Dickey-John Control Point User manual

CONTROL POINT®

CONTROL SYSTEM

Operator’s Manual

SINCE 1966

®

OPERATOR’S MANUAL

Control Point®

11001-1489-201702 Rev B

I

Safety Notices ..................................................................................................... 1

Introduction ......................................................................................................... 3

Granular Channel Configuration ....................................................................................... 3

Liquid Channel Configuration ............................................................................................ 4

Spinner Channel Configuration ......................................................................................... 4

Product Application Mechanisms ...................................................................................... 4

Console ............................................................................................................................................ 5

Switch Module .................................................................................................................................. 6

Keyboard .......................................................................................................................................... 6

Ground Speed Sensor ..................................................................................................................... 6

Feedback Sensors ........................................................................................................................... 6

Valve Control Devices ...................................................................................................................... 7

Hopper Level Sensor (optional) ....................................................................................................... 7

Harnesses ........................................................................................................................................ 7

Technical Support ............................................................................................................. 7

System Installation ............................................................................................. 9

Hardware Kits ...................................................................................................................9

Standard Hardware Kit Console and Switch Module ........................................................................ 9

Optional Hardware Kit for Console only ............................................................................................ 9

Console Placement ......................................................................................................... 10

U-Bracket Mounting ........................................................................................................ 10

Console and Switch Module Installation ......................................................................... 10

Switch Module to Console Connection ........................................................................... 11

Console Mounting ........................................................................................................... 11

Harness Connection ....................................................................................................... 11

Main Harness Connection ............................................................................................... 12

Checking Operation ........................................................................................................ 13

Start-up and Familiarization ............................................................................. 15

Start-up Preparation ........................................................................................................ 15

Start-up Procedure .......................................................................................................... 15

Operate Screen Display Functions ................................................................................. 17

Material/Manual Speed Select ....................................................................................................... 18

Accessing the Current Totals Screen .............................................................................................20

Clearing the Current Totals ............................................................................................. 21

Accessing the Season Totals Screen ............................................................................. 22

Using the Blast Button .................................................................................................... 22

Master Switch in the Unload Position ............................................................................. 23

Keyboard Programming ................................................................................... 25

Logging Configuration Data ............................................................................................ 25

Pre-programming ............................................................................................................ 25

Using the Keyboard and Screens ................................................................................... 26

Miscellaneous Menu (F12) .............................................................................................. 29

Blast Setup ..................................................................................................................................... 29

Time/Date Setup ............................................................................................................................ 30

System Units .................................................................................................................................. 30

Serial Port Configuration ................................................................................................................ 31

Service Menu .................................................................................................................................. 32

OPERATOR’S MANUAL

Control Point®

11001-1489-201702 Rev B

II

Keyboard Programming continued

Sensor Selection ............................................................................................................ 35

Gate Height Sensor ........................................................................................................................ 36

Gate Height Calibration .................................................................................................................. 36

Road Temperature Sensor ............................................................................................................. 37

Temperature Sensor Calibration .................................................................................................... 38

Air Temperature Sensor ................................................................................................................. 39

Air Temperature Sensor Calibration ............................................................................................... 40

12V Boom Switched Output ........................................................................................................... 41

Down Pressure Sensor ................................................................................................................... 42

Down Pressure Sensor Calibration ................................................................................................42

Bed Height Sensor ......................................................................................................................... 43

Bed Height Sensor Connection ...................................................................................................... 43

Bed Height Sensor Calibration ....................................................................................................... 44

Accessing the Operate Mode (F1) .................................................................................. 45

Setting Up Granular Configuration (F3) .......................................................................... 45

Programming Granular Application Rates (F2) .............................................................. 48

Liquid Configuration Setup (F5) ...................................................................................... 50

Setting Liquid Configurations .......................................................................................................... 50

Tank Level Sensor Configuration ................................................................................................... 52

