Dinamap 7300 User manual

NIBP SINGLEWIDE MODULE

INTRODUCTION

This area contains component information about the

singlewide Model 7300 Non-Invasive Blood

Pressure (NIBP) Module. The singlewide NIBP

module monitors blood pressure noninvasively,

using the oscillometric method that measures the

amplitude of the pressure oscillations within the

blood pressure cuff. Systolic pressure, diastolic

pressure, mean arterial pressure, and cuff pressure

are all measured by the module. Heart rate values

are also derived from the pulse rate determined by

the oscillometric blood pressure measurement

technique.

PHYSICAL

DESCRIPTION

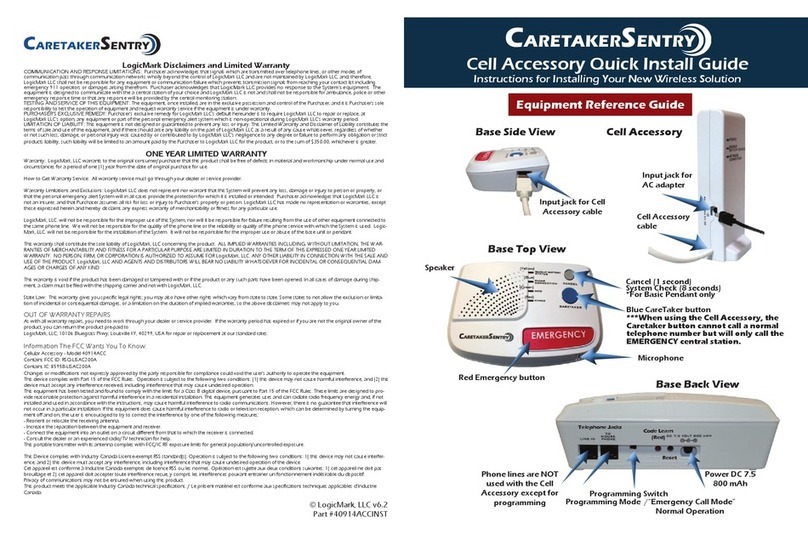

The singlewide version of the NIBP module, shown

in FO-42B, occupies a single module slot. The

module consists of two PWAs, interconnect cabling,

a pump manifold assembly, a cuff manifold

assembly, and a mechanical enclosure. Digital

PWA 315459 includes an interface to the PNet

communication bus, module core logic, and the

analog to digital conversion subsystem.

Analog PWA 315452 includes the pressure

transducer amplifiers and filter circuitry, pneumatic

system overpressure detection circuit, and the

pneumatic valves and pump control. The digital

PWA, with its PNet connector, occupies the left slot in

the module enclosure when viewed from the sensor

connector end (front) of the module. The analog

PWA occupies the right slot in the module enclosure.

Flex cable W100 connects the digital and analog

PWAs. It is soldered to the analog PWA, and

attaches to a pin header on the digital PWA. Flex

PWA 313-113 connects the analog PWA to

transducer XD2, mounted on the cuff manifold

assembly. Flex PWA 313-114 connects the analog

PWA to transducer XD1, mounted on the pump

manifold assembly. Cable assembly W102

connects the analog PWA to the pump, zero/deflate

valve, and dump valve mounted on the pump

manifold assembly.

FUNCTIONAL

PRINCIPLES OF

OPERATION

A schematic diagram of the pneumatics system is

shown in Figure 4-1. It illustrates all connections to

valves, transducers, and pump. The pump draws air

in and forces it through the check valve to the system

manifold. The filtered orifice is used to bleed off air

in the chamber between the pump and check valve.

This allows the pump to start up without back

pressure. The check valve prevents pressurized air

in the system from going back through the pump

when it shuts off. Transducer XD2 monitors the total

system pressure and provides an overpressure

signal to the analog PWA when the pressure gets

too high. During an overpressure condition,

deflate/zero valve V2 energizes and vents the

pressurized air to the atmosphere. Transducer XD1

monitors pressure through the cuff during a blood

pressure measurement. After the blood pressure

measurement is complete (or after power failure),

dump valve V3 deenergizes and vents the

pressurized cuff to the atmosphere.

A functional block diagram of the NIBP Singlewide

Module is shown in FO-42A. The diagram is divided

into analog circuits and core logic circuits. The

analog circuits are shown in the top half of sheets 1

and 2 and the core logic circuits are shown in the

bottom half of sheets 1 and 2.

Figure 4-1. NIBP Singlewide Pneumatics Schematic

Analog Circuits

The analog circuits consist of cuff measurement,

overpressure, and pneumatics circuits.

Transducers XD1 and XD2 shown on sheet 1

receive excitation voltage from +10V references.

Differential signal XD1SIG+/- from transducer XD1

representing blood pressure is applied to the analog

multiplexer through the pre-amp and low pass filter.

The pre-amp is gain controlled and the filter

removes any erratic and false data from the signal.

Differential signal XD2SIG+/- representing system

pressure from transducer XD2 is applied to the

overpressure amplifier. Overpressure threshold is

programmed by the CPU to a specific level. This

threshold level and the actual system pressure are

summed together by the summing amplifier and

applied to the delay circuit. This built-in delay

prevents a false overpressure caused by transient

surges in the system pressure. The overpressure

threshold control also allows selection of either

neonatal or adult pressure limits via ADULT-0

signal. This signal is true when an adult cuff is

attached, and false when a neonatal cuff is attached.

