Page 6 CK and EQ Manual

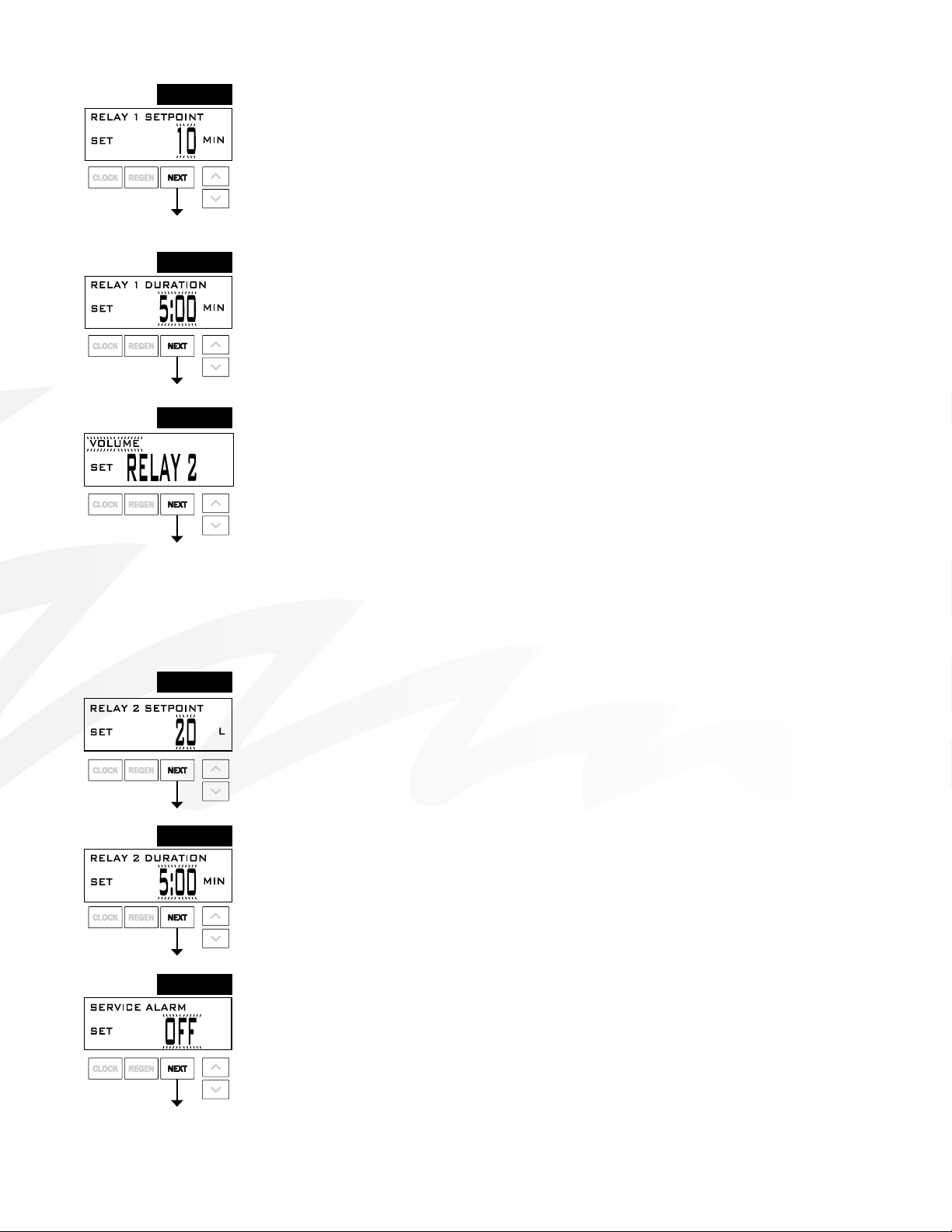

Once the OEM Cycle Sequence has been set, the other procedures can be accessed in any order. Details on each of the procedures

are provided on the following pages.

To “lock out” access to diagnostic and valve history displays and modications to settings except hardness, day override, time

of regeneration and time of day by anyone but the manufacturer, press ▼, NEXT, ▲, and CLOCK in sequence after settings are

made. To “unlock”, so other displays can be viewed and changes can be made, press ▼, NEXT, ▲, and CLOCK in sequence.

