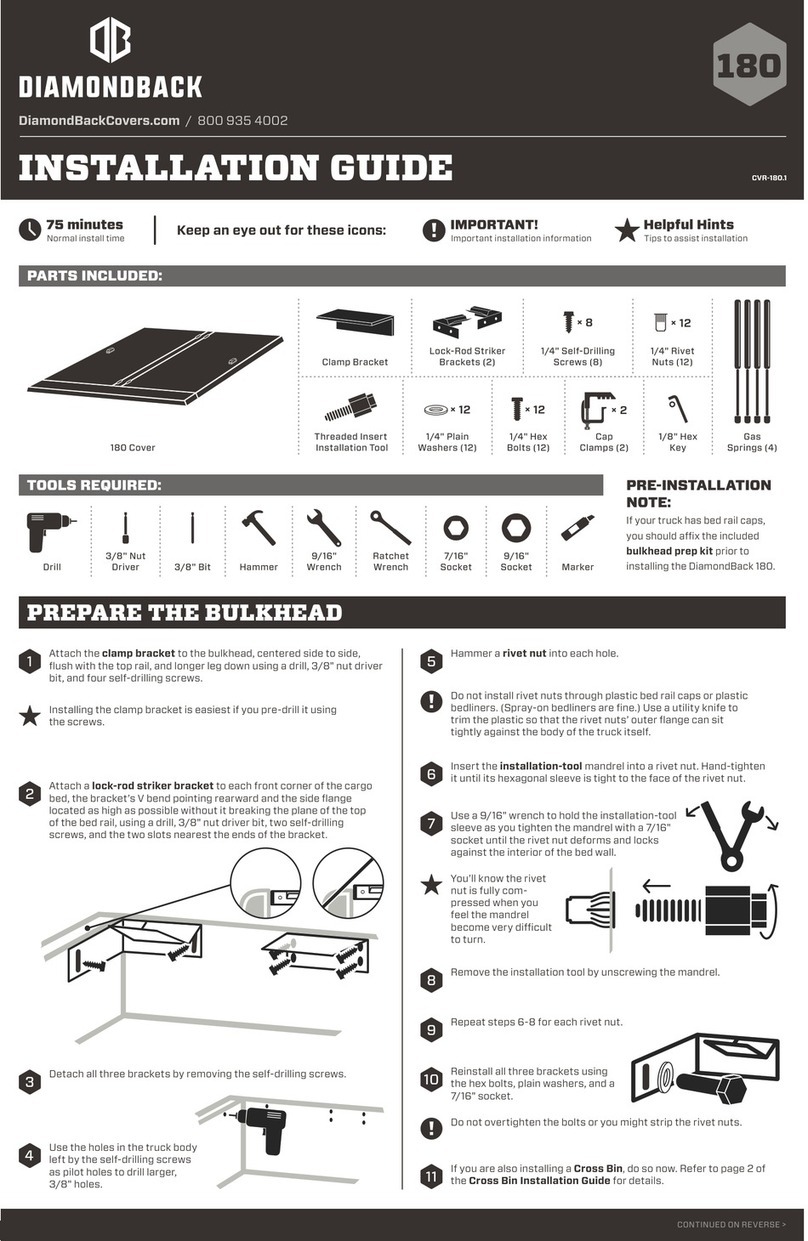

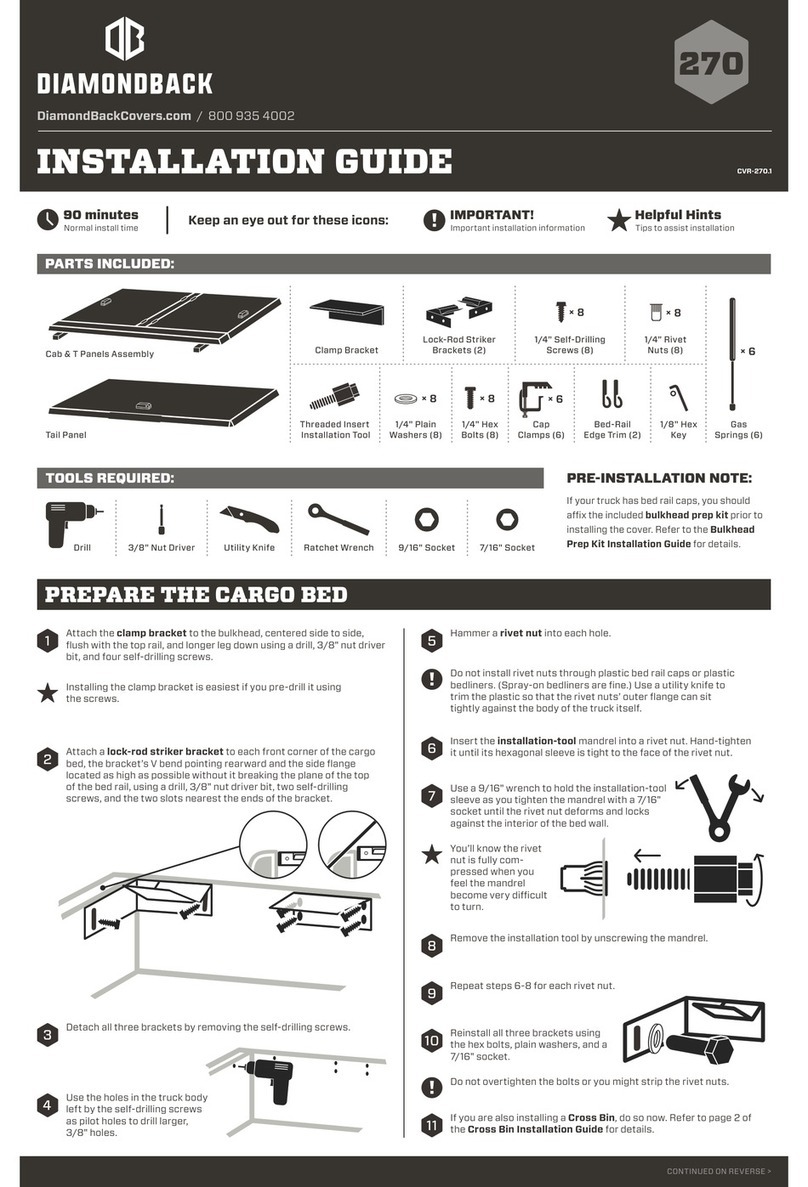

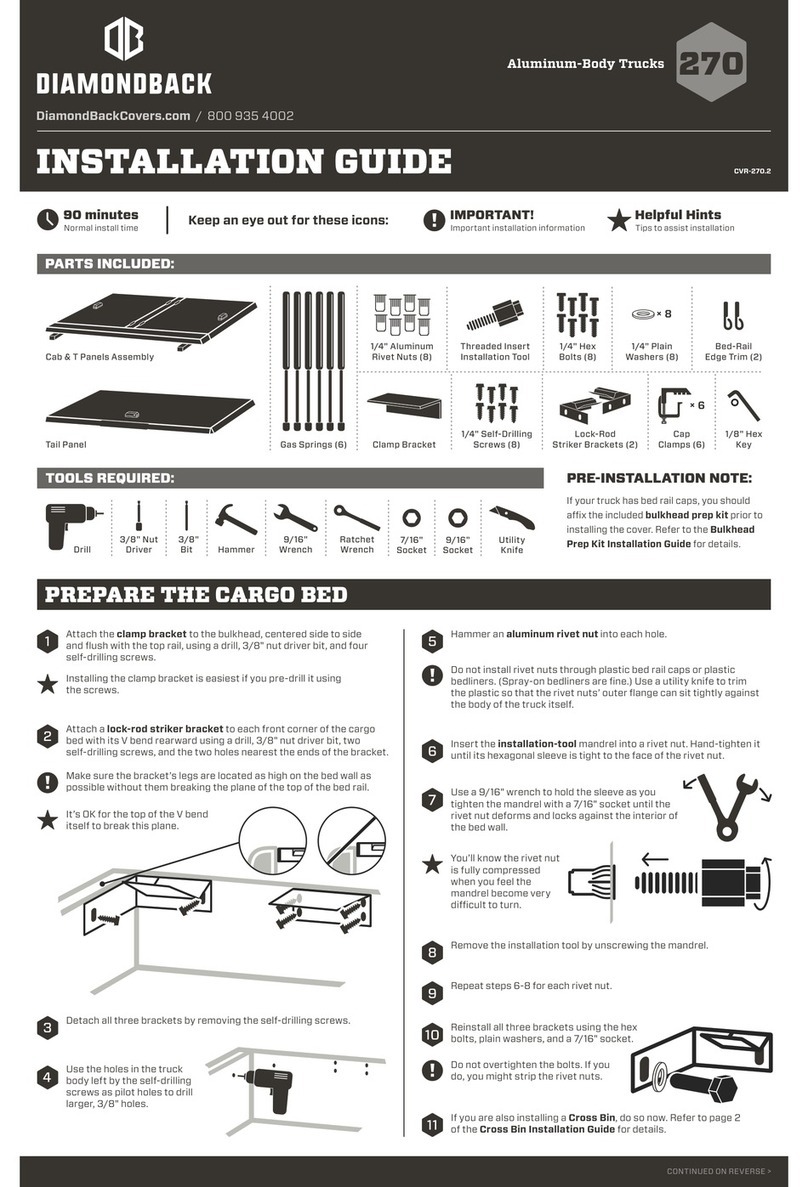