The CPU addresses the analog multiplexer through

ASEL0 through ASEL2. This allows the multiplexer

to poll any of seven inputs (AIN1 through AIN7).

Thus, the multiplexer monitors transducer

references and outputs, system pressure and

overpressure, and pump drive outputs. This

multiplexed analog signal (BUF_ANA_MUX) is

converted to digital by the A/D converter and sent to

the CPU for evaluation and response.

The pneumatics decode logic circuits shown on

sheet 2 provide a logical sequence of inflation after

receiving a RESET-0 signal. CLAMP1 and CLAMP2

signals control the transducer gain circuits shown

on sheet 1. ADULT-0 signal is generated when an

adult cuff is attached, and provides higher

overpressure limits. This logic also controls the

pneumatics latch and solenoid drive circuits.

The pneumatics latch and solenoid drive circuits

control the pump drive and the dump and

deflate/zero valves. Pneumatic reset or failsafe

signals from the CPU shut down the pump and open

the dump valve. Signal PUMPC measures pump

current. This allows the CPU to monitor when the

pump is running. DEFLATE_VAL signal from the

pneumatics latch and solenoid drive circuit

energizes deflate valve V2, releasing cuff pressure.

DUMP_VAL signal deenergizes dump valve V3,

releasing all system pressure. Both valves receive

+12V power from the analog PWA.

Core Logic Circuits

The core logic circuits are shown on sheet 2 of

FO-42A. Functional blocks include the PNet

interface, reset/failsafe, 68302 CPU, 128Kx8 data

memory, 128Kx8 program memory, the model and

serial number EEPROM, and logic analyzer/test

interface.

The Module will not be damaged when plugged into

a live slot. Core logic power inputs to a Module are

limited to a peak inrush current during hot-plugging.

Within 2 seconds the Module will respond to

identification and wake up in a minimized power

state until registered with the system.

The PNet interface allows asynchronous and

synchronous data transfer between the core logic

and the external devices. Synchronous operation is

always used in MPS systems. Asynchronous

operation is for test and development only. The

reset/failsafe logic provides power-on reset,

processor reset and halt, and failsafe if a problem

occurs with the microprocessor. The

microprocessor controls and transfers data within

the core logic. The program memory is a FLASH

device that can be loaded with program information

from the PNET interface or the logic analyzer

interface. Data memory temporarily stores status

and monitoring data for processing.

COMPONENT

PRINCIPLES OF

OPERATION

The following paragraphs describe the function of

the two rigid PWAs. The NIBP analog PWA provides

the circuitry for the excitation, amplification, and

signal conditioning (filtering) for measurement of

non-invasive blood pressure within the NIBP

module. Also included are the associated circuitry

for a separate, independent direct overpressure

interactive channel. The NIBP digital PWA provides

the processor, communication, and analog to digital

conversion for the NIBP module. Schematic

diagrams SC315-452 and SC315-459 are provided.

The mapping of signals located in the CPU Port

Register A and Port Register B are listed in Table

42-1.