When in operation normal user displays such as time of day, volume remaining before regeneration, present ow rate or days

remaining before regeneration are shown. When stepping through a procedure, if no buttons are pressed within ve minutes, the

display returns to a normal user display. Any changes made prior to the ve minute time out are incorporated.

To quickly exit OEM Softener Setup, OEM Filter Setup, Installer Display Settings, Diagnostics or Valve History press CLOCK.

Any changes made prior to the exit are incorporated.

When desired, all programming and information in Diagnostics may be reset to defaults when the valve is installed

in a new location. To reset, press NEXT and ▼simultaneously to go to the Softening/Filtering screen. Press ▲and ▼

simultaneously to reset programming and diagnostic values. Screen will return to User Display.

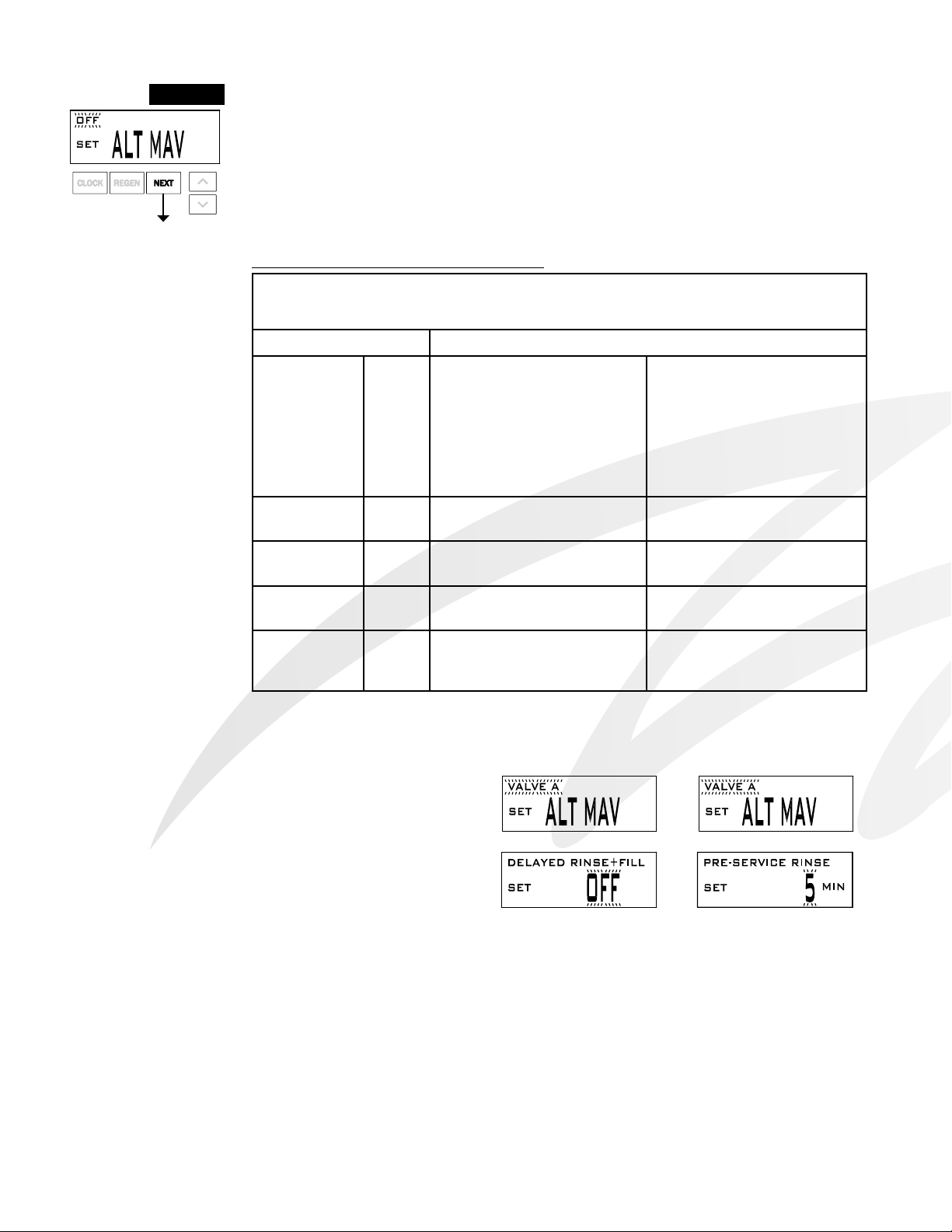

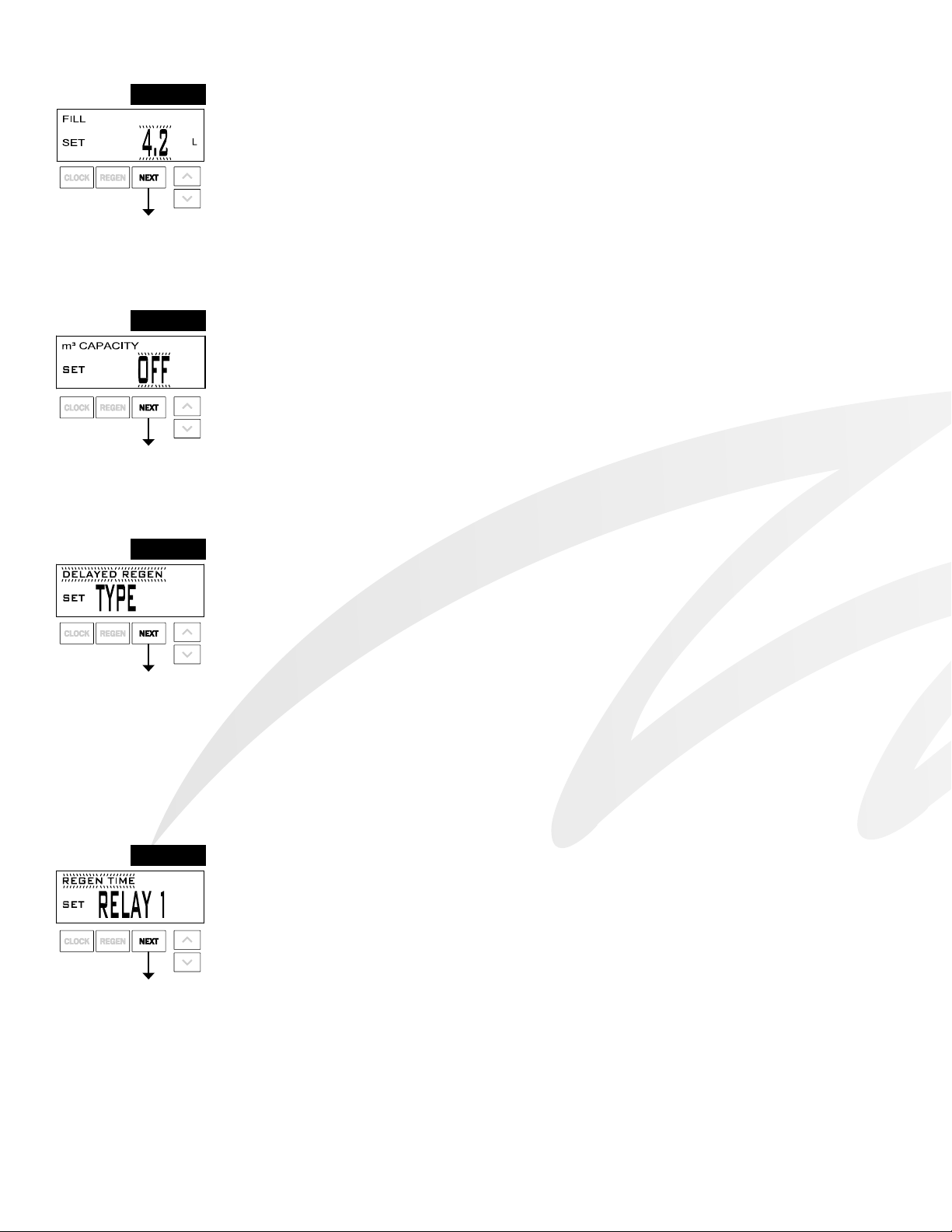

Sometimes it is desirable to have the valve initiate and complete two regenerations within 24 hours and then return to the preset

regeneration procedure. It is possible to do a double regeneration if the control valve is set to “DELAYED REGEN” or “BOTH”

in OEM Softener System Setup or OEM Filter System Setup. To do a double regeneration:

1. Press the “REGEN” button once. REGEN TODAY will ash on the display.

2. Press and hold the “REGEN” button for three seconds until the valve regeneration initiates.

Once the valve has completed the immediate regeneration, the valve will regenerate one more time at the preset regeneration time.

