Digitrax Zephyr User manual

RDigitrax

Command

Control

TM

Digitrax Command Control

Starter Set Manual

Includes:

DCS50 Command Station Booster,

PS315 Power Supply,

LT1 LocoNet Cable & Decoder Tester

Digitrax, Inc.

450 Cemetery ST #206

Norcross, GA 30071 USA

(770) 441-7992 Fax (770)441-0759

www.digitrax.com

L

o

c

o

N

e

t

R

Digitrax Manuals & Instructions are updated periodically.

Please visit www.digitrax.com for the latest version of all manuals.

This manual was updated 11/03.

1

1.0 Introduction 3

2.0 Zephyr Components 3

3.0 Preparing Your Locomotives 3

4.0 Preparing Your Layout 3

5.0 Zephyr Hook Up-As Easy As 1-2-3! 4

6.0 DCS50 Front Panel Controls And Indicators 6

7.0 DCS50 LED Display 8

8.0 Run A Locomotive Without a DCC Decoder 9

9.0 Run A DCC Equipped Locomotive 10

10.0 Shutting Down the System 12

11.0 Resuming Operation 13

12.0 Quick Start Troubleshooting 13

13.0 Decoder Programming 14

13.1 Setting Up A Service Mode Programming Track 15

13.2 Using the Programming Track to Change the Decoder Address 17

13.3 Using The Programming Track To Program CVs Other Than

Addresses 19

13.4 Programming On The Mainline: Operations Mode Programming

21

13.5 Programming Error Messages 22

13.6 Reading Back CV Values Programmed 23

14.0 Locomotive Speed Control 24

14.1 Speed Limit 24

15.0 Locomotive Direction Control 25

15.1 Setting A Loco to Zero Speed 25

15.2 Brake Operation 25

15.3 Emergency Stop 26

16.0 Functions 27

16.1 Controlling Functions F0-F8 27

16.1.1 Function 0 (F0) 27

16.1.2 Functions 1, 4, 5, 6, 7, & 8 28

16.1.3 Function 2 (F2) 28

16.1.4 Function 3 (F3) 28

16.2 Function Operation Troubleshooting 29

17.0 MU (Multiple Unit) Operations 29

17.1 Adding a Locomotive To An MU 30

17.2 Removing A Loco From An MU 31

17.3 MU of Mismatched Locomotives 32

17.4 Controlling Functions On MU’ed Locomotives 32

18.0 Stealing: When An Address Is Running on Another Throttle 33

Digitrax Zephyr Set Manual

Includes DCS50 Command Station,

PS315 Power Supply and LT1 LocoNet Cable & Decoder Tester

Table of Contents

19.0 Releasing An Address From A Throttle 34

19.1 Dispatching Addresses or MUs 34

20.0 The FuLL Message 35

21.0 DCS50 Error Messages 36

22.0 Decoder Speed Step Settings 36

22.1 Changing Speed Step Settings: Status Editing 37

23.0 SWITCH Mode 38

24.0 Adding Throttles: LocoNet & Jump Ports 39

24.1 Adding LocoNet Throttles To Your DCS50 39

24.2 Jump Ports: Using A Smooth DC Power Pack As An Additional

Throttle 40

24.3 Adding Another DCS50 45

24.3.1 Making LocoNet Cables 47

25.0 Shut Down Procedures 48

26.0 Troubleshooting 48

26.1 Nothing is responding 48

26.2 No Power or Intermittent Operation 48

26.2.1 The Quarter Trick 48

26.2.2 The LT1 Tester 49

26.3 Emergency Stop 49

26.4 Mechanical Drive Train Problems 49

26.5“Strange” Locomotive Lights 49

26.6 Decoder Won’t Respond 49

26.7 I’m totally lost! 50

26.8 DCS50 Shutdown 50

27.0 DCS50 Option Switch Setup 51

28.0 LocoNet: The Digitrax Difference! 52

28.1 System Architecture 53

29.0 FCC Information 54

30.0 Warranty and Repair Information 55

2

Digitrax, the Digitrax Train Logos, LocoNet, Super Empire Builder, Super

Chief, Transponding, SuperSonic, AutoReversing, Zephyr, Jump & others are

trademarks of Digitrax, Inc. This manual may not be reproduced in any form or

translated into other languages without Digitrax permission.

©Digitrax, Inc. All Rights Reserved. Printed in USA REV 11/03

Components included in the Zephyr set are covered by US Patents

6,275,739, 6,536,716, 6,220,552 B1, 6,318,678 B2, 6,533,223, 6,367,742

B1, 6,533,224, and others.