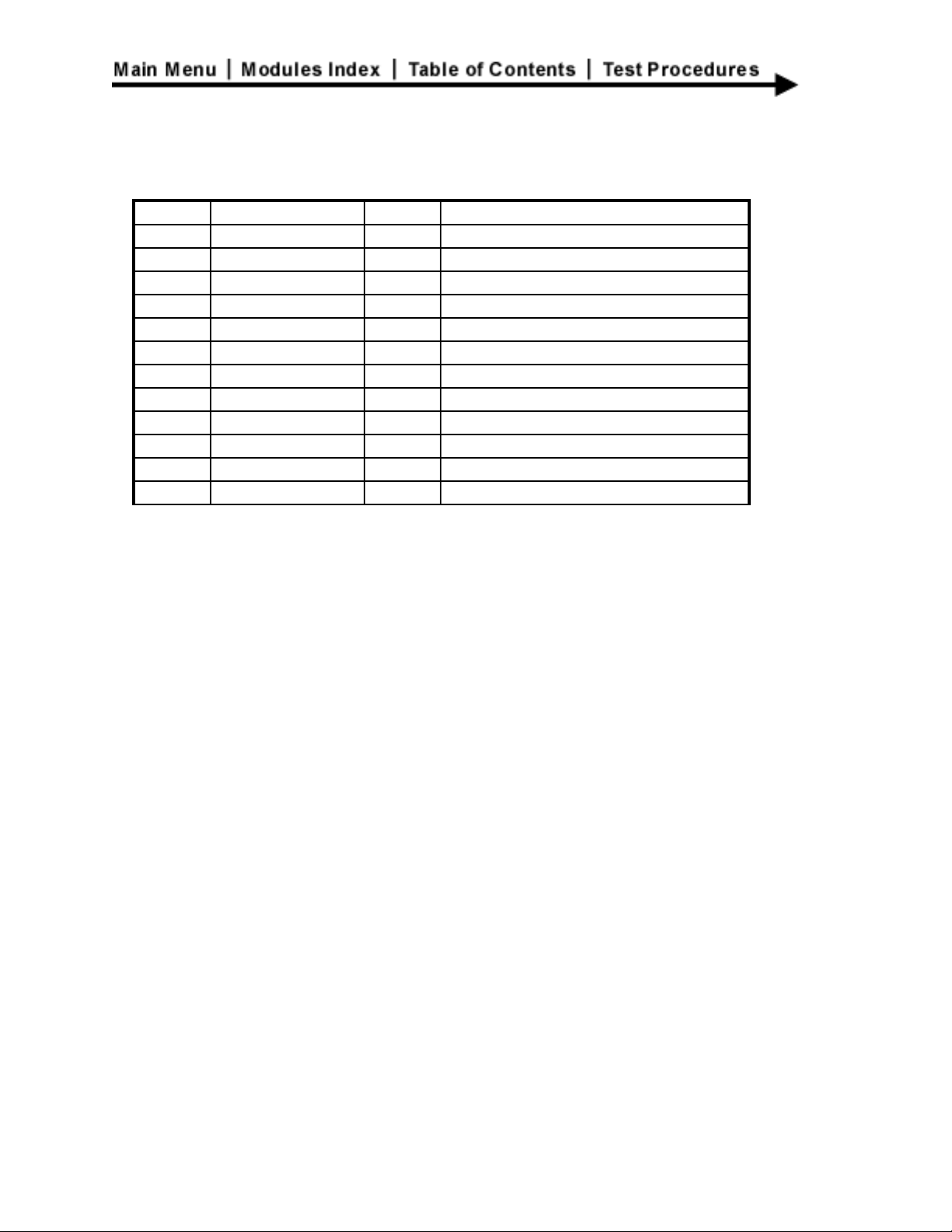

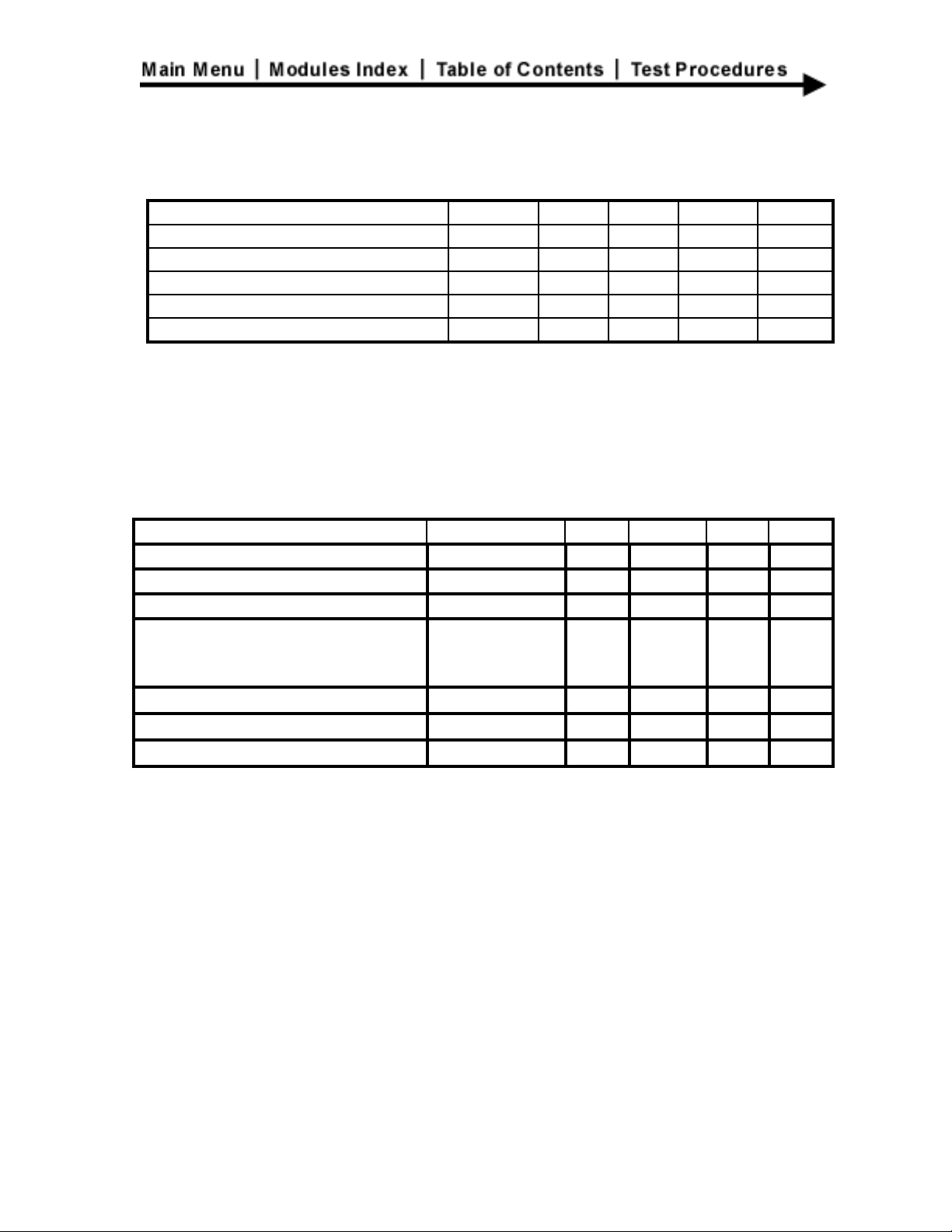

Table 42-1. CPU Register Mapping

Mapping of Bits in Port A:

