Digital Control FALCON F5 SUB-K REBAR User manual

FALCON F

SUB-K REBAR USER MANUAL

DCI DigiGuide 07.08.2022

DIGITAL CONTROL, INC

19625

nd Ave S Suite B

Kent, WA 98032 U.S.

dci@digital-control.com | digital - control.com

1.800.288.3610 | 1.425.251.0559

FALCON F

SUB-K REBAR

DCI DigiGuide User Manual

07.08.2022

Important Safety Info

Bootcamp

Initial Setup

Jobsite Setup

During Drilling

Post Drilling

Advanced Topics

FALCON F

SUB-K REBAR USER MANUAL

DCI DigiGuide 07.08.2022

DIGITAL CONTROL, INC 2

Important Safety Info

GENERAL SAFETY WARNING

Only operate your DCI guidance system in accordance with the

operating instructions for your system.

Serious injury and death, as well as property damage, can result if

underground drilling equipment strikes a natural gas line, high-voltage

electrical cable, or other utility.

Work slowdowns and cost overruns can occur if you do not use your

system correctly.

You must properly calibrate your DCI guidance system in connection

with each drilling project. If you fail to do so, depth readings will likely be

inaccurate.

Interference can lead to inaccurate depth readings and/or interruption

of data. See "Special Notes About Interference" for more details.

DCI guidance systems are used to locate and guide the transmitter

(housing) underground. They cannot be used to locate underground

utilities.

Failure to

fi

nd the front and rear locate points can lead to inaccuracies

which may result in drilling o

ff

-path and striking an underground utility.

The locate line on a DCI locator does not indicate the position of the drill

head. DCI locators track the transmitter in its housing, which sits behind

the drill bit. Also, when drilling steep and/or deep, the locate line may

indicate a position behind or ahead of the transmitter. Please see "Steep

and Deep" under Advanced Topics for important information about

accurately locating the drill head when drilling steep and/or deep.

FALCON F

SUB-K REBAR USER MANUAL

DCI DigiGuide 07.08.2022

DIGITAL CONTROL, INC 3

Ensure that all underground utilities have been located, exposed, and/or

accurately marked prior to drilling. Follow all proper safety precautions,

such as potholing.

DCI equipment is not explosion-proof and should never be used near

fl

ammable or explosive substances.

Wear jobsite protective/safety clothing such as dielectric boots, gloves,

hard hat, high-visibility vest, and safety glasses.

Maintain a minimum distance of 8 inches (20 cm) from the front of the

locator to the user

’

s torso to ensure compliance with RF exposure

requirements.

Comply with federal, state, and local governmental regulations (such as

OSHA) and all other customary or required safety precautions.

If you have any questions about the operation of your guidance system,

please contact DCI Customer Service for assistance.

SPECIAL NOTES ABOUT INTERFERENCE

While DCI guidance systems provide you with technology to combat active

interference (and passive interference, with the Sub-K Rebar transmitter),

no guidance system is immune to all interference.

Interference can lead to inaccurate depth readings and/or interruption or

loss of data. Never rely on data that does not display quickly and/or remain

stable.

The Falcon frequency optimizer selects frequencies based on measured

interference at a speci

fi

c time and location.

Interference levels change with time and with even minor changes in

location. The frequency optimizer is not a substitute for prudent operator

judgment. If performance drops while drilling, consider switching to the

other selected band (not available on the Falcon F

) or use Max Mode.

FALCON F

SUB-K REBAR USER MANUAL

DCI DigiGuide 07.08.2022

DIGITAL CONTROL, INC 4

An

A

on the screen can indicate signal Attenuation due to the presence of

excessive interference, which can make depth readings inaccurate.

Attenuation is normal in shallow depths less than 8 ft (2.4 m). If the signal

strength is also

fl

ashing; this indicates extreme interference. Depth and

locate points may be compromised and the locator will not calibrate.

Interference is classi

fi

ed as either active (generating electro-magnetic

signals) or passive (material that can conduct or block electro-magnetic

signals). Sources of interference may include:

Active

Tra

ffi

c signal loops

Buried dog fences

Cathodic protection

Radio communications

Security systems

Microwave towers

Power, phone,

fi

ber-trace and cable TV lines

Passive

Metal pipes

Rebar

Trench plates

Chain-link fences

Vehicles

Saltwater/salt domes

Conductive earth, such as iron ore

FALCON F

SUB-K REBAR USER MANUAL

DCI DigiGuide 07.08.2022

DIGITAL CONTROL, INC 5

If you have any questions about the operation of your guidance system,

please contact DCI Customer Service for assistance.

ENVIRONMENTAL REQUIREMENTS

System working altitude: up to 6562 ft (

m).

Storage and transportation temperature: -40° to

°F (-40° to

°C).

Operation may be compromised if the equipment is subjected to conditions

outside these speci

fi

ed limits.

Ship in original carrying case or packaging of su

ffi

cient durability to prevent

mechanical shock to equipment during transportation.

If you have any questions about the operation of your guidance system,

please contact DCI Customer Service for assistance.

