Dini Argeo DGT4 User manual

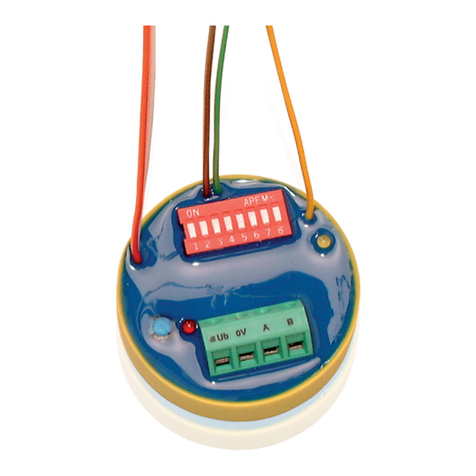

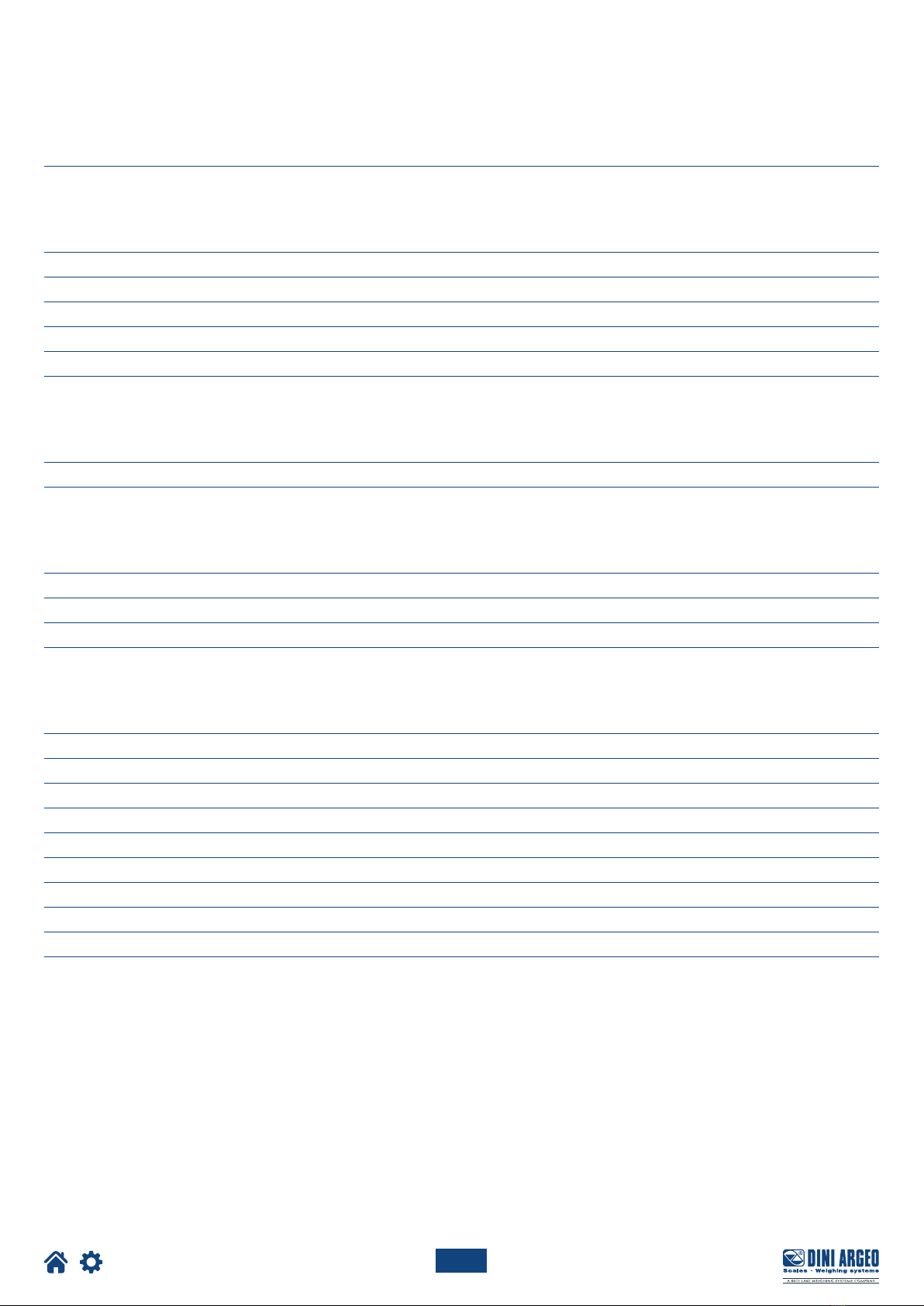

+24Vdc GND

3

COM

4

IN1

5

IN2

6

RL1

7

RL2

8

COM I+ I- V+ V-

13

A(+)

