this reversal occurs, either

inverse the flow from your machine,

or switch the QD couplers on the

pressure and return hoses.

QD COUPLERS

(1)

9

© Diamond Mowers®, LLC

The carrier must be equipped with a

case drain and be rated for the hydraulic

flow and lift capacity listed below.

The motor has been factory tuned to

match the GPM and PSI settings on the

tag (#10) at left. To maintain warranty

coverage, your Diamond Dealer can

fine-tune or adjust these settings

and update the GPM and PSI tag. For

attachments that are outside of the

warranty period, follow the Motor

Calibration instructions below:

Motor Calibration:

•Remove the motor side top

access cover(1).

•Temporarily remove the plug(2)

marked “G” from the motor and

install the adapter(3), hose(4), and

5000PSI (345Bar) rated gauge(5).

◦Use teflon tape on pipe threads.

◦Adapter(3), hose(4), and 5000PSI

(345Bar) rated gauge(5) are from

Diamond kit part #44-0949.

•Place the gauge(5) in a location so

the dial and markings are clearly

visible to the operator.

INSTALLATION

MACHINE REQUIREMENTS

DECK GPM (LPM) LBS (KG)

60” (1524mm) 27-31 (102-118) 2300 (1044)

60” (1524mm) 32-45 (122-171) 2300 (1044)

72” (1829mm) 32-45 (122-171) 3190 (1447)

CONTINUED ON NEXT PAGE

Keep away from the spinning drum

when operating the unit; serious

injury or death can result from

contact with the drum.

(1)

(2)

(3)

(4)

(5) (6)

(7)

10

© Diamond Mowers®, LLC

•Start the carrier and set the throttle to full speed.

◦DO NOT stand near the rotating drum when it is running.

•While observing the gauge(5), start the drum mulcher (engage the

carrier’s auxiliary hydraulics); The gauge(5) will spike to a high pressure

reading then drop with readings oscillating slightly up and down. The

gauge(5) will eventually STEADY for a short periord of time (This is the

motor SHIFT POINT), after which the pressure readings will drop off.

◦Note the pressure reading when the gauge is STEADY with minimal

oscillation (the motor SHIFT POINT).

◦NOTE: If the test must be repeated, the drum mulcher must be shut

down and come to a complete stop before repeating the test.

◦NOTE: If the pressure setting is too high, the motor displacement will

not change, resulting in low torque and slow recovery; if too low, it will

shift into high displacement too early, resulting in slow drum speed

and low pressure / performance.

•The pressure reading (motor SHIFT POINT) noted when the gauge(5) was

STEADY should be between 6-700PSI (42-48Bar) BELOW the carrier’s

auxiliary hydraulic relief setting (refer to the carrier’s operators manual).

◦If Adjustment Is Needed:

-Confirm the machine and drum mulcher are shut down and not

in motion.

-Loosen the locknut(6) on the adjustment screw(7) with a 10mm

combination wrench.

-Use a 3mm Allen wrench to turn the adjustment screw(7) clockwise

to lower the SHIFT POINT, or counter-clockwise to raise it (adjust

in ⁄ turn increments).

-Repeat these steps until the desired SHIFT POINT is reached, then

tighten the locknut(6) to retain the adjustment screw(7) position.

•Remove the adapter(3), hose(4), and gauge(5) and replace the plug(2) into

the motor port marked “G”, and replace the top access cover(1).

11

© Diamond Mowers®, LLC

OPERATING YOUR DRUM MULCHER

CONTINUED ON NEXT PAGE

Before you operate, note that the primary responsibility for safety on this

equipment falls to the operator. Only trained individuals who have read and

understood this manual should operate this unit.

If any portion of this manual is not understood, contact:

Diamond Mowers’ Service/Warranty at 888.960.0364 or 605.977.3300.

Be sure to read all warnings carefully. They are included for your safety,

and for the safety of others working with you.

SAFETY TIPS

Indicates where SERIOUS injury or death WILL result if instructions

are not followed.

Indicates where SERIOUS injury or death COULD result if instructions

are not followed.

Indicates where MINOR injury COULD result if instructions are

not followed.

Indicates a property damage hazard ONLY, no PERSONAL injury.