1.0 Introduction

Congratulations on your purchase of a Digitrax Zephyr Starter Set!

The Zephyr is designed for easy operation and expandability with Digitrax

LocoNet. With LocoNet, just plug in system components to build the layout

control system that you’ve always wanted! Your success with and enjoyment

of our products are very important to us. After all, this is a hobby and it is

FUN!!! Please read this manual carefully before you install your system. We

have included lots of hints and operating ideas based on our experience with

the Digitrax system. If you have questions not covered by this manual please

contact your dealer.

2.0 Zephyr Components

Your Zephyr Starter Set contains:

DCS50 All-in-one command station, throttle and booster to run your trains.

PS315 Power supply to provide power to run your DCS50.

LT1 Decoder and LocoNet Cable Tester

Zephyr Manual

Digitrax Decoder Manual

3.0 Preparing Your Locomotives

You will need to install decoders in the locomotives you want to run with

DCC. We don’t include decoders with our starter sets because there are so

many different decoders available for so many different locomotives. We want

to be sure you don’t spend money on a decoder that may not be the best choice

for your particular locomotives. Your dealer can help you select the best

decoder choices for your layout from Digitrax wide variety of decoders. Our

website www.digitrax.com contains information about decoder installations and

which decoders are best for particular locomotives.

Digitrax includes a Digitrax Decoder Manual with all Starter Sets so that you

will have it available to use with the decoders you choose to go with the set.

You will be able to run one locomotive without a decoder on your Zephyr sys-

tem along with the ones with decoders. So, even if you don’t have a loco with

a decoder, you can still hook up your new system and try it out right away!

4.0 Preparing Your Layout

Digitrax simplifies layout wiring for new layouts. If you already have a layout,

you probably won’t need to rewire to install your Digitrax Zephyr.

3

Since the DCC signal travels with the power on the rails, you must have power

to the track in all locations so that the decoders can receive the signal and

respond to your commands.

For more information about layout wiring, see the Digitrax Big Book of DCC

or visit our website at www.digitrax.com.

5.0 Zephyr Hook Up-As Easy As 1-2-3!

These simple instructions will help you get up and running quickly. A full

description of all controls and technical reference information are included later

in this manual. This section assumes that you are using a new set straight out

of the box.

4

315

2

B

A

JUMP 1

GROUND

RAIL B

JUMP 2

PROG A

RAIL A

PROG B

LOCONET

R

POWER IN

15V AC

2.5 AMPS

PS315

Power Supply

Plugged Into

Wall Outlet

Layout Power

District

(Double Gapped)

Rail A

Rail B

DO NOT USE WITH TRACK

OVER 16 VOLTS

1. RAIL A & B for connecting the

DCS50 to the rails on the layout.

2. PROG A & B for hooking up the

programming track.

3. JUMP 1 & 2 for connecting one or two

smooth DC power packs to the system for

use as additional throttles.

4. POWER IN plug in the PS315 here.

5. LOCONET PORTS A & B for connecting

the DCS50 to other LocoNet devices for

expanding your layout.

6. YOUR LAYOUT. You can connect Zephyr to

most existing layouts.

DCS50 Rear Panel Hook Up Diagram

4

6

1. Hook up the wires from the track to the RAIL A & RAIL B terminals

on the DCS50. Insert the wire from one rail of the track into the

RAIL A terminal on the back of the DCS50. Insert the wire from the

other rail of the track into the RAIL B terminal. Turn the screw

counter clockwise to open the connector and clockwise to close it

once the wire is in place.

2. Plug the barrel connector from the PS315 into the POWER IN jack

on the back of the DCS50. Plug the body of the PS315 in to a regu-

lar wall outlet. Once power is applied, the DCS50 will

briefly flash “-cS-” to let you know it

is running as a command station.

The DCS50’s display will change auto-

matically to “Loco” or the last address

that was on the throttle when you turned

it off.

3. Turn track power on. Check the TRACK STATUS Indicator. If it is

on, you are ready to go. If the TRACK STATUS Indicator is unlit,

press the POWER key to turn track power on. When track power is

on the TRACK STATUS Indicator will be lit.

