Instruction Manual SAFELINE VARIO Diagnostics

Table of contents

Table of contents

1 Online-Diagnostics 6

1.1 Starting the Online Diagnostics

1.2. Display of the symbols in the online diagnostics

2 Rack-Diagnostics 11

2.1. Starting the Rack Diagnostics

2.2. Diagnostics Buttons

2.3. Read out Rack information

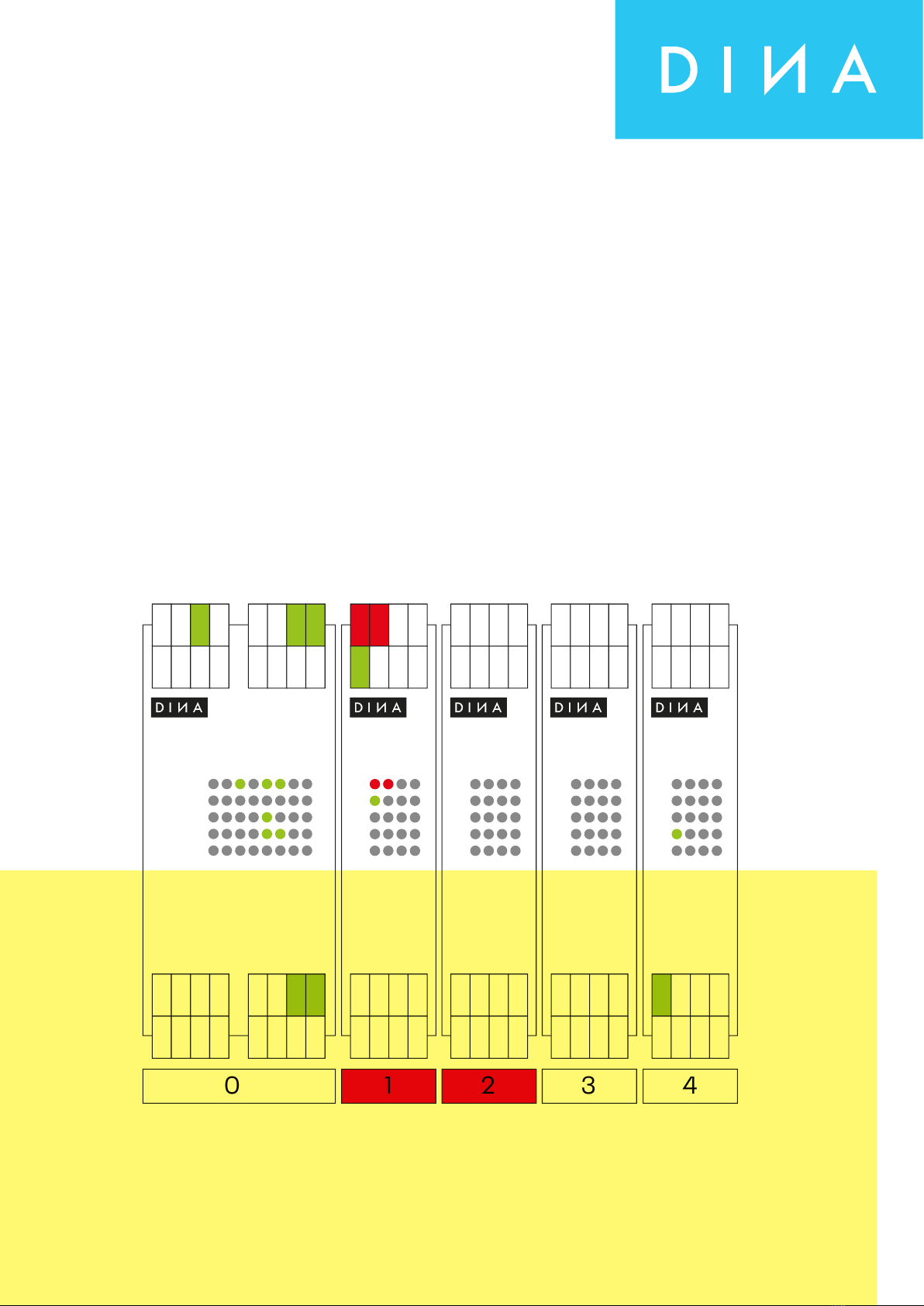

2.3.1. Overview of possible representation types of modules

2.4. Module Diagnostics

2.4.1. Overview of possible module terminals representation

2.4.2. Overview of LED display possibilities

2.4.3. Overview of LED display possibilities to speed monitoring

2.5. Status information

2.5.1. Status information central module ZMV

2.5.2. Latch for speed monitoring at ZMV

2.5.3. Status information about timers

2.5.4. Status information about counters

2.5.5. Status information about safety mats

2.5.6. Status information about copier

2.5.7. Status information about cams

2.5.8. Status information about synchronicity comparator

2.5.9. Status information about analog-terminals

2.5.10. Status Information about Analog-Input Comparator

2.5.11. Status Information about Safe brake test

2.5.12. Tables

2.6. Status information for the speed monitoring modules

2.6.1. Latch function

2.7. Status information about Fieldbus Module FBV

2.8. Status information about Input Module INV

2.9. Status information about In/Output Module IOV

2.10. Status information about module RMV

2.11. Status information about network module NIV

3 Error Diagnostics 35

3.1 Show detailed information

4 History 38

4.1. Read out History

4.2. Delete History