R25 Maintenance Instructions Issue 4 20/07/2020

4

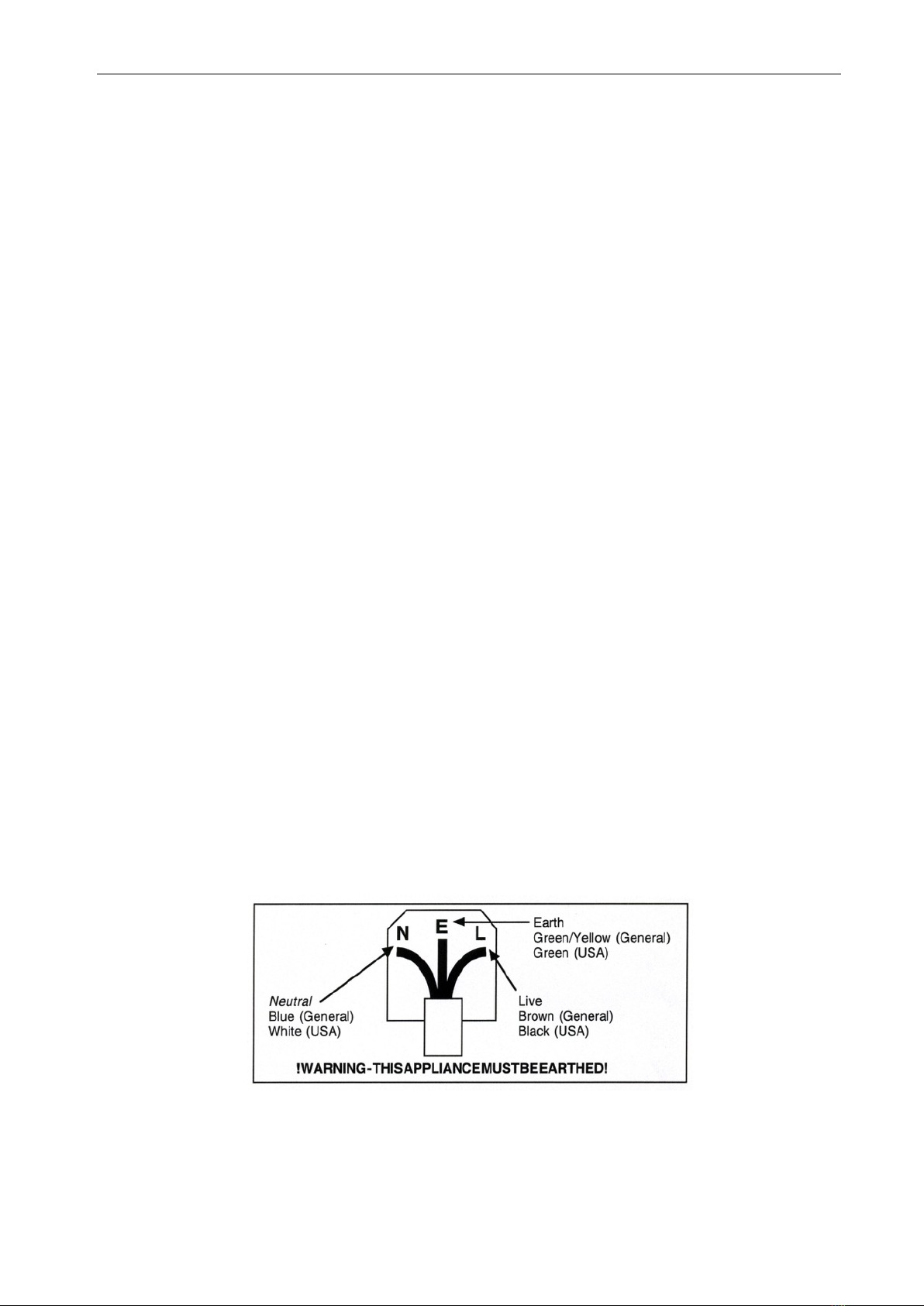

Warning - read instructions before installation and use.

If in doubt about electrical supply or connection refer to your supplier or consult a qualified electrician.

4. Running the Machine

Always wear hearing protection, eye protection and gloves when operating the R25.

Always perform a visual inspection before running the machine, to ensure that guards are in place and

undamaged. Do not use the machine under any circumstances if there is any damage to guards or

electrics.

Plug the machine into a suitable mains socket, and switch on.

Switch the machine on at the main isolator, and ensure that the Emergency Stop button is released.

Remove the cover from the infeed hopper to allow access to load material.

Switch the machine on using the green Start button. Note that upon starting, the cutting blades turn

backwards for a couple of seconds to clear any residual plastic that may be lodged in them. They then

start turning forwards. Wait for the cutting blades to reach a steady speed before loading the first

material to be granulated.

Feed your waste plastics into the infeed hopper, and listen as they get granulated. Do not overload the

machine, once it has finished chopping one load of material (you will hear the noise level of the machine

reduce when this happens), feed another load into the machine.

When you have loaded the last batch of material into the infeed hopper, allow the machine to fully

granulate it and then leave it running for two minutes or so before switching off using the black button.

This extra time ensures that the cutting chamber has been fully cleared out, to avoid any problems

restarting the next time.

Replace the infeed hopper cover when the machine is not in use, to prevent stray/unwanted items being

placed into it. Holes in the infeed hopper and cover allow it to be locked using a padlock if required.

5. After Use

After use, the R25 can simply be switched off.

6. Suitable Materials & Material Sorting

The R25 is suitable for processing many of the common plastic materials that are found in the workshop,

for example HIPS, Polyropylene, Polyethylene, ABS etc. Acrylics and PET can be broken up in the R25,

however there is currently no way of re-processing the resulting material using the Schred system. Note

that the R25 is not suitable for non-plastic materials. Should there be any queries regarding the suitability

of the machine for a particular material, please refer to the manufacturer or local distributor prior to

processing.

Obviously different colours of material can be granulated together to form a mottled effect. However it

may be preferred to separate the colours. Also, it is normally wise to separate material types, as mixed

materials may not blend well when processing after granulating. To change colour/type, it is easiest to

leave the machine running when the old material has finished, and then feed some scraps of the new

material through to purge the cutting chamber. When the granules run true to the new material/colour,

the collection bin can be emptied so that all of the granules from that point are of the new

material/colour.