Digga Profila 150 User manual

Profila

450 x 150 Road Profiler

Operator’s Manual

This manual is the copyright property of:

DIGGA AUSTRALIA Pty Ltd

4 Octal Street, Yatala, Queensland, Australia

Phone: (07) 3807 3330Fax: (07) 3807 1499

Int’l Phone: +61 7 3807 3330 Fax: +61 7 3807 1499

Manufacturers of Planetary Drives, Augers, Trenchers, Wear

Parts, Pallet Forks, Brooms, Aluminium Ramps, Cement Mixers,

Spreader Bars, etc.

Profila Operator’s Manual Table of Contents 1

1TableofContents

1TABLE OF CONTENTS 1

2TO THE PURCHASER 2

3TECHNICAL SPECIFICATIONS 3

4PREPARATION FOR USE 3

5SAFETY 4

6PRE-OPERATION 9

7INSTALLATION INSTRUCTIONS 11

8MAINTENANCE AND SERVICE 17

9TROUBLESHOOTING 23

10 BOLT TORQUE SPECIFICATIONS 25

11 PARTS LIST 26

12 WARRANTY 29

2TothePurchaser

GENERAL COMMENTS

Congratulations on the purchase of your new DIGGA product! This product was

carefully designed and manufactured to give you years of dependable service. Only

minor maintenance (such as cleaning and lubricating) is required to keep it in top

working condition. Be sure to observe all safety precautions and maintenance

procedures as described in this manual.

ABOUT THIS MANUAL

This manual has been designed to help you do a better, safer job.

Read this manual carefully and become familiar with it's contents. Remember, never

let anyone operate this unit without reading the "Safety Precautions" and "Operating

Instructions" sections of this manual. (See Sections B and G respectively.)

Unless noted otherwise, right and left sides are determined from the position of the

operator when behind the product facing forward.

SAFETY ALERT SYMBOL

This is the "Safety Alert Symbol" used by this industry. This symbol

is used to warn of possible injury. Be sure to read all warnings

carefully. They are included for your safety and for the safety of

others working with your.

SERVICE

When servicing your product remember to use only manufacturer replacement parts.

Substitute parts may not meet the standards required for safe, dependable operation.

To facilitate parts ordering, record the model and serial number of your unit in the

space provided on this page. This information may be obtained from the identification

plate located on the product.

MODEL____________________________________

SERIAL NUMBER___________________________

DATE PURCHASED_________________________

The parts department needs this information to insure that you receive the correct

parts for your specific model.

Profila Operator’s Manual To the Purchaser 2

Profila Operator’s Manual Technical Specifications 3

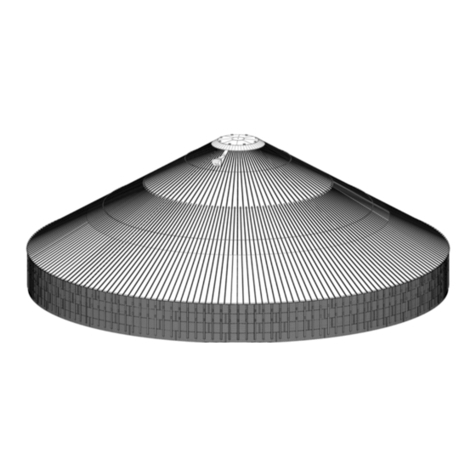

3TechnicalSpecifications

DESCRIPTION

A. Overall Width…………………………………………….……………1000MM

B. Overall Height ……………………………………………….………..1050MM

C. Overall Length…………………………………………….…………..1050MM

D. Planing Width…………………………………………………………...400MM

E. Planing Depth……..………………………………………………….…150MM

Drum Diameter……………………………………………………………..700MM

Number of Picks ………………………………………...…………………60 approx

Weight ………………………………………………………………………950kgs

High Flow Requirement ..........................................85-150 LPM (22-40 GPM)

Operating Pressure.................................................17MPa (2500-3500 PSI)

4PreparationforUse

The DIGGA Profila 150 receives its power from the Parent Machine through the

Auxiliary Valve circuit with Quick Release Couplers normally located on the machine

arms near the front.

Attaching points on the Profila 150 are the same as the bucket attaching points on

your machine.

Assemble Profila 150 if required. Refer Pg.4 Preparation for use.

Install DIGGA Profila 150 on the Skid Steer as you would a bucket. (See Skid Steer

Manual).

