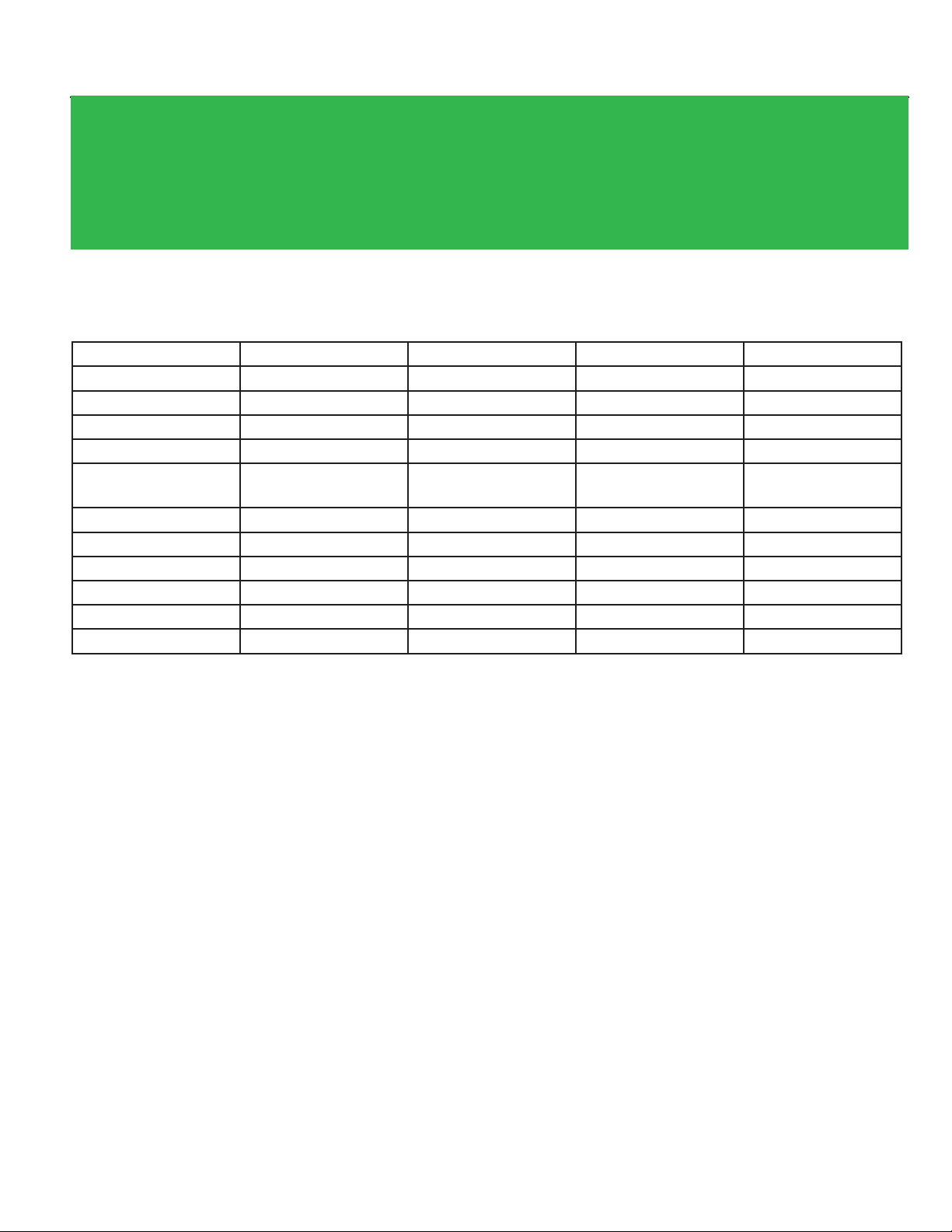

DRUM MULCHER MAINTENANCE SCHEDULE............................................................................................... 4

MAINTENANCE INTERVALS ................................................................................................................................................ 4

MOTOR TUNING ...................................................................................................................................................... 5

VALVE BLOCK SCHEMATIC.................................................................................................................................................. 5

TOOTH AND TOOTH HOLDER MAINTENANCE................................................................................................ 6

TEETH..........................................................................................................................................................................................6

REPLACING TOOTH HOLDERS.............................................................................................................................................7

BELT AND PULLEY MAINTENANCE.................................................................................................................... 8

PULLEY AND BELT INSPECTION........................................................................................................................................8

BELT INSPECTION..................................................................................................................................................................8

PULLEY INSPECTION ............................................................................................................................................................9

BEARING MAINTENANCE.................................................................................................................................. 10

GREASING BEARINGS.........................................................................................................................................................10