Bit Signal Type Comment

PA(0) SCC2 RXD input debug serial data to

PA(1) SCC2 TXD output debug: serial data from

PA(2) SP_CS output Enable for Serial EEPROM

PA(3) Failsafe-1 input Monitor status of Failsafe latch

PA(4) PNEURESET output Pulsed low-high-low to reset

PA(5) ASYNC-EN output Selects Com Mode for PNET, H=Async

PA(6) MOTOR_PWR_CNTL output Delayed Power to Motor & Valves

PA(7) LATCHED_OVC input Latched Over_Current, normal=1

PA(8) DATA FROM ISO input (Unused)

PA(9) DATA TO ISO output (Unused)

PA(10) SPARE 1

PA(11) ADCLK output SCC3 (TxCLK)

PA(12) UFIL_OVP-0 input Unfiltered Overpressure (OVP-0)

PA(13) ASEL0 output Analog Mux -LSB

PA(14) ASEL1 output Analog Mux

PA(15) ASEL2 output Analog Mux -MSB

Table 42-1. CPU Register Mapping (Continued)

Mapping of Bits in Port B:

Bit Signal Type Comment

PB(0) LATCH_OVP input Latched Overpressure, normal =1

PB(1) POTCS-0 output init_val =1

PB(2) POTINC-0 output init_val = 1

PB(3) POTU~D-0 output init_val = 0

PB(4) TOUT1-0 output (Not used)

PB(5) TIN2 input **Debug Only

PB(6) PT1_CLAMP-0 output init_val = 1

PB(7) WDOG-0 output WatchDog Timer, normal =1

PB(8) FPTTST-0 output init_val = 1

PB(9) ADCBUSY-0 input busy = 0

PB(10) SYNC-0 input PNet

PB(11) SELECT-0 input PNet

Analog PWA

The NIBP analog PWA includes four functional

circuits: analog mux, filtered NIBP, overpressure,

and pneumatics.

Analog Mux

The analog mux functional block consists of a single

eight-to-one analog multliplexer and includes an

output buffer amplifer. Data is transferred to the

digital card via a single analog channel

BUF_ANA_MUX (MUX_OUT) on J100, Pin2. Channel

selection is defined by three address lines

ASEL0-ASEL2 in connector J100. These channel

assignments are defined in Table 42-2.