Hook up hoses to Auxiliary Hydraulics. Engine must be shut off.

To assure optimum motor life, run Hydraulic motor for one hour on approx. 1/3 RPM

before application of full load.

Ensure your machines flow and pressures do not exceed the maximum rated flow

and pressures of the Profila 150.(Refer Pg 3 To the Purchaser / Serial Tag)

If you are in any doubt contact your nearest DIGGA Dealer for

assistance

5Safety

TAKE NOTE! THIS SAFETY ALERT SYMBOL FOUND THROUGHOUT THIS

MANUAL IS USED TO CALL YOUR ATTENTION TO INSTRUCTIONS INVOLVING

YOUR PERSONAL SAFETY OR OTHERS. FAILURE TO FOLLOW

THESE INSTRUCTIONS CAN RESULT IN INJURY OR DEATH.

THIS SYMBOL MEANS:

ATTENTION!

BECOME ALERT!

YOUR SAFETY IS INVOLVED!

SIGNAL WORDS: Note the use of signal words DANGER, WARNING, and

CAUTION with the safety messages. The appropriate signal word for each has been

selected using the following guidelines:

DANGER: Indicates an imminently hazardous situation, which if not avoided, will

result in death or serious injury. This signal word is to be limited to the most extreme

situations, typically for machine components which, for functional purposes,

cannot be guarded.

WARNING: Indicates a potentially hazardous situation, which if not avoided, could

result in death or serious injury, and includes hazards that are exposed when guards

are removed. It may also be used to alert against unsafe practices.

CAUTION: Indicates a potentially hazardous situation, which if not avoided, may

result in minor or moderate injury. It may also be used to alert against unsafe

practices.

SAFETY PRECAUTIONS

GENERAL INFORMATION

Profila Operator’s Manual Safety 4

This section is composed of various warnings and safety tips. Read and learn all the

information in this section before you attempt to use your attachment. Also

Profila Operator’s Manual Safety 5

read your vehicle owner's manual before using your equipment. This knowledge will

help you operate your unit safely. Do not take this information lightly, it is

presented for your benefit and for the benefit of others working around you.

The "Safety Alert Symbol" (as described in Section A and at the beginning of Section

B) will be used throughout this manual. It will appear with the word DANGER,

WARNING, or CAUTION, and a safety message pertaining to the specific topic being

covered. Take the time to read these messages as you come across them.

TO THE OPERATOR

The primary responsibility for safety with the equipment falls to the operator. Make

sure that the equipment is operated only by responsible individuals with the proper

instruction. It is the skill, care, common sense, and good judgement of the operator

that will determine how efficiently and safely the job is performed. Know your

equipment before you start. Know its capabilities and how to operate all the controls.

Visually inspect your equipment before you start and never operate equipment that is

not in proper working order.

BEFORE YOU START

1. Read the entire loader and attachment operator's manuals before ever

attempting to use the loader. This knowledge is necessary for safe operation.

2. Follow all safety decals. Keep them clean and replace them if they become

worn, damaged or illegible.

2. Do not paint over, remove or deface any safety signs or warning decals on your

equipment.

4. Know your equipment inside and out. Know how to operate all controls and

know emergency shut down procedures.

5. Keep all stepping surfaces, pedals, and controls free from dirt, grease and

oil. Keep equipment clean to help avoid injury from a fall when getting on or off

equipment.

6. Use handholds and step plates when getting on/off . Failure to do so could cause a

fall.

7. Be alert to others in the work area. Be sure others know when and where you

will be working. Make sure no one is behind equipment.

8. Never take passengers on your equipment. There is no safe place for a

passenger.

9. Never try to board equipment while it is moving.

10. Turn off engine before performing maintenance. All maintenance can be

performed with the machine lowered. If lift arms must be left raised for any reason,

use a positive lift arm lock to secure the arms in place. Serious damage or personal

injury could result from lift arms accidentally lowering.

11. Reduce speed when driving over rough terrain, on a slope, or turning to avoid

overturning the loader.

12. Test all controls before you begin.

13. Do not smoke when refueling. Allow room in the gas tank for expansion.

Wipe up any spilt fuel. Secure cap tightly when done.

WORKING WITH THE ATTACHMENT

1. Never operate the unit without first reading and understanding the operator's

manual.

2. Operate the attachment only in daylight or sufficient artificial light.

3. Do not carry load with arms in the raised position. Always carry loads close to

the ground. Do not step off platform with load raised.