STORAGE AND SHIPPING OF BATTERIES

Remove the batteries from all system components during shipping and

prolonged storage. Failure to do so may result in battery leakage, which may

lead to risk of explosion, health risks, and/or damage.

Store and transport batteries using a suitable protective case that will keep

batteries safely isolated from one another. Failure to do so may result in

short circuits, which may lead to hazardous conditions including

fi

re.

Lithium-ion batteries must be packaged and shipped by trained and

certi

fi

ed personnel only. Never ship damaged batteries.

If you have any questions about the operation of your guidance system,

please contact DCI Customer Service for assistance.

FALCON F

SUB-K REBAR USER MANUAL

DCI DigiGuide 07.08.2022

DIGITAL CONTROL, INC 6

Bootcamp

HDD LOCATING HISTORY

Locating in the horizontal directional drilling (HDD) industry was initially

based on locating a buried cable by sweeping the locator back and forth to

fi

nd the highest signal strength (peak signal), indicating that the locator was

over the cable. Unfortunately, this method did not always guarantee an

accurate location of the cable, nor did it provide any depth information.

This

“

peak signal

”

method was adapted to HDD with the introduction of a

transmitter that provides information on the position and depth of the drill

head. However, this method is unreliable and inaccurate because the peak

signal strength is not always directly above the transmitter housing.

In addition, peak signal locating doesn

’

t show where the drill tool is headed.

Think of drilling like driving a car: it is more e

ff

ective to look ahead through

the windshield to see where you are going than to look down at the road

through the

fl

oorboard to keep the car (drill tool) on the road (drill path).

BALL-IN-THE-BOX GUIDANCE

DCI

’

s design uses a

“

locate point

”

in the transmitter signal. The Front Locate

Point (FLP), which is out ahead of the transmitter, shows where the

transmitter housing

is heading.

DCI invented the

Ball-in-the-Box

user interface to make it quick and intuitive

to

fi

nd a locate point, speeding up drilling jobs: just move the locator so the

ball moves into the box on the screen.

Finding a locate point also helps you

fi

nd the drill head itself.