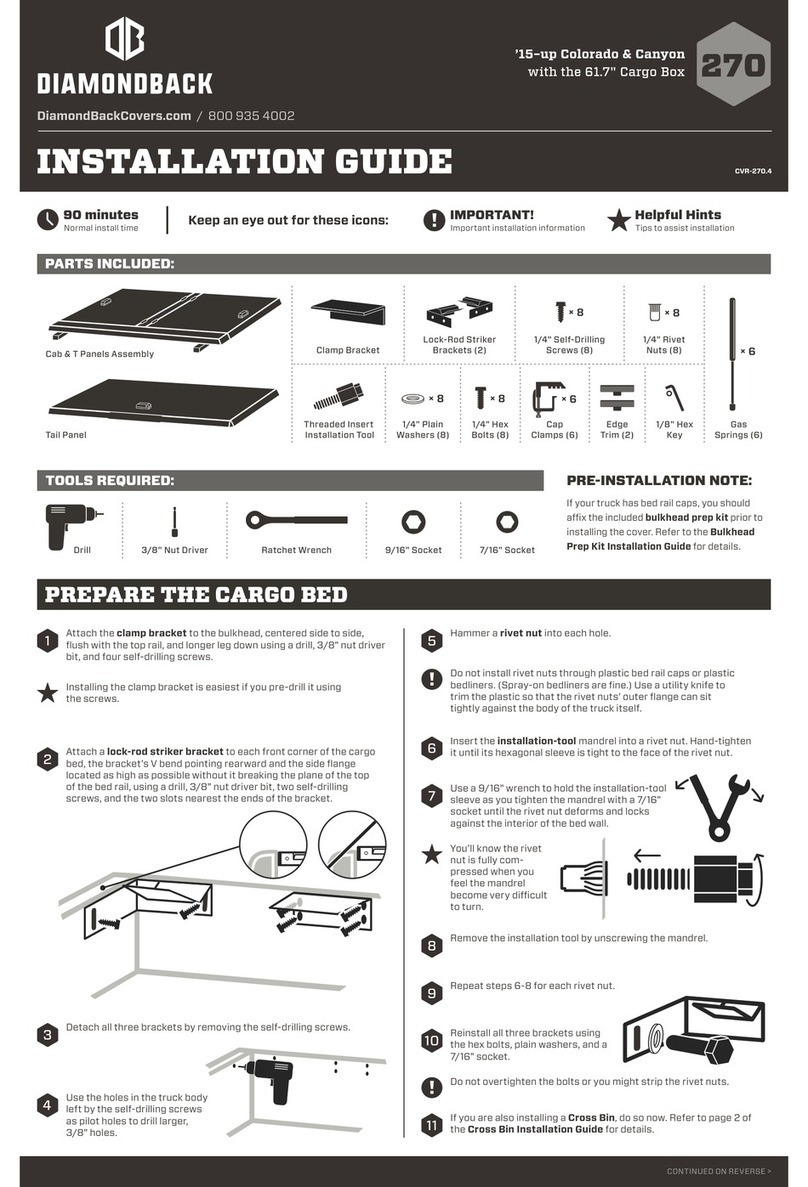

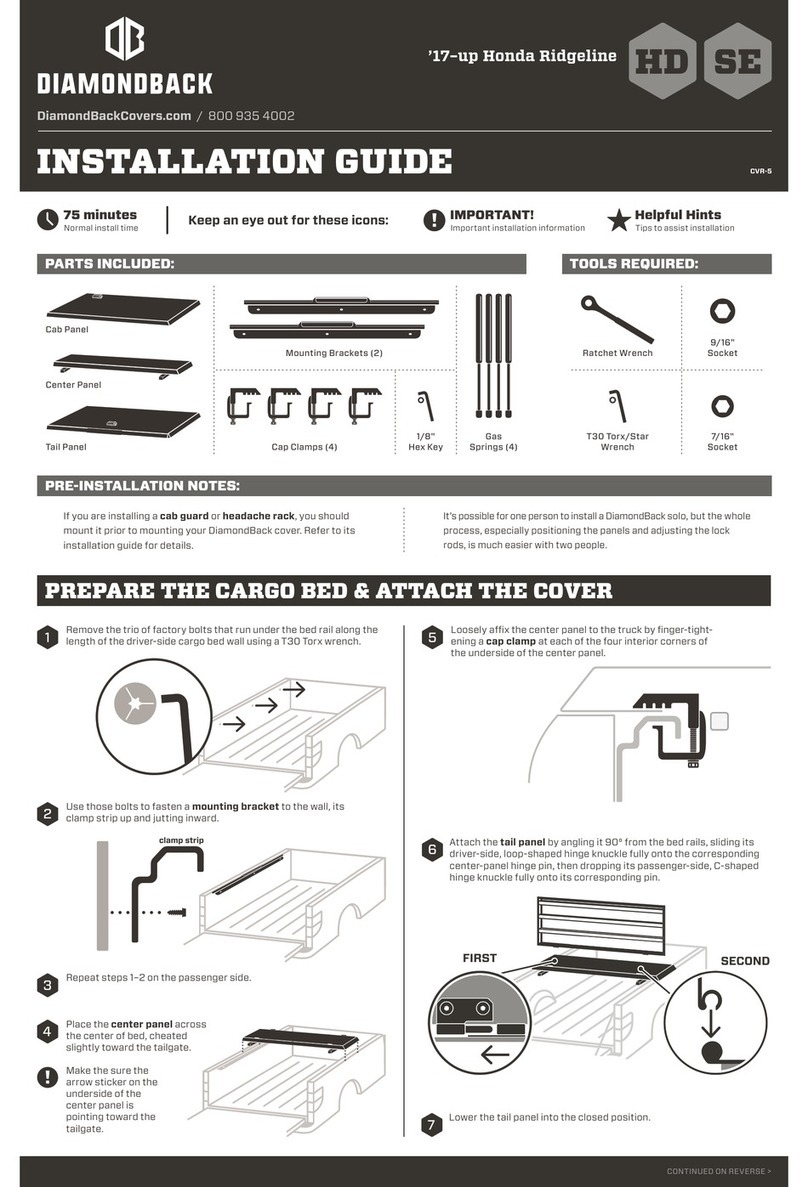

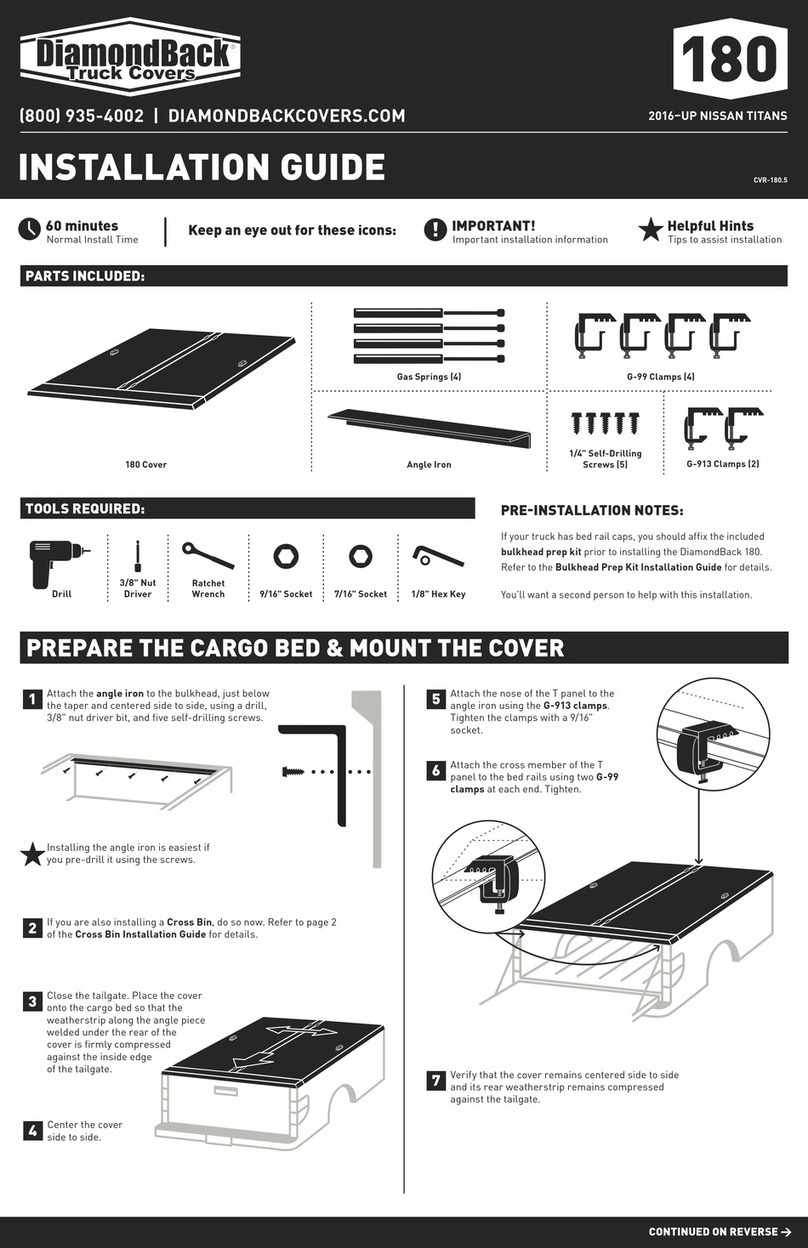