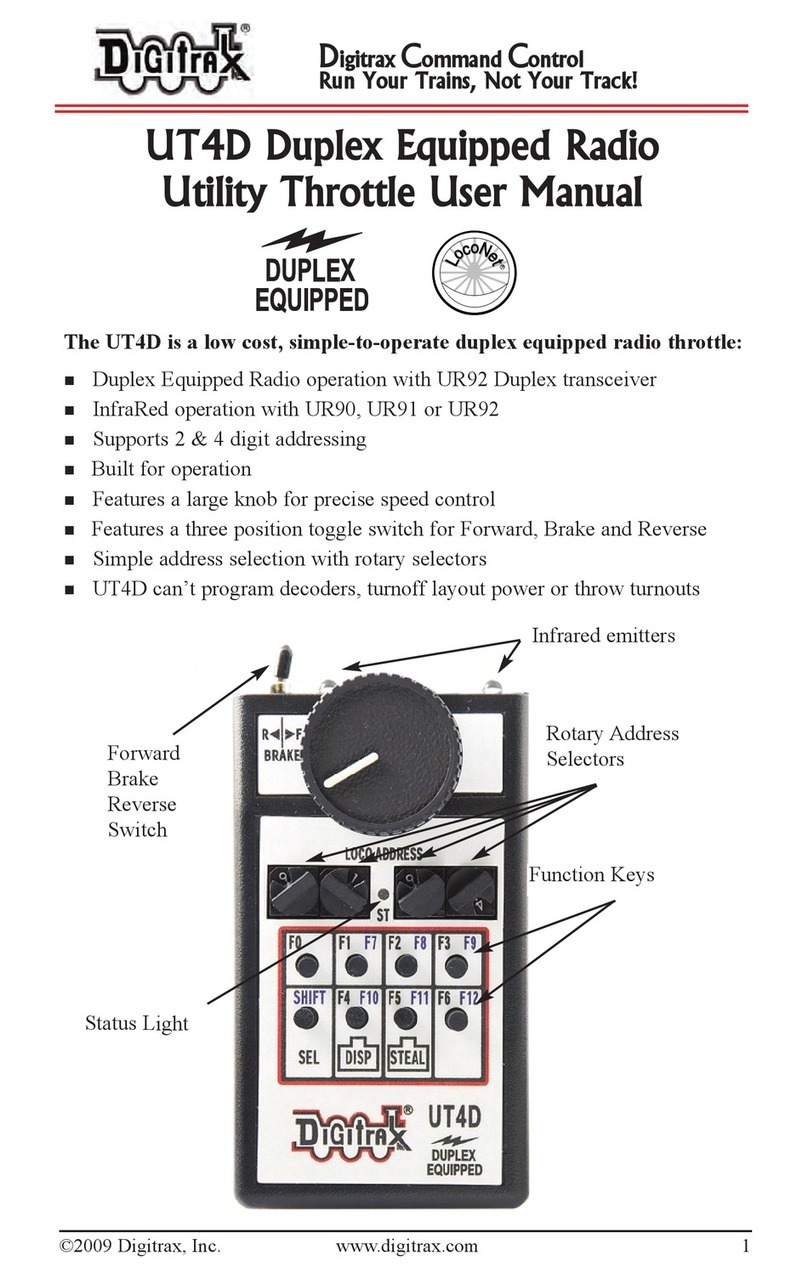

6.0 DCS50 Front Panel Controls And Indicators

Before you select and run a locomotive, take a few minutes to look at the

DCS50’s controls and display.

1. The Throttle Knob is the large silver and black knob on the right side

of the DCS50. The Throttle Knob controls locomotive speed from

STOP to FULL speed. Turn it clockwise to increase speed and

counter clockwise to decrease speed.

2. The Direction Control Lever is the small silver lever (located on the

left side of the DCS50) that controls the locomotive’s direction of

travel, FORWARD or REVERSE. This knob also controls the

BRAKE. When you have a loco address selected and the Direction

Control Lever lever is in the BRAKE position, the BRAKE

INDICATOR will blink until the loco stops and then remain on

steady to let you know that the brake is on. When you move the

SWITCHMUJUMPFUNCTION

SWITCHMUJUMPFUNCTION

5

lever to FORWARD or REVERSE, the BRAKE INDICATOR will

flash to let you know that the brake is released and the loco is accel-

erating to the speed shown on the Throttle Knob.

3. There are 20 keys on the DCS50’s keypad, including a full numeric

keypad. Selecting a loco to run is as simple as entering the loco’s

address on the keypad.

4. The TRACK STATUS Indicator is lit when track power is on and

unlit when track power is off. Track power must be on to operate the

trains on the track. Simply press the POWER key to toggle between

power on and off. If you need to stop the whole layout, press the

POWER key to turn off track power and put everything on the lay-

out into “Emergency Stop.”