4. Check your work area and know where all utility lines are. Avoid hitting

underground electrical wires, cables, pipes, fence posts, gas lines, etc.

5. Never operate equipment while under the influence of alcohol, or prescription

drugs which could inhibit physical and/or mental capacity.

6. Do not exceed rated operating capacity, as machine may become unstable which

may result in loss of control.

7. Slow down before turning. Sharp turns on any terrain may cause loss of control.

8. Always lower the loader arms to the ground, shut off the engine and remove

the key before getting off the unit.

TRANSPORTING THE ATTACHMENT

1. Follow all federal, state and local regulations when transporting the unit on public

roads.

2. Use extra care when loading or unloading the machine onto a trailer or truck.

MAINTENANCE

1. Never work on equipment while it is running.

2. Never make hydraulic repairs while the system is under pressure.

Injury or death could result.

3. Observe proper maintenance schedules and repairs to keep the unit in safe

working order.

4 Always wear safety goggles or glasses when working on equipment.

5. Use a drift and hammer when pressing out pins to prevent the pin from shattering.

6. Use only manufacturer recommended replacement parts. Other parts may be

substandard in fit and quality.

Profila Operator’s Manual Safety 6

WARNING! Escaping fluid under pressure can have sufficient force to

penetrate the skin causing serious personal injury. Fluid escaping

from a very small hole can be almost invisible. Use a piece of

cardboard or wood, rather than hands to search for suspected

leaks.

Keep unprotected body parts, such as face, eyes, and arms as far away as possible

from a suspected leak. Flesh injected with hydraulic fluid may develop gangrene or

other permanent disabilities.

If injured by injected fluid, see a doctor at once. If your doctor is not familiar with this

type of injury, ask him to research it immediately to determine proper treatment.

For additional safety information please see Risk Management booklet.

Profila Operator’s Manual Safety 7

INTERNATIONAL SYMBOLS

Profila Operator’s Manual Safety 8

Profila Operator’s Manual Pre-Operation 9

6Pre-Operation

GENERAL INFORMATION

The purpose of this manual is to assist in setting up, operating and maintaining your

DIGGA planer. Read it carefully. It furnishes information and instructions that will help

you achieve years of dependable performance.

Unless otherwise noted right and left are determined from the position of the

skidsteer operator sitting in the operator's seat facing forward.

Remember to read the "Safety Precautions" and "Operating Instructions" sections of

the manual BEFORE you attempt to install or use the planer.

NOTE: The illustrations and data used in this manual were current (according to the

information available to us) at the time of printing, however, we reserve the right to

redesign and change the Profilas as may be necessary without notification.

PREPARING THE VEHICLE

WARNING! Never let anyone operate this attachment without understanding all of

the "Safety Precautions" and "Operating Instructions" sections of this manual. (See

Section B and G respectively.)

Always choose hard, level ground to park the attachment on and set the brake so the

vehicle cannot roll.

SKID-STEER

The DIGGA 150 planers are designed for use on high flow skidsteers.

Profila and skid-steer compatibility is determined by the recommended lifting capacity

and hydraulic output of your skid-steer.

WARNING! Do NOT attach or operate any attachment that exceeds the

recommended lifting capacity of your skid-steer.

Skid-steers MUST be equipped with optional high flow, auxiliary boom hydraulics,

case drain and a multi-function electric control kit to run the Profila.

BEFORE OPERATION

The primary responsibility for safety with this equipment falls to the operator. Make

sure that the equipment is operated only by trained individuals that have read and

understand this manual. Don't hurry the learning process or take the unit for granted.

Practice the operation of your new equipment and become familiar with the controls

and the way it handles on your machine.

If there is any portion of this manual or function you do not understand, contact your

local authorized dealer or the manufacturer.

MAJOR NOMENCLATURE

Throughout this manual, reference is made to various attachment components.

The purpose of this section is to acquaint you with the various names of these

components. This knowledge will be helpful when reading through the manual or

when ordering service parts.

Profila Operator’s Manual Pre-Operation 10

7InstallationInstructions

GENERAL INFORMATION

The following instructions will help you to mount your planer onto your

skidsteer loader. The planer uses the quick-attach system for ease of

installation. Therefore, if you know how to attach your loader bucket, attaching

the Profila should prove no problem.

Remember to read all safety warnings, decals and operating instructions

before operating the attachment. If there is any portion of this manual that you

do not understand, contact your dealer.