For Valve Type 1.0T, press and hold CLOCK and ▲for about 3 seconds to initiate an exchange of the tank in Service without

cycling the regeneration valve. After tank switch, days remaining and capacity remaining status is retained for each tank until the

next regeneration.

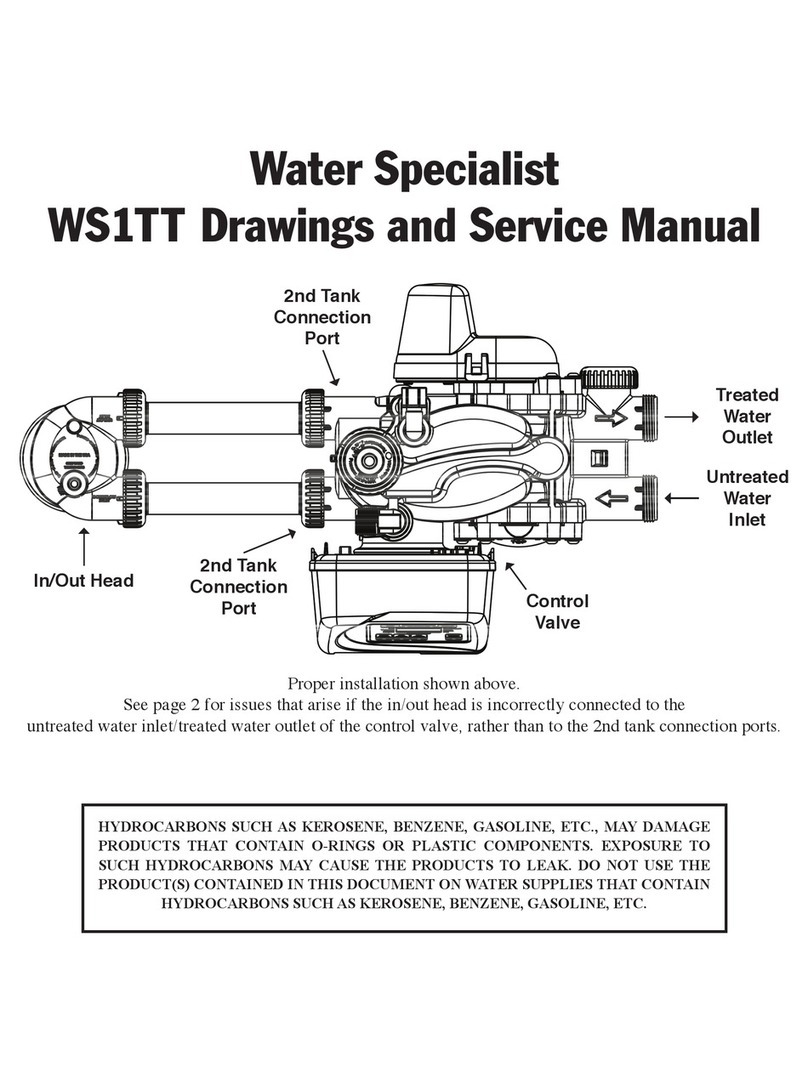

Prior to selecting the upow regeneration cycle, verify that the correct body, main piston, regenerant piston and stack are being

used, and that the injector plug(s) are in the correct location. Refer to the Service Manual for drawings and part numbers.