7.0 DCS50 LED Display

The DCS50’s LED Display is made up of 4 digits/letters and 4 Indicator

Dots across the top of the screen.

When you are running a locomotive, you will see the address of that

locomotive in the display and the FUNCTION Indicator Dot will be

lit. This means that the throttle knob will control speed, the direction

lever will control direction and braking and the number keys 0-8

will control functions on the locomotive. This following is the dis-

play you will see if you are running loco address 1873 on your local

throttle.

The LCD has three additional Indicator Dots associated with more

advanced features available on the DCS50:

The JUMP Indicator Dot lets you know if one or more Jump™

ports are active. See Section 24.2.

The MU Indicator Dot lets you know if MU or consisting is active.

See Section 17.

The SWITCH Indicator Dot lets you know when you are in switch

mode for controlling turnouts or setting up system options. See

SWITCHMUJUMPFUNCTION

Function

Indicator

Dot On Locomotive

Address

6

7

R

BRAKE STOP FULL

1

2

3

4

5

SWITCHMUJUMPFUNCTION

12

45

78

SWITCH

+

-

EXIT

POWER

PROG

MODE

tc

3

6

9

STEPS

LOCO

JUMP

MU

TRACK

STATUS

0

CV CV-RD CV-WR

DCS 50

FORWARD

REVERSE

1

2

3

4

DCS50 Front Panel Diagram

Section 23 for turnout operation and Section 27 for option switch set

up information.

The following examples will help you learn about your new DCS50. The

first example shows how to select and run a locomotive without a DCC

decoder. The second example shows how to select and run a DCC

equipped locomotive.

8.0 Run A Locomotive Without a DCC Decoder

A locomotive without a DCC decoder is called an analog locomotive

because it is not digital. While an analog locomotive, without a

decoder, is sitting still on your digital layout, you will hear a

“singing” sound. This is caused by the DCC track signal when it is

applied to an analog locomotive. Once the analog locomotive is

moving, this sound will change and be less noticeable. (To avoid

heat build up in your locos without decoders, Digitrax recommends

that analog locos not be left sitting on DCC powered track for long

periods of time when they are not running.)

1. Set the DCS50’s Throttle Knob to STOP.

2. Place an analog locomotive, one without a decoder installed, on your

digital layout that is controlled by your DCS50.

3. Check the DCS50’s TRACK STATUS Indicator to be sure that track

power is turned on. Press POWER to turn track power on if neces-

sary.

4. Press the LOCO Key to begin the selection process. The LED will

begin flashing either “Loco” or the last address selected on the

throttle.

Use the numeric keypad to enter “00”, the address used to control the

locomotive without a decoder. Your display will show:

SWITCHMUJUMPFUNCTION

Display

is blinking

8

5. Press the LOCO Key again to confirm your selection and set address

00 on the throttle. The display will stop blinking and you will have

control of the analog locomotive.

6. Set the Direction Control Lever to FORWARD and turn the

Throttle Knob clockwise slowly to increase the speed of the analog

locomotive. As the speed increases, the locomotive on the track will

begin to move. The direction of an analog locomotive is determined

by track polarity not by the DCC signal so, forward may not mean

forward for your analog loco. The DCS50’s TRACK STATUS

Indicator should slightly change color as you change the speed set-

ting.

7. Change the Direction Control Lever to REVERSE and the loco will

move in the opposite direction.

8. Change the Direction Control Lever to the BRAKE position and the

loco will slow down and stop. Move the Direction Control Lever

back to FORWARD or REVERSE and the loco will move again.

9. Turn the Throttle Knob to STOP and the loco will stop moving.

10. If you have a headlight installed in your loco, it will be on because

with DCC there is constant power to the track.

9.0 Run A DCC Equipped Locomotive

Before your run your first DCC equipped locomotive, there are a few things

you need to know:

1. Each DCC decoder has a unique address that is used by the system to

send commands to that decoder. The address is remembered by the

decoder in the loco until you change it.

SWITCHMUJUMPFUNCTION

Display is

steady once

you have

selected an

address to run

.

SWITCHMUJUMPFUNCTION

Display

is blinking

9

2. You program each of your locomotives with its own unique address so

that you can run them independently.

3. To select a DCC locomotive and run it, you must know its address.

4. Digitrax decoders are set up at the factory with address 03. This means

that when you take a Digitrax decoder out of the package and install

it in your loco, you can select address 03 on your throttle and run the

decoder. The first CV programmed by most DCC users is the

decoder’s address since it is not very useful to have all of your locos

run on address “03.” Programming is covered in Section 13.