THE 150 PLANERS ARE DESIGNED FOR USE ON HIGH

FLOW HYDRAULIC SYSTEMS.

DO NOT ATTACH OR OPERATE ANY ATTACHMENT

THAT EXCEEDS THE RECOMMENDED LIFTING

CAPACITY OF YOUR SKIDSTEER.

INSTALLATION INSTRUCTIONS

1. Remove the shipping banding from around the planer and skid.

2. Remove any attachments from the front of the loader.

3. Following all standard safety practices and the instructions for installing

an attachment in your skid-steer operator's manual, install the planer

onto your skid-steer.

NOTE: It is important to make sure the locking mechanism on your

quick attach is engaged, therefore locking the attachment onto the

skid-steer.

4. Lower the unit to the ground and remove the key.

5. Relieve any pressure from the auxiliary hydraulic system and after

making sure that there is not any foreign matter on the hydraulic

couplers, connect the power and return couplers to the high flow

auxiliary hydraulic system of your skid-steer loader.

6. Connect the case drain coupler to the case drain on your skid-steer

loader.

7. Route the hoses in such a fashion as to avoid pinching or chafing.

BE SURE CASE DRAIN COUPLER IS COMPLETELY

ENGAGED.

IMMEDIATE HYDRAULIC MOTOR SEAL FAILURE AND

PLANETARY DAMAGE WILL OCCUR IF CASE DRAIN IS

Profila Operator’s Manual Installation Instructions 11

NOT SUCCESSFULLY CONNECTED.

8. Connect the electrical wire harness from the Profila to the auxiliary

electrical connector on the front of the skid-steer (if so equipped). If

your skidsteer is not equipped with an electrical connector and you are

using the

9. DIGGA control handle, connect the wiring harness to the control handle

and place the control handle inside of the skid-steer operator's station.

Profila Operator’s Manual Installation Instructions 12

Do not operate the Profila from outside of the skid-steer

operator's station.

10.Following all standard safety practices, start the skid-steer and run all

cylinders through their full cycle to purge any air from the system.

Check that all controls function in accordance with the operating control

decal.

11.If your planer is equipped with an optional water kit, install the female

coupler supplied to your water line coming from the water tank on the

skid-steer.

Connect the female coupler to the male coupler on the planer water kit.

Your planer is now installed and ready for operation.

DISCONNECT INSTRUCTIONS

1. Center the planer on the sideshift frame.

2. Adjust depth and tilt setting to "0".

3. Set Profila on a firm level surface.

4. Following Safety Shut Down Procedures; stop the engine and set the

parking brake. Relieve any pressure in the hydraulic lines.

5. Disconnect the power and return hoses from the auxiliary hydraulics.

6. Disconnect the electrical wire harness from the auxiliary electrical

connector or the DIGGA control handle and after turning the ball valve

to the shut off position disconnect the water line at the couplers.

7. Following all standard safety practices and the instructions for

disconnecting an attachment in your skid-steer operator's manual,

disconnect the planer from your skid-steer allowing the mounting

bracket to lower toward the ground as the skid-steer is disengaged.

8. Connect the hydraulic couplers on the attachment together to prevent

contaminants from entering the hydraulic system.

GENERAL INFORMATION

The DIGGA planer attaches to the toolbar/quick-attach mechanism of your

skid-steer loader. Due to this arrangement, thorough knowledge of the skid-

steer controls is necessary for machine operation. Read and understand your

skid-steer operator's manual for information regarding skid-steer operation

before attempting to use the planer.

Check the surface to be planed. The standard all purpose picks can be used

to mill both asphalt and concrete. There are optional concrete picks that are

recommended if the planer is to be used extensively for concrete. These picks

do not perform as well when milling asphalt, especially in warmer weather.

Review the job at hand and determine the required depth and tilt of the cut

and also the side shift position of the planer. Best performance is obtained

when the Profila is in the center position. Side shift should be used when

visibility is a determining factor such as milling around manholes or when

milling next to an obstacle such as a building.

NOTE: The optional wheel assemblies may be removed when distance is

a factor such as milling next to an obstacle or building.

OPERATING INSTRUCTIONS

1. Clear area of all bystanders.

2. Lift the planer until the drum is off the ground and start planer rotation.

(Teeth at the bottom of the drum must be moving in the same forward

direction that the planer travels.)

NOTE: Mill only when the skid-steer is traveling forward. Do not operate

when traveling in reverse.

