Horizontal-Schrumpfgerät

Horizontal Shrinking Device

HS 1100-P

Copyright © Diebold 2017-04 Ersteller: kh

English..................................................................................................................... 33

14. Foreword........................................................................................................... 33

14.1. Outline ........................................................................................................ 33

14.2. Note............................................................................................................ 33

15. Symbols and pictograms ................................................................................... 34

16. General Safety instructions ............................................................................... 35

16.1. Operating location ...................................................................................... 35

16.2. Hazards from electric components ............................................................. 36

16.3. Hazards from hot parts ............................................................................... 36

16.4. Avoid overheating “ThermoGrip” Chucks.................................................... 37

16.5. Hazards from electromagnetic radiation..................................................... 37

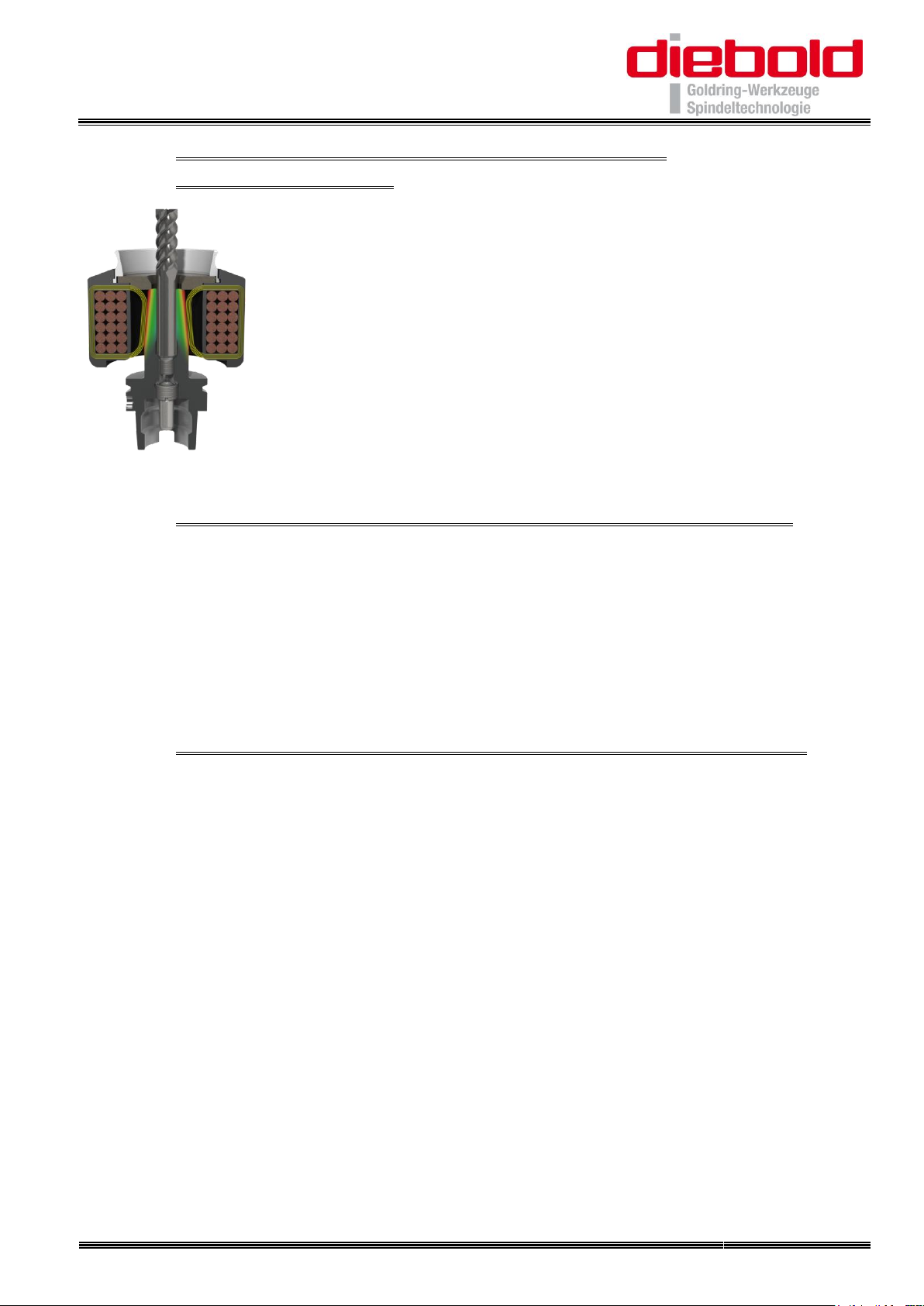

