Digga TORQUE LOGIC User manual

1

PM-000121 Digga Torque Logic Installation Manual

MORE THAN JUST TORQUE

INSTALLATION

MANUAL

PM-000121

2PM-000121 Digga Torque Logic Installation Manual

TABLE OF CONTENTS

Tools Required for Installation.…………………………………………………..…...3

Personal Protective Equipment………………...………………………………….....3

Digga Torque Logic Installation Kit Contents…..…………………………………...3

Installation Directions…………………………………...…………………………......4

Removing OEM pin

Remove Knuckle/Wishbone

Inserting the Digga Torque Logic

Leveling

Marking Placement

Stopper…….………………………………..…………………………………………..5

Replacing Knuckle/Wishbone

Using The Pull Rod…..…………………………………….………………………......6

Pull Rod

Assembling Pull Rod

Tightening the nuts

End Cap………………………….………………………….……………………….......7

Assembling the End Cap

Securing the End Cap

Cabling………………………………..………………………………………………...8

Attaching the Extension Cable

Attaching the Pran Harness………………………………………………………......9

Attaching Pran Harness

Mounting Display Using Ram Mount Connections

Final Check

Warnings and Important Notes………………………………………………..…......9

General Safety Precautions……………………………...……………………….......10

Spare Parts……………………………...……………………….................................11

3

PM-000121 Digga Torque Logic Installation Manual

INSTALLATION INSTRUCTIONS

THE DIGGA TORQUE LOGIC HAS A COMPUTER PROCESSOR BOARD INSERTED

IN THE END OF THE PIN THESE ACTIONS WILL VOID THE WARRANTY!

TOOLS REQUIRED FOR INSTALLATION

• LEVEL

• ZIP TIES

• HEX SOCKET SET

• WELDER & RODS

• HAMMER WRENCH

• COMBINATION WRENCH

• STOPPER

• SHOP RAGS

PERSONAL PROTECTIVE EQUIPMENT

• SAFETY GLASSES

• COVERALLS

• HARD HAT

• STEEL CAP BOOTS

• GLOVES

• SAFETY GLASSES

TORQUE LOGIC INSTALLATION KIT

• DIGGA TORQUE LOGIC

• DOWEL & END CAP

• STEEL SOCKET CAP SCREW

• 2 WASHERS

• 3 NUTS

• THREADED ROD

CABLES

• MAIN CABLE JIB CABLE

• EXTENSION CABLE

• JUNCTION BOX

• 2 WASHERS

DIGGA TORQUE LOGIC DISPLAY

• 8.4” OR 4.3” DISPLAY

• PRAN HARNESS

• RAM MOUNT

• HITTING THE DIGGA TORQUE LOGO WITH A HAMMER OR ANY OTHER OBJECT.

• GROUNDING TO THE DIGGA TORQUE LOGO WHILE WELDING.

• USING EXCESSIVE HEAT ON OR CLOSE TO THE DIGGA TORQUE LOGIC

UNDO CABLE CONNECTIONS TO DIGGA TORQUE LOGIC

BEFORE WELDING IN ANY LOCATION ON PRIME MOVER.

WARNING

4PM-000121 Digga Torque Logic Installation Manual

DIRECTIONS

Once the OEM Pin is removed from the drive, remove the Knuckle/Wishbone.

Fasten the drive in a sturdy position and remove the OEM pin out from the top of the drive.

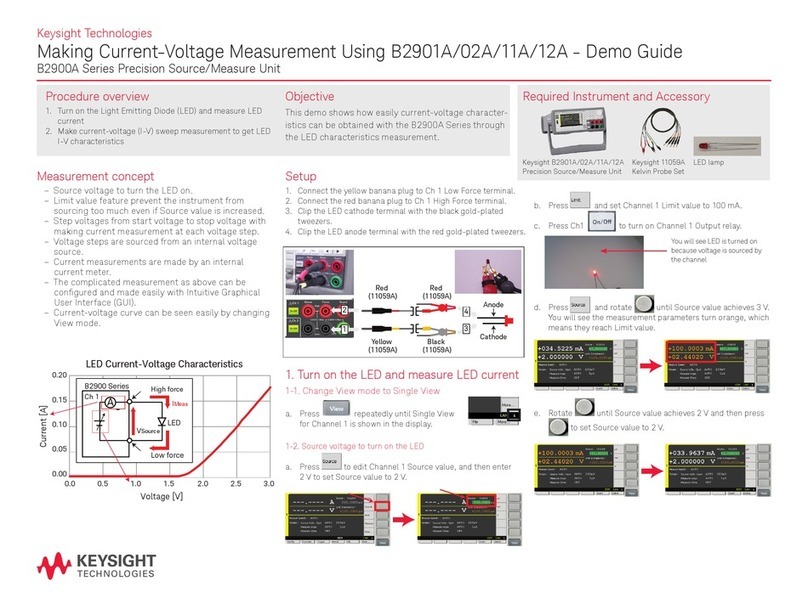

Insert the Digga Torque Logic into the holes of

the bails/ears to align pin placement.