14

B(-)

15

TX RX

16 17

GND

POWER INPUT RELAYS RS232

RS485

ANALOG

9 10 11 12

1 2

34

SIG-

33

SIG+

32

EXC-

31

EXC+

30

EXC-

29

SIG+

28

SIG-

27

EXC+

26

EXC+

25

SIG+

24 23 22 21 20 19

CELL1CELL2CELL4 CELL3

35

EXC- SIG- EXC+

EXC- SIG+

SIG-SEN- SEN+

18

www.diniargeo.com

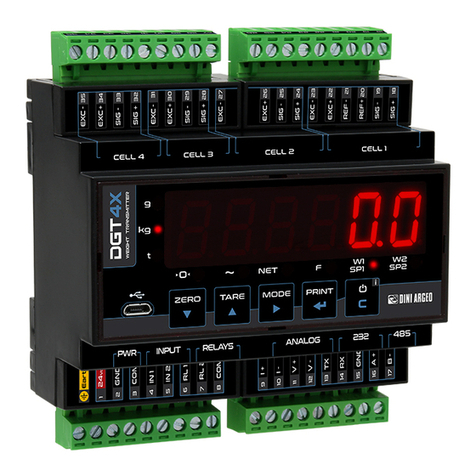

DGT4

Digital weight transmitter with 4 channels

ENGLISHUSER MANUAL

For DGT4 with firmware release minimum 08.03

3

Optimized layout for A4 print.

TECH_MAN_ENG_DGT4_V8

Contents

Introduction 7

Transmitter installation 8

Installation requirements 8

Electrical precautions 9

Earthing of the system 11

Technical features 14

Load cell installation 15

Wiring diagrams 16

DGT4 16

DGT4AN 17

DGT4PB 18

DGT4ETHIP, DGT4ETHCAT, DGT4PRONET, DGT4MODTCP 19

DGT4CANOP 20

DGT4DEVNET 21

Display and function of the keys 22

Quick menu 22

Advanced programming menu 23

Access to the menu and saving the changes 23

Function of the keys in the menu 23

Block diagram of the menu 24

Mode of use of the DGT4 26

On / Off 27

Theoretical calibration 28

Dependent channels 28

Independent channels / transm 29

Calibration with sample weights 30

Dependent channels (with digital equalisation) 30

Independent channels / transm 32

Equalisation 34

4

Optimized layout for A4 print.

TECH_MAN_ENG_DGT4_V8

Manual calibration 35

Manual calibration 35

Quick zero calibration (pre-tare zeroing) 35

Filter and stability 36

Filter adjustment 36

Stability detection sensitivity 36

Display updating frequency 37

Gravity 37

Zeroing parameters 38

Auto-zeroing on ignition 38

Maximum percentage of manual zeroing 38

Zero tracking 38

Restoring zero 39

Semi-automatic zeroing 39

Tare functions and parameters 40

Tare mode 40

Semi-automatic tare 40

Predetermined tare 40

Clearing the tare 40

Alibi memory 41

Enabling the alibi memory 41

Saving a weighing operation in the alibi memory 41

Reading the alibi memory 42

Initialising the alibi memory 42

Use functions 43

High resolution 43

Peak detection 43

Converting units of measurement 43

Alibi memory 43

No function 43

Input configuration 44

Output configuration 45

5

Optimized layout for A4 print.

