KTR Kupplungstechnik

GmbH

D-48407 Rheine

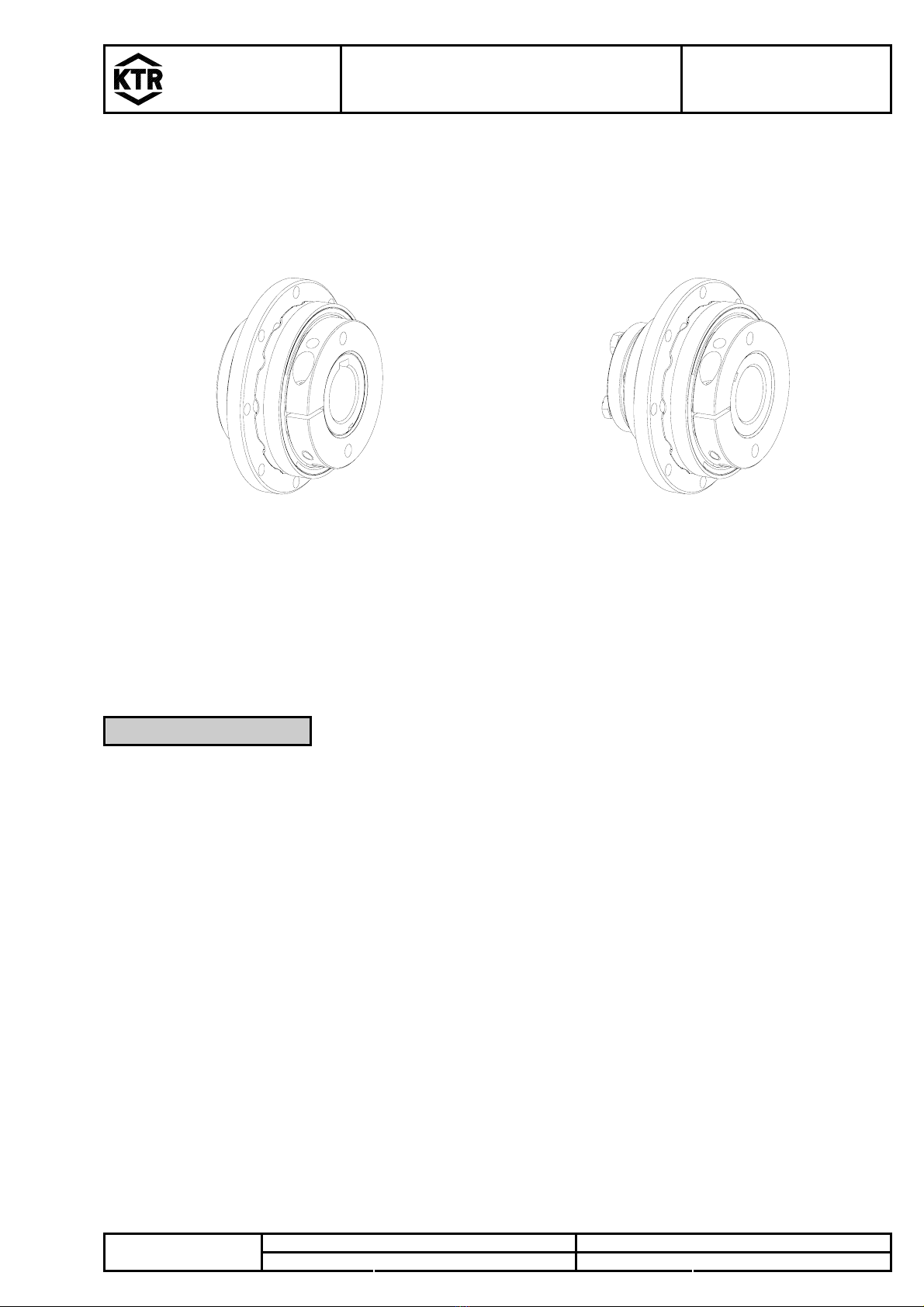

SYNTEX®

Operating-/Assembly Instructions

design DK (ratchet)

KTR-N

sheet:

edition:

46210 EN

3 of 8

6

Gezeichnet: 30.06.10 Li/Lm Ersatz für: KTR-N vom 17.03.10Schutzvermerk

ISO 16016 beachten. Geprüft: 30.06.10 Li Ersetzt durch:

2 Hints

2.1 General Hints

Please read through these mounting instructions carefully before you set the coupling into operation.

Please pay special attention to the safety instructions!

The mounting instructions are part of your product. Please keep them carefully and close to the coupling.

The copyright for these mounting instructions remains with KTR Kupplungstechnik GmbH.

2.2 Safety and Advice Hints

STOP

DANGER! Dangerofinjurytopersons.

! CAUTION! Damagesonthemachinepossible.

)A TTENTION! Pointing to important items.

2.3 General Hints of Danger

STOP

DANGER!

With assembly, operation and maintenance of the coupling it has to be made sure that the

entire drive train is protected against unintentional engagement. You can be seriously hurt

by rotating parts. Please make absolutely sure to read through and observe the following

safety instructions.

•All operations on and with the coupling have to be performed taking into account "safety first".

•Please make sure to disengage the power pack before you perform your work.

•Protect the power pack against unintentional engagement, e. g. by providing hints at the place of engagement

or removing the fuse for current supply.

•Do not touch the operation area of the coupling as long as it is in operation.

•Please protect the coupling against unintentional touch. Please provide for the necessary protection devices

and caps.

2.4 Proper Use

You may only assemble, operate and maintain the coupling if you

•carefully read through the mounting instructions and understood them

•had technical training

•are authorized to do so by your company

The coupling may only be used in accordance with the technical data. Unauthorized modifications on the coupling

design are not admissible. We do not take any warranty for resulting damages. To further develop the product we

reserve the right for technical modifications.

The SYNTEX®described in here corresponds to the technical status at the time of printing of these mounting

instructions.