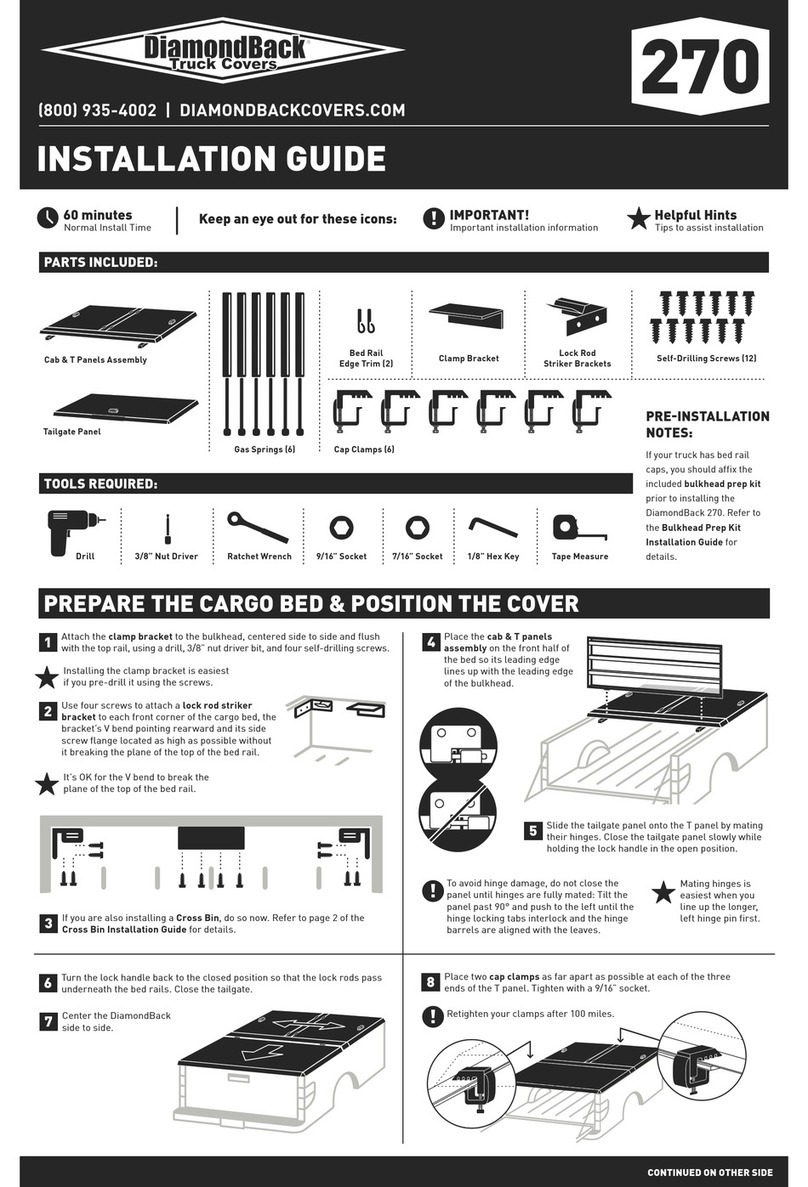

ADJUST THE LOCK RODS

Press the plastic bushings until they snap

into place in each of the factory holes in

the bed walls under the panel. (See

step 10 illustration for location.)

With the lock handle in the closed

position, position the lock rods

tight against the top rims of the

factory holes in the bed wall so that

they’ll draw the panels down and

compress the weatherstrip. Tight-

en the rod guide brackets with a

7/16" socket.

There may be plastic plugs in the

factory holes. Remove them.