TECH_MAN_ENG_DGT4_V8

Analog output configuration 46

Serial communication configuration 48

Selection of the PC serial port 48

Configuration of the printer port (COM.PRN) 49

Transmission mode 49

Baud rate, parity, data bits, stop bits 50

Printer power on mode 50

CTS signal 50

Print language 50

Reactivation of printing 51

Configuration of the PC port (COM.PC) 51

Transmission mode 51

Baud rate, parity, data bits, stop bits 52

Communication protocols 53

Standard string 53

Extended string 53

Multi-scale string 54

Serial commands 55

Diagnostics 58

Cells / converter test 58

Firmware release 58

Serial number 58

Display 58

Keypad 58

Serial ports 59

CTS signal 59

Inputs 59

Outputs 59

Analog output (mod. DGT4XAN) 59

Programming the Setpoints 59

Restoring factory settings 60

Date and time setting 60

Alarms 61

7

Optimized layout for A4 print.

TECH_MAN_ENG_DGT4_V8

Dear Customer,

Thank you for purchasing a DINI ARGEO product.

This manual contains all the instructions for a correct installation and commissioning of the DGT4 4-channel digital weight transmitter.

While thanking you for purchasing this product, we would like to draw your attention to some aspects of this manual.

This booklet provides useful information for the correct operation and maintenance of the scale to which it refers; it is therefore essential

to pay the greatest attention to all those paragraphs that illustrate the simplest and safest way to operate.

It is recommended that you carefully follow the instructions for programming the weight transmitter; performing actions not indicated in

this manual could compromise the proper functioning of the scale.

The utmost care has been taken in compiling this manual, but reports of any inaccuracies are always welcome.

The instrument is covered by warranty and MUST NOT BE TAMPERED WITH BY THE USER under any circumstances.

Any attempt at repair or modification may expose the user to the danger of electric shock and voids any warranty conditions, relieving

the Manufacturer from all liability.

Any problem with the product must be reported to the manufacturer or to the retailer where it was purchased.

In any case, always TURN OFF THE POWER SUPPLY before any installation or repair operation.

Introduction

8

Optimized layout for A4 print.

TECH_MAN_ENG_DGT4_V8

Transmitter installation

Installation requirements

Observe the following conditions for correct installation of the transmitter and of the load receiver:

• Flat, level support surface.

• Stability and absence of vibrations.

• Absence of aggressive dusts and vapours.

• Absence of draughts.

• Make sure that the platform is levelled or that the load cells are evenly supported.

• Moderate temperature and humidity (15°C - 30°C and 40% - 70%).

• Do not install in an environment where there is a risk of explosion.

• All transmitter connections must be made in accordance with applicable regulations in the area and environment of installation.

Observe the electrical precautions listed in the section “Electrical precautions”.

• Ensure that it is correctly earthed, see the relevant section “Earthing of the system”.

• Do not perform welding when the load cells have already been installed.

• If necessary, use watertight sheaths and fittings to protect the load cell cables.

• Any junction boxes must be watertight.

• Anything not expressly described in this manual constitutes improper use of the equipment.

9

Optimized layout for A4 print.

TECH_MAN_ENG_DGT4_V8

Electrical precautions

• Use a regulated mains supply within ± 10% of the rated voltage.

• The electrical protections (fuses, etc.) are the responsibility of the installer.

• Observe the recommended minimum distances between cables of dierent categories (see table on page 10).

• The following cables must comply with the maximum permissible lengths (see table on page 10), they must be shielded and must

beinserted alone in metal conduits or pipes:

- the load cell extension cables;

- the signal amplifier cables;

- the cables for connecting the serial ports;

- the analog output cables.

• The cell or amplifier cables must have an independent input in the electrical panel. They must be connected (if possible) directly to

the terminal block of the transmitter without passing through the conduit with other cables.

• Fit “RC” filters:

- on the contactor coils;

- on the solenoid valve coils;

- on all devices that produce electrical interference.

• If condensation can occur inside the weight transmitter, it is advisable to keep the equipment powered at all times.

• Connections to load cells and any external device must be as short as possible.

• The cable ends (connectors, leads, terminals, etc.) must be installed correctly; the cable shielding must be kept intact until close to

the connection point.

• If the transmitter is placed inside an electrical panel, a shielded cable must also be used for the power supply.

10

Optimized layout for A4 print.

TECH_MAN_ENG_DGT4_V8

Category I Category II Category III Category IV

Distance

≥ 100 mm

≥ 200 mm

≥ 500 mm

≥ 100 mm

≥ 500 mm

≥ 500 mm

Classification

Fieldbus, LAN network

(PROFIBUS, Ethernet,

Devicenet...).

Shielded data cables

(RS232...).