NOTE: Hydraulic cylinders tilt the planer, adjust the depth of both the

left and right side of the planer individually, and also shift the planer to

the left or right.

3. Increase engine RPM and with the drum turning you can make any

necessary adjustments to the side shift. Do not side shift the Profila during

milling operation. Once the desired side shift position has been achieved you

are ready to begin. The drum will not cut in a side to side motion. Tilt and

Depth control can both be activated during milling.

IMPORTANT: The drum MUST be turning to make any hydraulic

adjustment to the planer.

Profila Operator’s Manual Installation Instructions 13

4. Position the planer at the desired starting point. Set the left and right depth

gauge to the desired depth mark on the planer. Maximum depth of each cut is

determined by the type of material, the horsepower of the skid-steer being

used and the size of the planer. It is recommended for maximum performance

that you start at approximately .75" to 50mm in concrete and 1.50" to 100mm

in asphalt.

5. With the engine at full RPM and the planer rolled back, lower the loader

arms completely down and slowly roll out the planer until the weight of the

planer is resting on the rear wheel assemblies. Continue to exert down

pressure by rolling the loader forward until the front wheels of the planer are

on the ground and the front wheels of the skid-steer are raised approximately

2-3 inches off the planing surface to assure sufficient pressure for stable

operation.

NOTE: It is recommended to try a sample cut until the desired depth is

achieved.

6. Slowly advance forward.

NOTE: If drum stalls you have been traveling too fast or cutting too

deep. Back out of the cut until the drum restarts (make necessary

adjustments) and then continue operation.

NOTE: If the drum tends to ride up out of the cut, decrease travel speed,

be sure the planer is level (front to back) and exert down pressure until

the planer is riding on the skids/wheel assemblies. For optimal cutting

and reduced vibration, maintain down pressure on the planer with all

four planer wheels on the ground when cutting.

NOTE: Avoid side to side movement while planing as this may cause

excessive drum wear or planetary failure.

7. When you have reached the end of the pass, stop the skid-steer and raise

the planer out of the cut. Reposition skid-steer for the next cut and repeat

steps 4, 5 & 6. If you are not starting a new cut, raise the planer and retract

the drum into the planer housing using the depth control cylinders. Do not

transport the planer with drum turning.

Periodic observation must be made of the

transmission oil temperature indicator when planing

with high flow hydraulic systems.

Profila Operator’s Manual Installation Instructions 14

Depending on the ambient temperature and the duty

cycle of the machine, hydraulic oil may overheat.

If indicator comes on, shut off the Profila and allow

the skid-steer to idle until the temperature falls below

160° Fahrenheit.

If the system continues running hot it may be

necessary to clean any debris from the oil cooler and

radiator. Check engine air filter and also the hydraulic

oil level.

Continuous or excessive overheating may cause machine damage.

SPECIAL APPLICATIONS

LARGE AREA

DIGGA'S independent depth control design allows for continuous milling.

Instead of planing pass 1, 3, 5 and then going back and resetting the planer

for passes 2 and 4, the DIGGA planer allows for individual depth control from

the operator's seat to enhance performance and continually mill large areas.

MILLING AROUND

MANHOLES

For best visibility when milling

around manholes it is

recommended that the planer

be shifted to the right. The

planer is not designed to mill

around tight corners, therefore

it is recommended that four to

six passes be made on each

side of the manhole. NOTE:

The more passes the less

amount of manual clean-up

required.

DEEP CUTS

To achieve a deep cut the width of the drum, make the first cut at the

recommended depth for the material being milled and then reposition the

planer at the beginning of the pass and reset for double the recommended

depth. Example: Make the first cut with the depth controls set at 100mm and

then set the depth control at 100mm for the second pass and so on and so

forth until the desired depth is obtained.

Profila Operator’s Manual Installation Instructions 15

To achieve a 150mm cut of a large area it is recommended to cut the entire

area at the recommended depth and then clear the spoil from the area before

making the second cut.

Removing the spoil between cuts will enhance the productivity of the planer

and maintain an even cut.

If trying to achieve a critical cutting depth it is recommended that the spoil

from one cut be cleared away before making another pass. This will eliminate

the possibility of the planer riding on and off the spoil and creating an uneven

surface.

MILLING TAPER CUTS

When adding to or joining new paved surfaces to existing paving, a taper cut

may be required at the interacting joints so the new paving would appear

seamless. See the chart below for the angle of cut per size of Profila.