FALCON F

SUB-K REBAR USER MANUAL

DCI DigiGuide 07.08.2022

DIGITAL CONTROL, INC 7

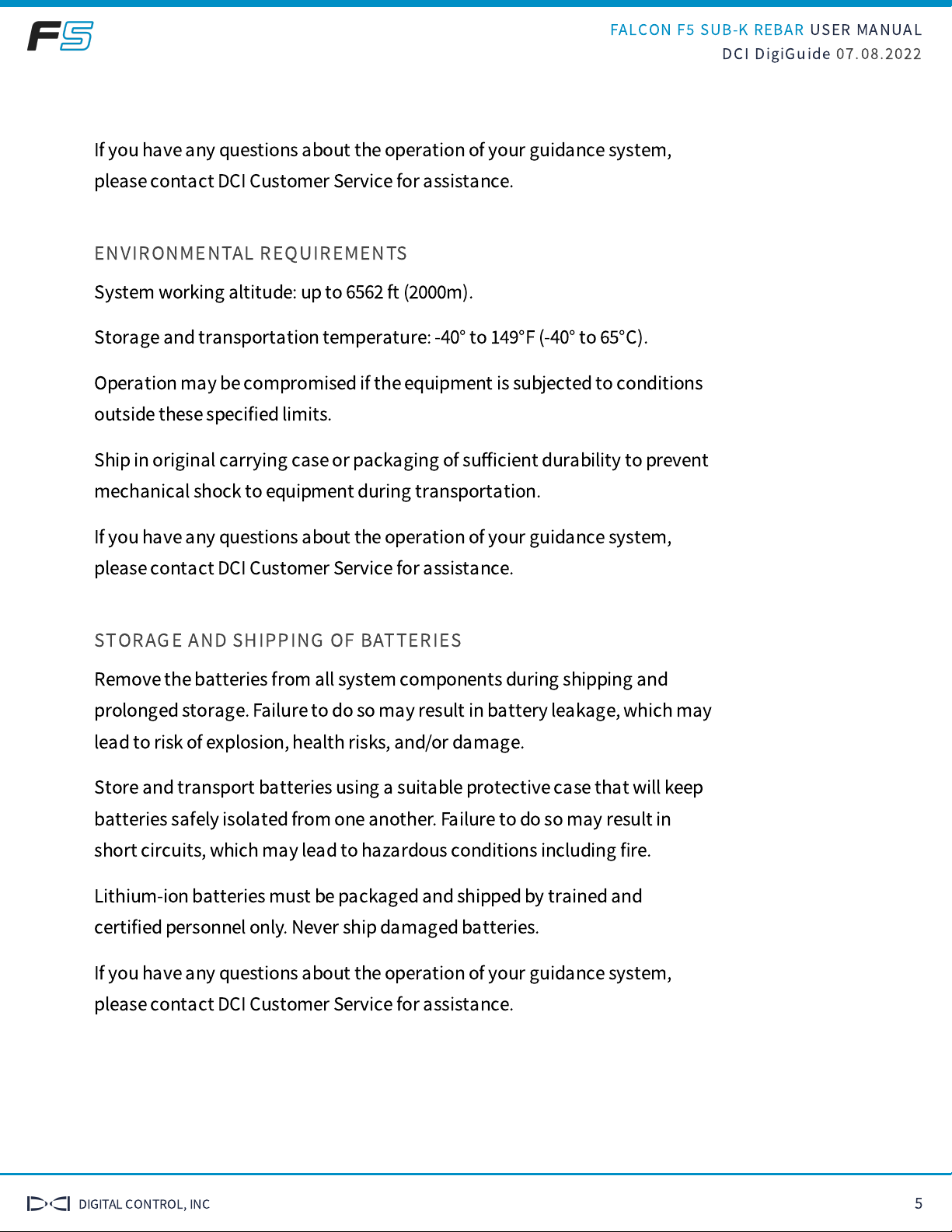

There is a second locate point behind the transmitter called the Rear Locate

Point (RLP). The two locate points, combined with a Locate Line (LL),

pinpoint the precise location of the

transmitter housing

below ground.

They are arranged like an airplane, where the Front Locate Point is the

plane

’

s cockpit, the Rear Locate Point is the tail, and the Locate Line is the

wings.

If your drill path requires a certain amount of depth or to maintain a

constant pitch, use the predicted depth feature at the Front Locate Point.

This eliminates the need for depth readings over the transmitter, speeding

up the drilling process.

INTERFERENCE AND SIGNAL STABILITY

Interference can cause incorrect locate data that reduces locating

accuracy. There are two di

ff

erent types of interference that can distort the

transmitter signal: active and passive.

Active interference, or

“

noise

”

, consists of anything that emits a signal that

interferes with the transmitter signal. Example sources include power lines,

radio towers, cathodic protection,

fi

ber tracer lines, invisible dog fences,

security systems, and tra

ffi

c signal loops. Falcon

’

s frequency optimizer

fi

nds

the best frequencies to avoid noise.

FALCON F

SUB-K REBAR USER MANUAL

DCI DigiGuide 07.08.2022

DIGITAL CONTROL, INC 8

Passive interference consists of anything that blocks or distorts the

transmitter signal resulting in incorrect depths or missing data. Example

sources include rebar, guard rails, bridge abutments, chain link fencing,

salt/saltwater and soil high in metal ore. The Falcon sub-kHz transmitter

(available for Falcon F

and F

+ only) helps cut through passive interference

without distorting the signal.

An A on the screen can indicate signal Attenuation due to the presence of

excessive interference, which can make depth readings inaccurate.

Attenuation is normal in shallow depths less than 8 feet (2.4 m). If the signal

strength is also

fl

ashing, this indicates extreme interference. Depth and

locate points may be compromised and the locator will not calibrate.

OPTIMIZE EVERY JOB

Noise varies by amount and frequency depending on where you are and

even the time of day. That

’

s why it

’

s important to

fi

nd the best frequencies

for

every bore

.

This is called

frequency optimization

, and only Falcon has it. Using

frequencies with the highest probability of success against noise increases

locating accuracy and reduces the risk of tripping out.

Falcon

’

s frequency optimizer scans through

hundreds

of frequencies, then

bundles those with the lowest noise into

fi

nely-tuned bands that work best

for the current job.

Select two bands and switch between them mid-bore if needed (not

available on the Falcon F

with singleband).

The Falcon locators with

Quick Scan Pair

o

ff

er features to make the selection

of bands faster and easier. Two clicks select the two preset bands selected

for your region.

FALCON F

SUB-K REBAR USER MANUAL

DCI DigiGuide 07.08.2022

DIGITAL CONTROL, INC 9

MENU NAVIGATION

The Falcon F

/F

/F

+/F

+ has a toggle switch on top and a trigger switch

under the handle to navigate the menu system and select options.

Use the

-way toggle switch to access a menu, move between menu options,

and open shortcuts.

Shortcuts require you to hold the toggle for a second or longer; we call this a

“

hold toggle

”

. For example, from the Locate Mode screen, open a transmitter

band selection shortcut by holding the toggle right.

Use the trigger switch to power on the locator, select a menu option, and to

take a depth reading.

Pull and release (click) the trigger to select. In some cases, you

’

ll need to

hold the trigger for a second or more to use a function, such as turning the

locator on or taking a depth reading.

BENEFITS OF DATALOGGING

Utilities increasingly require a digital as-built report to ensure drilling

parameters were met.

The DataLog® feature on your locator lets you easily capture and store the

rod-by-rod data of your pilot bore.

When used with DCI

’

s LWD Mobile app, geo-tagging the entry and exit

automatically ties the as-built to a physical location.

FALCON F

SUB-K REBAR USER MANUAL

DCI DigiGuide 07.08.2022

DIGITAL CONTROL, INC 10

With a DigiTrak DataLog Management (DDM) subscription, use your mobile

device to upload DataLogs to your cloud account even during drilling to

show progress to back-o

ffi

ce personnel.

After importing your DataLog job into our Log-While-Drilling (LWD) 3.0

software, you can edit, annotate, and

fi

nalize the precise report you or your

customer requires.

On the DigiTrak Aurora remote display, use our free LWD Live app to view the

drill pro

fi

le in real-time as each rod is completed.