Shielded cables for

analog digital signals

< 25 V (sensors, load

cells...).

Low voltage power sup-

ply cables (< 60 V).

Coaxial cables.

DC supply cables with

voltage > 60 V and <

400 V.

AC supply cables with

voltage > 25 V and <

400 V.

Power supply cables

with voltage > 400 V.

Telephone cables.

Any cable subject to

lightning danger.

Load cell RS232 RS485 Analog output

50 metres with

6 x 0.25 mm2cable;

100 metres with

6 x 0.5 mm2cable.

15 m with baud rate up

to19200.

1200 m with shielded 2 x

24 AWG twisted pair with

outer braid + aluminium

strip.

CURRENT:

100 metres with 2 x 0.25 mm2cable;

150 metres with 2 x 0.5 mm2cable;

300 metres with 2 x 1 mm2cable.

VOLTAGE:

50 metres with 2 x 0.25 mm2cable;

75 metres with 2 x 0.5 mm2cable;

150 metres with 2 x 1 mm2cable.

RECOMMENDED DISTANCES AND CABLE CLASSIFICATION

MAXIMUM ALLOWED LENGTHS

11

Optimized layout for A4 print.

i

TECH_MAN_ENG_DGT4_V8

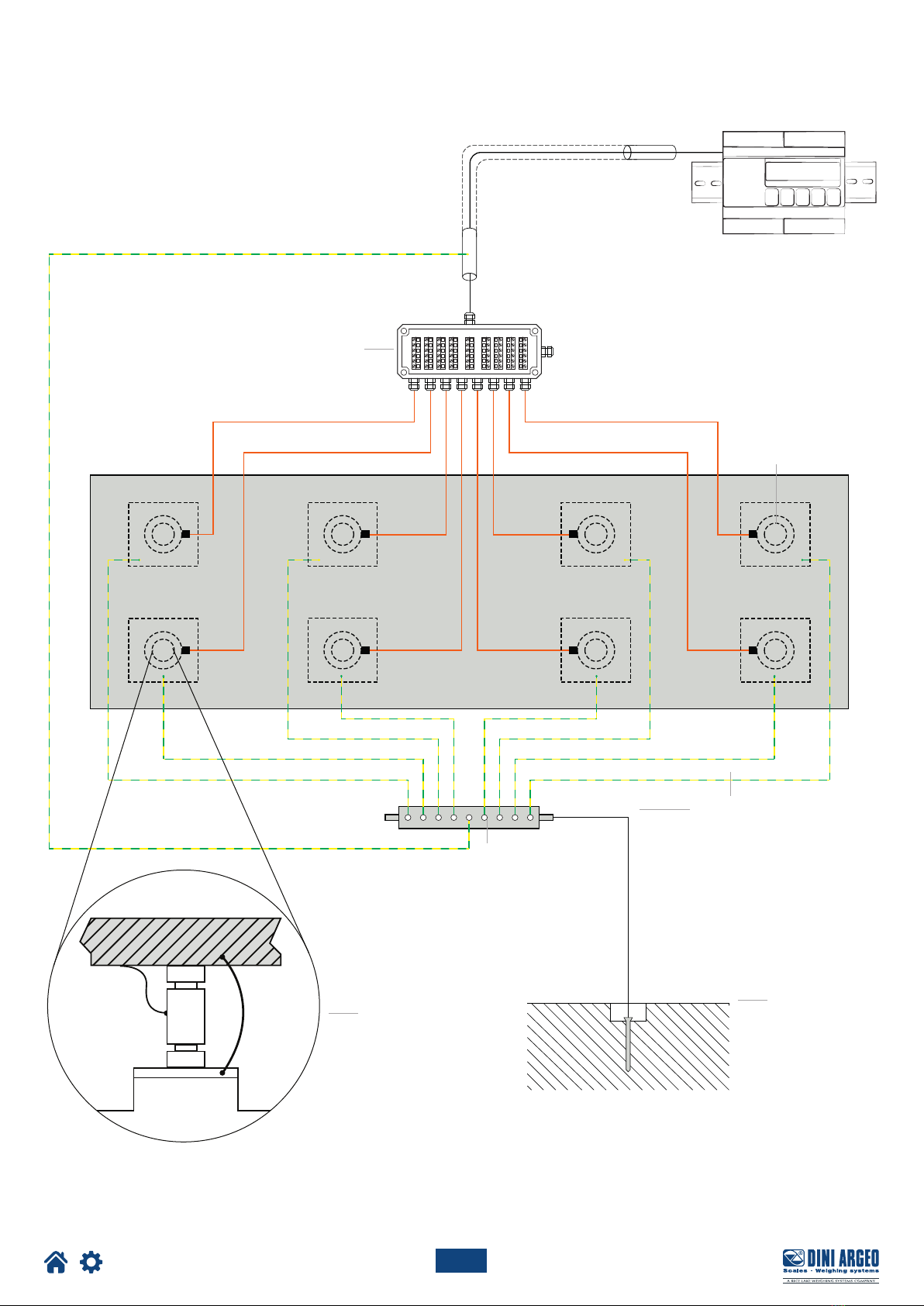

Earthing of the system

For correct earthing and optimal system operation, the load cells, junction box, if any, and weighing structure must be earthed.

LOAD CELLS AND JUNCTION BOX

The connection must be made by connecting the earth cables to the earth bar (cables that must have a cross-section of at least 16 mm2);

finally, connect the earth bar to the earth post with a cable having a cross-section of at least 50 mm2.

EXAMPLES:

• If the load cells are connected to the transmitter through a junction box, the cable shield from the transmitter and the cell cable shields

must be connected to the earth socket of the junction box (refer to the junction box manual) and the junction box must be earthed using

a copper cable with a cross-section of not less than 16 mm2.

• If the load cells are connected directly to the transmitter (without using the junction box), the cell cable shields must be connected to the

earthing point (or earth bar).

• If the weighing system involves large and/or outdoor structures (weighbridges, silos, etc.) and the distance between the junction box and