Enabling Tank Level Sensor ........................................................................................................... 53

Tank Empty and Tank Full .............................................................................................................. 53

Tank Alarm ..................................................................................................................................... 53

Tank Capacity ................................................................................................................................. 54

Boom Configuration ........................................................................................................ 55

Programming Liquid Application Rates (F4) ................................................................... 57

Ground Speed Configuration (F7) .................................................................................. 61

Ground Speed Calibration (F7-1) ................................................................................... 63

Spinner Channel Configuration (F8) ............................................................................... 65

Monitor & Reset Accumulators (F9) ............................................................................... 67

Reading System Information (F10) ................................................................................. 69

Performing System Response (F11) .............................................................................. 71

System Calibration ........................................................................................... 73

Recording Calibration Data ............................................................................................ 73

Repeating Calibration Runs ............................................................................................ 73

Maintaining Calibration Accuracy ................................................................................... 73

Calibration System Response (F11) ............................................................................... 75

Granular System Response Calibration ......................................................................................... 75

Fine Tuning System Response Constants ..................................................................... 77

SYS RSPNS Constant .................................................................................................................... 77

Valv Boost ...................................................................................................................................... 78

AFILT .............................................................................................................................................. 78

Proportional Valve Spinner Calibration ........................................................................................... 78

Granular Materials Calibration (F6) ................................................................................ 79

Granular Calibration Fine Tuning ................................................................................... 81

Liquid Materials Calibration (F6) ..................................................................................... 81

Liquid Calibration Fine Tuning ........................................................................................................ 84

Calibrating Spinner Width (F6) ....................................................................................... 84

Troubleshooting ............................................................................................... 87

OPERATOR’S MANUAL

Control Point®

11001-1489-201702 Rev B

III

Appendix A Converting Constants ................................................................. 97

Fine Tuning Application .................................................................................................. 97

Calculating Spreader Constants ..................................................................................... 98

Calibration Data Record Sheet ..........................................................................99

Warranty ............................................................................................................107

OPERATOR’S MANUAL

Control Point®

11001-1489-201702 Rev B

IV

OPERATOR’S MANUAL

Control Point

®

11001-1489-201702 Rev B

SAFETY NOTICES / 1

SAFETY NOTICES

Safety notices are one of the primary ways to call attention to potential

hazards.

This Safety Alert Symbol identifies important safety

messages in this manual. When you see this symbol,

carefully read the message that follows. Be alert to

the possibility of personal injury or death.

Use of the word WARNING indicates a potentially hazardous

situation which, if not avoided, could result in death or serious

injury.

Use of the word CAUTION with the Safety Alert Symbol indicates a

potentially hazardous situation which, if not avoided, may result in

minor or moderate injury.

Use of the word CAUTION without the safety alert symbol

indicates a potentially hazardous situation which, if not avoided,

may result in equipment damage.

DISCLAIMER

DICKEY-john reserves the right to make engineering refinements or

procedural changes that may not be reflected in this manual. Material

included in this manual is for informational purposes and is subject to

change without notice.

OPERATOR’S MANUAL

Control Point

®

11001-1489-201702 Rev B

2 / SAFETY NOTICES

OPERATOR’S MANUAL

Control Point

®

11001-1489-201702 Rev B

INTRODUCTION / 3

INTRODUCTION

The DICKEY-john Control Point®system uses three-channels (three

separate controlled servo loops) on spreader vehicles to simultaneously

control the spreading of granular and liquid ice-control materials. Two

channels control granular and liquid application rates and the third channel

precisely controls spinner speed to maintain even material coverage over

the desired spread width. The dispensing rate varies directly with ground

speed to ensure accurate product application.

Material can also be spread at a preset “BLAST” application rate. This is

normally a very large rate to instantly adjust the target APR (application

rate) coverage for bridges and intersections with a much heavier amount of

material.

