Table of Contents

1. Introduction ............................................................................................................................... 5

1.1. Product description, FRAX ........................................................................................................ 5

1.2. Company website .................................................................................................................... 5

1.3. Receiving Instructions .............................................................................................................. 5

1.4. Support, service & repair ......................................................................................................... 5

1.5. Calibration .............................................................................................................................. 6

1.6. Warranty ................................................................................................................................. 6

1.7. Contact information ................................................................................................................ 7

1.8. Shipping with battery ............................................................................................................... 7

2. General safety ............................................................................................................................ 8

2.1. Symbols on the instrument ...................................................................................................... 8

2.2. Warning and caution notices .................................................................................................... 8

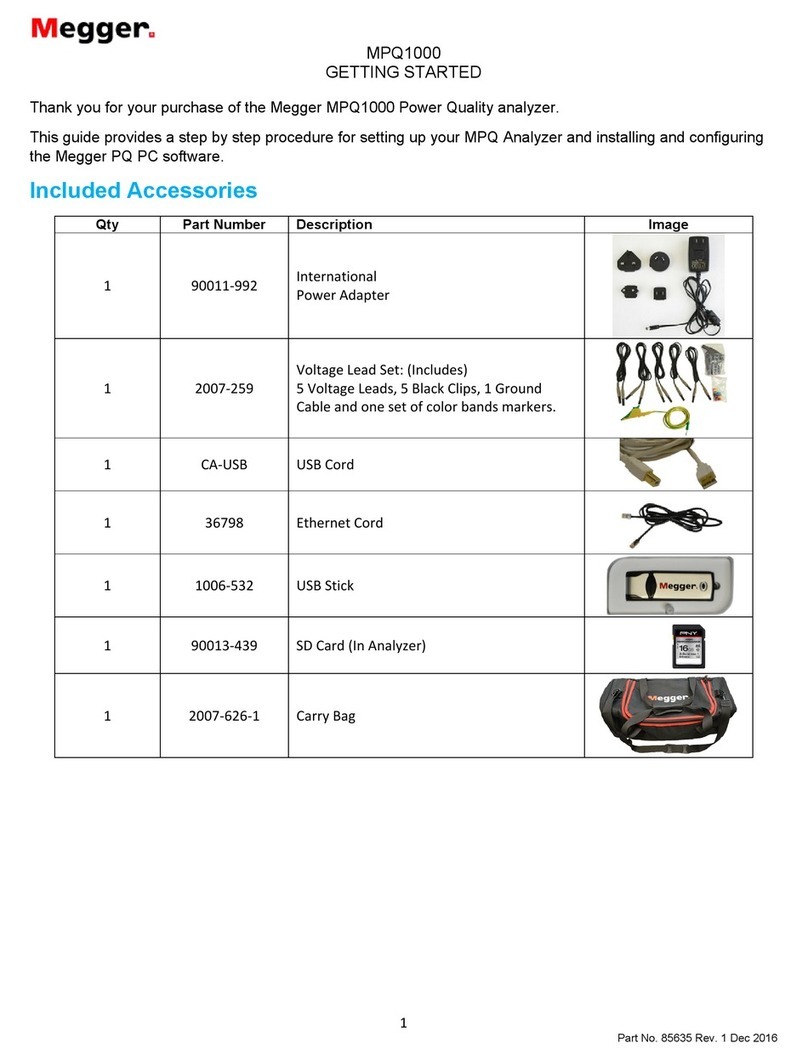

2.3. Accessories ............................................................................................................................. 8

2.4. Cables .................................................................................................................................... 8

2.5. Placement ............................................................................................................................... 9

2.6. Cleaning .................................................................................................................................. 9

2.7. Damaged product ................................................................................................................... 9

2.8. Inputs and outputs .................................................................................................................. 9

2.9. Lightning ............................................................................................................................... 10

2.10. Servicing ............................................................................................................................. 10

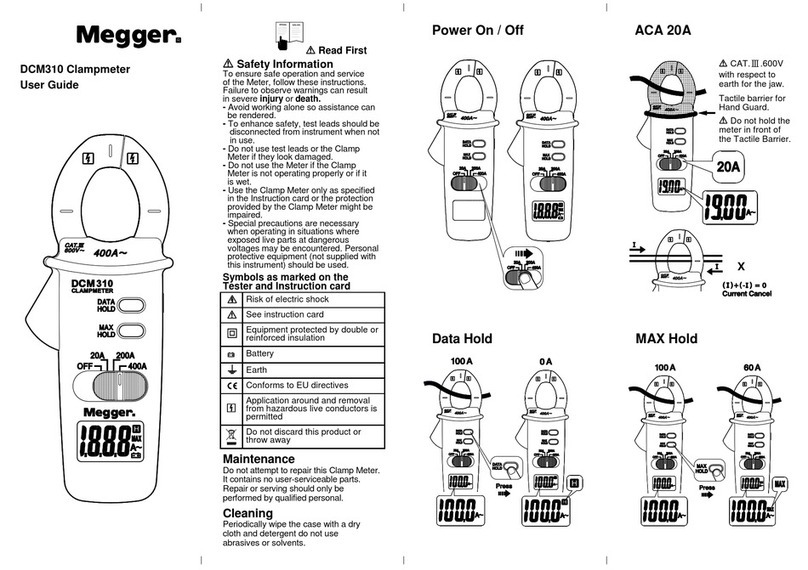

2.11. Safety instructions ............................................................................................................... 11

2.12. Battery inside ...................................................................................................................... 12

3. Instrument description ............................................................................................................ 13

3.1. Front panel FRAX 99/101 ....................................................................................................... 13

3.2. Front panel FRAX 150 ............................................................................................................ 14

3.3. Bluetooth Communication (only FRAX 101) ............................................................................. 14

3.4. Built-in battery pack and charger ............................................................................................ 16

3.5. Ground loop detector ............................................................................................................ 17

3.6. Sweep frequency response .................................................................................................... 17

4. Quick start tutorial ................................................................................................................... 19

4.1. Preparatory procedures ......................................................................................................... 19

4.2. Ground loop control .............................................................................................................. 19

4.3. Start FRAX and establish communication ................................................................................ 19

4.4. Create a new test .................................................................................................................. 20

4.5. Test lead connection .............................................................................................................. 21

4.6. Start Measurement ............................................................................................................... 24

5. FRAX Software ........................................................................................................................... 26

5.1. Installing FRAX Software ......................................................................................................... 26

5.2. Overview ............................................................................................................................... 26

5.3. File Menu .............................................................................................................................. 28

5.4. Edit menu ............................................................................................................................. 36

5.5. Conguration menu ............................................................................................................... 36

5.6. Windows menu ..................................................................................................................... 46

5.7. Action buttons ...................................................................................................................... 47

5.8. Legend ................................................................................................................................. 48

5.9. Usage overview ..................................................................................................................... 49

5.10. File description .................................................................................................................... 49

5.11. Test description ................................................................................................................... 49

5.12. Measurement settings ......................................................................................................... 50

5.13. Views .................................................................................................................................. 50

5.14. Legend action button description ......................................................................................... 51

5.15. Correlation analysis ............................................................................................................. 51

5.16. Exit (Alt+F4) ......................................................................................................................... 52

5.17. Connect .............................................................................................................................. 52

www.megger.com FRAX-series 3