the weight transmitter is greater than 10 m, connect the cell cable shields to the earth socket in the junction box.

WEIGHING STRUCTURE

Earth the weighing structure and/or any unconnected structures (e.g. silos that release material onto the weighing structure) using cables

with a cross-section of not less than 16 mm2.

Also connect the upper part with the lower part of each cell by means of a copper braid with a cross-section not less than 16 mm2(refer

to the earthing examples on page 12 and page 13).

SERIAL CABLES AND CONNECTED INSTRUMENTS

Connect the serial cable shield to the earthing point (or earth bar) inside the panel. To avoid any undesired eects, the earth reference

ofthe connection cable, power supply and transmitter must be at the same potential.

GENERAL NOTES:

• All earth cables must be of suitable length, so as to obtain an overall resistance of the earthing system of less than 1 .

• If the weighing system involves large and/or outdoor structures (weighbridges, silos, etc.):

- the earth connection must be made by connecting the earth cables to an earth bar and the earth bar to the earth post

with a cable having a cross-section of not less than 50 mm2;

- the thickness of the cables must be greater (50 mm2instead of 16 mm2and 100 mm2instead of 50 mm2), because the

voltages at stake are greater (e.g. lightning);

- the earth post must be placed at a distance of at least 10 m from the structure.

• If the load receiver is more than 10 m from the transmitter, we recommend using the SENSE line and load cells equipped

with a (SENSE) compensation circuit.

12

Optimized layout for A4 print.

TECH_MAN_ENG_DGT4_V8

EXAMPLE OF EARTHING OF A WEIGHBRIDGE

Load cell bypass jumper

Weighbridge

Weight transmitter

Load cell

Earth cables

Ø 8 - sec. 50 mm2

Ø 11.3 - sec. 100 mm2

Earth post posi-

tioned under or

near the weigh-

bridge

Drilled copper plate positioned

on the side wall

Junction box placed on

the side wall of the pit

Weighbridge

14

Optimized layout for A4 print.