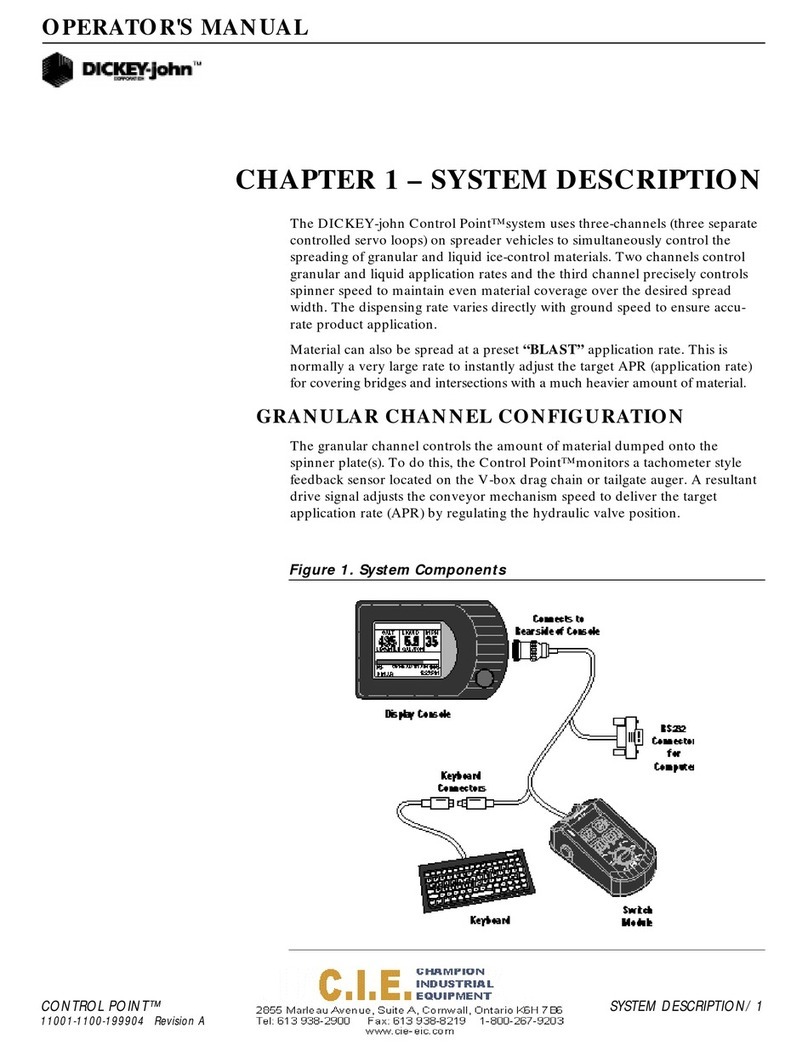

Figure 1 illustrates the Console, Switch Module, and Keyboard.

Figure 1

System Components

GRANULAR CHANNEL CONFIGURATION

The granular channel controls the amount of material dumped onto the

spinner plate(s). The Control Point®monitors a tachometer-style feedback

sensor located on the V-box drag chain or tailgate auger. A resultant drive

signal adjusts the conveyor mechanism speed to deliver the target

application rate (APR) by regulating the hydraulic valve position.

435

SALT

LBS/MILE

LIQUID

GAL/TON

MPH

0% 100%

SPREAD WIDTH

8 MAR 12:25:PM

1234567890-=

QWERTYUIOP[]\

ASDFGHJKL;'

Back

Space

ZXCVBNM

,./

RS232

Connector

for

Computer

Display Console

Keyboard

Connectors

Switch

Module

Keyboard

Connects to

Rear side of Console

OFF AUTOUNLOAD

MASTER

0

0

40

60

80

100

BLAST

OPERATOR’S MANUAL

Control Point

®

11001-1489-201702 Rev B

4 / INTRODUCTION

LIQUID CHANNEL CONFIGURATION

The liquid channel controls the application rate of pre-wetting or de-icing

materials. When pre-wetting, the Control Point® console monitors a

flowmeter-style feedback sensor. Flowmeter feedback can be used when

de-icing. Using feedback data, the pumping mechanism output adjusts the

target application rate by either regulating pump speed or flow blocking.