•Always wear personal protective equipment (safety glasses, goggles,

etc.), when operating.

•DO NOT operate this unit without a shatter resistant cab enclosure

installed on your skid-steer / compact track loader; this unit will cause

flying debris.

•Block off work area from bystanders, livestock, etc.

•Bystanders must keep a distance of 300ft/100m from the unit

when operating.

•Mulcher teeth are always sharp and can cause injury, even when not

in motion.

12

© Diamond Mowers®, LLC

•DO NOT use extremities to dislodge debris from teeth or disc.

•Operate only from the operator’s station.

•Hydraulic fluid is hot and will heat any exposed steel, hoses, or motor in

its proximity.

•Route hoses correctly to ensure a full range of motion.

•Make certain hoses are out of the way of tires, tracks or the ground.

•Be certain the drum has come to a complete stop before exiting the cab.

•Stop the drum rotation prior to using the push bar to push or drag

material with the front of the machine pointing downward and exposing

the cutting drum to the operator.

When transporting Diamond’s Drum

Mulcher OD Pro X between operations,

make sure to protect it from collisions

and accidental damages by placing it in

the stowed position.

Failure to place the head in its stowed

position could result in

structural damage.

STOWED POSITION

Contact with the drum and teeth while the drum is in motion will

cause serious injury or death. The drum spins at a very high speed and

can take several minutes to stop. Be sure all personnel are clear of

the machine before engaging the Drum Mulcher.

START-UP PROCEDURES

•Start the carrier (reference the carrier’s operator manual for starting

recommendations and procedures) and allow the carrier to warm up and

instruments to stabilize.

•Prior to operation, ensure both engine and hydraulic oil temperature

reaches the carrier’s recommended operational temperature range.

13

© Diamond Mowers®, LLC

VERTICAL MULCH - TREES 2”-9” (51mm-229mm)

Be aware when cutting standing trees as there is a potential for

treetops to fall onto the operator’s cab.

Use to mulch trees from the top down.

•To top the tree - Reach as high as possible. Cut the top of the tree and

push it away from the cutter head to mulch it later.

◦Make certain to allow enough recovery time for the drum to

rebuild momentum.

•Mulch the tree - Angle the head back 45oand move the attachment

quickly but smoothly through the tree, raising the head slightly to allow

the drum to recover speed as necessary.