5. If you do not know the address of the DCC locomotive you want to

run, you can either read back the decoder’s address or program it to

the address you want to use. These procedures are covered in

Section 13.6.

To select and run a DCC equipped locomotive with a known address

follow these steps:

1. Set the DCS50’s Throttle Knob to STOP.

2. Place a DCC equipped locomotive, one with a decoder installed, on

your digital layout that is controlled by your DCS50. In this example

we assume that you have a new Digitrax decoder that is pro-

grammed to address 03. If your decoder is using a different address,

simply use that address as you follow these instructions.

3. Check the DCS50’s TRACK STATUS Indicator to be sure that track

power is turned on. Press POWER to turn track power on if neces-

sary.

4. Press the LOCO Key to begin the selection process. The LED will

begin flashing either “Loco” or the last address selected on the

throttle. If you are continuing on from the previous example of run-

ning an analog locomotive, your display will be blinking address 00

as shown here since 00 was the last address you used:

SWITCHMUJUMPFUNCTION

Display

is blinking

10

Use the numeric keypad to enter “03”, the address used to control the

locomotive with the decoder. Your display will show:

5. Press the LOCO Key again to confirm your selection and set address

03 on the throttle. The display will stop blinking and you will have

control of the DCC equipped locomotive with address 03.

6. Set the Direction Control Lever to FORWARD and turn the

Throttle Knob clockwise slowly to increase the speed of the analog

locomotive. As the speed increases, the locomotive on the track will

begin to move forward. The direction of digital locomotives is deter-

mined by the DCC signal so, forward means that the loco will move

in the direction the decoder is set up to recognize as forward..

7. Change the Direction Control Lever to REVERSE and the loco will

move in the reverse.

8. Change the Direction Control Lever to the BRAKE position and the

loco will slow down and stop. Move the Direction Control Lever

back to FORWARD or REVERSE and the loco will move again.

9. Turn the Throttle Knob to STOP and the loco will stop moving.

10. If you have a headlight installed in your loco, press the LAMP 0 Key

to toggle between lights on and off. If you have other functions

installed in you loco, you can also operate them by pressing the

associated number key (0-8) for the function you want to operate.

10.0 Shutting Down the System

When you are finished with your session, shut down the Zephyr by turning off

power to the system.

SWITCHMUJUMPFUNCTION

Display is

steady once

you have

selected an

address to run

.

SWITCHMUJUMPFUNCTION

Display

is blinking

11

1. Turn track power off: Press the POWER Key, the DCS50’s TRACK

STATUS Indicator will go off. The display will briefly display Po

followed by two characters, the Po means power off, the two char-

acters indicate which software version is installed in the unit. The

display will automatically revert to showing the last loco address

selected on the throttle but since track power is now off, it will not

run the layout until you turn on track power again.

2. Unplug the PS315 from the wall outlet.

The power to the command station can be left on all the time if desired.

11.0 Resuming Operation

When you are ready to run trains again:

1. Set the DCS50’s Throttle Knob to STOP.

2. Plug in the PS315 to the wall outlet and to the DCS50.

3. Press the POWER Key to turn on track power.

4. The DCS50 will display show the last locomotive address you were

running and be ready to begin right where you left off.

12.0 Quick Start Troubleshooting

If you encountered problems at any step in this Quick Start Section:

1. Try backing up a step until you get results described. The steps includ-

ed in this installation procedure are set up so that if you follow them

carefully, any problems you encounter will be easy to isolate &

debug.

2. If you still have problems or if you have other questions or problems,

we encourage you to call, fax or e-mail your favorite Digitrax dealer.

If your dealer is not able to help, please contact Digitrax directly.

There are thousands of successful Digitrax installations around the world and

we want to be sure that yours is one of them.

QUICK INSTALLATION Notes for users of Digitrax decoders that have

already been programmed and decoders not made by Digitrax:

1. The DCS50 command station operates in 128 speed step mode. If you

are using a locomotive with a decoder that does not have 128 step

capability you will have to adjust either the decoder or the DCS50

so that both are using the same number of speed steps to communi-

12

cate. We call this procedure status editing. You can status edit each

individual decoder (see Section 22) or you can change the DCS50’s

system default by setting the DCS50’s Option Switches 21-23 and

run all of your decoders with fewer speed steps to accommodate

these decoders (see Section 27).