9

8

DiamondBackCovers.com MARCH 2022

ADJUST THE LOCK RODS

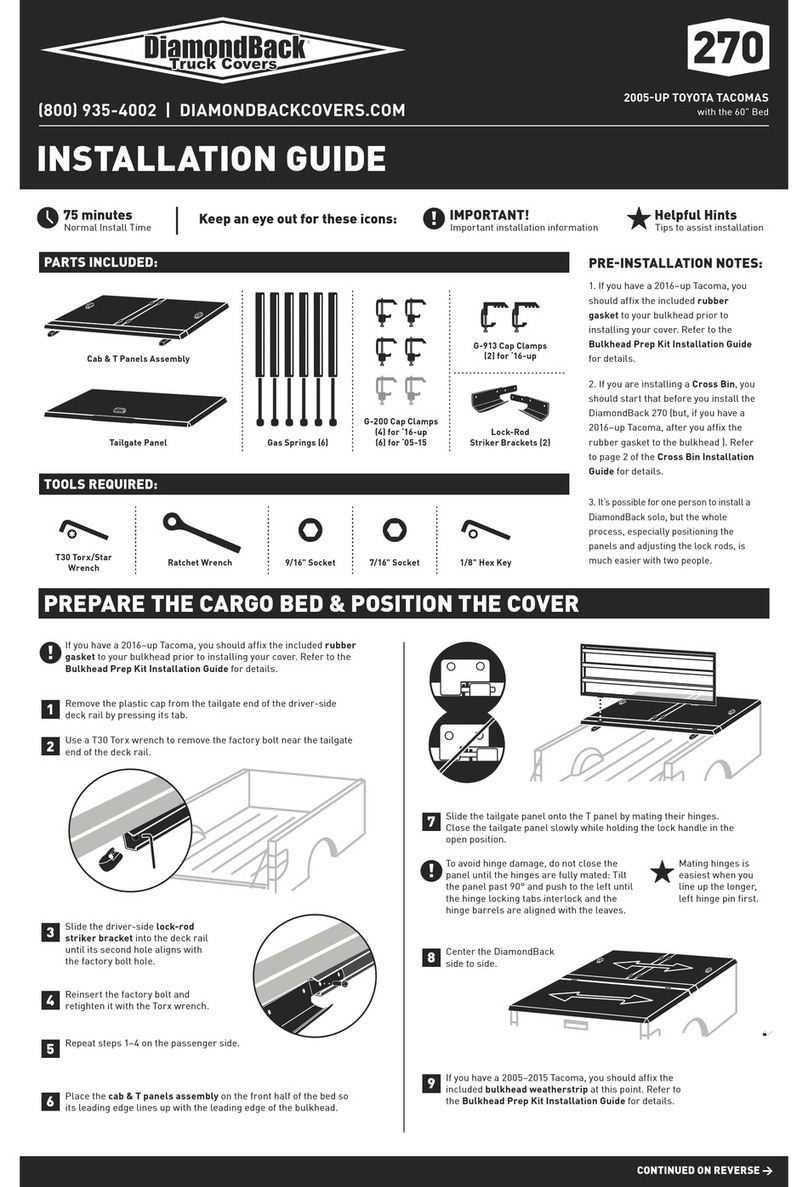

ATTACH THE SAFETY CATCH & GAS SPRINGS

10 With the lock handle in the open position, adjust the length of the lock

rods so that their tips stop about 1/4" short of the factory holes.

11

For best weather

protection, have a

second person press

down on the cover while

you adjust the lock rods.

Using the access panels is easiest when you

press down as you open or close them.

12 Repeat steps 8 through 11 for

the cab panel.

Your panels should be hard to operate

at first. After finishing install below,

leave the panels closed as much as possible for 3–4 days

to break in the weatherstrip. After that period, you should

find that the panels open and close without diculty.

If you are also installing a Cross Bin, do so now. Refer to

the Cross Bin Installation Guide for details.

If the lock rods are still dicult to operate after the break-in

period, rub a small amount of petroleum jelly on the top of their

rubber end caps.

1/8"hex key

Attach the two remaining gas springs—barrel up, shaft

down—to the ball studs on the tail panel.

17

If your truck has bed rail caps, ax the included bulkhead

weatherstrip if you haven’t already. Refer to the Bulkhead

Prep Kit Installation Guide for details.

18

Adhesive cure time

24 hours

Leave the cover closed and locked for 24

hours to allow the weatherstrip adhesive,

which is pressure-sensitive, to fully cure.

19

Slip the looped ends

of the cable tethers

attached to the

underside of the cab

panel around the

center-panel ball stud

arms, well past the

ball studs and nuts.

Attach a gas spring—barrel up, shaft down—to each of

the pairs of ball studs on the cab panel.

15

14

Open the cab panel. Have a second person support it

in the open position.

13

THIS END

UP

Push the keyhole at the bottom of the

safety catch hanging from the cab

panel’s driver side around the nut

protruding from the outboard side

of the ball stud arm, flexing the

spring clip so the nut can pass

through, then allowing the panel

to open fully so the nut can slide

into the narrower part

of the keyhole and

spring clip come

back into place

behind the nut.

16

If two of your gas springs have heavier poundage printed on the

side of their barrels than the others, use them here. If just one of

the springs is stronger, use it on the driver side.

Loosen the set screws on the

tail-panel lock-rod linkages.

7/16" socket