OPERATING YOUR DRUM MULCHER

1

2

1

2

14

© Diamond Mowers®, LLC

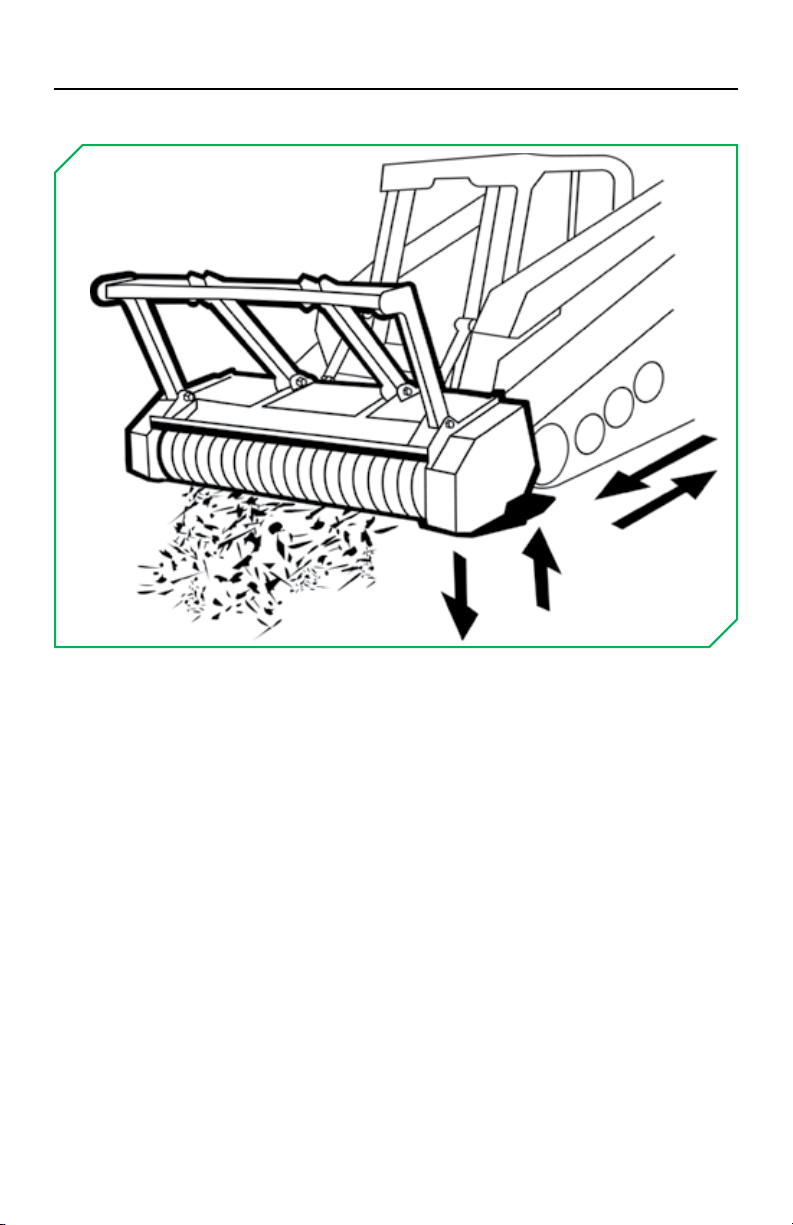

Use to pull in and mulch debris laying on the ground.

•Lift the front of the head slightly to pull in branches or tree tops

underneath the drum for mulching.

•Tip the drum’s nose down to re-process material on the ground for a

finer finish.

GROUND MULCH

15

© Diamond Mowers®, LLC

Be aware when cutting standing trees as there is a potential for

treetops to fall onto the operator’s cab.