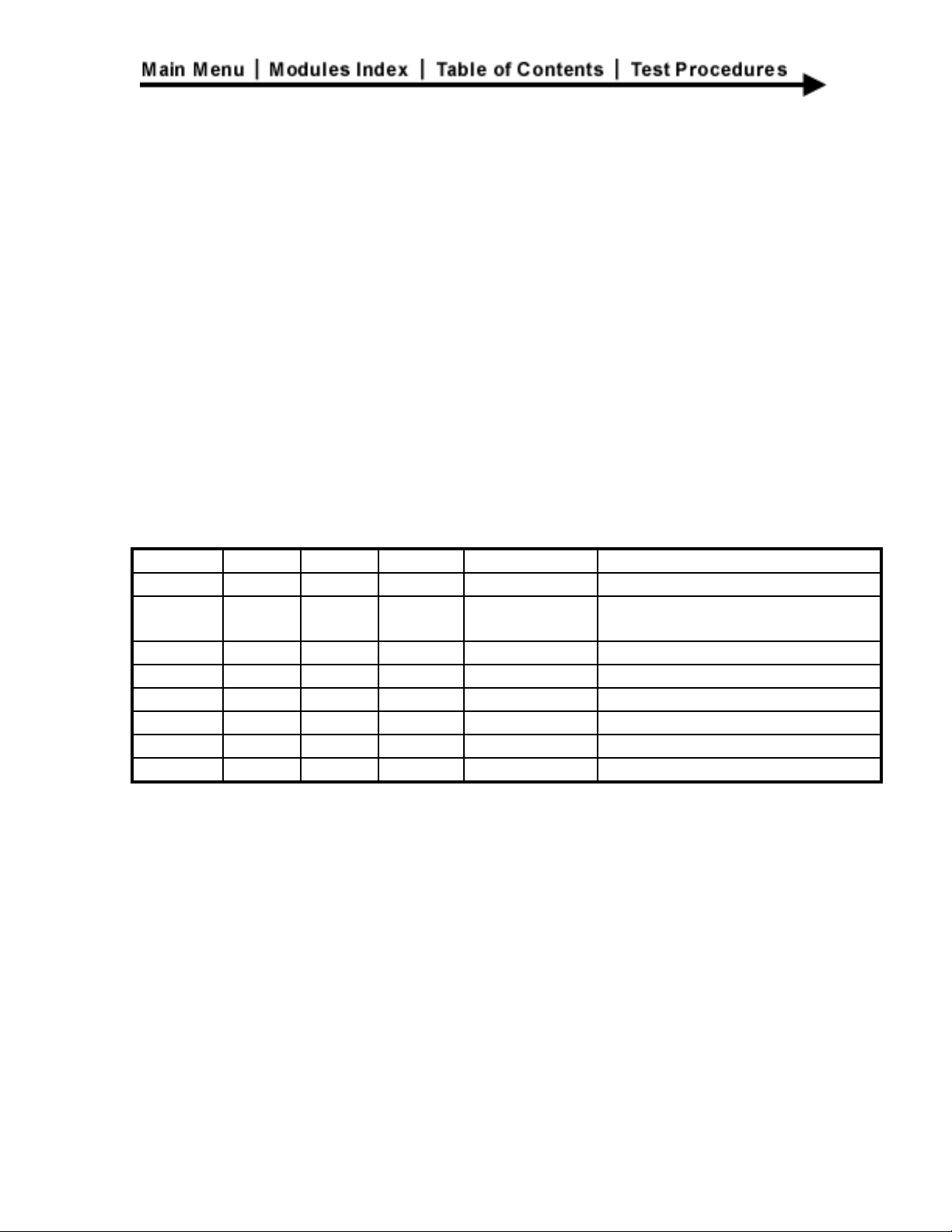

Table 42-2. Analog Multiplexer Channel Assignments

Channel ASEL0 ASEL1 ASEL2 Signal Description

AIN0 0 0 0 MOTRC_REF Motor Current Limit Ref Voltage

AIN1 1 0 0 TH_VREF Overpressure Threshold

Voltage

AIN2 0 1 0 PT2 Unfiltered Manifold Pressure

AIN3 1 1 0 PT2_REF XDCR2 Excitation Voltage Ref

AIN4 0 0 1 FPT1 Filter Cuff Pressure

AIN5 1 0 1 PT1 Unfiltered Cuff Pressure

AIN6 0 1 1 PT1_REF XDCR1 Excitation Voltage Ref

AIN7 1 1 1 PUMPC Pump Current Sense Voltage

Filtered NIBP

The filtered NIBP functional block consists of signal

conditional circuitry required to measure the cuff

oscillatory pressure (PT1) and acquire a blood

pressure determination. Circuitry for offset, voltage

clamping, and test pulse injection are also included.

The excitation voltage for the cuff transducer is

derived from the analog-to-digital converter, located

on the digital PWA. Changes in the A/D derived

reference produce a ratiometric change in the

channel and tend to compensate for the initial

reference change.

A +350mV nominal offset is added to the PT1

channel to insure its signal remains positive, since

the A/D converter input signal is limited to a uni-

polar, 0 to 5.0 Volts range. The FPT1 channel has a

+200mV nominal offset.

The pulse component (typically one percent) of the

cuff pressure signal is separated from the cuff

pressure signal by a cascaded high-pass filter

section followed by a low-pass filter section. Each

filter section contains two poles. The passband of

this filter is nominally 0.5 to 7.2 Hz. Testing of filter

characteristics is accomplished using the FSTTST

signal.

The blood pressure algorithm requires the ability to

initialize (clamp) the high pass filter in the process of

separating and measuring the pulse signal. Two

clamps are used in this process. FLT_Clamp-0

provides a clamp to ground of the input to the

second stage and also clamps the output buffer to a

+200 mV offset reference voltage. The second

clamp, PT1_Clamp-0 is used to isolate the input

channel to zero. This clamp is applied to disconnect

the input pressure transducer signal from the

channel. This permits a true, uncorrupted test signal

to be injected in to the input of the channel to

measure filter characteristics. This test pulse is

accomplished by toggling the FPTTST-0 signal.

FPTTST-0 should normally be held HIGH, otherwise

it will inject a nominal offset of 37.5 mV in the PT1

channel.

The inputs to both pressure measurement channels

PT1 and PT2 are derived from a pressure transducer

having the characteristics defined in Table 42-3.

Table 42-4 defines the range of parameter variations

for the cuff measurement channel.

