A010018 Rev. 4 Pag. 6 di 18

6. INSTALLATION

6.1 Preliminaries

The usermust install the powersupply in accordance with the instructionsgiven in Fig. 3(inthe case of fixedassembly) and in

compliance with thestandards in force.

6.2 Positioning

Move the equipment into place with the aid of apallet truck, where necessary. If theunit is moved after it hasbeenunpacked,protect

the surfaces from knocks.

The standard equipmentis issued with wheels. If mounted on feet (optionalextra), regulate the adjustable feet to obtainthedesired

height and compensate forany unevenness orslopeofthefloor. During this phase, make sure any doors on the lower compartment

are properly closed. Once installation iscomplete, the protective film can be removed. This operation should beperformed very slowly

toprevent the glueremaining attached to the surfaces. If this happens, use kerosene or petrol to remove it.

6.3 Electrical connections

Connectionsmust bemadeby aqualified electrician in accordance with the localstandards in force. The equipment’s electric circuit is

designedto work with asingle-phasesupply voltageof 230Volts andafrequency of 50/60 Hz. See the wiringdiagram in Fig. 2

referring to the model purchased.

The equipment isconnected by means oftheplug undertheinstrumentpanel: simply plugit intoaportable socket-outlet connectedto

the room’s power mains.

The cable must have thefeatures of typeH05 RNF or better, andmust featurean efficient earthwire ofan appropriate size for thetotal

power of this unit andany other units oraccessories connected on the same terminal board (see rating plate).

The unit’s electrical supply systemmust featurean appropriately sizedautomatic omnipolarcircuit breaker upstream that assures a

gap between the contacts of at least 3mm. Theremust not be any breaks in theearth cable.

The electrical safety of this equipment is only assured whenthe above-mentioned conditions aremet and if the system’s equipotential

situation is also in order(usethe connection screw locatednearthe power cable entry and thelabel featuring thesymbol)

The manufacturer declines all responsibilityin the eventthese safetystandards are not complied with.

7. OPERATION / USE

7.1 Operating tips

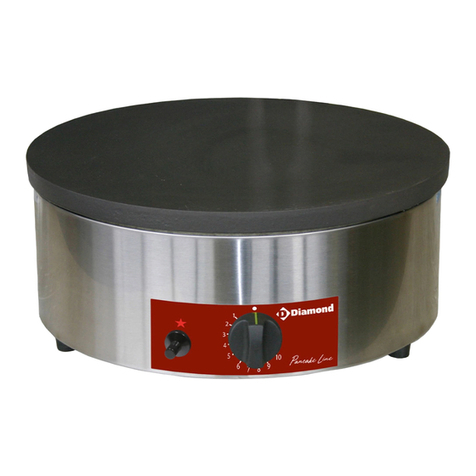

•This equipment must beused solely for the use for which it was expressly designed: i.e.displaying foods contained in pots and

pans andforkeepingthem warm, andfor storingand warmingcrockery in thelower compartment. Any otheruse shall be

considered improper.

•In orderto avoid scratching the safety glass top, you arerecommended to use pots and pans with smooth, flat bottoms. If the

safety glass topis usedas a worktop(whencold),it must becleanedthoroughly before it is next switched on. If pans are placedon

top of abrasive residues, the safety glass top may be scratched.

•Before usingtheequipment forthe first time,clean the safety glass top with asuitable product andkitchen towel. Avoid using

abrasivedetergents or scouringpowders.

•Lastly, wipe the top with a dampcloth and dry thoroughly.

7.2 Starting up

•Powerup the glass top by setting switch Cto 1, turnknob Aclockwiseuntil light Bcomes on. If you keep turning, thetemperature

is increased. When the knob is at themaximumsetting, the heating remains on constantly.

•Inordertoswitch on the heated compartment,turnknob Dclockwise until light Ecomeson.Turningfurther, you can set the

desired temperature. The graduatedscale is meant as a roughguideonly.

7.3 Switchingoff

Switch the equipment off by turningknobs A(top) and D(heated compartment,where fitted), in Fig. 1, anticlockwisealltheway,

making sure that lights B (top) and C (heated compartment, wherefitted) go off.

Turnoff the circuit breaker upstreamfrom the equipment.

Inthe event the unit is to be left off for a lengthy period:

a)disconnect the power supply;

b)clean thetop thoroughly;

c)protect the stainless steel surfaces by smearing themwithVaseline oil, rubbing vigorously with acloth soaked in the oil;

d)airtheroom periodically, leaving thedoors of the cabinet open toprevent undesirable smells from forming.

8. CLEANING AND MAINTENANCE

8.1 Routine maintenance

The routine andpreventive maintenancebasically consists in the weekly cleaningof the stainless steel parts with lukewarmsoapy

water, rinsingabundantly and dryingthoroughly. Theunit must only be cleaned afterfirst disconnecting the powersupply upstream

fromthe equipment.

Inorder toget the most out of the safety glass top, it is essential you bear inmind a numberof tips and instructions:

•Before starting, remove any dirt or food left on the safety glass top with aspecial plastic scraper.

•Next, poura few drops of a suitable detergent onto the COLD safety glass top andrubwith kitchentowel (or a soft cloth).

•Rinsethe safety glass top and dry with aclean cloth orkitchentowel.

Important:

•Inthe event sheets of aluminium or plastic, sugar or food containingsugarmelt onto thesurface of the safety glass top, they must

be removedfrom the hot cooking area immediately with ascraper. This will prevent possible damageto the surface.

Before cooking food withahighsugarcontent (e.g. jams),apply a protective product onthe top’s surface to prevent damage fromspills

fromthe cooking receptacle.

Do not use abrasivesponges or productsofanykind, or detergentssuch as oven cleaning spraysor stain-removers.

Warning:

•Under nocircumstances should youuse abrasive orcorrosive detergents andutensils such as steelwool, brushes or metal

scrapers.

•Bleach, hydrochloric acid and other compounds containingchlorine willdamage the stainless steel.

•The coloured parts must be cleanedwith silicone wax.

•The floor underthe unit must not be washed with corrosivesubstances that might generate vapours damaging the equipment.

•During cleaning, do not wash the equipmentwith jets ofwater.

GB

PDF created with FinePrint pdfFactoryPro trial version http://www.fineprint.com