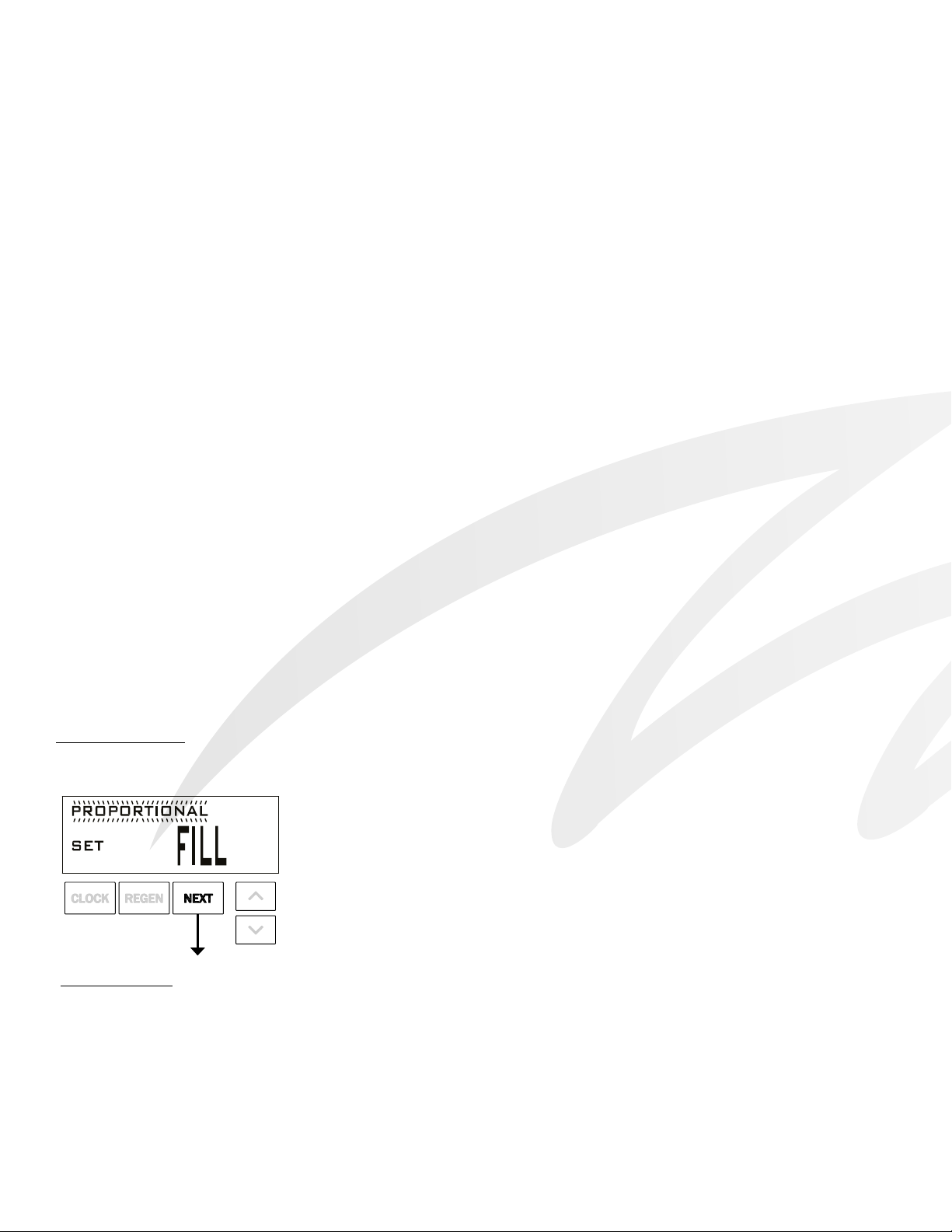

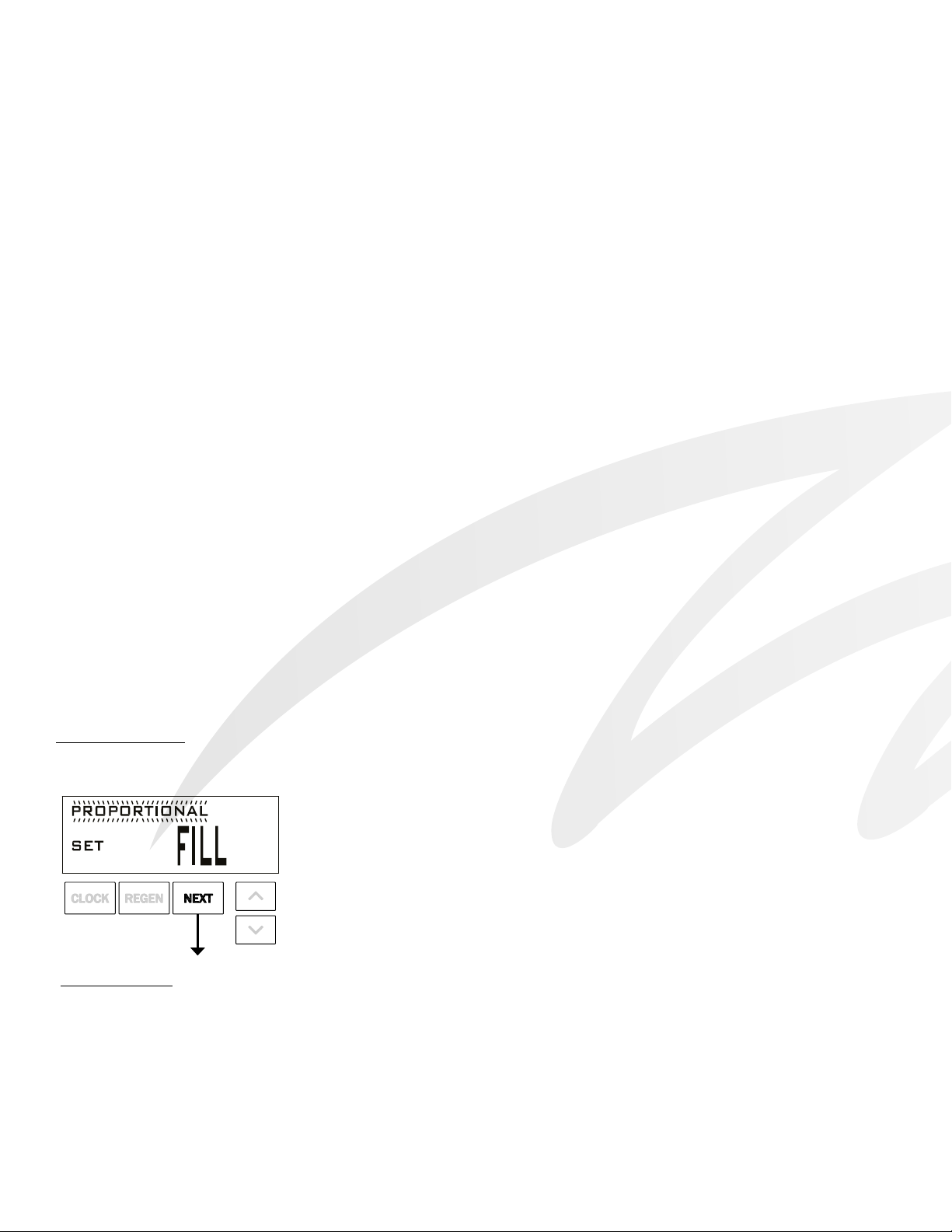

Proportional Brining

If the system is set up as a prell upow softener the control valve can also be set to normal or proportional brining.

This step will appear after Step 7S and before Step 8S if the system is set up as a prell

upow softener. The following options can be selected:

• NORMAL FILL - System always prells with the salt level selected.

• PROPORTIONAL FILL - If proportional brining is selected, the actual salt ll time will

be calculated by dividing the actual volume of treated water used by the full volumetric

capacity, then multiplying this value by the maximum salt ll time.

Press NEXT to go to the next step. Press REGEN to return to the previous step.

Backlight Control

As an energy-saving feature, the control will automatically turn off the display illumination after 5 minutes of inactivity. Any

further keypad activity will temporarily re-illuminate the display for 5 minutes. The Energy Saver feature default is ON.