Example: To achieve a taper cut from 0 to 100mm over a 1200mm distance with

a 600mm wide Profila it is recommended that you set one side of the planer at

100mm and the other at 100mm and the tilt set at 4° for the first pass. Then

make a second pass with both sides of the planer set at 0mm and the tilt still at

4°.

OFFSET 25mm 50mm 75mm

ANGLE OF CUT (degrees) 2 4 6

Profila Operator’s Manual Installation Instructions 16

8MaintenanceandService

GENERAL INFORMATION

Economical and efficient operation of any machine is dependent upon regular

and proper lubrication of all moving parts with a quality lubricant. Neglect

leads to reduced efficiency, wear, breakdown and needless replacement of

parts.

All parts provided with grease fittings should be lubricated as indicated. If any

grease fittings are missing, replace them immediately. Clean all fittings

thoroughly before using the grease gun.

IMPORTANT: Avoid excessive greasing. Dirt collects on exposed grease

and greatly increases wear. After greasing, wipe off excessive grease

from fittings.

LUBRICATION SYMBOLS

Profila Operator’s Manual Maintenance and Service 17

The following symbols are used on the lubrication diagram below. It is

reproduced here with its meaning for your convenience.

Lubricate daily or every 8 hours of operation, whichever comes last,

with SAE Multi-Purpose Lubricant or equivalent SAE Multi-Purpose

type grease.

Lubricate weekly or every 40 house of operation, whichever comes

last, with SAE Multi-Purpose Lubricant or equivalent SAE Multi-

Purpose type grease.

CAUTION! SHUT OFF ENGINE BEFORE LUBRICATING

EQUIPMENT.

The planer planetary is a sealed unit. If there is any sign of oil leaks

please contact your nearest DIGGA dealer before carrying out any repairs, as

there can be other causes for seal leaks. The planetary uses the Gear Oil

(Castrol SP 320) for lubrication of gears and bearings. The unit holds

approximately 2 quarts of gear oil.

The planetary gear oil should be drained and replaced after the first 8 months

of use. Thereafter every 12 months or 2500 hours - whichever comes first.

GENERAL INFORMATION

Regular maintenance is the key to long equipment life and safe operation.

Maintenance requirements have been reduced to an absolute minimum. However it

is very important that these maintenance functions be performed as described below.

Never do any maintenance to the planer while it is running.

Exercise the MANDATORY SAFETY SHUTDOWN PROCEDURE

BEFORE working on or around the planer.

DAILY

• Check to be sure case drain coupler is completely engaged.

• Check skid-steer hydraulic system to ensure an adequate level of hydraulic oil.

• Check all hardware and tighten if necessary. See Section "O" for Bolt Torque

Specifications.

• Check hydraulic system for hydraulic leaks.

• Check for missing or illegible Safety / Warning Decals.

• Check picks for freedom of rotation, flat spots and wear. Replace worn or missing

picks or any picks that are not rotating freely or have flat spots.

• Visually inspect the machine for worn parts or cracked welds and repair as

necessary.

• Lubricate grease fittings on Wheel pivot pins.

EVERY 40 HOURS

• Lubricate grease fittings on cylinder ends and front of planer.