A)

B) The connector on the Digga Torque

Logic must be facing up and parallel

with the drive. (Use a level to assure

correct placement)

The Digga Torque Logic has a at spot

on the bottom. Mark the placement of

the at area as this is where you will need

to secure the pin with a bolt on, or a bar

welded to the bushes/ears. This will keep

the Digga Torque Logic in position with the

drive to ensure accurate torque readings.

C)

1.

2.

5

PM-000121 Digga Torque Logic Installation Manual

Bolt or weld a stopper into place.

D)

Do not ground to the Digga Torque Logic. Tack the sides of the stopper, then remove

the Digga Torque Logic before solidly welding the stopper in place. Too much heat may

affect the “CPU” board.

WARNING

Replace the knuckle/wishbone and push the

Digga Torque Logic into the drive as far as it will

go, ensuring the connector is always facing up.

Do not hammer or tap the Digga Torque

Logic into place. This action will damage

the “CPU” and void the warranty.

WARNING

3.

6PM-000121 Digga Torque Logic Installation Manual

Assemble rod as shown.

B)

When placing a large heavy Digga Torque

Logic, it is advisable to use the threaded rod

and nuts (supplied) to draw the Digga Torque

Logic through the bails/ears.

Hold the 2nd nut tight while steadily turning the nut closest to

the end cap in a clockwise motion. This action will draw the

Digga Torque Logic through the bushes/ears. Be careful not

to apply to much pressure as this may damage the threaded

hole in the end of the Digga Torque Logic.

D)

Position the 2 end nuts on the rod and adjust according to

the amount of rod you will require to effectively pull the Digga

Torque Logic through the bails. Using 2 wrench’s tighten the

end nuts against one another.

C)

A)

NUT

NUT

THREADED ROD

NUT

FLAT WASHER

END CAP

7

PM-000121 Digga Torque Logic Installation Manual

END CAP

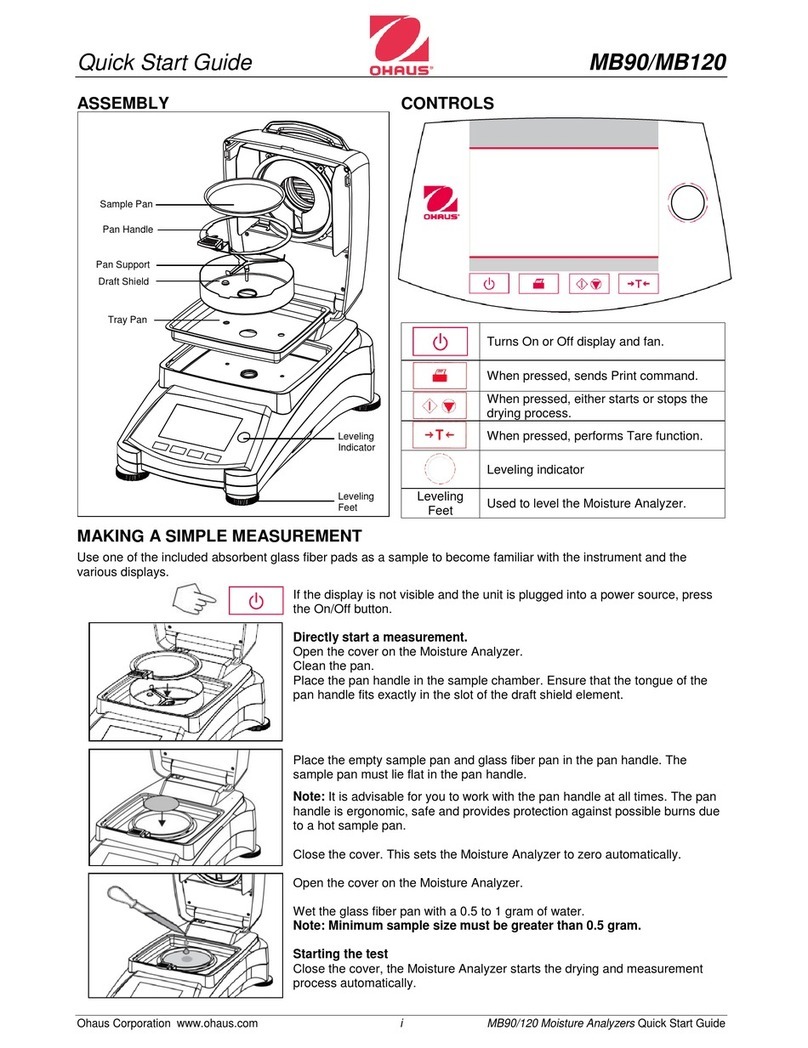

To apply the end cap to the Digga Torque

Logic, insert the provided dowel into the

unthreaded hole in the end of the End

Cap. Line up the dowel hole and the

threaded hole of the End Cap with the

dowel hole and the threaded hole on the

end of the Digga Torque Logic.