2. If you can’t control the operation of the lights in your decoder

equipped locomotive with the DCS50, be sure that the decoder itself

is programmed to run in 128 speed steps.

What’s Next?

Now that you have successfully set up your Zephyr Set, it’s time to learn more

about the features and options it has to offer. Read the manual and take time to

understand and master each topic. Your Zephyr Set is the gateway to all the

possibilities and options offered by Digitrax and LocoNet so the best advice is

to take it step by step and don’t try to do everything at once. The Digitrax Big

Book of DCC is an excellent resource available to you as you expand your lay-

out. The Big Book is full of examples that show you how you can have even

more fun with your layout.

13.0 Decoder Programming

Your DCC Decoders have many different configuration variables (CVs for

short) that let you set up a different set of characteristics for each decoder

installed in each locomotive. When you want to change a loco’s address, set up

how its lights work, change its momentum characteristics, etc. you will pro-

gram new CV values into the appropriate CVs to set it up just the way you

want.

Each CV controls a characteristic of the decoder. See your decoder manual for

a list of the most commonly used CVs and their meanings. Each decoder

comes pre-programmed with factory settings that will let you run it right away.

We recommend that you use the factory settings until you are comfortable with

running your layout with DCC.

The factory set address for all Digitrax decoders is 03. This is the first CV you

will want to change because it is not very useful to have all of your locos

respond to the same address.

Decoders are programmed when the command station sends programming

information to them through the rails. Your DCS50 supports two types of pro-

gramming:

Service Mode Programming is done on an electrically isolated programming

track. Using this mode, the command station broadcasts programming informa-

13

tion to all decoders on the layout. Because this is a broadcast mode, we must

isolate the decoder we want to program from the others on the layout by using

a separate programming track. This mode works with all DCC decoders. This

is the most commonly used programming method.

Operations Mode Programming is done on the layout by sending program-

ming commands to a specific locomotive address. To use this mode, you must

have decoders that are capable of operations mode programming.

Programming with LocoNet Throttles on a Zephyr is easy. All LocoNet

throttles will program as though they were connected to a DCS100 Command

station. See your Throttle or Starter Set Manual for programming key strokes

for these throttles.

