JetBox-FloydSC User Manual rev 0.1 www.diamondsystems.com Page 2

Contents

1. Important Safe Handling Information .............................................................................................................4

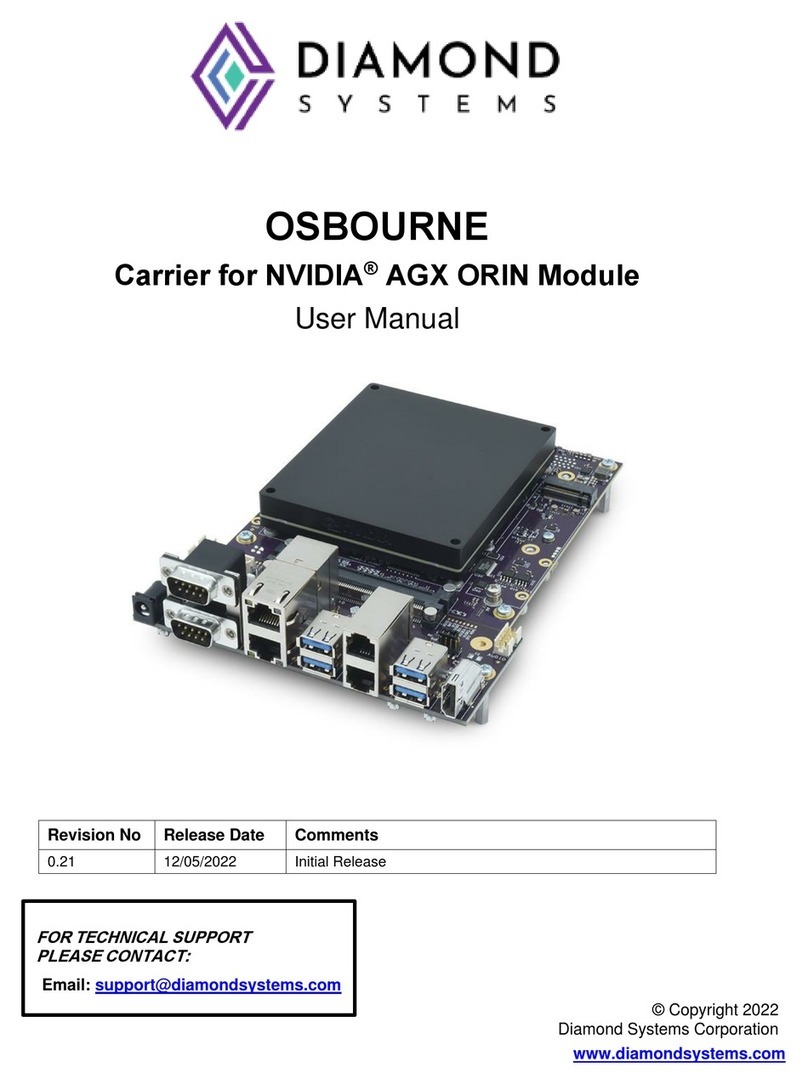

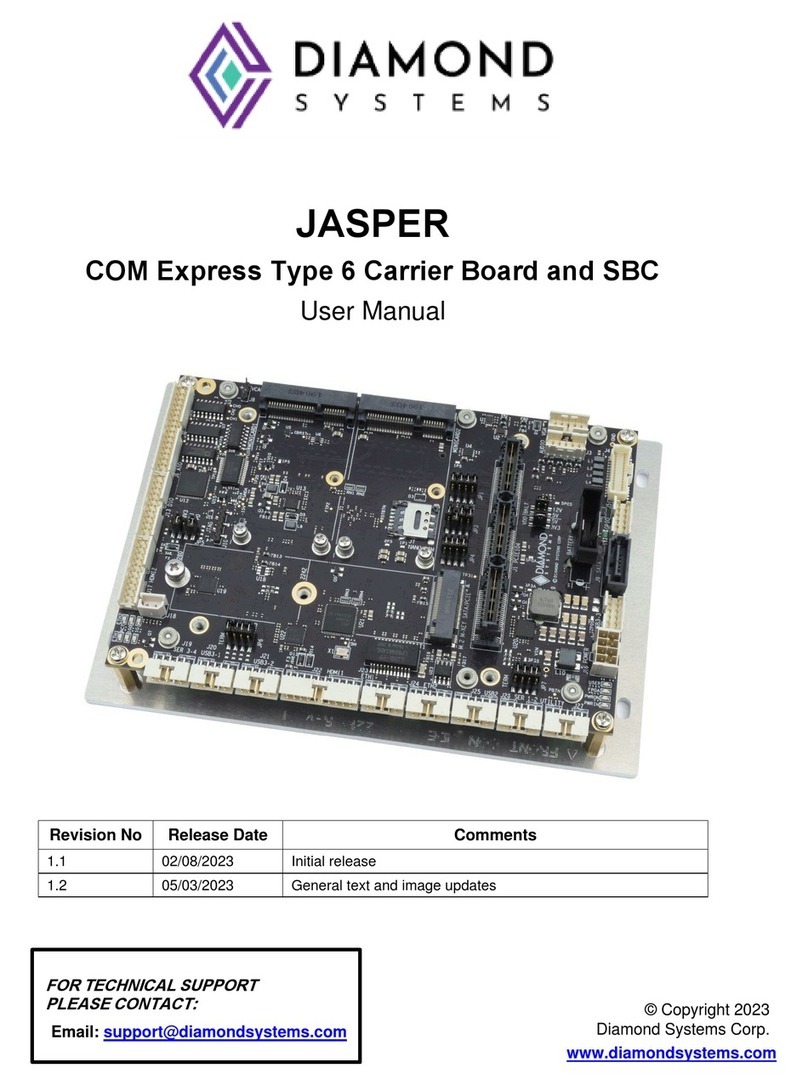

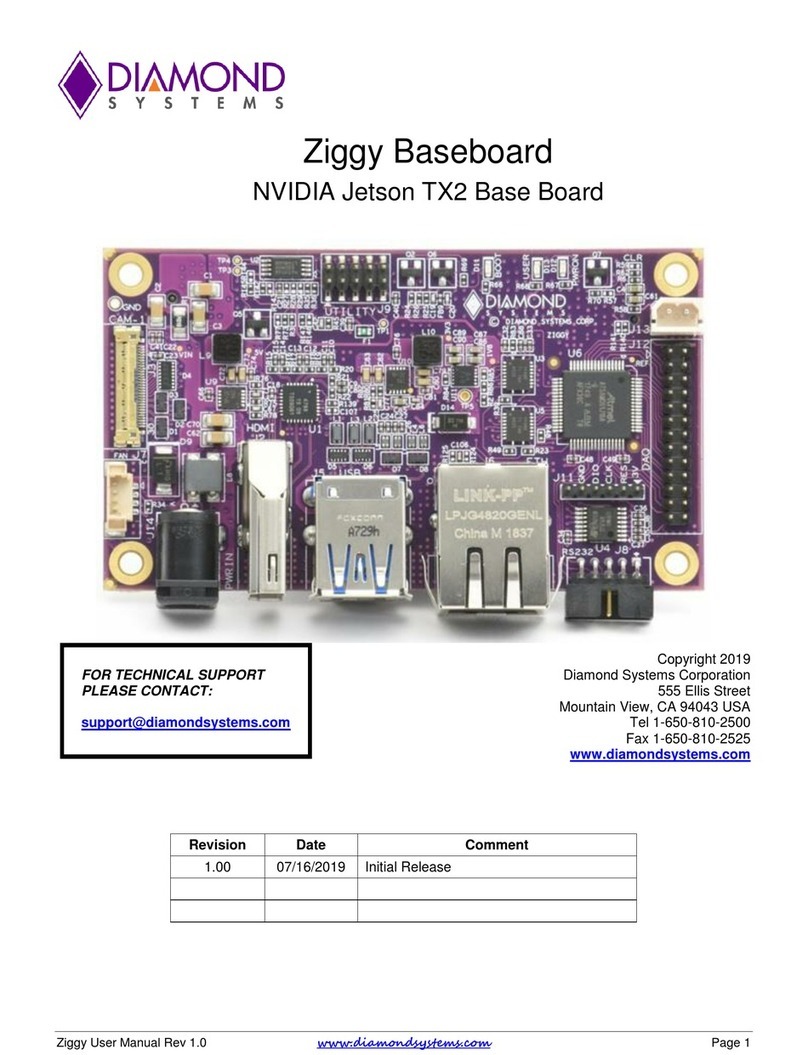

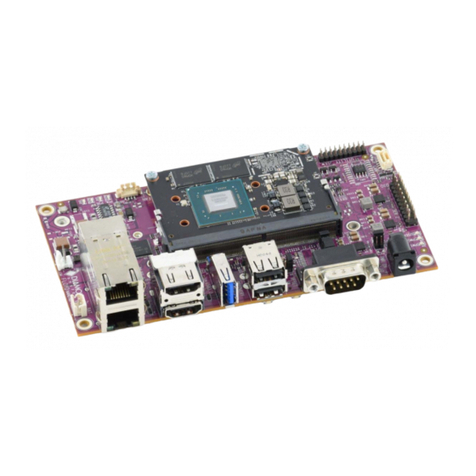

2. Introduction & System Configurations...........................................................................................................6

JetBox-FloydSC System Overview................................................................................................................6

System Configurations ..................................................................................................................................6

3. Functional Overview.........................................................................................................................................7

Power Supply Specifications.........................................................................................................................7

USB Ports......................................................................................................................................................7

Display...........................................................................................................................................................7

Ethernet Ports................................................................................................................................................7

Serial Ports....................................................................................................................................................7