Profila Operator’s Manual Maintenance and Service 18

Table of contents

Other Digga Construction Equipment manuals

Popular Construction Equipment manuals by other brands

MKT

MKT V-5Esc/HP-185T3A Service, Operating, Maintenance and Parts Manual

Komatsu

Komatsu WA95-3 Operation & maintenance manual

K-Line

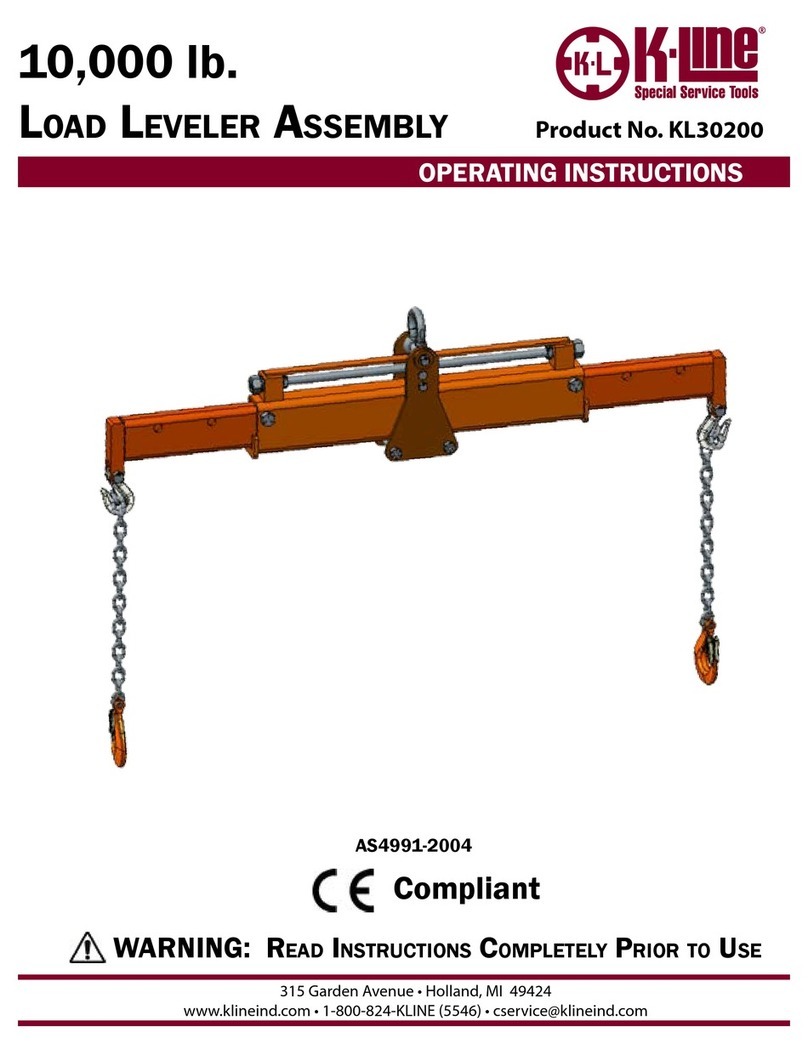