De-icing systems use up to five boom inputs for applying material to more

than one lane at a time.

SPINNER CHANNEL CONFIGURATION

The spinner channel controls the spinner plate(s) speed with either a

closed-loop (precision) or an open-loop configuration. In the closed-loop

configuration, a tachometer style feedback sensor, mounted on the spinner

assembly, monitors spinner activity. Using the feedback data, the spinner

mechanism speed adjusts for the target setting by controlling the hydraulic

valve position. In open loop systems, the hydraulic valve position is relative

to the width adjust knob setting on the Control Point® Switch Module.

The user must determine the spread-width accuracy needed. Technical

assistance is available through DICKEY-john Technical Support at

PH#1-800-637-2952.

PRODUCT APPLICATION MECHANISMS

The granular and spinner channels use, in addition to feedback (shaft

rotation) sensors, proportional valves to control the product application and

spinner speed. The liquid channel uses, in addition to feedback sensors

(flowmeter), a liquid pump to control product application. The liquid pump

output is controlled by either a 12 volt DC motor, servo valve actuator, or

proportional valve.

Features:

1. Surface-mount console kit for ease of installation.

2. Flexible Switch Module design allows mounting anywhere in the cab

for optimal operator use.

3. Large 160X128 dot-matrix LCD display with backlighting for nighttime

viewing.

4. Single Console button for system power on/off and screen selection.

5. RS-232 port for PC uploading and downloading of data.

6. Detachable keyboard for easy supervisor programming and calibration

using multilevel, menu-driven screens.

7. Custom programming available to minimize setup time.

8. Compatibility with a variety of sensors, servo valve actuators, and

proportional valves available from DICKEY-john or other

manufacturers.

9. Audible and visual alarms for system and operator errors.

OPERATOR’S MANUAL

Control Point

®

11001-1489-201702 Rev B

INTRODUCTION / 5

SYSTEM COMPONENTS

A DICKEY-john Control Point®system consists of six basic components:

1. Console

2. Switch module

3. Ground speed sensor

4. Feedback devices to monitor material application

5. Valve control devices to regulate material application

6. Harnesses to interconnect all system devices

NOTE: The detachable keyboard

(optional) and PC (not

provided) are programming

aids and are not part of a basic

Control Point®system.

Figure 2 shows components in a block diagram. The Console and Switch

Module are to be mounted inside the truck cab either side-by-side or the

Switch Module positioned elsewhere for operator convenience.

Figure 2

System Block Diagram

CONSOLE

The Console displays information on a dot-matrix LCD and uses a single

push-button switch to control system power and to view several operator

screens. Using an external keyboard for programming and placing operator

controls on the Switch Module simplifies the Console.

CONSOLE

• Store User Entered and

Accumulated Data

• Transfer User Entered and

Accumulated Data

• Display APRs (2)

• Display Spread Width

• Display Ground Speed

• Display Time & Date

• Display Current Totals

• Display Season Totals

• Control 3 Channels

KEYBOARD

• Alphanumeric Data Entry

• Program, Calibrate

• Service Access

SWITCH MODULE

• Master OFF/AUTO/UNLOAD

• Channel ON/OFF

• Channel APR INC/DEC

• BLAST Switch

• Spread WIDTH ADJUST Knob

3 Channel

Actuators

Gnd Spd

Sensor

3-Pulsed Feedback

Sensors

3-Analog Feedback

Sensors

RS232 Port

OPERATOR’S MANUAL

Control Point

®

11001-1489-201702 Rev B

6 / INTRODUCTION

An RS-232 port connector, located on the Switch Module harness, permits

data transfer to and from the Console. This port interfaces to a PC for

downloading accumulator and alarm information. Uploading and

downloading configuration information through the port allows data transfer

between consoles (replacing a console or when identical vehicles require

programming/calibration). For multiple units, only one system needs to be

programmed and then the constants can be transferred (downloaded) from

that console, stored in a PC file, and uploaded to the other vehicle's

console. Note: This is only useful on identical vehicles. Transferring

data does not fine-tune each system. It is recommended to run System

Response (F11) if constants are uploaded from another console.