Digital I/O.......................................................................................................................................................7

4. Block Diagram...................................................................................................................................................8

5. Mechanical Drawing .........................................................................................................................................9

3D STEP Model.............................................................................................................................................9

2D Drawing....................................................................................................................................................9

6. Connectors, LEDs & Jumper Locations...................................................................................................... 10

JetBox-FloydSC Front Panel Call Outs...................................................................................................... 10

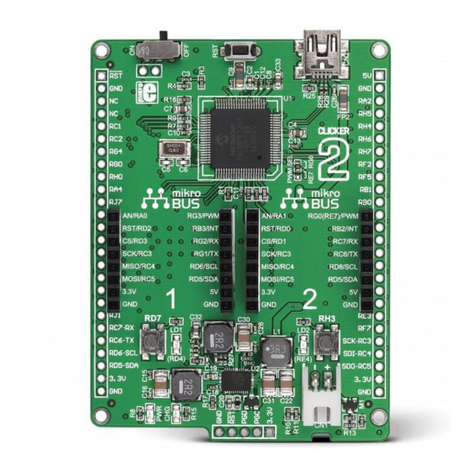

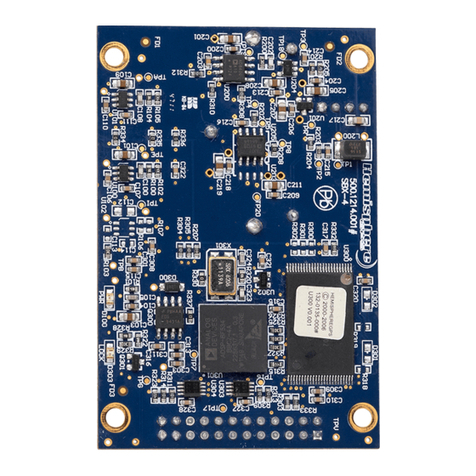

FloydSC Carrier board Callouts –TOP...................................................................................................... 11

FloydSC Carrier board Callouts –BOTTOM.............................................................................................. 11

7. Jumper Configuration ................................................................................................................................... 12

Digital I/O Configuration ............................................................................................................................. 12

USB2.0 Top Port Host/Device Selection.................................................................................................... 13

Serial Ports Configuration........................................................................................................................... 13

8. Connector Pinouts......................................................................................................................................... 14

System Front Panel Connectors................................................................................................................. 14

Input Power Connector.................................................................................................................... 14

HDMI Port........................................................................................................................................ 14

Display Port...................................................................................................................................... 14

Ethernet Ports.................................................................................................................................. 15

USB2.0 Ports................................................................................................................................... 15

USB3.0 Port..................................................................................................................................... 15

Serial Ports ...................................................................................................................................... 16

Digital I/O......................................................................................................................................... 16