17. General information about ThermoGrip ® Shrink technology............................. 38

17.1. Micro processor controlled Induction generator HS 1100-P........................ 38

17.2. Advantages of ThermoGrip ® Shrink technology at a glance:...................... 38

17.3. Quality of the tools and chucks ................................................................... 39

17.3.1. Tool shanks .......................................................................................... 39

17.3.2. Shrink fit chuck holes ........................................................................... 39

18. Initial Set-Up of the HS 1100-P........................................................................... 40

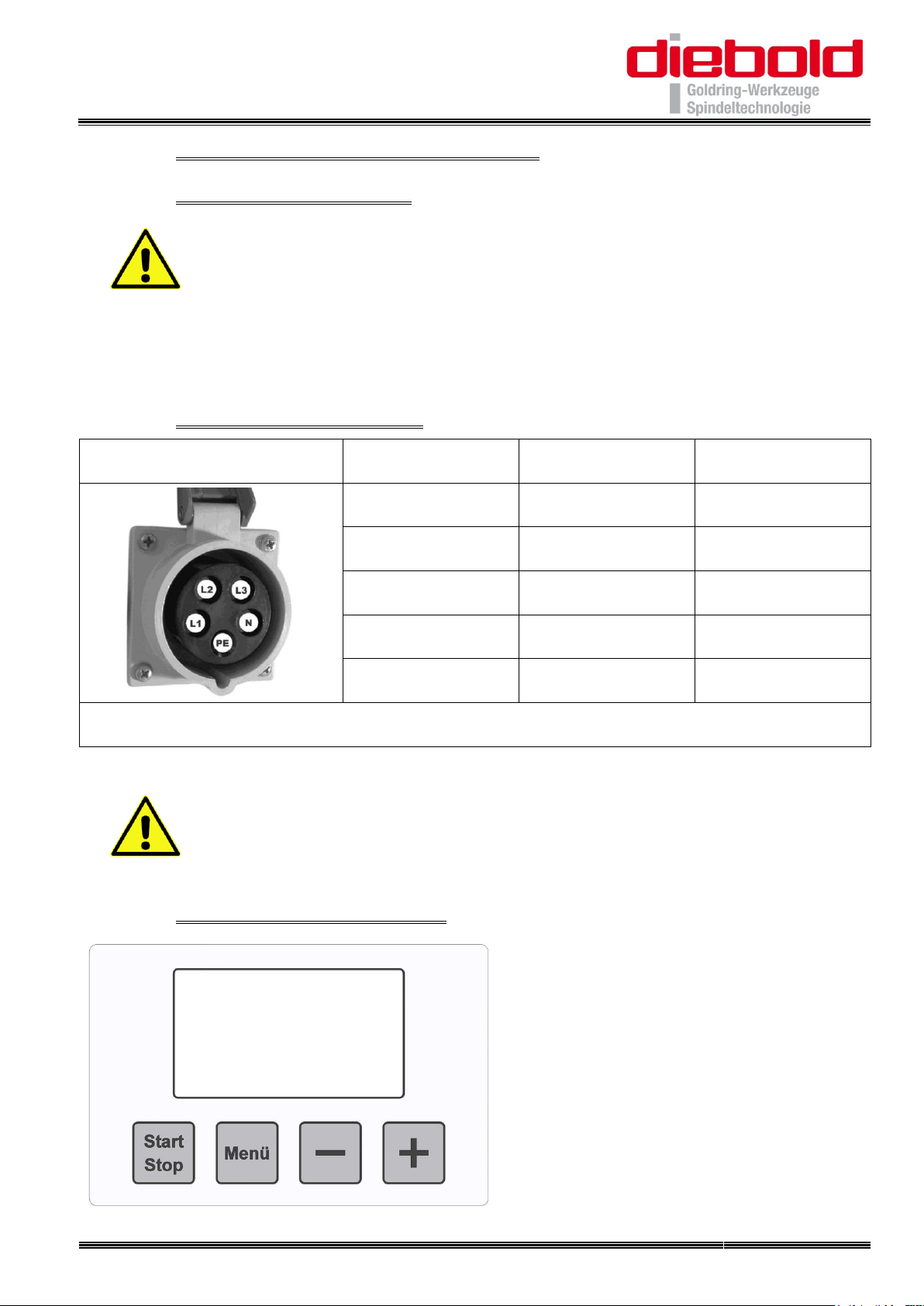

18.1. Connecting the device ................................................................................ 40

18.2. On-site socket and fuse............................................................................... 40

18.3. Controls of the HS 1100-P ........................................................................... 40

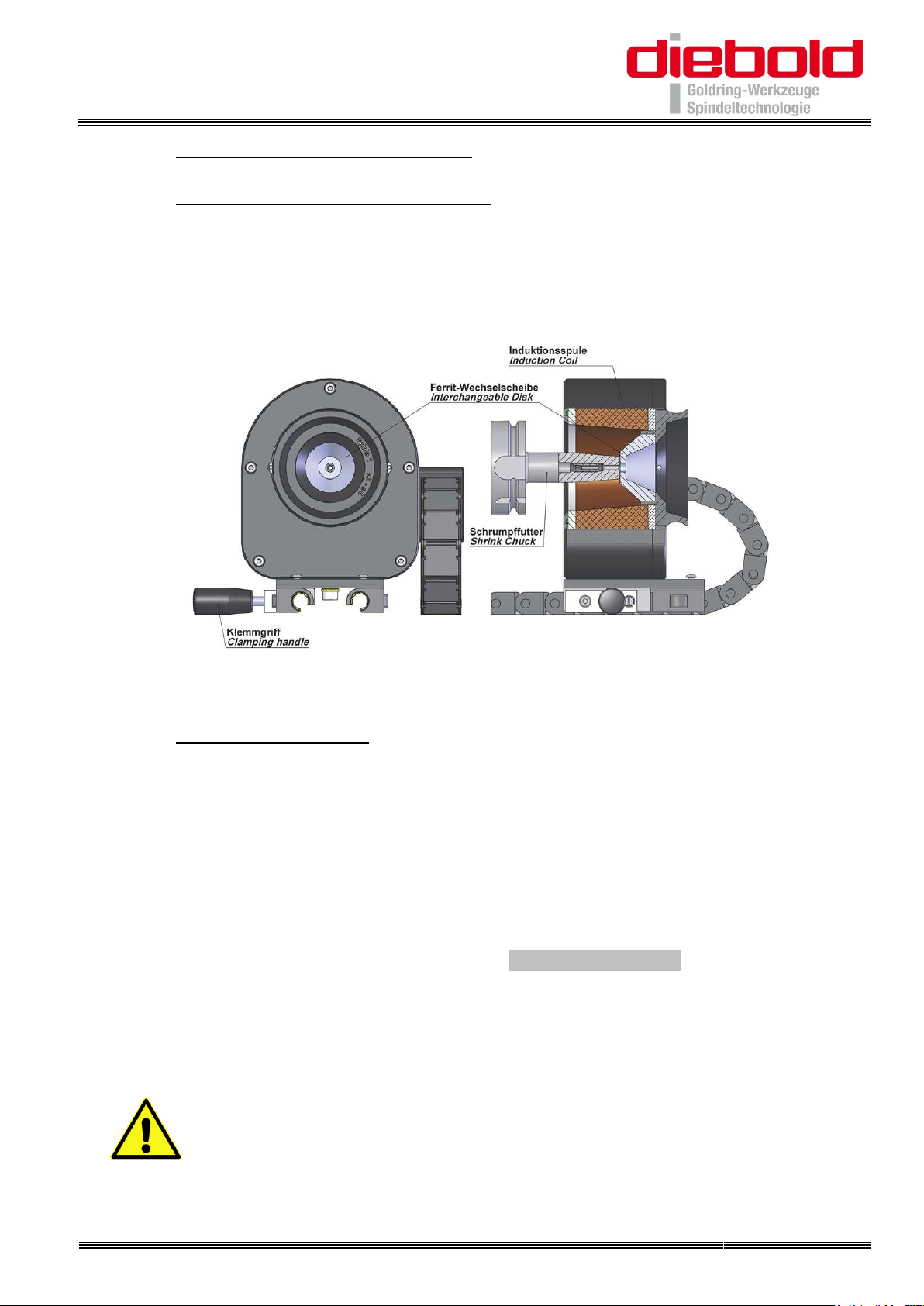

19. Operating the HS 1100-P ................................................................................... 41

19.1. Ferrite Interchangeable Discs..................................................................... 41

19.2. Shrinking Process....................................................................................... 41

19.3. LCD-Messages............................................................................................ 42

19.4. Shrinking with Parameters.......................................................................... 43

19.5. Shrinking without Parameters with indicating the power level .................... 44

19.6. Changing Standard Parameters.................................................................. 45

19.7. Reset to Factory Settings............................................................................ 46

20. Handling tool holders ........................................................................................ 47

20.1. Tool holder HSK-40 to HSK-100 .................................................................. 47

20.2. Tool holder SK / BT 30 to SK / BT 50 ............................................................ 48

20.3. Universal Adaptor for Clamping range Ø12 to Ø100 ................................... 48

21. Operation of the Length Setting Unit (Optional) ................................................. 49

21.1. Assembly .................................................................................................... 49

21.2. Measuring................................................................................................... 49

21.3. Shrink on length.......................................................................................... 49