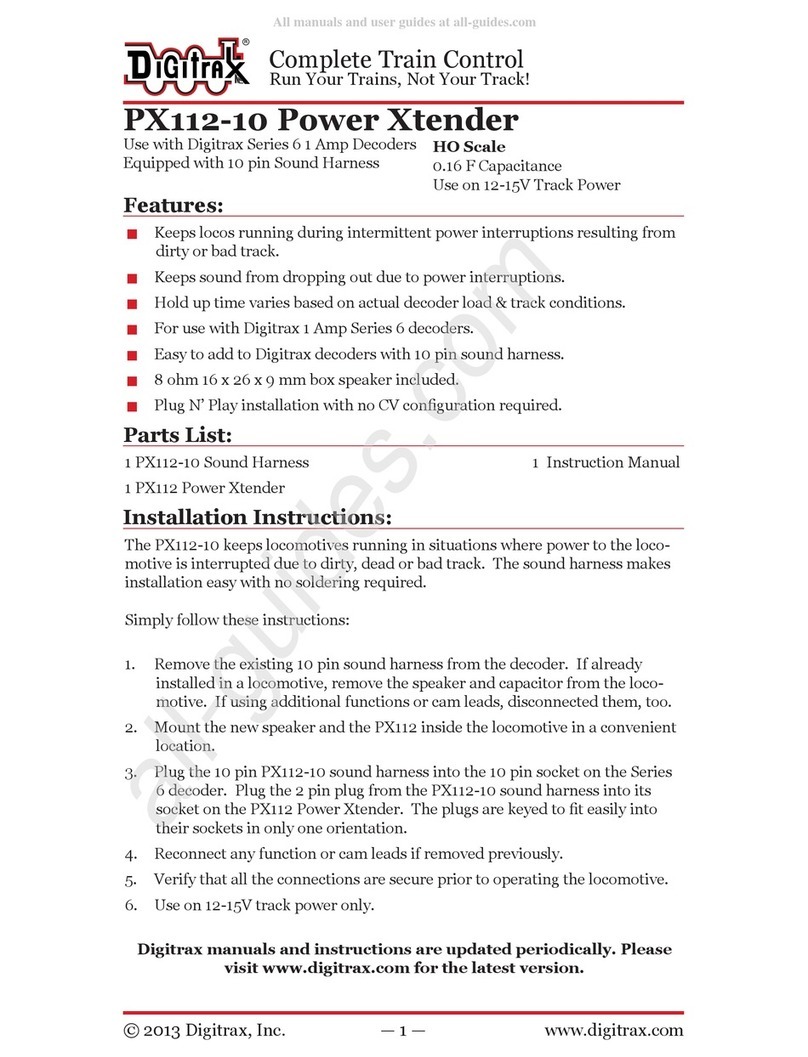

13.1 Setting Up A Service Mode Programming Track

Your DCS50 has two sets of DCC outputs. This means that you will be able to

program decoders using one set of DCC outputs while the layout is running on

the other set of DCC outputs. When you hooked up your DCS50 to the layout,

you used the RAIL A & B connections to the track. Now we will use the

PROG A & PROG B outputs to set up a service mode programming track.

DCS50 Rear Panel Programming Track Hook Up Diagram

B

A

JUMP 1

GROUND

RAIL B

JUMP 2

PROG A

RAIL A

PROG B

LOCONET

R

POWER IN

15V AC

2.5 AMPS

PS315

Power Supply

Plugged Into

Wall Outlet

Layout Power District

(Double Gapped)

Rail A

Rail B

Isolated Programming

Track

Rail A

Rail B

LocoNet Expansion Ports for

adding handheld throttles and

other equipment.

DO NOT USE WITH TRACK

OVER 16 VOLTS

14

Your programming track can be as simple as a spare piece of track not connect-

ed to the layout or it can be a double gapped section of track powered by the

DCS50’s PROG A & B outputs as shown below.

Programming Track Example Diagram

13.2 Using the Programming Track to Change the Decoder

Address

1. Be sure that only the locomotive you want to program is on the pro-

gramming track.

2. Press the PROG Key to enter programming mode. The DCS50 will

display one of the programming modes available. Digitrax recom-

mends the Paged Mode when you are using the programming track.

If you press the PROG Key repeatedly, you will cycle through the

following choices.

Once the mode you want to use is on the screen you can go to step 3.

For example, to use Paged mode stop pressing the PROG Key when the

following screen appears:

SWITCHMUJUMPFUNCTION

P

aged Mode

D

igitrax

P

referred

M

ethod

B

A

JUMP 1

GROUND

RAIL B

JUMP 2

PROG A

RAIL A

PROG B

LOCONET

R

POWER IN

15V AC

2.5 AMPS

DCS50 Command Station

NOTE: Some wiring ommitted for clarity

PROG B

PROG A

RAIL A

RAIL B

Programming Track

(Powered by DCS50 PROG A & B Outputs)

Double

Gaps

Main Layout (Powered by DCS50 RAIL A & B Outputs)

DO NOT USE WITH TRACK

OVER 16 VOLTS

15

If you are not using Paged programming, see Table I: DCS50

Programming Display Table below for information about how your

display will be different from this example.

3. Press the LOCO Key and you will see either Ad2 or Ad4.

Ad2 = two digit address

Ad4 = four digit address

Each time you press the Loco Key the display will toggle between Ad2

and Ad4. When the one you want to use is in the display move on to

the next step.

4. Press the CV-RD key to to read back the address programmed into the

decoder. Your display will flicker Ad2 or Ad4 while it is reading

then will display the decoder’s current address.

2 digit addresses are displayed with 3 digits, (001 through 127) and 4

digit addresses are displayed with 4 digits (0128 through 9983).

For example, if 03 is the two digit address, the display will show:

If 268 is the four digit address, the display will show:

5. To change the address of the loco, press the LOCO key to choose

Ad2 or Ad4 and use the NUMERIC KEY PAD to enter the address

you want to use for the loco.

6. Press CV-WR to write the address to the decoder. The display will

flicker while the address is programmed and then will show the new

address in the display.

For example, to change the address from the two digit address 03 to the

two digit address 96, press the LOCO Key until Ad2 appears in the

display then use the KEY PAD to enter 96 and press the CV-WR

Key to program the address.

SWITCHMUJUMP

F

UNCTION

FUNCTION

Four digit

address 268.

SWITCHMUJUMP

F

UNCTION

FUNCTION

Two digit

address 03.

SWITCHMUJUMP

F

UNCTION

FUNCTION

Four Digit

Address

SWITCHMUJUMP

F

UNCTION

FUNCTION

Two Digit

Address

16

7. When you are finished programming the address, press the EXIT Key

to resume normal operations. If you want to program CVs other than

the address, you must exit address programming before doing so.