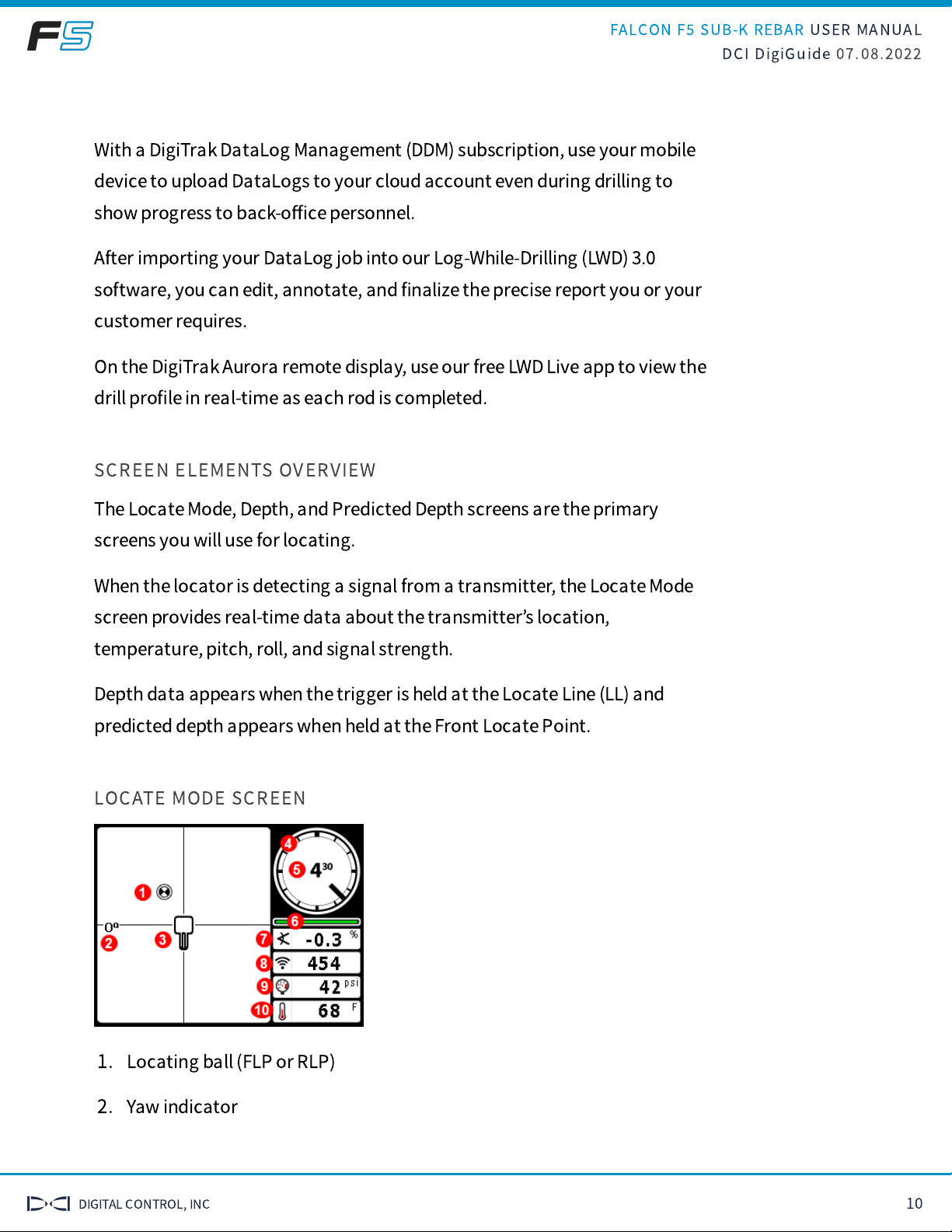

SCREEN ELEMENTS OVERVIEW

The Locate Mode, Depth, and Predicted Depth screens are the primary

screens you will use for locating.

When the locator is detecting a signal from a transmitter, the Locate Mode

screen provides real-time data about the transmitter

’

s location,

temperature, pitch, roll, and signal strength.

Depth data appears when the trigger is held at the Locate Line (LL) and

predicted depth appears when held at the Front Locate Point.