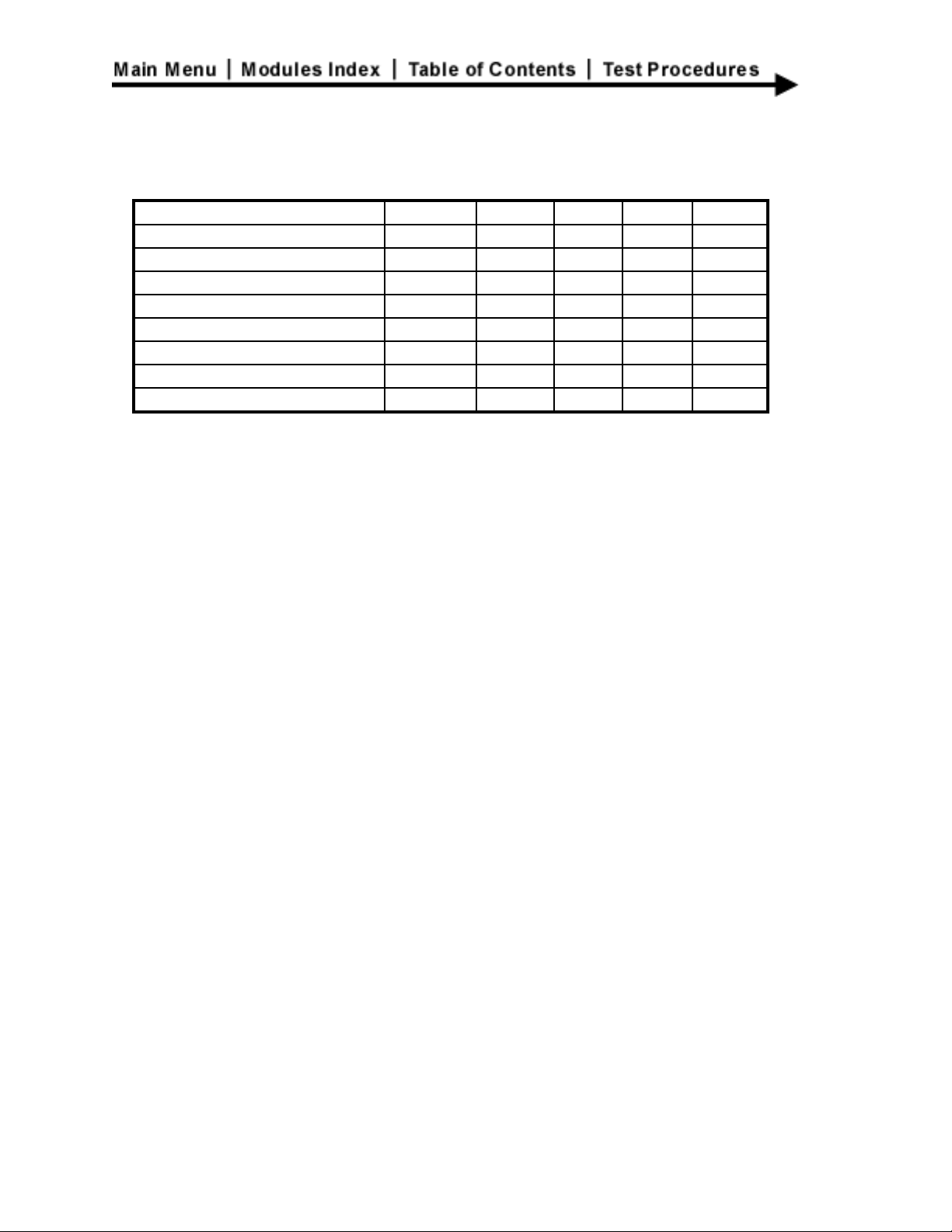

Table 42-3. Transducer Characteristics

Operating Conditions: Excitation voltage = +10.000V

Characteristics Symbol Min Typ Max Units

Pressure Range P 0 375 mmHg

XDCR,FSS VFSS 38.5 40 41.5 mV

XDCR, OFFSET VFSS -1.0 +1.0 mV

Linearity, of XDCR -0.25 +0.25 %FSS

FSS == Full Scale Span

Table 42-4. PT1 Output Characteristics

Operating Conditions: Power Supply Voltages=+5V+/-5%, +12V+/-5%, -12V+/-5%

Characteristics Symbol Min Typ Max Units

Gain* G2 88.83 91.89 94.96

Offset Voff 335 349 363 mV

Offset, including AD2 ref Voff 326 349 372 mV

XDCR,FSS VFSS 38.5 40 41.5 mV

XDCR, OFFSET VFSS -1.0 +1.0 mV

Linearity, with XDCR -0.25 +0.25 %FSS

Full Scale Scan, with XDCR VFSS 3511 3676 3842 mV

Offset Voltage, with XDCR Voff 178 349 495 mV

*Gain of signal [range 1-40mv] injected between pins J103-Pin4 and J103-Pin2

Overpressure

The overpressure circuit generates a separate,

independent pressure measurement channel (PT2),

including its own separate excitation voltage source

(Table 42-5). Also included is circuitry for

electronically setting the overpressure threshold

point. Both the excitation reference voltage PT2_REF

and the unfiltered pressure transducer (PT2), which

is amplified and buffered, are available as output to

the A/D converter. The PT2 channel also has a +350

mV offset voltage injected to insure the uni-polar A/D

converter input always remains positive (Table 42-6).

Table 42-5. PT2 Output Characteristics

Operating Conditions: Power Supply Voltages = +5V+/-5%, +12V+/-5%, -12V+/-5%

Characteristics Symbol Min Typ Max Units

Gain* G2 90.70 91.89 93.08

Offset Voff 339 349 359 mV

Linearity, with XDCR -0.25 +0.25 %FSS

Full Scale Scan, with XDCR VFSS 3555 3676 3904 mV

Offset Voltage, with XDCR Voff 178 349 495 mV

*Gain of signal [range 1-40mv] injected between pins J103-Pin3 and J103-Pin5

Table 42-6. Reference Output Characteristics

Operating Conditions: Power Supply Voltages = +5V+/-5%, +12V+/-5%, -12V+/-5%

Characteristics Symbol Min Typ Max Units

PT1 Reference Voltage PT2_REF 3253 3329 3406 mV

PT2 Reference Voltage PT2_REF 3253 3329 3406 mV

FPT1 Reference Voltage FPT1 170 200 230 mV

OverPressure Threshold Voltage

Adult Mode

Neonate Mode

TH_VREF

2952

1364

3290

1530

3700

2047

mV

mV

Motor Over Current Ref Voltage MOTR_C_Ref 2424 2500 2574 mV

PT1 EXCITATION Voltage EXC1+ 10.000 V

PT2 EXCITATION Voltage EXC2+ 10.000 V

The excititation reference voltage for transducer PT2

is used to generate a threshold voltage to compare

with the actual pressure of the cuff as measured by

transducer PT2. The reference voltage is buffered by

an adjustable gain amplifier to produce the

reference pressure point of 300 mmHg (150 mmHg

in neonate mode) for the trip point. The amplifier

gain is altered by modifing the feedback resistance

of the amplifier by means of a solid state non-

volatile, digital E2POT. The digital E2POT has a

resolution of 100 steps. Total adjustment trim range

is limited to about +/-10%.

Threshold trimming is accomplished by controlling

three input signals: CS-0 (Chip Select), U_D-0

(Direction: Up or Down), and INC-0 (Increment or

Decrement). A interlock jumper, JP1, which

connects CS-0 to the board edge pin, is required to

be installed or threshold adjustment is inhibited.