K-Line KL30200 operating instructions

Doka

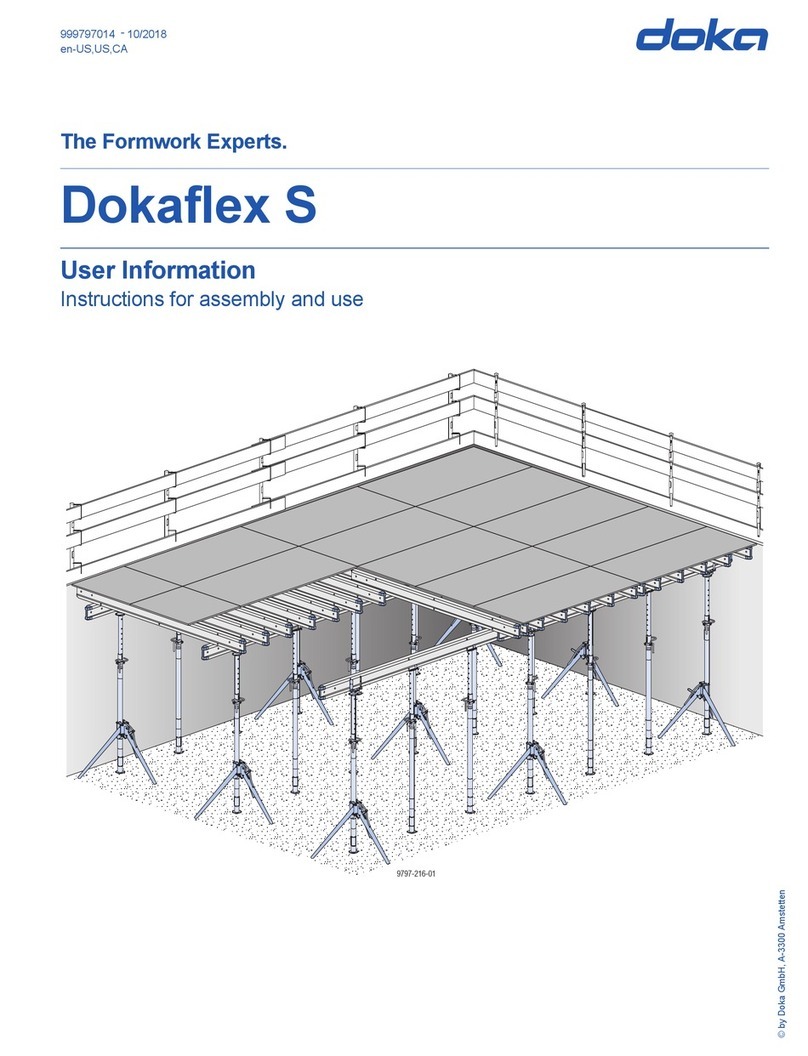

Doka Dokaflex S Instructions for assembly and use

Graco

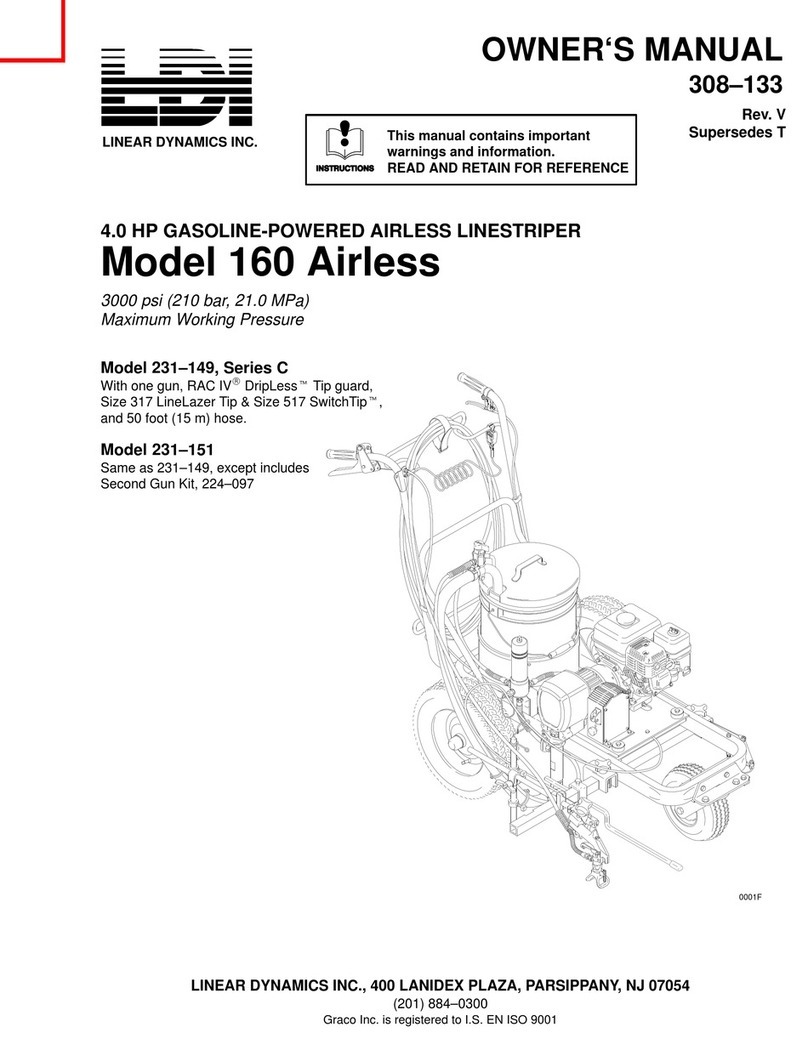

Graco LDI 160 Airless owner's manual

SFS

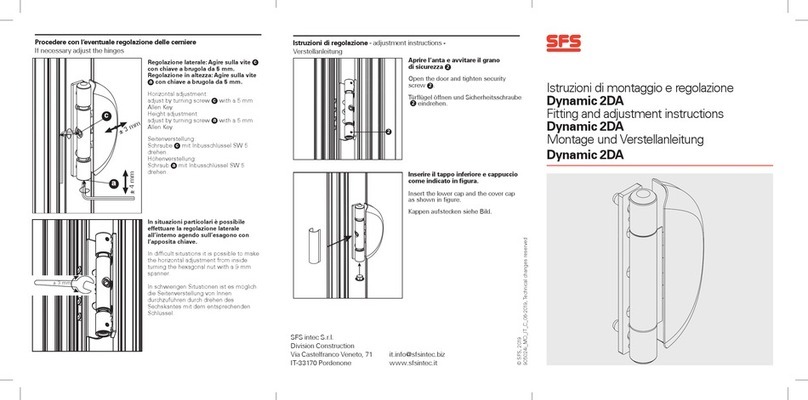

SFS Dynamic 2DA Fitting and adjustment instructions