LOCATE MODE SCREEN

1. Locating ball (FLP or RLP)

2. Yaw indicator

FALCON F

SUB-K REBAR USER MANUAL

DCI DigiGuide 07.08.2022

DIGITAL CONTROL, INC 11

3. Locator

4. Roll indicator

5. Roll value

6. Roll/pitch update meter

7. Transmitter pitch

8. Power Mode and Transmitter signal strength

9. Transmitter

fl

uid pressure

10. Transmitter temperature

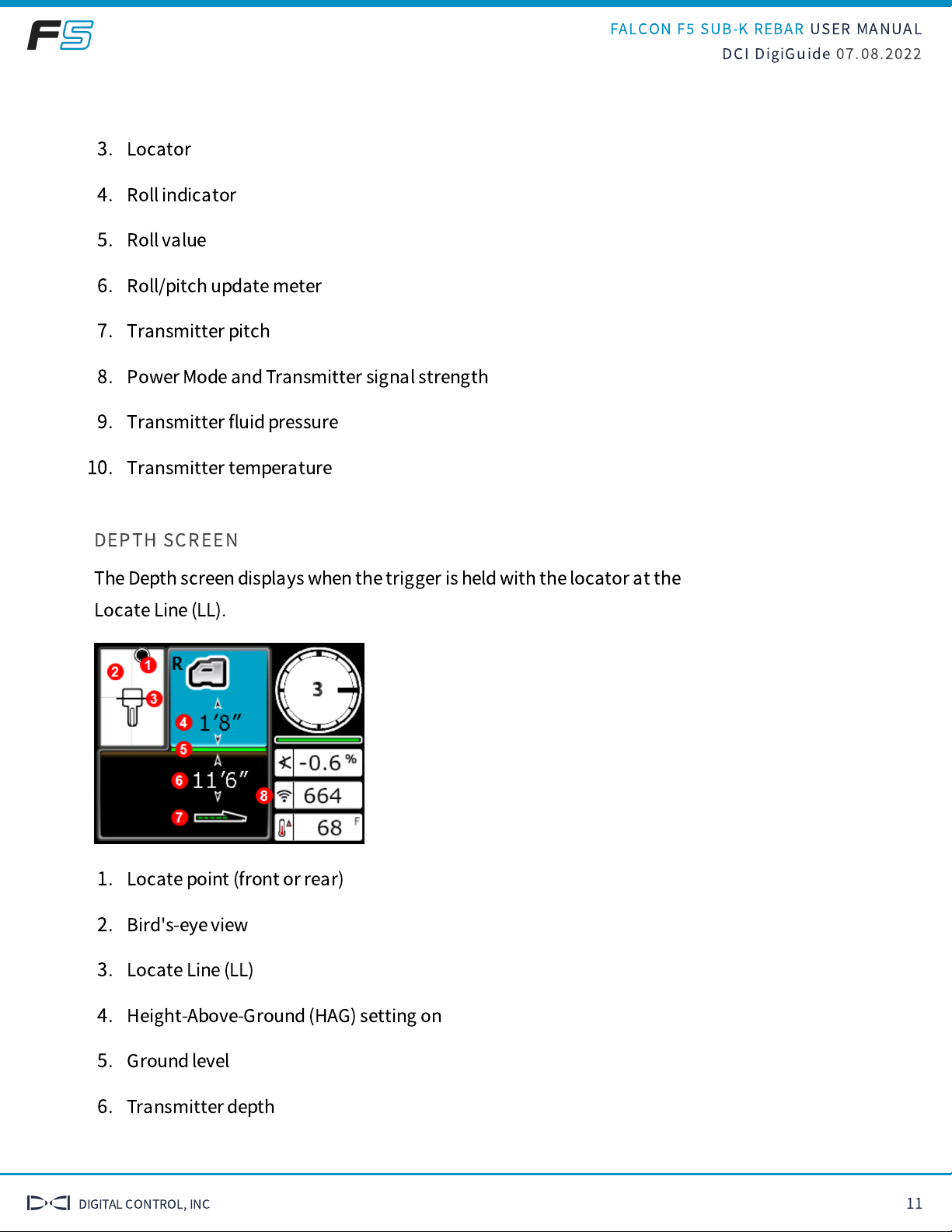

DEPTH SCREEN

The Depth screen displays when the trigger is held with the locator at the

Locate Line (LL).

1. Locate point (front or rear)

2. Bird's-eye view

3. Locate Line (LL)

4. Height-Above-Ground (HAG) setting on

5. Ground level

6. Transmitter depth

FALCON F

SUB-K REBAR USER MANUAL

DCI DigiGuide 07.08.2022

DIGITAL CONTROL, INC 12

7. Transmitter battery strength

8. Transmitter power level

When the HAG setting is disabled, the locator displays at

ground level and must be placed on the ground during depth

readings.

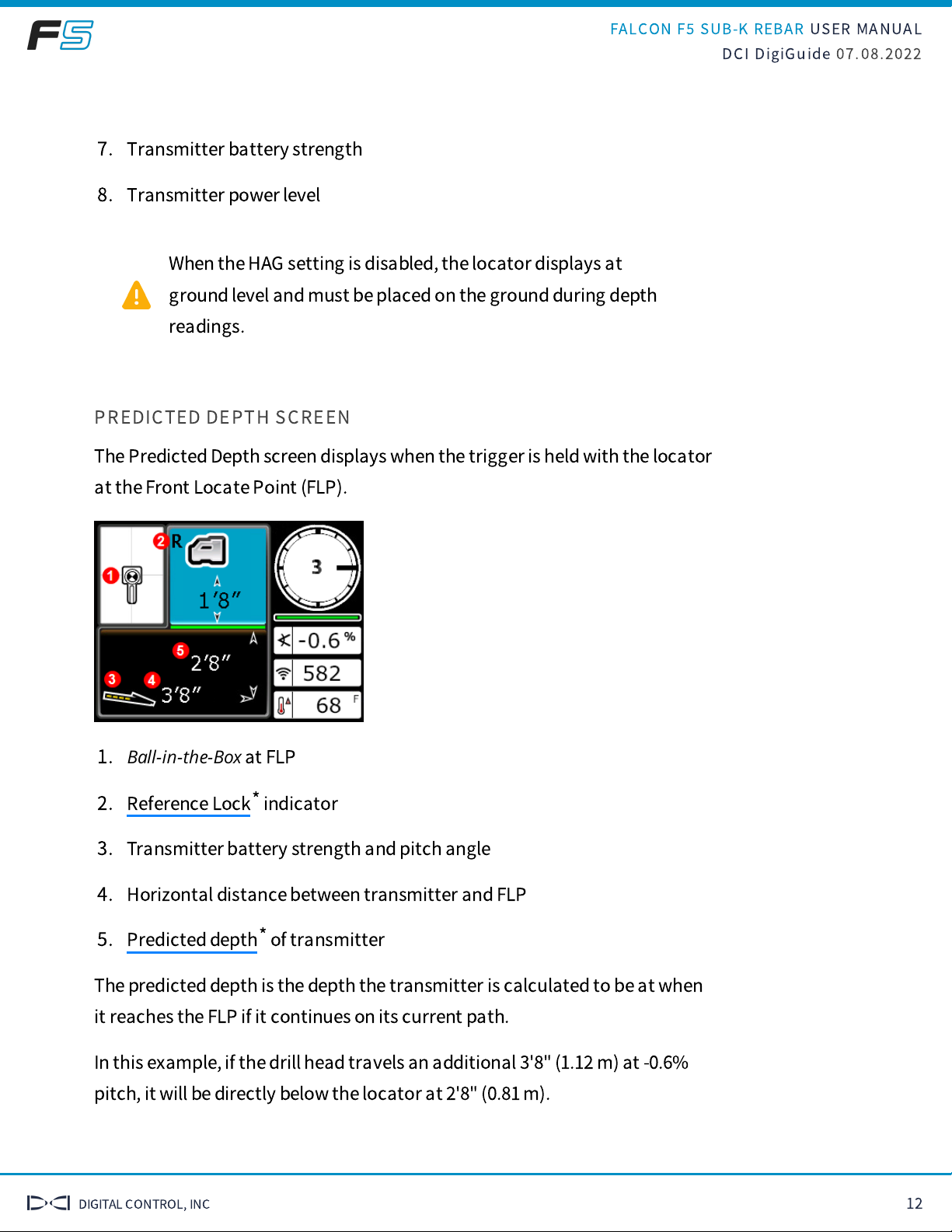

PREDICTED DEPTH SCREEN

The Predicted Depth screen displays when the trigger is held with the locator

at the Front Locate Point (FLP).

1.

Ball-in-the-Box

at FLP

2. indicator

3. Transmitter battery strength and pitch angle

4. Horizontal distance between transmitter and FLP

5. of transmitter

The predicted depth is the depth the transmitter is calculated to be at when

it reaches the FLP if it continues on its current path.

In this example, if the drill head travels an additional 3'8" (1.12 m) at -0.6%

pitch, it will be directly below the locator at 2'8" (0.81 m).

Reference Lock*

Predicted depth*

FALCON F

SUB-K REBAR USER MANUAL

DCI DigiGuide 07.08.2022

DIGITAL CONTROL, INC 13

Do not take a predicted depth reading when the locator is over

the Rear Locate Point (RLP).

GLOSSARY DEFINITIONS

*REFERENCE LOCK INDICATOR

Indicates a reference signal has been obtained for displaying the locate line.

Displays at the top of the Locate Mode screen.

*PREDICTED DEPTH

The Predicted Depth screen displays when the trigger is held with the locator at the

Front Locate Point (FLP). The predicted depth is how deep the transmitter is

calculated to be when it reaches the front locate point if it continues on its current

path.

FALCON F

SUB-K REBAR USER MANUAL

DCI DigiGuide 07.08.2022

DIGITAL CONTROL, INC 14

Initial Setup

REGISTERING YOUR EQUIPMENT

STEP 1 OF 2

Stu

ff

You Should Know

Registering your equipment activates the product warranty.

Registering also allows us to contact you if it is recovered after being lost or

stolen.

If you want to enable the Lock Out Capability (LOC) feature, contact DCI

support.

See the DCI website for warranty terms and conditions.

STEP 2 OF 2

Contact your authorized DCI dealer or DCI to register your equipment.

You will need the equipment serial number and your company contact

information.

Here

’

s where to

fi

nd your serial number:

Locator: in the battery compartment

Transmitter: engraved on the steel body

Remote display: decal on the back

POWER ON

FALCON F

SUB-K REBAR USER MANUAL

DCI DigiGuide 07.08.2022

DIGITAL CONTROL, INC 15

STEP 1 OF 5

Check the charge level of your battery; each of the

fi

ve lights on a li-ion

battery represents about 20% capacity.

NiMH batteries do not have a power meter. You can view

battery life in the top banner of the Main menu.

STEP 2 OF 5

Insert battery in the locator.

FALCON F

SUB-K REBAR USER MANUAL

DCI DigiGuide 07.08.2022

DIGITAL CONTROL, INC 16

STEP 3 OF 5

Pull the trigger to turn on the locator.

STEP 4 OF 5

Click to con

fi

rm you

’

ve read the manual.

STEP 5 OF 5

Click again to continue.

TRANSMITTER SETUP

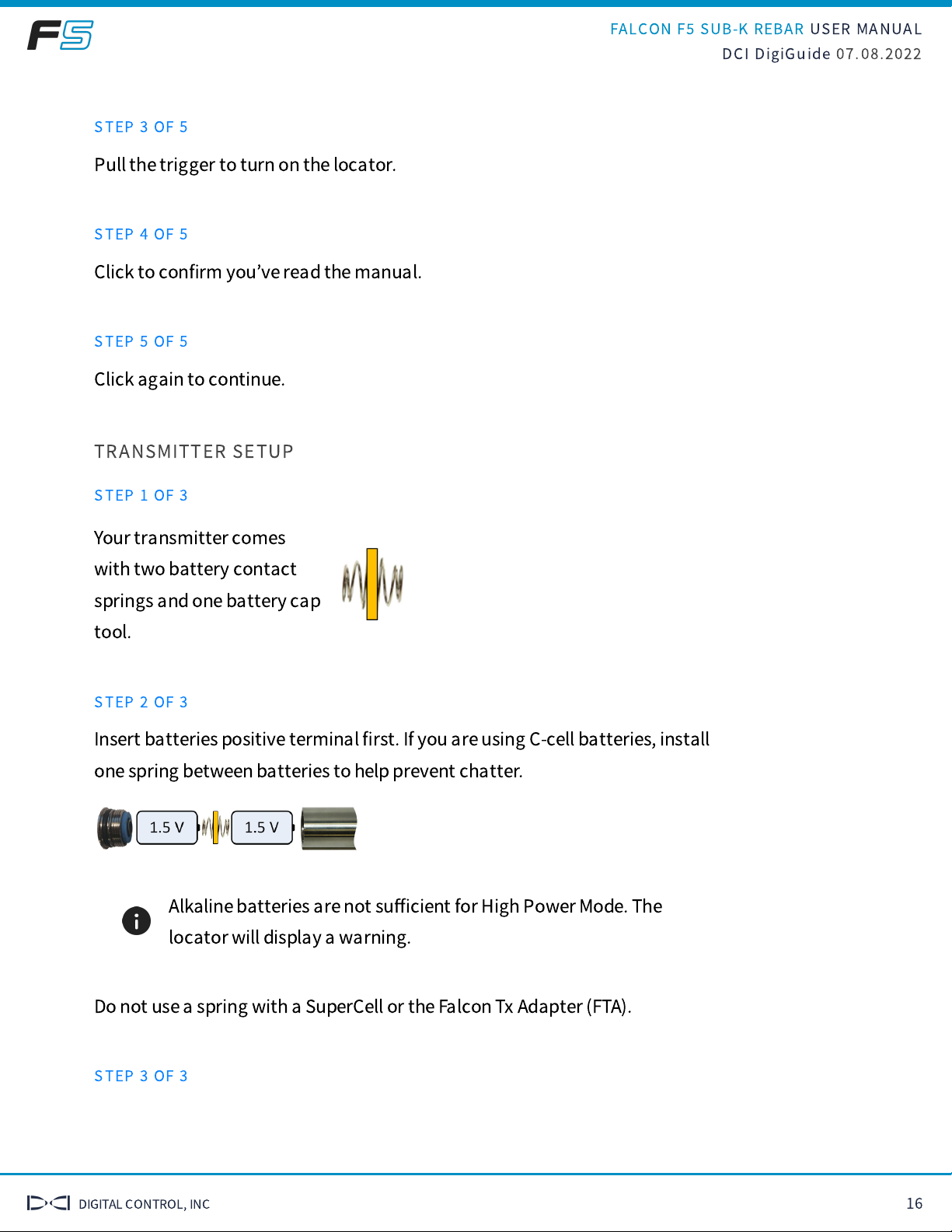

STEP 1 OF 3

Your transmitter comes

with two battery contact

springs and one battery cap

tool.

STEP 2 OF 3

Insert batteries positive terminal

fi

rst. If you are using C-cell batteries, install

one spring between batteries to help prevent chatter.

Alkaline batteries are not su

ffi

cient for High Power Mode. The

locator will display a warning.

Do not use a spring with a SuperCell or the Falcon Tx Adapter (FTA).

STEP 3 OF 3

FALCON F

SUB-K REBAR USER MANUAL

DCI DigiGuide 07.08.2022

DIGITAL CONTROL, INC 17

SET HEIGHT-ABOVE-GROUND

STEP 1 OF 6

Stuff You Should Know

Use Height-Above-Ground (HAG) to set a height measurement on the locator

so you don

’

t have to put it on the ground for a depth reading.

Raising the locator above the ground also provides separation from

underground interference that might otherwise reduce the transmitter

’

s

range or cause variable readings.

STEP 2 OF 6

Hold the locator at your side as if you were holding a suitcase.