SWITCH MODULE

Standard

The Standard Switch Module harness plugs into the Console and contains

connectors for both keyboard and PC interface as described above. The

operator controls the real-time functions of the Control Point® system from

the seven switches on the Switch Module (refer to Figure 3).

Wireless

The Wireless Switch Module is similar to the Standard, however, it provides

for data transfer to a PC via a wireless transmission to a base station.

KEYBOARD

The keyboard is used to program and calibrate the system. The 86-key,

alphanumeric, PC-compatible keyboard has been environmentally

hardened for use in the ice-control field. After programming and calibration

are finished, the keyboard is usually disconnected and stored.

GROUND SPEED SENSOR

The ground speed sensor generates vehicle speed information for the

console. Sensor electrical pulses proportional to the vehicle ground speed

are vital to system operation because true vehicle ground speed is

necessary for accurate product application. The system can function with a

wide variety of electronic and mechanical speedometer sensors, including

Hall-Effect and Reluctance sensors.

FEEDBACK SENSORS

The feedback sensors send product flow information to the console for

accurate product application. Both granular and spinner channels require

pulsed electrical sensors having an output proportional to the mechanism

speed. The liquid channel accepts either electrical-pulsed sensors or

analog sensors with outputs proportional to material flow (pulsed). A liquid

prewetting system only accepts pulsed feedback while higher capacity

anti-icing systems accept either pulsed or analog.

OPERATOR’S MANUAL

Control Point

®

11001-1489-201702 Rev B

INTRODUCTION / 7

VALVE CONTROL DEVICES

Valve Control devices regulate material flow for accurate control of product

application rates. Normally, granular and spinner channels regulate the

hydraulic oil flow rate to a motor. Liquid channels use several different

configurations.

HOPPER LEVEL SENSOR (OPTIONAL)

The optical light beam of this level sensor is blocked by the granular

material in the spreader bed. When the material level falls beneath the

sensor mounting level, a repetitive beep sounds and an appropriate

message displays in the warning/alarm area of the Operate screen.

HARNESSES

Main Harness Assembly-Connects the Console to the ground speed

sensor, feedback sensors, channel valve (or DC motor) actuators, vehicle

battery, ignition, and additional optional connections (including two-speed

axle, hopper level sensor, and boom sense inputs).

Retro Harness Assembly-Connects a Control Point console to an

ICS2000 harness (refer to Figure 53 in Troubleshooting section).

Other extension harnesses-Other extension harnesses are available that

allow for flexible sensor arrangement. Contact Technical Support for

harnessing alternatives.

TECHNICAL SUPPORT

For technical assistance, call DICKEY-john Technical Support at (217)

438-3371 or Fax (217) 438-6012 or 438-6539. For toll-free calls in either the

USA or Canada, dial 1-800-637-3302.

OPERATOR’S MANUAL

Control Point

®

11001-1489-201702 Rev B

8 / INTRODUCTION

OPERATOR’S MANUAL

Control Point

®

11001-1489-201702 Rev B

SYSTEM INSTALLATION / 9

SYSTEM INSTALLATION

The Console mounts on the vehicle dashboard or other surface suitable for

operator viewing using a U-bracket. The standard (combination) mounting

plate secures the Switch Module immediately to the left of the Console. An

optional mounting plate mounts the Console only.