Secure the End Cap to the Digga Torque

Logic using steel socket cap screw and lock

washer (provided). It is recommended to use

BLUE LOCK TIGHT on the cap screw.

Recommended torque applied to the steel socket cap screw on the end cap.

1” bolt: 767 ft. lbs. 3/4” bolt: 317 ft. 1bs. 1/2” bolt: 93 ft. lbs.

A)

B)

SOCKET HEAD CAP SCREW

HIGH COLLAR LOCK WASHER

GROOVED DOWEL PIN

END CAP

8PM-000121 Digga Torque Logic Installation Manual

CABLING

Attach the main extension cable to the Digga

Torque Logic. Be sure to align the pins inside

the cable connector with the holes on the

Digga Torque Logic connection.

A Jib cable is recommended between the Digga Torque Logic and the disconnect of

your drive. Using a jib cable in this area will prevent damage to the main cable and is

easier to replace in the event it does get damaged.

Tuck and weave all cables in and behind the

hydraulic lines running along the boom, zip

tying into place as you go. At the end of the

boom run the main cable between the body of

the vehicle and the cab.

B)

A)

ZIP TIES

BOOM EXTENSION HARNESS

ADAPTER LEAD

9

PM-000121 Digga Torque Logic Installation Manual

CABLING CONTINUED

Attach the Pran Harness (provided) to the main cable. Make sure to

avoid pinch points when routing the Pran Harness inside the cab of

the machine.

Decide where to mount the Digga Torque Logic Display, which will

be convenient to the operator, close to a power source and avoid

excessive bumping or banging of the monitor.

Use the Ram Mount (provided) and attach it to the area inside the

cab that you have selected.

Tripple Suction Cup Ram Mount Single Suction Cup Ram Mount

E)

F)

G)

Attach the Pran Harness to the Digga Torque Logic Display, then the

Display to the Ram Mount. Ensure all connections are secure. (Note

the area at the back of the Digga Torque Logic Display screw hole

pattern to match the Ram Mount).

Do a nal check outside the cab to ensure the Digga Torque Logic

and end cap are secured properly, and all cable connections are

tight, with cabling free and clear of pinch points

Important Note: The Pran Harness is equipped with battery back up in the event of

accidental disconnection, however it is not recommended for steady use.

Protect the Digga Torque Logic Display by carefully following the

recommendations below.

When using the display always use the on/off switch on the harness to control power.

Never disconnect the power by pulling the plug from the power source. This can result

in corruption of data stored in your Display.

Do not tap on the screen of the Digga Torque Logic Display with any object other than

your nger. Hard or pointed objects may damage the screen.

Never use ngers to align hood to linkage when installing or removing the Digga

Torque Logic.

WARNING

D)

C)

10 PM-000121 Digga Torque Logic Installation Manual

GENERAL SAFETY PRECAUTIONS

• Always wear the proper personal protective equipment for the job you’re doing.

• When working on or near heavy equipment, approved hard hat and steel cap

boots are recommended.

• Lower the boom of the machine onto solid footing and stabilize before attempting to

remove the OEM.

• Turn off the power supply and apply the parking brake.

• Use your knees, not your back when picking up and placing heavy Digga Torque Logic

• Wear approved welding shield when welding stopper into place.

• Inspect all tools for weak points, wear and tear, and proper guards in place.

• Safety is the responsibility or the individual. Observe all safety procedures as outlined

by your employer.

11

PM-000121 Digga Torque Logic Installation Manual

SPARE PARTS

For further information on spare parts please contact your nearest Digga Dealer

AUSTRALIA

NORTH AMERICA

QLD

Head Office - Brisbane

4 Octal St, Yatala QLD 4207

Phone: (07) 3807 3330

Fax: (07) 3807 1499

DIGGA NORTH AMERICA

2325 Industrial Parkway SW

Dyersville, IA 52040

USA

Ph: +1 563 875 7915

Cell: +1 563 845 9177

www.diggausa.com

12 PM-000121 Digga Torque Logic Installation Manual

4 OCTAL STREET

YATALA QLD 4207

AUSTRALIA

PH: +61 (0) 7 3807 3330

MOBILE: +61 (0) 418 343 241

EMAIL: [email protected]

WWW.DIGGA.COM

DIGGA AUSTRALIA

2325 INDUSTRIAL PARKWAY SW

DYERSVILLE, IA 52040

USA

PH: +1 563 875 7915

CELL: +1 563 845 9177

EMAIL: [email protected]

WWW.DIGGAUSA.COM

DIGGA NORTH AMERICA

PM-000121

Other manuals for TORQUE LOGIC

1

Table of contents

Other Digga Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

3M

3M SpotOn 370 Operator's manual

Hanna Instruments

Hanna Instruments HI 84102 instruction manual

Crompton

Crompton Tyco Electronics SWITCHBOARD INTEGRA 1540 Installation and operating instructions

Greystone Energy Systems

Greystone Energy Systems CR3 Series installation instructions

CPN

CPN MC3 ELITE operating manual

Mahr

Mahr Millimar S 1840 operating instructions