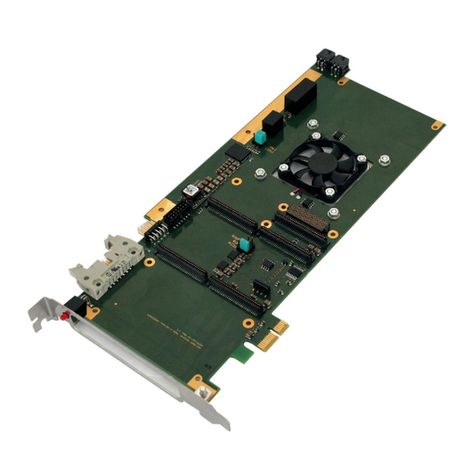

FloydSC Base Board Connectors............................................................................................................... 16

RTC Battery (J18)............................................................................................................................ 16

Daughter Board Power Feed (J21).................................................................................................. 17

Camera (J15,J16,J20) ..................................................................................................................... 17

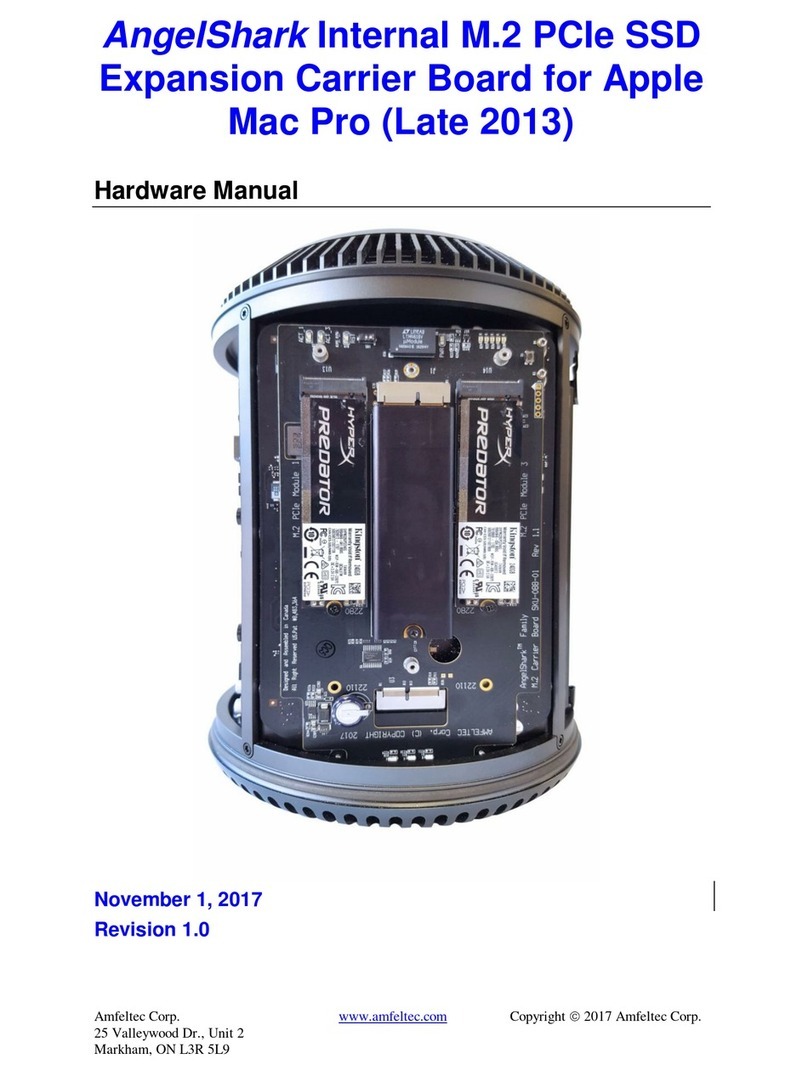

M.2 PCIe Connector (J19)............................................................................................................... 18

Daughter Board Expansion Connector (J9)..................................................................................... 19

Controlled Area Network (J14) ........................................................................................................ 20

Fan Connector (J17)........................................................................................................................ 20

Utility Connector (J12)..................................................................................................................... 20

9. I/O Connector List.......................................................................................................................................... 21