The Switch Module cable, which plugs into the Console, is long enough to

allow the Switch Module to be placed near the vehicle seat or elsewhere for

operator convenience. If the combination mounting plate is used, the option

remains to later remove the Switch Module from the mounting plate and to

relocate it for convenience.

The system main harness is laid out and connections are made to the

sensor and actuator cables, battery, ignition switch, and additional options

(two-speed axle, hopper level sensor, and boom sense inputs), as required.

Verify all items in the appropriate hardware mounting kit are present:

HARDWARE KITS

STANDARD HARDWARE KIT (46649-0380) FOR CONSOLE

AND SWITCH MODULE:

(1) Combination mounting plate (46649-0580)

(2) U-bracket (46649-0590)

(3) Two 1/4 - 20 x 1 inch hex bolts

(4) Five 1/4 inch split washers

(5) Two rubber washers (46390-0900)

(6) Two knob screws (20072-0022)

(7) Three 1/4 - 20 x 3/4 inch hex bolts

(8) Retaining clip (46649-0350)

(9) Two #6 self-locking hex nuts

(10) Three #6 plastite screws

OPTIONAL HARDWARE KIT (46649-0390) FOR CONSOLE

ONLY:

(1) Console mounting plate (46649-0370)

(2) U-bracket (46649-0590)

(3) Two 1/4 - 20 x 1 inch hex bolts

(4) Five 1/4 inch split washers

(5) Two rubber washers (46390-0900)

(6) Two knob screws (20072-0022)

(7) Three 1/4 - 20 x 3/4 hex bolts

(8) Retaining clip (46649-0350)

(9) Two #6 self-locking hex nuts

OPERATOR’S MANUAL

Control Point

®

11001-1489-201702 Rev B

10 / SYSTEM INSTALLATION

CONSOLE PLACEMENT

The Console mounts inside the cab on any surface permitting easy

readability of the display without obstructing the operator’s view to the road

while driving (See Figure 3). Be sure the opposite side of the mounting

surface chosen has clearance for installing and tightening the mounting

bolts. The combination mounting plate positions the Switch Module to the

left of the Console.

U-BRACKET MOUNTING

1. Place the U-bracket in the exact location for mounting and mark both

drill holes with a pencil or scribe. If the Console is being mounted on

the dash, move and secure wiring and other obstructions located

beneath the dash.

2. Drill two 9/32 inch holes.

3. Position the U-bracket in place on the mounting surface and insert the

two 1 inch bolts.

4. Install the lock washers and nuts and tighten them.

CONSOLE AND SWITCH MODULE INSTALLATION

1. Install the Console onto the mounting plate using three 3/4 inch bolts

and lock washers.

2. When using the combination mounting plate, install the Switch Module

onto the mounting plate using three plastite screws.

3. Two sets of holes exist in the mounting plate to allow for optional

spacing between the Switch Module and Console. If only the Console

mounting plate is used, install the Switch Module at the desired

location. If placed on the vehicle seat, it must be secured in a suitable

manner (possibly using Velcro™ strips) to ensure the control settings

are not accidently changed or activated.

OPERATOR’S MANUAL

Control Point

®

11001-1489-201702 Rev B

SYSTEM INSTALLATION / 11

Figure 3

Console Mounting

SWITCH MODULE TO CONSOLE CONNECTION

1. Plug the circular connector of the Switch Module cable into the rear of

the Console, rotating the connector collar fully-clockwise to lock it.

2. Place the keyboard mating connector (with its pins pointing upward)

between the two studs on the rear of the mounting plate. Capture this

connector with the retaining clip and two self-locking nuts. The 9-pin

RS-232 connector can be secured to the Switch Module cable with a

cable tie, if desired. Figure 1 shows how the Switch Module cable

connects to the Console and keyboard.

CONSOLE MOUNTING

1. Secure the Console and mounting plate (and Switch Module if the

combination mounting plate is being used) to the U-bracket using the

two knob screws. The rubber washers fit between the U-bracket and

the mounting plate tabs.

