Digi-Sense 3622566 User manual

This manual suits for next models

3

Other Digi-Sense Measuring Instrument manuals

Digi-Sense

Digi-Sense 20250-16 User manual

Digi-Sense

Digi-Sense 20250-11 User manual

Digi-Sense

Digi-Sense 20250-14 User manual

Digi-Sense

Digi-Sense 20250-22 User manual

Digi-Sense

Digi-Sense 20250-63 User manual

Digi-Sense

Digi-Sense 20250-31 User manual

Digi-Sense

Digi-Sense 20250-29 User manual

Digi-Sense

Digi-Sense 20250-55 User manual

Digi-Sense

Digi-Sense 20250-57 User manual

Digi-Sense

Digi-Sense 20250-21 User manual

Digi-Sense

Digi-Sense 20250-26 User manual

Digi-Sense

Digi-Sense 20250-61 User manual

Digi-Sense

Digi-Sense 20250-15 User manual

Digi-Sense

Digi-Sense 20250-40 User manual

Digi-Sense

Digi-Sense 20250-65 User manual

Digi-Sense

Digi-Sense 20250-12 User manual

Digi-Sense

Digi-Sense 20250-23 User manual

Digi-Sense

Digi-Sense 20250-63 User manual

Digi-Sense

Digi-Sense 20250-13 User manual

Digi-Sense

Digi-Sense 20250-19 User manual

Popular Measuring Instrument manuals by other brands

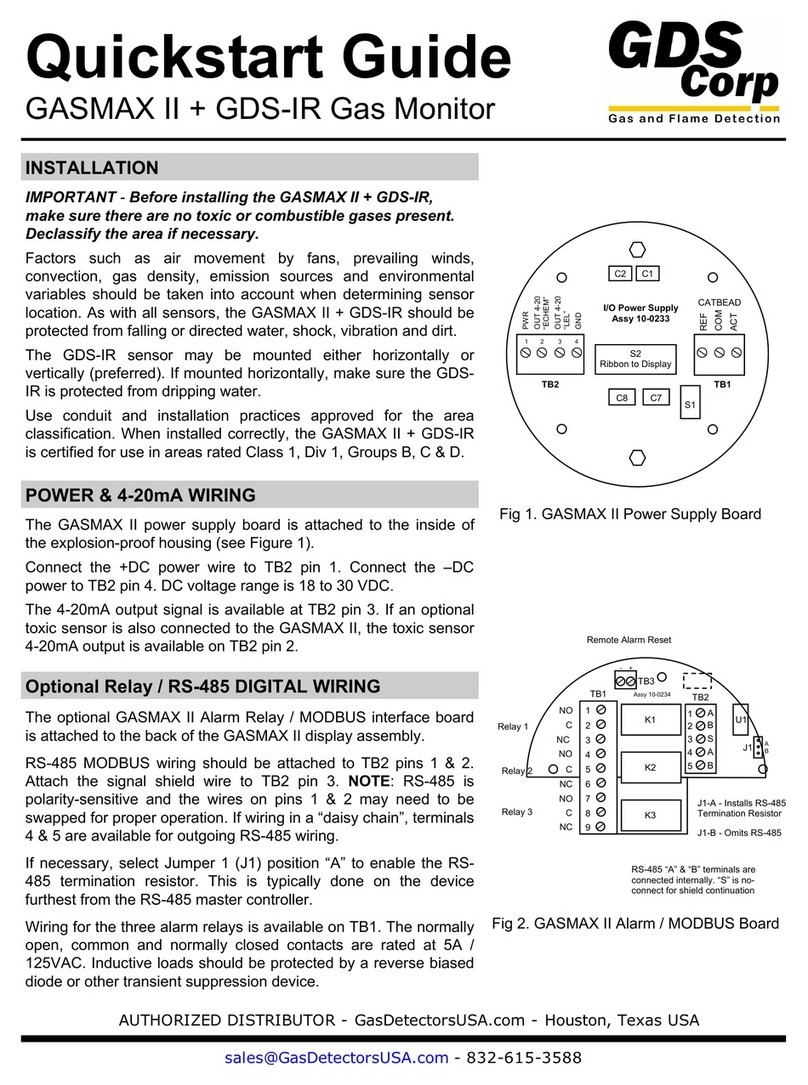

GDS

GDS GASMAX II + GDS-IR quick start guide

Riiot

Riiot blue quick start guide

Bindicator

Bindicator MP Series Installation & operation manual

PCB Piezotronics

PCB Piezotronics IMI Sensors TO625B01 Installation and operating manual

Endress+Hauser

Endress+Hauser Liquicap T FMI21 manual

ABB

ABB Relion 670 series Product guide