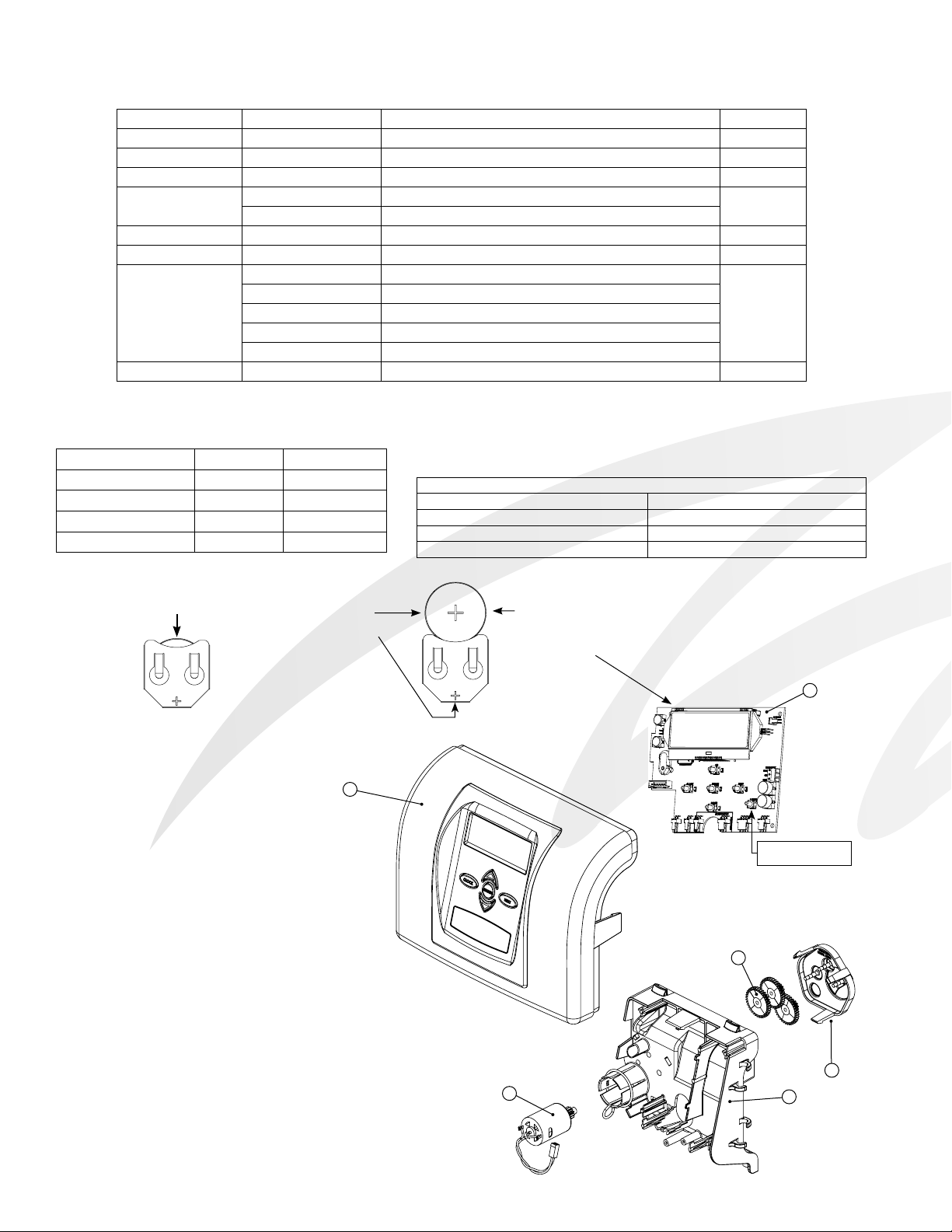

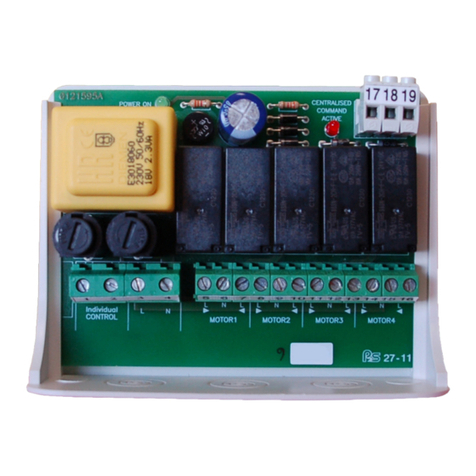

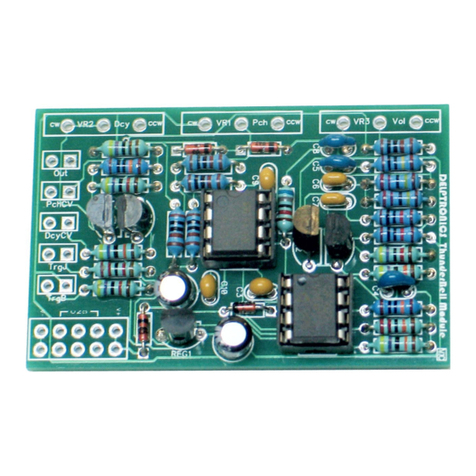

The Master Illumination button is located in the lower right hand portion of the board. The purpose of the button is to manage

the keypad backlights and the Energy Saver feature. When the keypad backlights are OFF, pressing and holding this button for

about 5 seconds will turn the lights ON, and turn the energy-saver feature OFF, which will be indicated with a display “ENERGY

SAVER OFF”. If the button is not held until the Energy Saver Off display is shown, the backlights for the display and the

keypad will both go OFF after 5 minutes of no keypad activity. (The keypad backlights will remain OFF until either the Master

Illumination or any keypad button is pressed to turn them back ON.)