The E2POT incorporates a storage mode that

permits maintaining the threshold setting once

adjusted. The last state saved is recalled from non-

volatile storage on system power-on, returning the

overpressure threshold point to the previous set

point.

Pneumatics

The pneumatic functional block includes the control

signal decode logic, the valve driver circuitry, the

pump driver circuitry, pump current measurement

circuit, and a safety interlock circuit.

Control signals for the board are derived via three

different sources: direct control from registered

outputs of the processor, controls signal derived

from processor address write commands (which are

stored in an addressable latch), signals derived

from the watchdog timer, and signals generated by

the overpressure functional block. The four valve

control signals and the pump control signal are

derived from the write address and stored in an

addressable latch. The latch signals are defined in

Table 42-7. Latch values are cleared by application

of system RESET generated by the processor. Refer

to Table 42-8 for reset conditions. Each latch signal

is individually gated in a programmable logic device

(22v10) with the fail safe input signal (watchdog

timer) and the overpressure latch output to ensure

pressure is removed from the patient cuff should

either overpressure or processor hang-up condition

occur.

Table 42-7. Latched Control Signals and Decode Matrix

Operating Conditions: RESET-0 =1; PNEURESET=1; FAILSAFE-0 =1; FLT_0VP-0=1

Pneu_Enab Data LSEL0 LSEL1 LSEL2 Signal Value Description

¥ 0

1

000TK_Inflate_Val Open

Closed

Not Used

¥ 0

1

000Cuff_Deflate_Val Closed

Open

When open, deflates Cuff

¥ 0

1

100Cuff_Dump_Val Open

Closed

When closed,

dumps pressure in Cuff

¥ 0

1

100Pump OFF

ON

When ON, activates PUMP

¥ 0

1

010Unload_WD ON

OFF

Pneumatic Watchdog Signal

¥ 0

1

010OVP_MODE ‡ OFF

ON

Controls Overpressure Mode

¥ 0

1

110FLT_Clamp-0 ‡ OFF

ON

When ON , Injects Offset

into Filtered Channel Output

¥ 0

1

111Adult ‡ Adult

Neonatal

When ON, Selects Neonatal

for OP Threshold Voltage Ref

¥ == negative pulse condition

‡ == independent of pneureset, failsafe, flt_ovp

Table 42-8. System Reset State

Operating Conditions: PNEURESET=1; FAILSAFE-0 =1; FLT_0VP-0=1

Reset Data LSEL0 LSEL1 LSEL2 Signal Value Description (Reset Condition)

0 XXXXTK_Inflate_Val Open Not Used

0 XXXXCuff_Deflate_Val Closed Valve UnEnergized

0 XXXXCuff _Dump_Val Open Valve Energized

0 XXXXPump OFF PUMP

0 X X X X FLT_Clamp-0 ON Clamped

0 XXXXAdult Adult Over Pressure = Adult Level

1 XXXXLatched_OVP HIGH Cleared Low if HIGH Fil-OVP Occurred

1 XXXXLatched_OVC HIGH Cleared Low if Motr-OVC

A cross coupled latch for overpressure is included in

the programmable logic device. It is set by the

occurrence of an overpressure condition existing for

a period greater than 500 milliseconds, nominally.

When this condition occurs, Filter_OVP-0 transitions

low setting the internal latch. The latch output state

is indicated by the Latched_OVP signal. The latch

can only be cleared by an occurrence of a

PNEURESET pulse. Refer to Tables 42-9 and 42-10

for additional clarification.

Table 42-9. Processor Pneureset State

Operating Conditions: RESET=1; FAILSAFE-0 =1; FLT_0VP-0=1

PneuReset Data LSEL0 LSEL1 LSEL2 Signal Value Description (Reset Condition)

§ XXXXTK_Inflate_Val Vn+1 = Vn Not Used

§ XXXXCuff_Deflate_Val Vn+1 = Vn Same, before and after pulse

§ XXXXCuff_Dump_Val Pn+1 = Pn Same, before and after pulse

§ XXXXPump Vn+1 = Vn Same, before and after pulse

§ XXXXLatched_OVP HIGH Set

§ XXXXLatched_OVC HIGH Set

§ == positive pulse condition

Table 42-10. Overpressure and FailSafe States

Operating Conditions: RESET=1

PneuReset Filtered_OVP FailSafe Signal Value Description

X 0 X TK_Inflate_Val Open Not Used

X 0 X Cuff_Deflate_Val Closed Valve Energized

X 0 X Cuff_Dump_Val Open Valve UnEnergized

X 0 X Pump OFF PUMP

X 0 X Latched_OVP LOW LOW is active

X 0 X Latched_OVC HIGH LOW is active

X 1 0 Tk_Inflate_Val Open Not Used

X 1 0 Cuff_Deflate_Val Closed Valve Energized

X 1 0 Cuff_Dump_Val Open Valve UnEnergized

X 1 0 Pump OFF PUMP UnEnergized

X 1 0 Latched_OVP Ln+1 =Ln+1 Unchanged

§ 1 1 Tk_Inflate_Val Vn+1 = Vn Not Used

§ 1 1 Cuff_Deflate_Val Vn+1 = Vn Same, before and after pulse

§ 1 1 Cuff_Dump_Val Vn+1 = Vn Same, before and after pulse

§ 1 1 Pump Pn+1 = Pn Same, before and after pulse

§ 1 1 Latched_OVP HIGH High is inactive

§ 1 1 Latched_OVC HIGH High is inactive

§ == positive pulse condition

Digital PWA

The NIBP digital PWA block diagram is shown in

sheet one of hierarchical schematic SC315-459. It

includes the core logic blocks PNET IF (PNET

Interface), RESET-FS (Reset - FailSafe), UP8-144

(microprocessor-8 bit), EIGHT BIT MEMORY, and

LOGIC ANALYZER TEST IF.

Unique to this PWA is the analog-to-digital converter

functional block. The NIBP digital PWA is based on

the eight bit version of the module core logic. The

microprocessor clock frequency is 19.5104 MHz.

Analog to Digital Converter Functional Block

The analog to digital converter functional block

includes the analog to digital converter, bus isolation

logic, and a buffer to condition the precision voltage

reference. The analog to digital converter is a twelve

bit successive approximation, with an internal

track/hold and reference. Input range is zero to

+5.000 V, establishing a LSB value of 1.22 millivolts.

The internal reference is, -5.000 V, is filtered and

inverted to provide a +5.000V reference, labeled

VREF. The ADC is powered by the +5V rail and the

-12V rail. An eight wide data bus (DATA0 - DATA7)

connects the ADC to the microprocessor. Data

transfers consist of two consecutive byte transfer per

data point conversion. The data bus is isolated with

a three state buffer to reduce bus noise in the

converter. With a 1.219 MHz clock on ADCCLK,

conversion time is 10.667 microseconds.

Processor Digital I/O and Chip Select Assignments

68302 PORT SIGNAL

I/O

TYPE COMMENT

PA0 debug serial SCC2 RXD output

PA1 debug serial SCC2 TXD input

PA2 SERIAL EEPROM CS output

PA3 undefined

PA4 PNEUMATIC RESET output

PA5 ASYNC_EN (PNET)

PA6 Motor Power Control output

PA7 LATCHED_OVC input Latched Motor Overcurrent Indication

PA8 DATA FROM ISO (FOR FUTURE TEMP I/F)

PA9 DATA TO ISO (FOR FUTURE TEMP I/F)

PA10 SPARE 1

PA11 ADCLK output AD Converter clock

PA12 UNFIL_OVP-0 input Latched Overpressure Indication

PA13 analog mux sel 0 output

PA14 analog mux sel 1 output

PA15 analog mux sel 2 output

PB0 LATCH OVERPRESSURE input

PB1 POTCS-0 output

PB2 POTINC-0 output

PB3 POTU~D-0 output

PB4 undefined

PB5 timer 2 input (FROM LA I/F)

PB6 CLAMP3-0 output

PB7 WATCHDOG TIMER output

PB8 FPTTST-0 output

PB9 ADC BUSY-0 output

PB10 undefined

PB11 SELECT-0 input (PNet)

CS0 FLASH ROM

CS1 Static RAM

CS2 ADC_CS

CS3 PNEU_ENAB-0

Core Logic

The core logic is shown on sheets 2 through 7 of the

schematic. The core logic provides communication

between the system host and Module through the

PNet synchronous serial interface. The Module is an

8-bit version of the core logic, with one 128Kx8 RAM

and 128Kx8 ROM device. The microprocessor runs

at 19.5104 MHz.

PNet Interface. The PNet interface, shown on sheet

2of the schematic, provides the following functions:

•RS485 drivers (U7 and U8) for serial data and

clock,

•Module select and presence detection (U2),

•Module synchronization.

Core signals are received on PNet connector J1

(sheet 2) with the following pin-out:

PIN NAME PIN NAME

1A,1B +5V 6B M_SELECT

2A DATA+ 7A M_PRESENT

2B DATA- 7B TXOC-0

3A,3B +3.3V 8A M_SYNC-0

4A CLK+ 8B -12V

4B CLK- 10A,10B +12V

5A,5B GROUND 1,2 GROUND

6A M_RESET

The NIBP Module is designed to be hot-plugged, or

inserted and removed from powered systems.

Ground pins 1 and 2 are longer than the other

connector pins, thus they make first and break last to

protect circuitry. This is partially because of

protective impedance located on the system

backplane, in series with the Modules +5V and +12V

power. Also series impedance on PNet control lines

limits inrush and protects logic devices from

excessive currents during a hot-plug power up.

The PNet protocol defines two modes of operation:

synchronous and asynchronous. The normal mode

of operation is synchronous, with half duplex

transmitted and received data on differential signals

DATA+ and DATA-. As shown on sheet 2 of the

schematic, the device transmitting the serial data

also generates differential clock signals CLK+ and

CLK-. Transceiver direction for data and clock are

controlled by the 68302 processor-generated

TX_EN-0 (low true transmit enable) signal through

U2. In the synchronous mode, both data and clock

transceivers U7 and U8 are set to receive (i.e.,

transmit disabled) when fail-safe signal FS-0 is

asserted.

The alternate serial mode, full duplex asynchronous,

is entered by asserting processor generated control

bit ASYCH_EN. This mode transmits data onto the

differential signals CLK+ and CLK-, and receives

data from the differential signals DATA+ and DATA-.

The transmitter in the Module is disabled unless the

Module has been commanded to transmit per the

PNet protocol. The Module transmitter is

immediately disabled after the last character of a

transmission has been sent.

The Module select input (M_SELECT, hi true)

instructs the Module to respond to identification

requests. When both M_SELECT input and

M_RESET input (hi true) are asserted, a Module

performs a hardware reset.

Table of contents

Other Dinamap Medical Equipment manuals