BEARING INSPECTION.......................................................................................................................................................10

SKID SHOE MAINTENANCE ...............................................................................................................................11

SKID SHOE REPLACEMENT................................................................................................................................................11

DRUM MAINTENANCE ........................................................................................................................................ 12

DRUM MOTOR BOLT MAINTENANCE............................................................................................................. 13

SAFETY POLYCARBONATE MAINTENANCE.................................................................................................. 14

SAFETY POLYCARBONATE CLEANING ........................................................................................................................... 14

HOSE MAINTENANCE.......................................................................................................................................... 15

HOSE AND FITTINGS........................................................................................................................................................... 15

QUICK DISCONNECT COUPLERS .................................................................................................................................... 15

HOSE POSITION.................................................................................................................................................................... 15

TROUBLESHOOTING ............................................................................................................................................ 16

TROUBLESHOOTING............................................................................................................................................................16

APPENDIX ................................................................................................................................................................17

REPLACEMENT PARTS.........................................................................................................................................................17

30” ASSEMBLIES .................................................................................................................................................................18

50” ASSEMBLIES .................................................................................................................................................................24

DECAL INSTALLATION ....................................................................................................................................................... 30

BOSS FITTINGS ....................................................................................................................................................................32

TORQUE SPECS .................................................................................................................................................................... 33

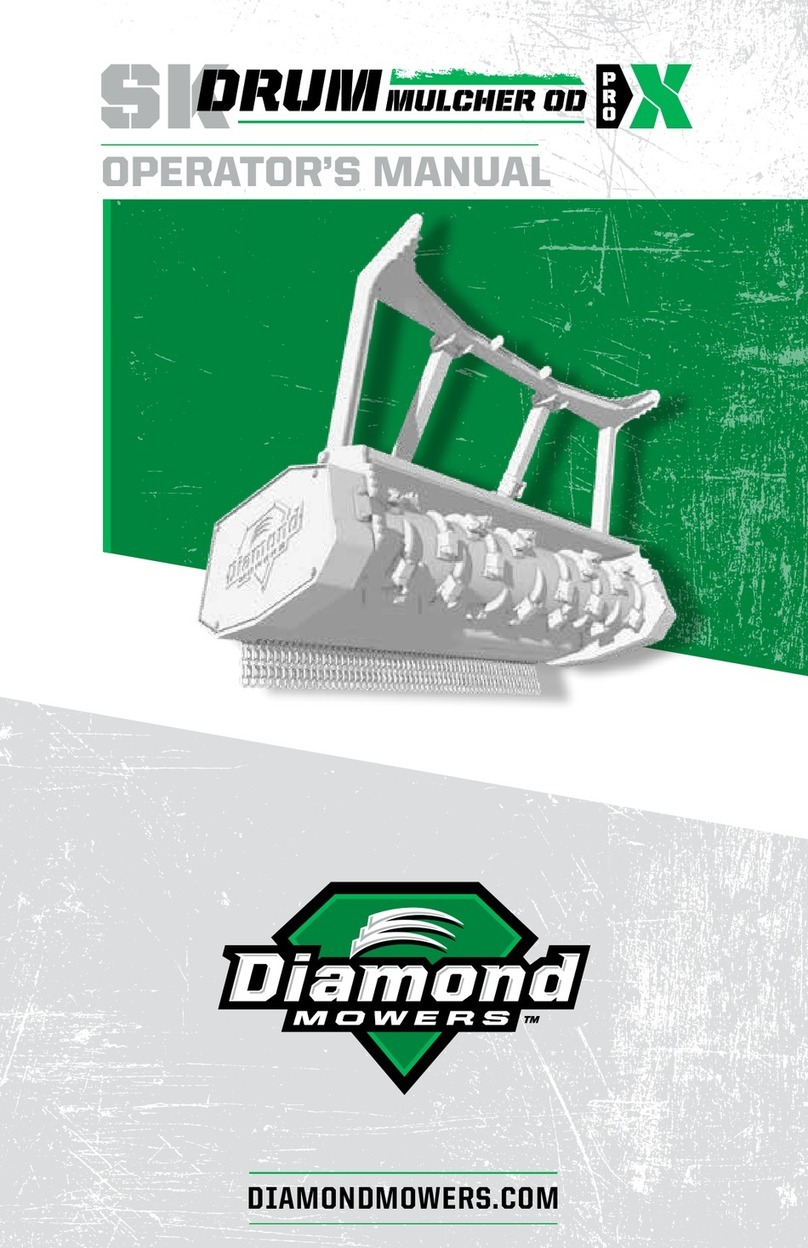

TABLE OF CONTENTS