2. Pivot the Console for the best viewing angle and tighten the two knob

screws.

HARNESS CONNECTION

1. Verify all required “exterior system cables” are installed on the

spreader vehicle according to their separate, individual instructions.

These are defined as the sensor, actuator, ground speed, boom sense,

and hopper level cables.

2. Use dust caps provided on all unused connectors, both internal and

external. This includes keyboard and RS-232 connectors.

U-Bracket

(46649-0590)

Combination

Mounting Plate

(46649-0580)

Optional Console Only

Mounting Plate

(46649-0370)

#6 Self-Locking

Hex Nuts

#6 Self-Locking

Hex Nuts

#6 x 1/2 inch

Plastite Screws

Knob Screw

(20072-0022)

Knob

Screw

(20072-0022)

1/4-20 x 3/4 Inch

Hex Bolts &

Lockwashers

1/4-20 x 3/4 inch

Hex Bolts &

Lockwashers

Retaining Clip

(holds Switch Mod

keybd connector)

(46649-0350)

Note: Mounting hardware for securing

mounting bracket to dash/mounting

panel are not supplied with kit.

OPERATOR’S MANUAL

Control Point

®

11001-1489-201702 Rev B

12 / SYSTEM INSTALLATION

NOTE: Labels have been supplied in

the dust cap kit to be placed on

external extension cables

routed to the flowmeter,

granular and spinner sensors.

Make the Control Point®battery connections last to ensure no

accidental shorts occur during harness handling.

MAIN HARNESS CONNECTION

1. Plug the largest circular connector of the main harness into the

Console, rotating the connector collar fully-clockwise to lock it.

2. Route the harness to a clean, safe area (inside the cab) suitable for

connection to the exterior system cables (from the sensors and

actuators). All connectors on the main harness are identified with

labels to simplify hookup. If a suitable “punch-out” hole in the rear cab

wall or floor is not available to bring in the exterior system cables, cut a

hole approximately two and one-half (21/2) inches in diameter. The

edges of this hole should be covered with a piece of plastic or rubber

U-channel material to protect the insulation of the cables passing

through the hole. Anchor all cables suitable with nylon cable ties to

prevent damage due to flexing and scraping. RTV or silicone caulk can

be used to seal the hole.

Do not connect the RED ignition lead directly to the battery

voltage. This will prevent the system from storing data properly!

3. Connect the RED ignition lead to the “switched” terminal of the ignition

switch. The correct terminal is at 12 volts DC or higher only when the

ignition switch is turned on.

4. If the vehicle has a two-speed axle, connect the terminal of the

YELLOW 2-Speed Axle lead to the appropriate terminal on the

axle-shifter switch.

5. If the vehicle does not have a two-speed axle, insulate the terminal

with electrical tape and tie back this YELLOW lead with a cable tie.

6. Connect the hopper level sensor and boom sense inputs, if used. The

Boom Sense 5 (gray wire) line can be connected to a pre-wet/anti-ice

selector input switch.

Verify battery voltage is 12 volts, NOT 24 volts.

7. Connect both Control Point®main harness battery leads directly to the

vehicle battery. Attach the RED wire to the positive battery terminal

and the BLACK wire to the negative terminal.

IMPORTANT: Use dust caps provided on all unused connectors, both

internal and external. This includes keyboard and

RS-232 connectors.

OPERATOR’S MANUAL

Control Point

®

11001-1489-201702 Rev B

SYSTEM INSTALLATION / 13

CHECKING OPERATION

1. After completing the installation, turn on the ignition switch. The

Console screen should power on displaying the DICKEY-john name,

logo screen, software version, and then the OPERATE screen (refer to

Figure 9).