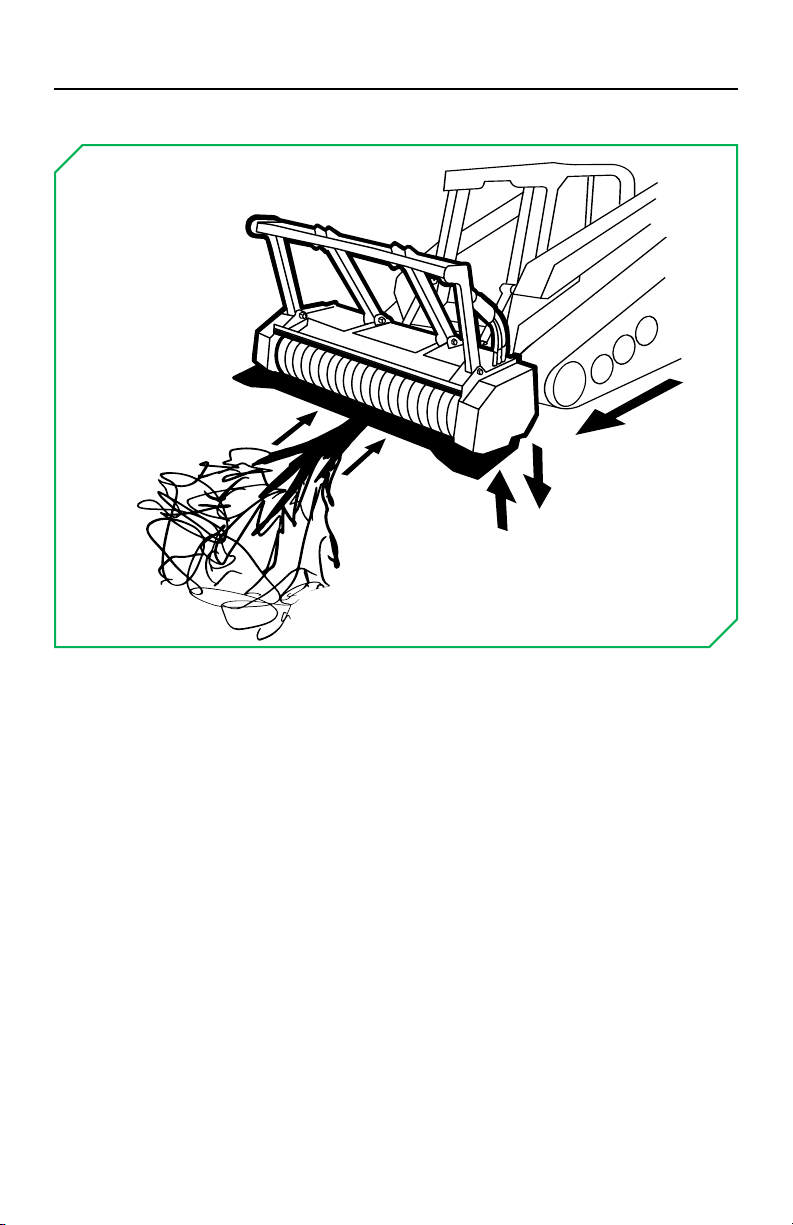

BASE CUT

OPERATING YOUR DRUM MULCHER

Use to cut trees at their base, push over, and process on the ground.

•Pitch the mulcher back slightly to engage the drum into the tree.

•Drive forward to engage the tree with the drum.

•Tip forward using the push bar to guide the tree away from the carrier.

•Tree tops should fall forward away from the carrier, ready for mulching.

•For very large trees, notch it (similar to using a chainsaw), and approach

them from the other side to cut and drop the tree.

1

2

3

4

16

© Diamond Mowers®, LLC

Use to cut stumps at, or below ground level.

•With the drum angled slightly down, cut the stump low to the ground.

◦Rebuild speed before proceeding with a stump cut.

•Angle the drum’s nose down, cutting the stump flush to the ground.

◦NOTE: The more you use the stump cut application, the more wear your

teeth will incur.

STUMP CUT

17

© Diamond Mowers®, LLC

For more tips, visit us online at www.DiamondMowers.com

Use to clean up branches and large debris. Re-processing the debris

will provide a groomed finish.

•Raise lift arms about 6” (152mm) and drop the front of the drum toward

the ground.

•Back over the remaining debris for a more finished look.

CLEANING & RE-PROCESSING

OPERATING YOUR DRUM MULCHER

18

© Diamond Mowers®, LLC

MAINTENANCE

Regular maintenance will make certain your unit stays productive and retains

a long operating life. The following chart represents the minimum intervals

recommended for inspection and maintenance.

MAINTENANCE INTERVALS

PROCEDURE

10

HOURS/

DAILY

50

HOURS/

WEEKLY

150

HOURS

AS

NEEDED

ANTI-WRAP GUARDS Inspect

BEARINGS Grease Inspect

BELT & PULLEYS Inspect

CHAIN GUARD Inspect

DRUM Inspect

DRUM LINER Inspect Replace

HOSE CARRIER Inspect

HYDRAULIC HOSES & FITTINGS Inspect

MOTOR BOLTS Inspect

PUSH BAR Inspect

QD COUPLERS Inspect

SAFETY POLYCARBONATE Inspect Clean

SKID SHOES Inspect Replace

TEETH Inspect Replace

TOOTH HOLDERS Inspect Replace

When replacing parts, use Genuine Diamond Parts. Guaranteed to ship within

72-hours of your order being placed, or the parts and shipping are free.

Call: 888-960-0361 or 605.977.3300 | Email: [email protected]

Order online: www.diamondmowers.com

19

© Diamond Mowers®, LLC

MAINTENANCE

ANTI-WRAP GUARDS

•Anti-wrap guards(1) should be

inspected every 150 hours

or monthly.

◦Anti-wrap guards(1) are located

behind the drum in the interior of

the machine.

•Replace the anti-wrap guards(1) as

needed.

◦Remove the side access covers(2).

-Anti-wrap guard(1) hardware is

accessed from inside the side

access covers(2).

◦Mounting bolts(3) are located in

the low center of the frame for

each anti-wrap guard(1).

-Use Loctite 262.

-Torque the mounting bolts(3)

to 212ft-lbs (287Nm).

(3)

(1)

(2)

20

Table of contents

Other diamond mowers Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions