Digital Electronics Corporation PL-3900T Series User manual

1

PL-3900T Series

Installation Guide

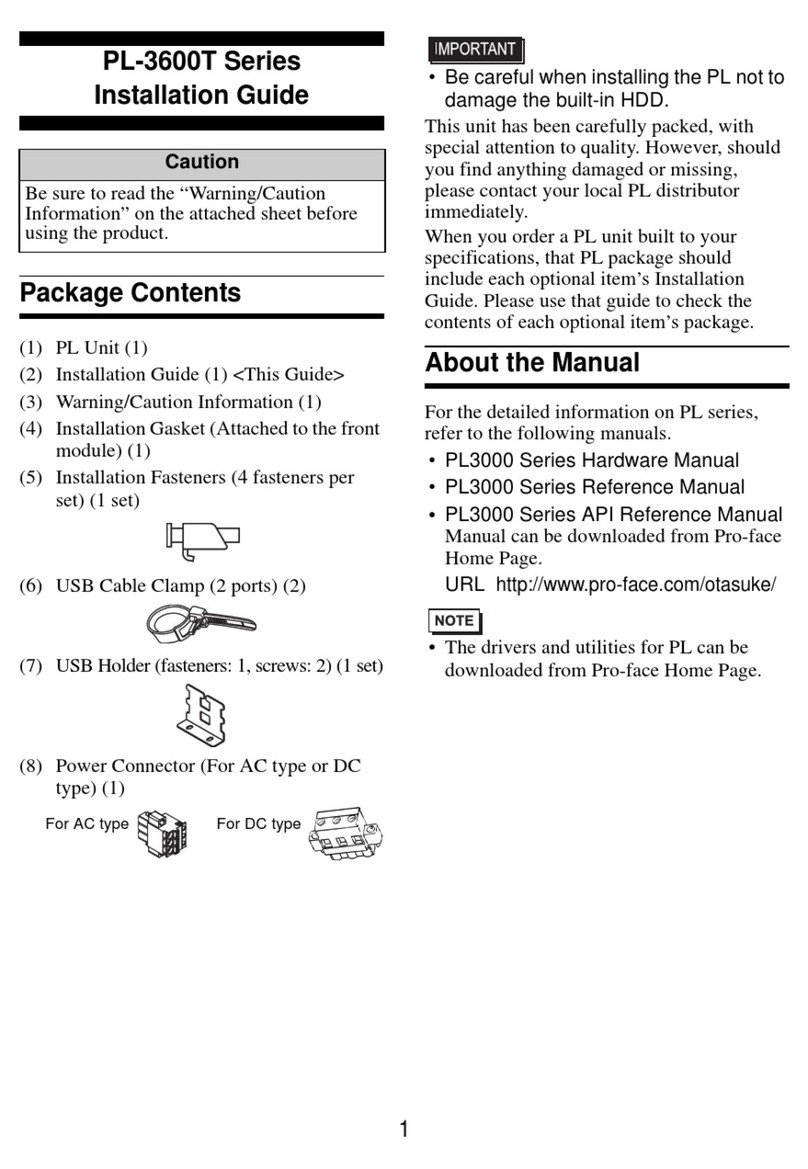

Package Contents

(1) PL Unit (1)

(2) Installation Guide (1) <This Guide>

(3) Warning/Caution Information (1)

(4) Installation Gasket (Attached to the front

module) (1)

(5) Installation Fasteners (4 fasteners per

set) (3 set)

(6) USB Cable Clamp (2 ports) (2)

(7) USB Holder (fasteners: 1, screws: 2) (1 set)

(8) Power Connector (For AC type or DC

type) (1)

• Be careful when installing the PL notto

damage the built-in HDD.

This unit has been carefully packed, with

special attention to quality. However, should

you find anything damaged or missing,

please contact your local PL distributor

immediately.

When you order a PL unit built to your

specifications, that PL package should

include each optional item’s Installation

Guide. Please use that guide to check the

contents of each optional item’s package.

About the Manual

For the detailed information on PL series,

refer to the following manuals.

• PL3000 Series Hardware Manual

• PL3000 Series Reference Manual

•PL3000 Series API Reference Manual

Manual can be downloaded from Pro-face

Home Page.

URL

http://www.pro-face.com/otasuke/

• The drivers and utilities for PL can be

downloaded from Pro-face Home Page.

Caution

Be sure to read the “Warning/Caution

Information” on the attached sheet before

using the product.

For AC type For DC type

2

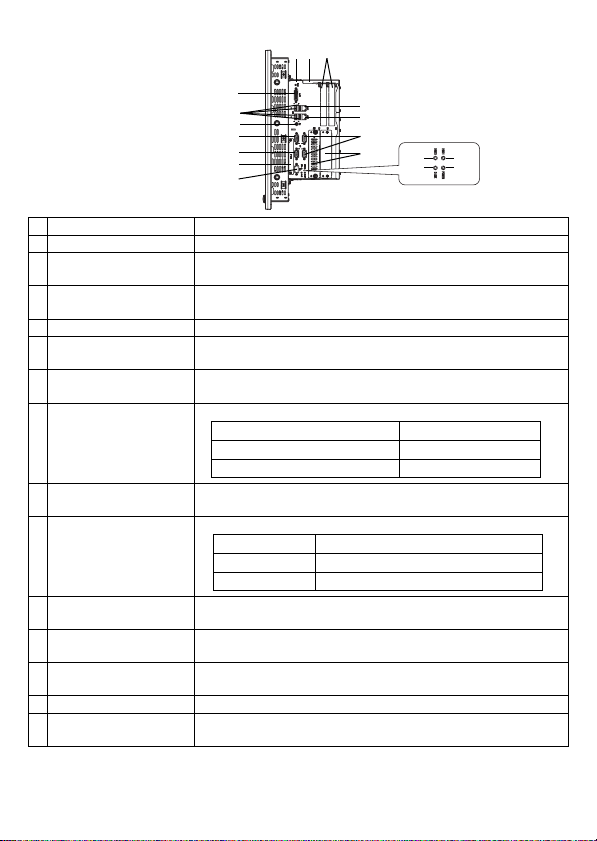

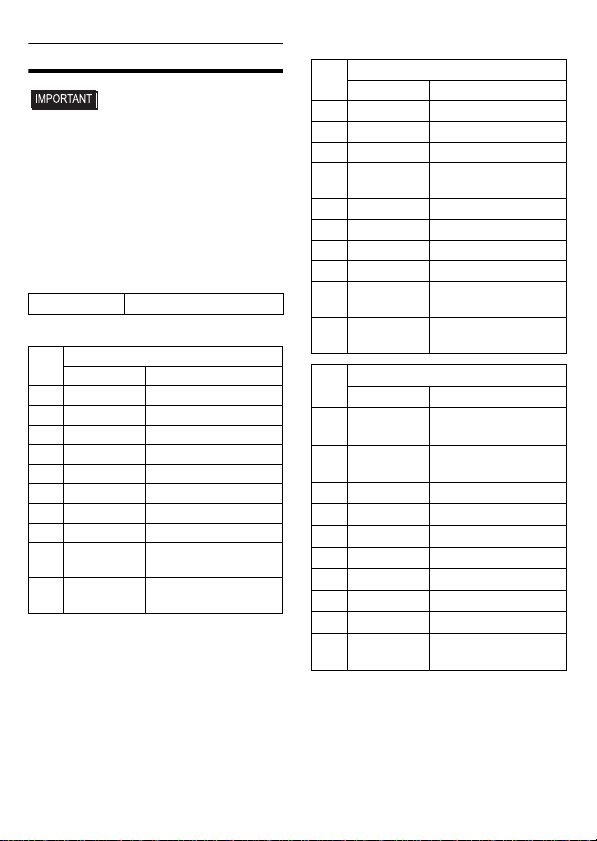

Part Names and Functions

Name Description

APower LED /

RAS status lamp (POWER)

B Disk access lamp (DISK)

CFrontcover —

DHardware reset switch

(RESET) Resets the PL unit and returns the system from Soft

OFF.*1

*1 The Soft OFF refers to the state when Windows®has been shut down and the power is provided

only for the electric circuit to boot system. This Soft OFF State is different from Windows®System

Standby.

EUSBinterface

1 port. USB2.0 compatible. Type-A connector is used.

Front AB

CDE

LED Indicates

Green (lit) Normal operation (power is on)

Green (blinking) Soft OFF state

Orange (lit) System monitor error (RAS error)

/ Touch Panel Self Test Error

Orange/Red

(blinking) Backlight burnout is detected.

Not lit Power is OFF

LED Indicates

Green (lit) When HDD or IDE is accessed

Not lit When neither HDD nor IDE is

accessed

Power supply voltage DC5V±5%

Output current 500mA (Max.)

Maximum

communication distance 5m

3

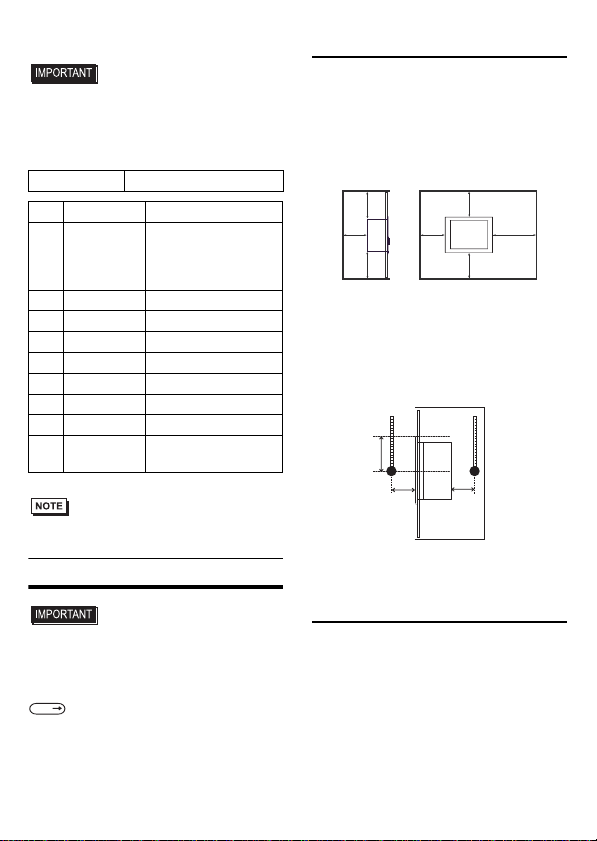

Name Description

F DVI-I interface (DVI-I) For analog RGB output only.*1

*1 DVI monitor cannot be connected.

GEthernet interface

(LAN1) 10BASE-T/100BASE-TX/1000BASE-T Auto Changeover. This

interface uses an RJ-45 type modular jack connector (8 pins).

HEthernet interface

(LAN2) 10BASE-T/100BASE-TX Auto Changeover. This interface uses

an RJ-45 type modular jack connector (8 pins).

I Expansion slot For expansion board (PCI). 2 slots or 4 slots.

J Expansion slot cover Expansion slot cover is removed when mounting expansion

board and DIM module.

K HDD slot For serial ATA HDD unit. HDD slot 0 and then HDD slot 1

from the left.

LUSB interface

(USB1/2/3/4)

4 ports. USB2.0 compatible. Type-A connector is used.

MSpeaker output

interface (SPK) Mini pin jack connector

NHDD status lamp

(HDD0/HDD1)

For HDD0 and for HDD1 from left to right.

OSerial interface

(COM1) D-Sub 9-pin plug type. RS-232C, RS-422, RS-485

Changeover. CI (RI)/+5V Changeover.

PSerial interface

(COM2) D-Sub 9-pin plug type. RS-232C. CI (RI)/+5V Changeover.

QSerial interface

(COM3/COM4) D-Sub 9-pin plug type. RS-232C. COM3 and then COM4

from the top.

R RAS interface (RAS) D-Sub 9 pin socket type.

SCFcardinterface IDE-type connection *2

CF card (Type I/II) is available.

*2 Since an IDE-type connection is used, the unit is not hot-swappable. When inserting/removing the

CF card, be sure that power is turned OFF.

Right side

(2 slot type)

F

IJ

L

M

O

P

S

R

N

BN

A

K

Q

H

G

D

Power supply voltage DC5V±5%

Output current 500mA (Max.)

Maximum communication distance

5m

LED Indicates

Green (lit) HDD mounted (Normal operation)

Not lit No HDD mounted

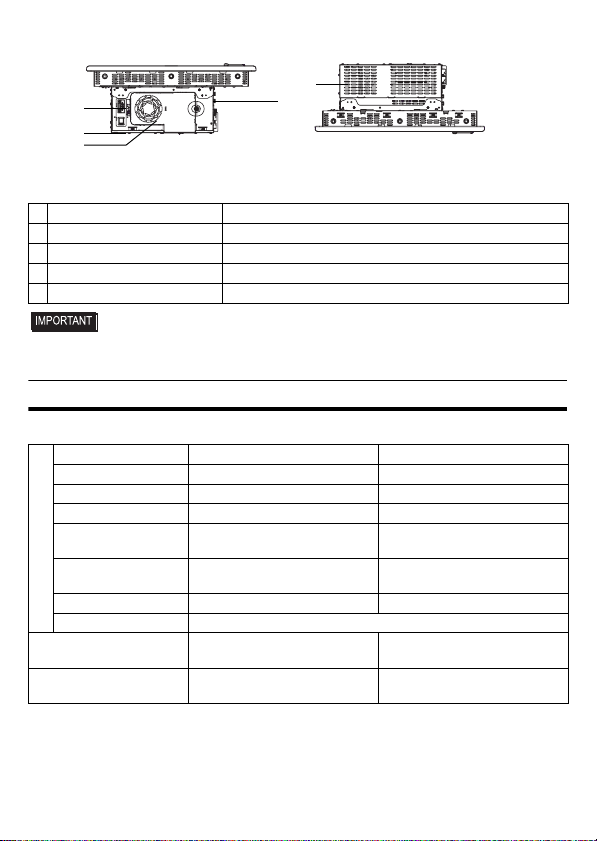

4

• When attaching peripheral units to the PL, be sure the PL’s power cord is

disconnected from the main power supply.

General Specifications

Electrical Specifications

Name Description

T Fan cover System fan inside

U System fan A fan for cooling the PL unit.

V Power connector —

W Power switch AC type only.

Power Supply

DC type AC type

Input Voltage DC24V AC100 to 240V

Rated Voltage DC19.2 to 28.8V AC85 to 264V

Rated Frequency — 50/60Hz

Allowable Frequency

Range — 47 to 63Hz

Allowable Voltage

Drop 5ms or less 1 cycle or less (Voltage drop

interval must be 1s or more.)*1

Power Consumption 145W or less 145VA or less

In-Rush Current 40A or less

Voltage Endurance AC1000V 10mA for 1 minute

(

between charging and FG terminals

)AC1500V 20mA for 1 minute

(

between charging and FG terminals

)

Insulation Resistance DC500V 10MΩ(min.)

(

between charging and FG terminals

)DC500V 10MΩ(min.)

(

between charging and FG terminals

)

Bottom

(2 slot type)

T

V

Top

(2 slot type)

W

U

J

5

Environmental Specifications

• When using any of the PL’s optional devices, be sure to check that device’s specifica-

tions for any special conditions or cautions that may apply to its use.

• Be aware that not only does the Hard Disk have a fixed lifetime, but that accidents

can always occur. Therefore, be sure to back up your Hard Disk’s data regularly, or

prepare another Hard Disk unit that can be used for backup.

• The Hard Disk lifetime given here may be reduced due to unforeseen environmental

factors, however, generally speaking, the disk should last for 20,000 hours (of opera-

tion) or approximately 5 years, whichever comes first at an operating temperature of

20°C and 333 hours of operation per month. (HDD access frequency of 20% or less)

• Using the Hard Disk in an environment that is excessively hot and/or humid will

shorten the disk’s usage lifetime. A wet bulb temperature of 29°C or less is recom-

mended. This is equivalent to the following data.

• In order to extend the lifetime of the hard disk, Pro-face recommends you set the

Windows®2000’s [Control panel]-[Power Management option]-[Turn off hard disks]

selection or the Windows®XP’s [Control panel]-[Performance and Maintenance]-

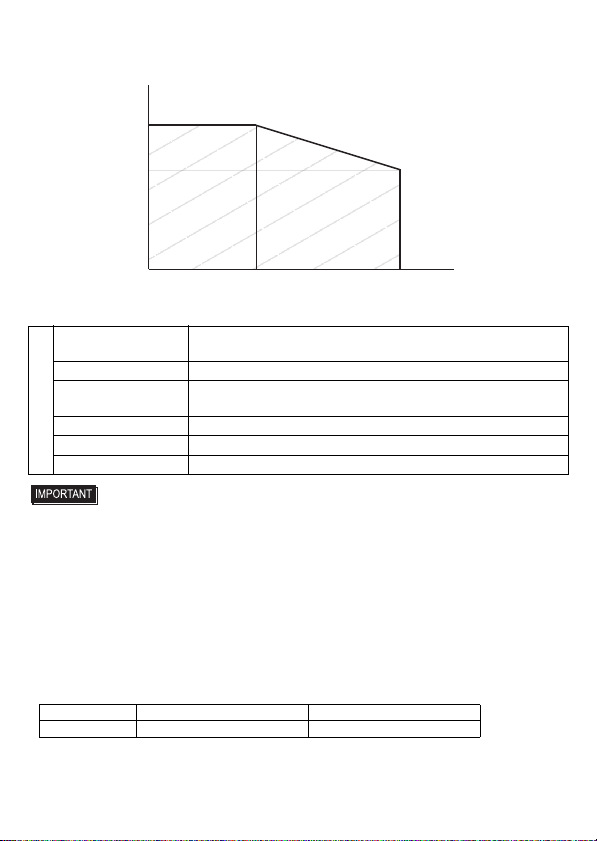

*1 When the total of the expansion slot power and theexternal load power exceeds 15W, the length of

the allowable voltage drop will be 20ms or less. For details, refer to the chart below.

Physical

Surrounding Air

Temperature 0 to 50°C :without HDD

5 to 50°C :with HDD

Storage Temperature -20 to +60°C

Ambient Humidity 10 to 90% RH (Not condensing, wet bulb temperature: 39°C or

less. Wet bulb temperature with HDD: 29°C or less.)

Storage Humidity 10 to 90% RH (Not condensing, wet bulb temperature:39°C or less.)

Dust Free of dust

Pollution Degree For use in Pollution Degree 2 environment

Temperature at 35°C at 40°C

Humidity no higher than 64% RH no higher than 44% RH

(ms)

20

14

035 40 (W)

15

Allowable Range

6

[Power Management option]-[Turn off hard disks] selection to turn the hard disk off

when the unit is not being operated. A setting of 5 minutes is recommended.

• Do not vibrate the hard disk continuously at the same frequency. Doing so may cause

the hard disk to reduce transfer speeds or stop temporarily.

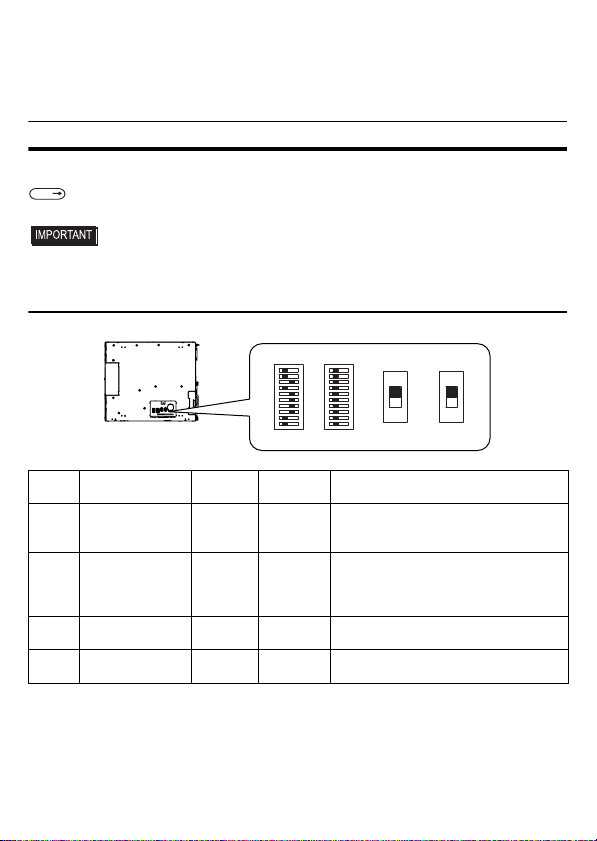

Internal Switches

To operate the internal switches, uninstall the control box and the front module.

• Make sure to turn off the power supply before using the switches. Adjusting the

switches while power is supplied may cause errors.

1. Internal switches of the control box

SEE

Installation/uninstallation of the front module and the control box (page 13)

Switch

Location

Switch Name

Compatible

I/F

Factory

Settings Description

SW1 System Set SW – See

System

Set Switch

10-point dip switch. For System Set

SW and the factory settings details,

see System Set Switch.

SW2 Serial Mode

Select SW COM1

All OFF

(RS-232C)

10-point dip switch. Designates COM1

communication settings. For Serial

Mode Select SW details, see Serial

Mode Select Switch.

SW3 CI(RI)/+5V

Changeover SW COM2 CI(RI) Changes # 9 pin (CI(RI) <---> +5V).

SW4 CI(RI)/+5V

Changeover SW COM1 CI(RI) Changes # 9 pin (CI(RI) <---> +5V).

1 10

1 10

SW4SW1 SW2 SW3

OFF

ON

ON

OFF

Bottom face of the control box

(CI)RI

5V

7

System Set Switch

Serial Mode Select Switch

Switch

No.

Description ON OFF

Factory

Settings

Notes

1 Internal setting.

Reserved Reserved

OFF Do not change. (Factory

setting)

2

Implements the

logical inversion

operation for RAS

output.

Normal

Close Normal

Open OFF

RAS output is a CLOSE state when

the SW and the system is ON. When

the SW is OFF, it is the opposite. The

RAS Output keeps Normal OPEN

when the Soft OFF state occurs or the

power turns OFF.

3

Sets up an enabled/

disabled state for the

front USB port execution

control function.

*1

*1 The Setting up an enabled/Disabled state for USB port execution control function is available for

only Windows®2000 and Windows®XP. Make sure to disable the function of the setting when

other OS is used.

Enabled Disabled ON

The front USB port is available

when the SW is ON. It is

unavailable when the SW is OFF.

4Internal setting.

Reserved Reserved

OFF Do not change. (Factory

setting)

5 to 8 ON

9 to 10

OFF

Switch

No.

Description ON OFF

RS-232C RS-422 RS-485

1

Internal setting.

Reserved Reserved OFF*1 OFF*1 OFF*1

2

Changes COM1’s

communication

method RS-422/RS-485 RS-232C

OFF ON ON

3

Changes COM1’s

communication

method RS-422/RS-485 RS-232C

OFF ON ON

4

Changes SD (TXD)

data’s output mode

SD (TXD) data

output is

controlled via the

RS (RTS) signal.

SD (TXD) data

output is NOT

controlledviathe

RS(RTS)signal.

(normally output)

OFF ON/

OFF ON/

OFF*2

5

Switches the SD

(TXD) termination

resistance ON/OFF

Inserts

termination

resistance of

220

Ω

between

SDA and SDB.

No termination

OFF ON ON/

OFF*3

8

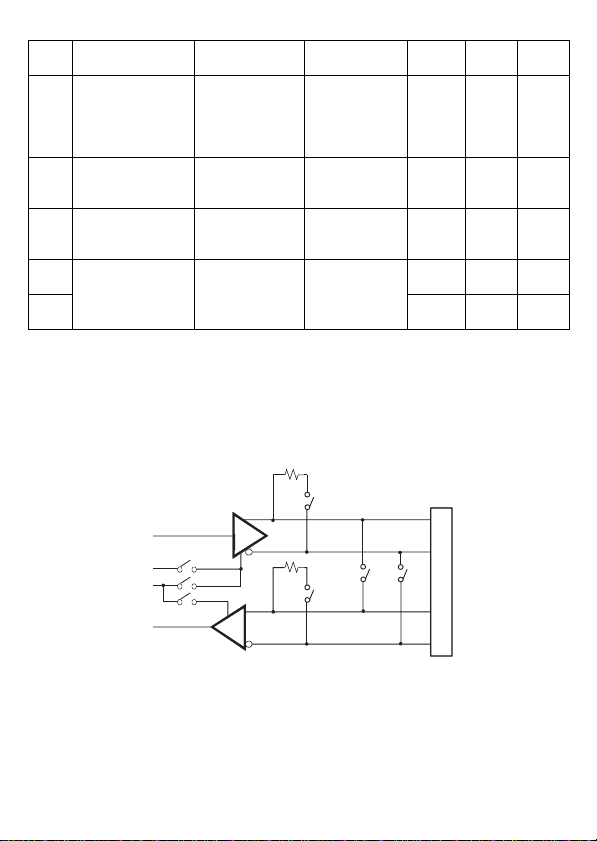

Serial Mode Select Switches (SW4 to SW10) operate as shown in the circuit diagram below.

6

Switches the RD

(RXD) termination

resistance ON/OFF

Inserts

termination

resistance of

220

Ω

between

RDA and RDB.

No termination

OFF ON ON/

OFF*3

7

Switches the

shorting of SDA and

RDA ON or OFF

Shorts SDA and

RDA

(RS-485 mode)

No shorting

(RS-422 mode)

OFF OFF ON

8

Switches the

shorting of SDB and

RDB ON or OFF

Shorts SDB and

RDB

(RS-485 mode)

No shorting

(RS-422 mode)

OFF OFF ON

9

RS(RTS)Automatic

control mode

(enabled only when

RS-485 mode)

The data is

automatically

controlled via the

RS (RTS) signal.

The data is not

automatically

controlledviathe

RS (RTS) signal.

OFF OFF ON/

OFF*2

10 OFF OFF ON/

OFF*2

*1 Be sure to keep the settings, “OFF”.

*2 Set switches number 9 and 10 to ON when the SD (TXD) output driver is automatically controlled

with RS (RTS). Set switch number 4 to OFF.

Set switches number 9 and 10 to OFF when the SD (TXD) output driver is controlled with the RS

(RTS) signal. Set switch number 4 to ON.

*3 If you use the termination resistance, base your settings on the connection specifications.

Switch

No.

Description ON OFF

RS-232C RS-422 RS-485

SW4

SW9

SW10

SW5

SW7

SW6

SW8

RT(RTS) Automatic

control

COM1

SD(TXD)

RT(RTS)

SDA

SDB

RDA

RDB

9

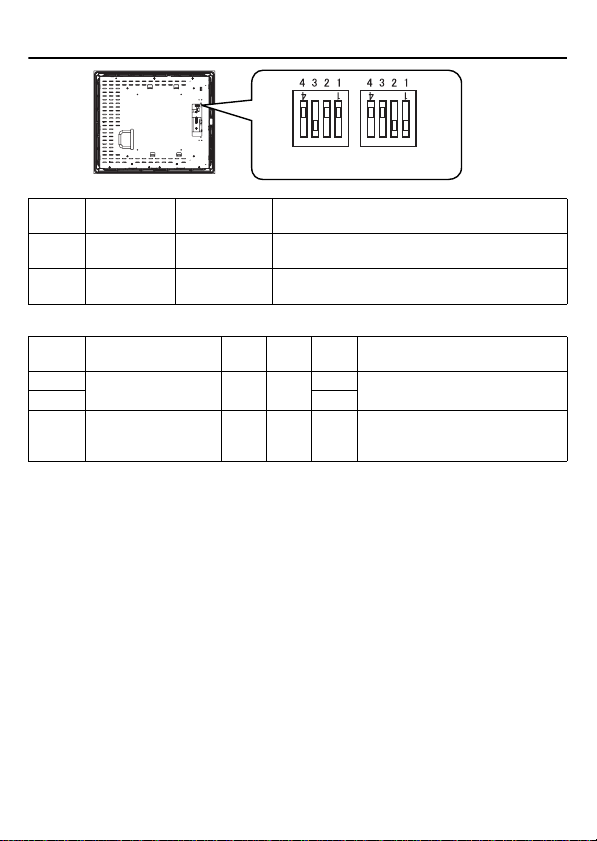

2. Internal switches of the front module

Touch Panel Set SW

Switch

Location

Switch Name Factory

Settings Description

SW1 Touch Panel

Set SW 1:ON, 2:ON,

3:OFF, 4:OFF 4-point dipswitch. For Touch Panel Set SW

details, see “Touch Panel Set SW”.

SW2 — 1:OFF, 2:OFF,

3:ON, 4:OFF Internal setting.

Do not change. (Factory setting)

SW1

SW2 ON

ON

Rear face of the front module

Switch

No. Description ON OFF

Factory

Settings

Notes

1 to 2 Internal setting

Reserved Reserved

ON Do not change. (Factory setting)

3OFF

4Cancellation function

of two point touch on

the touch panel*1

Enabled Disabled

OFF

The middle point is not considered to be

touched when the SW is ON. It is considered

to be touched when the SW is OFF.

*1 When two points are pushed, it is considered that middle point between the two points is touched

according to the nature of the analog resistive touch panel. When the switch, etc. is set on the middle

point,itwillbeenabledandmayoperate.Topreventsuchaswitchfrommalfunctionincaseofpushing

two points, turn ON the SW No.4 in advance, then the middle point will be disabled for two point touch.

10

External Interfaces

• This PL unit’s serial port is not isolated.

When the host (PLC) unit is also not

isolated, and to reduce the risk of dam-

aging the RS-232C/RS-422/RS-485

circuit, be sure to connect pin #5 SG

(Signal Ground) terminal.

• Never connect NC to COM1.

• Connect FG to shell.

Serial Interface

(COM1, COM2, COM3, COM4)

COM1, COM2, COM3, COM4

COM1

*3 To change the communication method, set

the dip switch located on the circuit board in

the PL unit to the desired position.

For details, see [Internal Switches].

Interfit Bracket #4-40 UNC

Pin #

RS-232C

Signal Name

Meaning

1 CD Carrier Detect

2 RD(RXD) Receive Data

3 SD(TXD) Send Data

4 ER(DTR) Data Terminal Ready

5 SG Signal Ground

6 DR(DSR) Data Set Ready

7 RS(RTS) Request to Send

8 CS(CTS) Clear to Send

9CI(RI)/+5VCalled status display/

+5V Output 0.5A*1 *2

*1 Only COM1 and COM2 are available for

switchingto+5V.COM3andCOM4areused

exclusively for CI (RI).

*2 Slideswitchon the circuitboardin the PLunit

switches between CI (RI) and +5 V. For

details, see [Internal Switches].

Shell

FG Frame Ground

(Common with SG)

Pin #

RS-422 *3

Signal Name

Meaning

1 RDA Receive Data A(+)

2 RDB Receive Data B(-)

3 SDA Send Data A(+)

4ERA Data Terminal Ready

A(+)

5 SG Signal Ground

6 CSB Clear to Send B(-)

7 SDB Send Data B(-)

8 CSA Clear to Send A(+)

9ERB Data Terminal Ready

B(-)

Shell

FG Frame Ground

(Common with SG)

Pin #

RS-485*3

Signal Name

Meaning

1DATA+ Send/Receive Data

(+)

2DATA- Send/Receive Data

(-)

3 NC No Connection

4 NC No Connection

5 SG Signal Ground

6 NC No Connection

7 NC No Connection

8 NC No Connection

9 NC No Connection

Shell

FG Frame Ground

(Common with SG)

11

RAS Interface

• Be sure to use only the rated voltage

level when using pin #1 (+12V) for

external power output. Failure to do so

can lead to a unit malfunction or acci-

dent.

• For the circuit diagram, refer to “PL3000

Series Reference Manual”.

Installations

• Before installing the PL unit on the

panel, detach the control box from the

front module to configure the settings

of the internal switches.

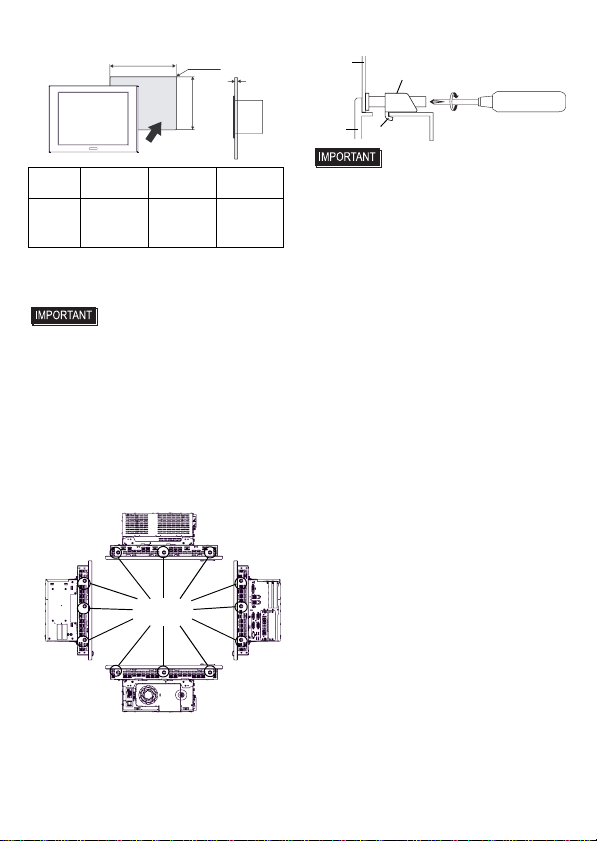

1. Installation Requirements

• For easier maintenance, operation, and

improved ventilation, be sure to install the

PL at least 50mm [1.97 in.] away from

adjacent structures and other equipment.

For the face to which the cable is con-

nected, however, a space of 120 mm [4.72

in.] or more is necessary for cable curve.

• Be sure that the surrounding air temperature

and the ambient humidity are within their

specified ranges.

When installing the PL on the panel of a

cabinet or enclosure, “Surrounding air tem-

perature” indicates both the panel face and

cabinet or enclosure’s internal temperature.

• Be sure that heat from surrounding equip-

ment does not cause the PL to exceed its

standard operating temperature.

2. PL Installation

(1) Create a Panel Cut following the dimen-

sions in the following table. Also, deter-

mine the panel thickness according to the

panel thickness range with due consider-

ation of panel strength.

Interfit Bracket #4-40 UNC

Pin #

Signal Name

Meaning

1 +12V

Output Current:

100mA or less

Output Voltage:

12V

±

5%

2 DOUT0(+) Data out 0(+)

3 DOUT1(+) Data out 1(+)

4 DIN0(+) Data in 0(+)

5 DIN1(+) Data in 1(+)*1

*1 Can be used as reset input.

6 GND Ground

7 DOUT0(-) Data out 0(-)

8 DOUT1(-) Data out 1(-)

9DINCOM Data in ground

common

SEE

Installation/uninstallation of the

front module and the control

box, Internal Switches

Unit:mm[in.]

120

[4.72]

50

[1.97]

50

[1.97]

50

[1.97]

50

[1.97]

50

[1.97]

50

[1.97]

Panel face Cabinet

interior

30

[1.18] 30

[1.18]

unit:mm[in.]

50

[1.97]

12

(2) Confirm that the installation gasket is

attached to the PL unit and then place the

PL unit into the panel from the front.

• It is strongly recommended that you

use the installation gasket, since it

absorbs vibration in addition to repel-

ling water.

For the procedure for attaching the

installation gasket, refer to “PL3000

Series Hardware Manual”.

(3) Insert each fastener’s hook into the slot

and tighten it with a screwdriver. Tighten

the 12 screws gradually in an even, criss-

cross pattern.

• Tightening the screws with too much

force can damage the PL unit.

• The torque required to tighten these

screws is 0.8 N•m.

PL X Y

Panel

thickness

PL-3900T

Series

419.5

[16.52 ]

352.5

[13.88 ]

1.6[0.06] to

10.0[0.39]

PL

X

Unit:mm[in.]

Y

Under

4-R3[0.12] Panel

thickness

+1

-

0

+

0.04

-

0

+1

-

0

+

0.04

-

0

Insertion

Slots

Panel

Hook

PL

Installation Fastener

Tighten against

the board.

13

Installation/uninstallation of the

front module and the control box

• To avoid an electric shock, prior to instal-

lation/uninstallation of the front module

and the control box, confirm that the PL

unit’s power supply is completely turned

OFF, via a breaker, or similar unit.

1. Uninstalling the front module and

the control box

(1) Unscrew the three attachment screws to

detach the cover for the flexible cable.

(2) Disconnect the flexible cable.

(3) Remove four screws on the installation

fasteners for the control box.

(4) Slide the control box in direction shown

by the arrow.

(5) Lift the control box and remove the front

module tabs from the slot on the installa-

tion fasteners for the control box. Then

remove the control box.

2. Installing the front module and the

control box

Install the control box to the front module

in the reverse order of the uninstallation

steps. The necessary torque is 0.5N•m to

0.6N•m in every step.

Flexible Cable

Cover

Flexible Cable

Use the bridge

position as a guide.

14

Wiring

• To avoid an electric shock, prior to con-

necting the PL unit’s power cord terminals

to the power terminal block, confirm that

the PL unit’s power supply is completely

turned OFF, via a breaker, or similar unit.

• Any other power level can damage

both the PL and the power supply.

• Since DC type has no power ON/OFF

switch, be sure to attach a breaker-

type switch to its power cord.

• When the FG terminal is connected, be

sure the wire is grounded.

1. Wiring the AC type power supply cable

• When the FG terminal is connected, be

sure the wire is grounded. Not

grounding the PL unit will result in

excessive noise. Use your country’s

applicable standard for grounding.

Power Cord Specifications

Use copper conductors only.

Wiring

When connecting the power code, use the

following items when performing wiring.

(Items are made by Phoenix Contact.)

• Accompanying power supply connector is

a CA7-ACCNL-01 of Pro-face or FKC2,5/

3-STF-5,08 of Phoenix Contact.

Connecting the Power Cord

(1) Confirm that the power is not supplied to

the PL unit.

(2) Push the Opening button by a small and flat

screw driver to open the desired pin hole.

(3) Insert each pin terminal into its each

hole. Release the Opening button to

clamp the pin place.

(4) After inserting all three pins, insert the

Power Plug into the Power Connector at

PL. Fix the plug with two minus screws.

• Confirm that all wires are connected

correctly.

• The torque required to tighten these

screws is 0.5 to 0.6 N•m [5-7Lb•In].

• To prevent the possibility of a terminal

short, use a pin terminal that has an

insulating sleeve.

2. Wiring the DC type power supply cable

• When the FG terminal is connected, be

sure the wire is grounded. Not ground-

ing the PL unit will result in excessive

noise. Use your country’s applicable

standard for grounding.

Power Cord

Diameter 0.75 to 2.5mm2

(18 - 12 AWG)

Conductor Type

Simple or Stranded Wire*1

*1 IftheConductor’send(individual)wiresarenot

twistedcorrectly,theendwiresmayeithershort

against each other, or against an electrode.

Conductor

Length

Recommended

Driver SZS 0.6x3.5 (1205053)

10mm [0.39in]

Recommended

Pin Terminals

AI 0.75-10GY(3201288)

AI 1-10RD (3200182)

AI 1.5-10BK (3200195)

AI 2.5-12BU (3200962)

Recommended

Pin Terminal

Crimp Tool CRIMPFOX ZA3

(1201882)

L

N

FG

Opening button

Black

White

Green/Yellow

AC power supply cable

15

Power Cord Specifications

Use copper conductors only.

Power Connector (Plug) Specifications

• Accompanying power supply connector is

CA5-DCCNL-01 of Pro-face or

GMVSTBW2.5-3-STF-7.62 of Phoenix

Contact.

When connecting the power code, use the

following items when performing wiring.

(Items are made by Phoenix Contact.)

Connecting the PL Power Cord

(1) Confirm that the power is not supplied to

the PL unit.

(2) Loosen three screws in the center of the

Power Connector (plug).

(3) Strip the power cord, twist the conductor’s

wire ends, insert them into the pin terminal

and crimp the terminal. Attach the terminal

to the Power Connector.

• Use a flat-blade screwdriver (Size 0.6 x

3.5) to tighten the terminal screws.

The torque required to tighten these

screws is 0.5 to 0.6 N•m [5-7Lb•In.].

• Do not solder the cable connection.

(4) Attach the Power Connector (plug) to the

PL and fix it to the PL main unit with

right/left tightening screws.

3. Power Supply Cautions

• Input and Output signal lines must be sepa-

rated from the power control cables for

operational circuits.

• To improve the noise resistance, be sure to

twist the ends of the power cord wires

before connecting them to the Power con-

nector (Plug).

• The PL unit’s power supply cord should

not be bundled with or kept close to main

circuit lines (high voltage, high current), or

input/output signal lines.

• To reduce noise, make the power cord as

short as possible.

• If the supplied voltage exceeds the PL

unit’s range, connect a voltage transformer.

• Between the line and the ground, be sure to

use a low noise power supply. If there is an

excess amount of noise, connect a noise

reducing transformer.

Power Cord

Diameter 0.75 to 2.5mm2

(18 - 12 AWG)

Conductor Type

Simple or Stranded Wire

*1

*1 If the Conductor’s end (individual) wires are not

twistedcorrectly,theendwiresmayeithershort

against each other, or against an electrode.

Conductor

Length

+ 24V

-

0V

FG

Grounding

Terminal

connected

to the PL

chassis

Recommended

Driver SZF 1-0.6x3.5

(1204517)

Recommended

Pin Terminals

AI 0.75-8GY (3200519)

AI 1-8RD (3200030)

AI 1.5-8BK (3200043)

AI 2.5-8BU (3200522)

Recommended

Pin Terminal

Crimp Tool CRIMPFOX ZA 3

(1201882)

7mm

[0.28in]

+

Insertion Direction

−

FG

FG

+

-

16

• The temperature rating of field installed

conductors: 75°C only.

• Use voltage and noise reducing trans-

formers with capacities exceeding

Power Consumption value.

• Branch Circuit Protective device shall be

use for rating 20A for DC24V input device.

• Connect a surge absorber to handle

power surges.

• Be sure to ground the surge absorber

(E1) separately from the PL unit (E2).

Select a surge absorber that has a maxi-

mum circuit voltage greater than that of

the peak voltage of the power supply.

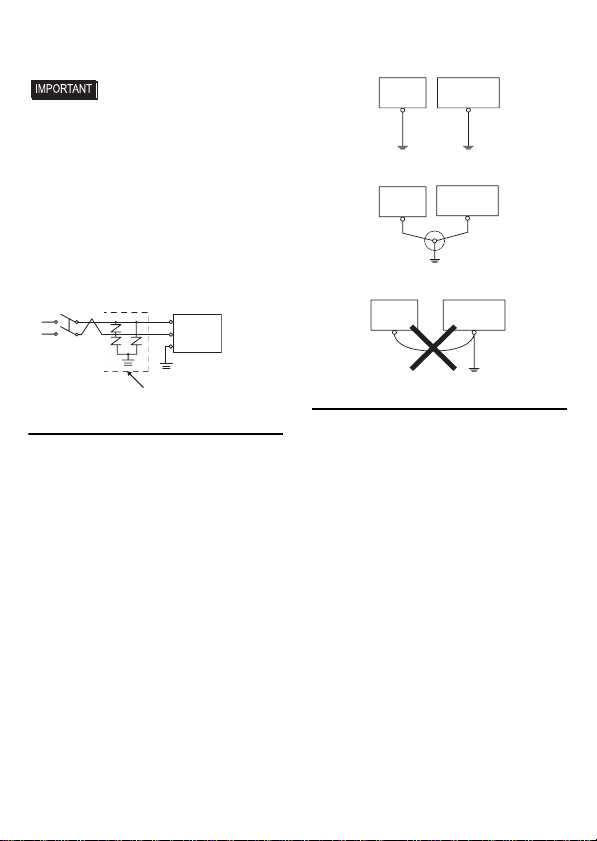

4. Grounding Cautions

• Be sure to create an exclusive ground for the

Power Cord’s FG terminal. Use a grounding

resistance of 100Ω, a wire of 2mm2or thicker,

or your country’s applicable standard.

• The SG (signal ground) and FG (frame

ground) terminals are connected internally

in the PL unit.

When connecting the SG line to another

device, be sure that the design of the system/

connection does not produce a shorting loop.

• The grounding wire should have a cross

sectional area greater than 2mm2. Create

the connection point as close to the PL unit

as possible, and make the wire as short as

possible. When using a long grounding

wire, replace the thin wire with a thicker

wire, and place it in a duct.

5. Input/Output Signal Line Cautions

• All PL Input and Output signal lines must

be separated from all operating circuit

(power) cables.

• If this is not possible, use a shielded cable

and ground the shield.

• To improve noise immunity, it is recommended

to attach a ferrite core to the power cord.

Lightening Surge Absorber

E1 E2

FG

PL

Other

Equipment

Exclusive Grounding

(BEST)

PL unit

Other

Equipment

Common Grounding (OK)

PL unit

Other

Equipment

Common Grounding

(Not OK)

PL unit

17

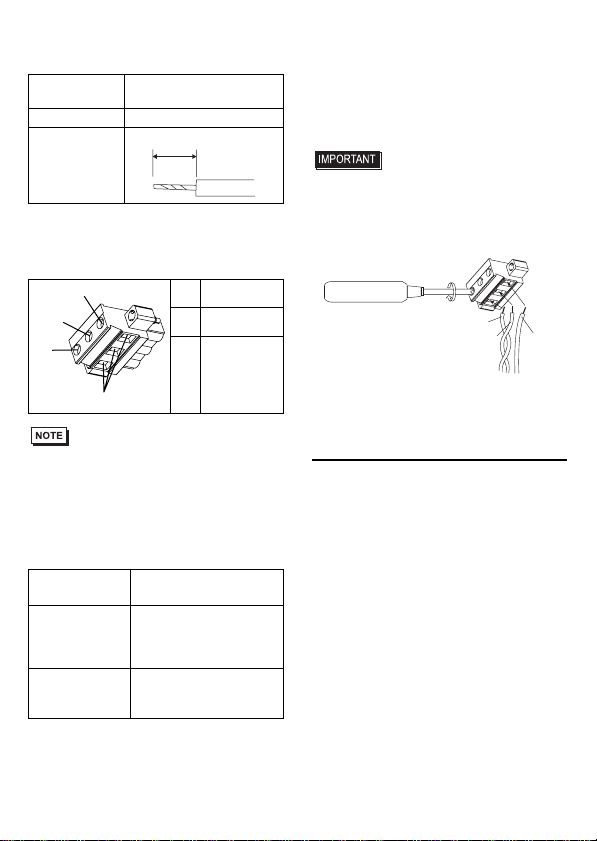

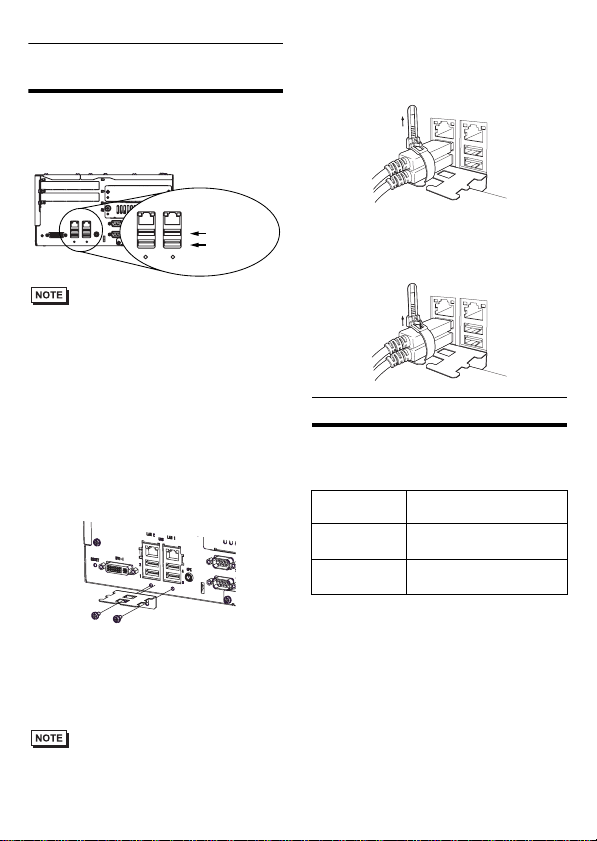

To prevent the USB cable

from coming off

Attaching the USB Cable Clamp

(1) Place the PL unit face-down on a flat sur-

face as shown below. Your PL unit has

four USB connectors.

• When using two or more USB ports, be sure

to first connect one USB cable to the lower

USB connector, and then connect the sec-

ond USB cable to the upper USB connector.

• When using only one of the USB ports, be

sure to use the lower USB connector. This

allows you to securely clamp the USB

cable in the cable clamp.

• The USB cable clamp is not compatible

with the USB connector on the front face.

(2) Fix the USB holder with two screws.

The torque required to tighten these

screws is 0.5 to 0.6 N•m.

(3) As the figure shows, pass the USB Cable

Clamp’s band around the depressed sur-

face of the holder, twist the USB Cable

Clamp’s band around the USB cable, pull

the band in the direction of the arrow,and

then fasten the band using the clamp.

• Be sure the clamp is securely holding the

USB cable’s plug and collar.

• Be sure the clamp is positioned as shown

below, with the clamp pointing upwards - not to

the side. This is to keep the clamp from interfer-

ing with nearby connectors and their cables.

Removing the USB Cable Clamp

(1) To remove the clamp from the USB cables,

push down on the clamp strap’s clip to

release it while pulling up on the clamp.