13.3 Using The Programming Track To Program CVs Other

Than Addresses

There are many different CVs that have been defined to handle many charac-

teristics you might want to use for your locomotives. Your decoder manual has

a complete listing of CVs that are available in specific decoders, what they do

and suggested values for each CV.

1. Be sure that only the locomotive you want to program is on the pro-

gramming track.

2. Press the PROG Key to enter programming mode. The DCS50 will

display one of the programming modes available. Digitrax recom-

mends the Paged Mode when you are using the programming track.

As you press the PROG Key repeatedly, you will cycle through the

following choices.

Once the mode you want to use is on the screen you can go to step 3.

For example, to use Paged mode stop pressing the PROG Key when the

following screen appears:

3. Press the CV Key and you will see P followed by the last CV number

used by the DCS50. The P reminds you that you are in paged mode

and the number displayed is the last CV used by the DCS50.

4. Enter the CV number you want to program. For example, if you want

to set up acceleration which is controlled by CV03, use the keypad

to enter 03.

5. Press the CV-RD key to to read back the data value currently pro-

grammed into the decoder for the CV selected. Your screen will

show something like this:

SWITCHMUJUMP

F

UNCTION

FUNCTION

SWITCHMUJUMP

F

UNCTION

FUNCTION

SWITCHMUJUMPFUNCTION

P

aged Mode

D

igitrax

P

referred

M

ethod

17

The numbers will flash for a few seconds as the command station reads

back the data value in the decoder. The d means that you are looking

at the CV’s data value that is programmed into the decoder, in this

case the CV value is 0.

6. Use the NUMERIC KEY PAD to enter the new CV data value you

want to program into the decoder. For example if you want to pro-

gram the value of 2 for CV03 which controls acceleration, enter 02.

Note: If you do not want to read back the CV’s data value as described

in step 5, you can simply press the CV Key again to go directly to

the data entry mode. In this case, the display will show “d” followed

by 3 digits. When you see this display, use the KEY PAD to enter

the new data value you want to program.

7. Press CV-WR to write the new data value selected to the CV. The

display will flicker while the command station programs the decoder

and the display will show the data value programmed.

8. To program another CV, press the CV Key and enter the CV number

you want to program next and repeat steps 3-7 again.

9. When you are finished programming press the EXIT Key to resume

normal operations.

SWITCHMUJUMP

F

UNCTION

FUNCTION

18

If you are using a programming mode other than Paged mode see the

chart below for the meanings of the screens you will see.

TABLE I: DCS50 Programming Display Table

Press PROG Key Press CV Key Press CV-RD Key

Press PROG Key Press CV Key Press CV-RD Key

Press PROG Key Press CV Key Press CV-RD Key

Press PROG Key Press CV Key Press CV-RD Key

13.4 Programming On The Mainline: Operations Mode

Programming

Operations mode programming lets you program CVs in DCC locomotives

equipped with Extended Packet Format decoders while they are on the main-

line. A typical use for Ops mode programming would be to change the acceler-

ation rate (CV03) or the deceleration rate (CV04) of your locomotives to simu-

late the weight and braking capability of the train to compensate for changing

the number of cars or power units on a train.

Your DCS50 can use ops mode programming to change the CV value in ANY

CV, including 2 digit and 4 digit addresses.

Ops mode programming can be performed by any

DCS50 or other LocoNet throttle, such as DT400,

DT300, UT1, etc., at any time since the throttles are not

competing for usage of the single programming track.

SWITCHMUJUMPFUNCTION

SWITCHMUJUMPFUNCTION

SWITCHMUJUMPFUNCTION

Operations

Mode

Mainline

Programming

SWITCHMUJUMPFUNCTION

SWITCHMUJUMPFUNCTION

SWITCHMUJUMPFUNCTION

Direct Mode

SWITCHMUJUMPFUNCTION

SWITCHMUJUMPFUNCTION

SWITCHMUJUMPFUNCTION

Physical

Register

Mode

SWITCHMUJUMPFUNCTION

SWITCHMUJUMPFUNCTION

SWITCHMUJUMPFUNCTION

Paged Mode

Digitrax

Preferred

Method

Press the CV-RD Key

CV Data Value

screen shows

d (for data) & the

current CV Data Value

Press the CV Key

CV# Screen shows

Progamming Mode and

CV#

Press the PROG Key to

cycle through the

programming modes

Press the CV Key to toggle between CV# & CV Data

19

Table of contents

Other Digitrax Control System manuals