STEP 3 OF 6

Measure the distance between the ground and the bottom of the locator

using a tape measure.

STEP 4 OF 6

From the

Main

menu, select

HAG

.

STEP 5 OF 6

Select

Set HAG.

STEP 6 OF 6

Use the keypad to enter the

FALCON F

SUB-K REBAR USER MANUAL

DCI DigiGuide 07.08.2022

DIGITAL CONTROL, INC 18

value you measured and

select

Enter

. HAG is now on.

The locator must now be held at the set height for accurate

depth readings.

HAG must be turned on manually each time after the locator is

powered on or calibrated.

FALCON F

SUB-K REBAR USER MANUAL

DCI DigiGuide 07.08.2022

DIGITAL CONTROL, INC 19

Jobsite Setup

POWER ON

STEP 1 OF 5

Check the charge level of your battery; each of the

fi

ve lights on a li-ion

battery represents about 20% capacity.

NiMH batteries do not have a power meter. You can view

battery life in the top banner of the Main menu.

STEP 2 OF 5

Insert battery in the locator.

FALCON F

SUB-K REBAR USER MANUAL

DCI DigiGuide 07.08.2022

DIGITAL CONTROL, INC 20

STEP 3 OF 5

Pull the trigger to turn on the locator.

STEP 4 OF 5

Click to con

fi

rm you

’

ve read the manual.

STEP 5 OF 5

Click again to continue.

SELECT/CHANGE TX TYPE

STEP 1 OF 4

Stu

ff

You Should Know

Your locating system can use di

ff

erent transmitters: FT

, FT

, or FTR.

The transmitter selected on your locator must match the transmitter in use.

Transmitter:

Other Digital Control Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

A to Z Rubber Stamps

A to Z Rubber Stamps RAPIDPRINT A Series manual

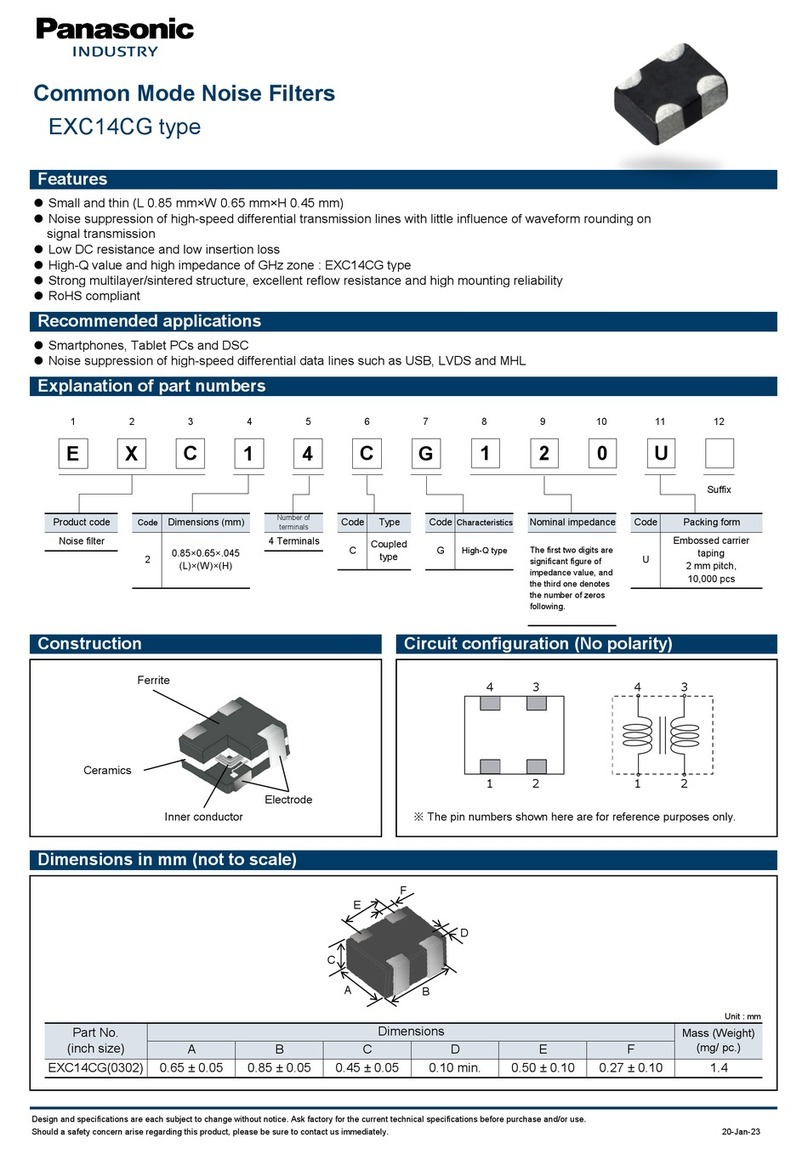

Panasonic

Panasonic EXC14CG quick start guide

Husky

Husky 31318 Assembly, Installation, Operation and Maintenance Instructions

Emerson

Emerson Liebert eXL installation manual

Orion

Orion L77-20 manual

Schmalz

Schmalz EVE-TR 4 - 8 DC operating instructions