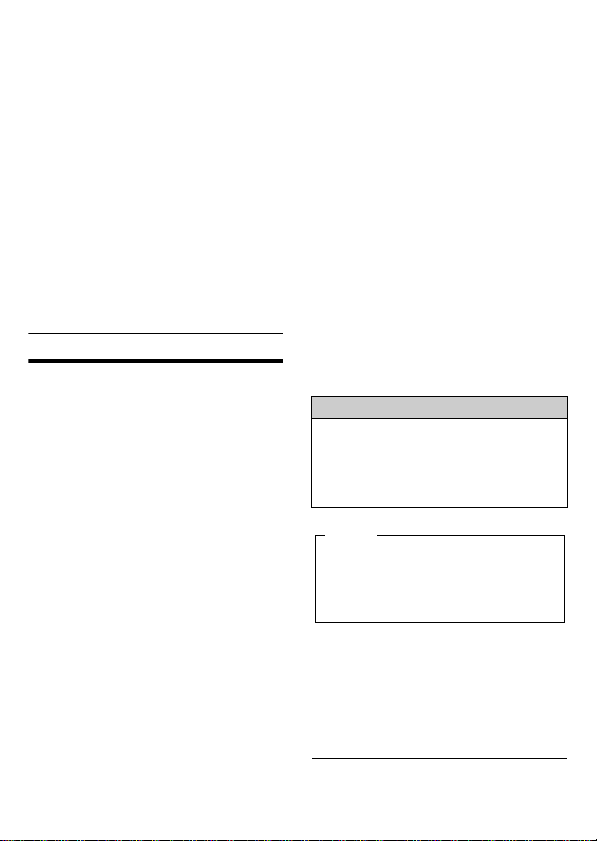

UL/c-UL Approval

The following units are UL/c-UL listed

products:

(UL File No.E220851)

These products conform to the following

standards:

UL508

Industrial Control Equipment

CSA-C22.2 No.142-M1987

(c-UL Approval)

Process Control Equipment

<Cautions>

Be aware of the following items when

building the PL into an end-use product:

1

24

3

USB

LAN1 LAN2

1

24

3

USB

LAN1 LAN2

SPK

DV1-I

RESET

LowerUSB

Interface

UpperUSB

Interface

Product

Model No.

UL/c-UL

Registration Model No.

APL3900-TA 3582302-0

Front Module:3620003-03

APL3900-TD 3582302-11

Front Module:3620003-03

18

• The PL unit’s rear face is not approved as

an enclosure. When building the PL unit

into an end-use product, be sure to use an

enclosure that satisfies standards as the

end-use product’s overall enclosure.

• The PL unit must be used indoors only.

• Install and operate the PL with its front

panel facing outwards.

• If the PL is mounted so as to cool itself

naturally, be sure to install it in a vertical

panel. Also, according to the installation

requirements, create space around the rear

face of the PL unit. The temperature must

be checked on the final product in which

the PL unit is installed.

• For use on a flat surface of a Type 1 Enclo-

sure.

CE Marking

• APL3900-TA unit is CE marked product

that conforms to EMC directives and Low

Voltage Directives EN55011 Class A,

EN61000-6-2, and EN60950-1.

• APL3900-TD unit is CE marked product

that conforms to EMC directives EN55011

Class A and EN61000-6-2.

Digital Electronics Corporation

8-2-52 Nanko-higashi

Suminoe-ku, Osaka 559-0031

JAPAN

TEL: +81-(0)6-6613-3116

FAX: +81-(0)6-6613-5888

http://www.pro-face.com/

© Copyright 2007 Digital Electronics

Corporation. All rights reserved.

Inquiry

Do you have any questions about

difficulties with this product?

Please access our site anytime that

you need help with a solution.

http://www.pro-face.com/otasuke/

Please be aware that Digital Electronics

Corporation shall not be held liable by the

user for any damages, losses, or third

party claims arising from the uses of this

product.

Note

Table of contents

Other Digital Electronics Corporation Industrial PC manuals

Digital Electronics Corporation

Digital Electronics Corporation PL-3700T Series User manual

Digital Electronics Corporation

Digital Electronics Corporation PS-2000B Series User manual

Digital Electronics Corporation

Digital Electronics Corporation PL-3600T Series User manual

Digital Electronics Corporation

Digital Electronics Corporation PL-FF020 User manual

Popular Industrial PC manuals by other brands

Beckhoff

Beckhoff CP6500-2000-0100 manual

IEI Technology

IEI Technology IVS-300-ULT3-i5/4G user manual

IBASE Technology

IBASE Technology SI-58 Series user manual

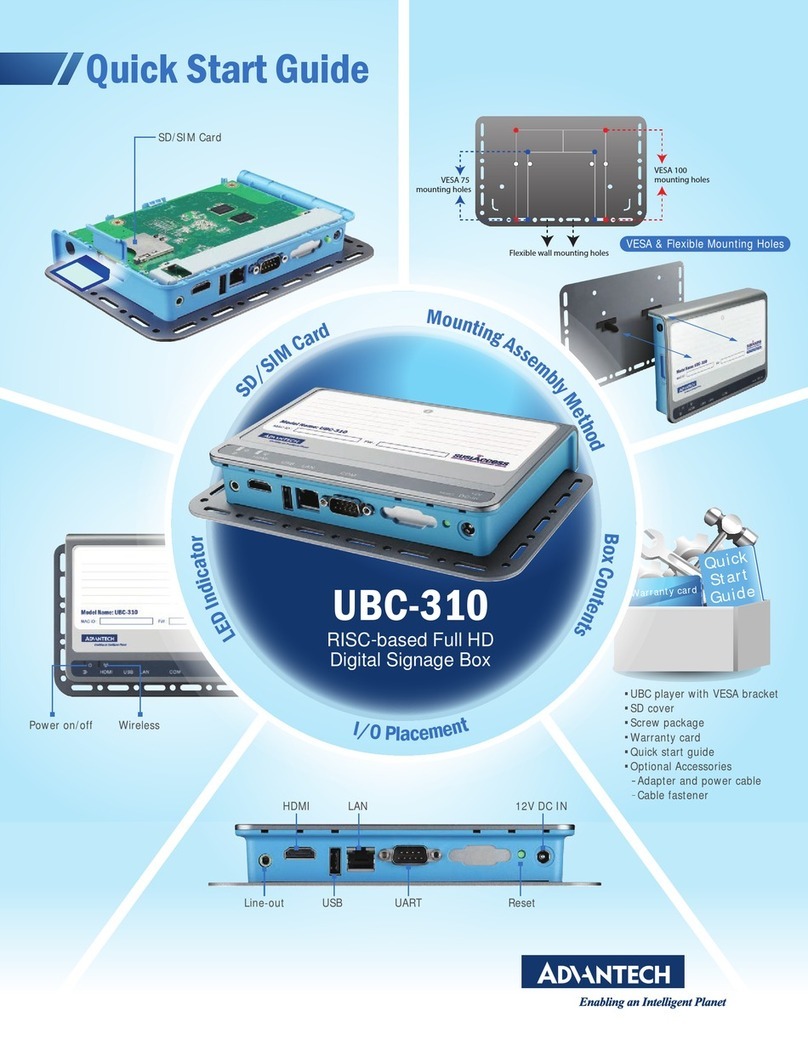

Advantech

Advantech UBC-310 quick start guide

Advantech

Advantech Watchdog Timer UNO-2170 user manual

Avalue Technology

Avalue Technology EPS-AT270 Quick reference guide