2. Refer to the Startup and Familiarization section for additional testing.

Figure 4

Switch Module Cabling

435

SALT

LBS/MILE

LIQUID

GAL/TON

MPH

0% 100%

SPREAD WIDTH

8 MAR 12:25:PM

1234567890-=

QWERTYUIOP[]\

ASDFGHJKL;'

Back

Space

ZXCVBNM

,./

RS232

Connector

for

Computer

Display Console

Keyboard

Connectors

Switch

Module

Keyboard

Connects to

Rear side of Console

OFF AUTOUNLOAD

MASTER

0

0

40

60

80

100

BLAST

OPERATOR’S MANUAL

Control Point

®

11001-1489-201702 Rev B

14 / SYSTEM INSTALLATION

Figure 5

System Harness Layout

Gnd Speed

Sensor

Hopper Level

Sensor

+

Battery

Ð

Boom

Sensors

Flowmeter

Tank Level

or

Down Pressure

Granular

Application Rate

Sensor

Spinner

Sensor

Liquid

Valve

Granular

(& Spinner)

2 Speed Axle

Ignition

Alternate sets of connectors

(Insulate and tie back

unused connectors)

CPC connector Main

Harness

12V Relay

Gate Height

Sensor

Road Watch

Adapter

OPERATOR’S MANUAL

Control Point

®

11001-1489-201702 Rev B

START-UP AND FAMILIARIZATION / 15

START-UP AND FAMILIARIZATION

This section defines how the operator (driver) of an ice-control vehicle uses

the controls on the Switch Module and Console to perform standard

operator functions.

NOTE: The detachable keyboard

(optional) is required to

program and calibrate the

system as described in

Keyboard Programming.

Programming during setup allows the operator to view three or four different

screens of data. The Operate screen is the home screen for monitoring

spreader operation and the remaining screens are supportive.

• Material Select/Manual Speed (accessible only when system is

stationary; no ground speed)

• Current Totals

• Season Totals

START-UP PREPARATION

The system must be installed, programmed, and calibrated before

performing the following procedures.

IMPORTANT: Practice the following procedures with the vehicle

stationary to gain familiarity with the operating controls

and screens before applying product.

Figure 6

Switch Module Controls

START-UP PROCEDURE

1. Verify the Switch Module Master Switch is in the OFF position as

shown in Figure 6. If the Master Switch is in the AUTO position during

OFF AUTO UNLOAD

MASTER

0

0

40

60

80

100

BLAST

MASTER Switch

• OFF position - Disables system.

• AUTO position - System operates

relative to ground speed.

• UNLOAD position - Runs system at

maximum speed to unload product.

BLAST Button

• Initiates a rapid pre-programmed

dispersal product rate

Liquid ON/OFF Switches

• Turns liquid channel on or off

Granular ON/OFF Switch

• Turns granular channel on or off

WIDTH ADJUST

Knob

• Adjusts spinner

speed

Liquid INC/DEC (+/–) Switch

• Increments up or down from

pre-programmed application rate.

Granular INC/DEC (+/–) Switch

• Increments up or down from

pre-programmed application rate.

Other manuals for Control Point

1

Table of contents

Other Dickey-John Control System manuals

Popular Control System manuals by other brands

Data Video

Data Video RMC-230 instruction manual

Aqua Control

Aqua Control SL3 Deluxe Wi-Fi manual

Carbide 3D

Carbide 3D SHAPEOKO 3 Assembly guide

Gema

Gema OptiFlex A1 Operating instructions and spare parts list

Foxtech

Foxtech Leo 2 manual

Astral Pool

Astral Pool LumiPlus 75813 Installation and maintenance manual

Securakey

Securakey Radio Key RK-600 Installation & operating guide

TECH FASS

TECH FASS APS mini MDEM 31 user guide

Landi Renzo

Landi Renzo A1 V05 Installation and adjustment manual

Air TEc

Air TEc Expert CYPRES 2 quick guide

HydroQuip

HydroQuip BALBOA BP7 Series Installation & operation manual

Raven

Raven DCS 300 Installation and service manual