TECH_MAN_ENG_DGT4_V8

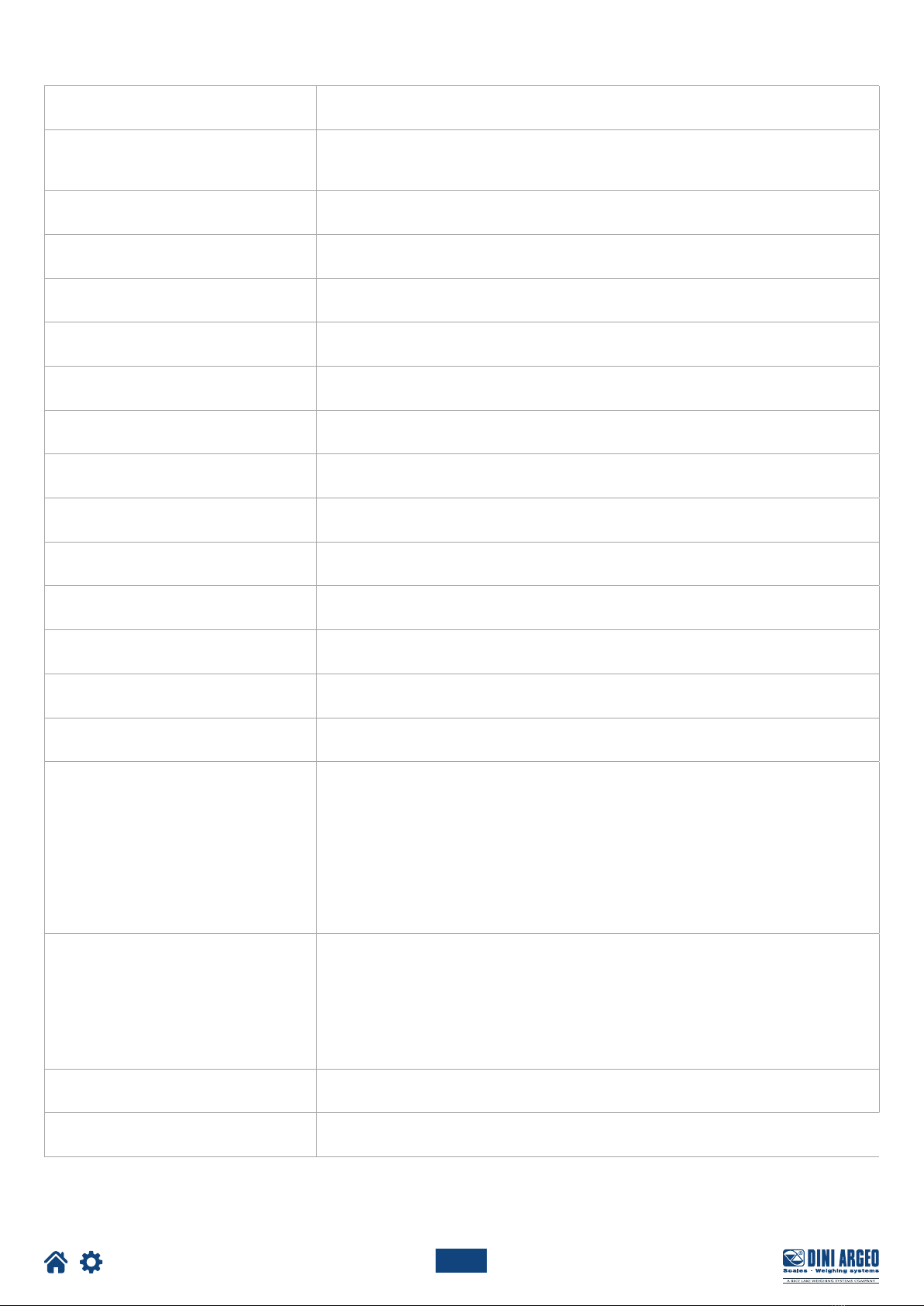

Technical features

POWER SUPPLY 12 - 24 Vdc LPS or with class 2 power supply.

MAXIMUM ABSORPTION

(without load cells)

DGT4: 100 mA at 12 V / 70 mA at 24 V (2 W);

DGT4AN: 185 mA at 12 V / 90 mA at 24 V (2.5 W);

DGT4 with fieldbus: 410 mA at 12 V; 220 mA at 24 V (5 W).

OPERATING TEMPERATURE From -15°C to +40°C.

DISPLAY DIVISIONS 10000e, 2 x 3000e for legal weighing, expandable up to 800,000 for internal use (with a

minimum cell signal of 1.6 mV/V).

SAMPLING SPEED Up to 400 conv. / sec.

MINIMUM VOLTAGE PER DIVISION 0.3 V (approved instrument); 0.03 V (non-approved instrument).

COUNTING RESOLUTION 1,500,000 points (with input signal 3 mV/V).

DISPLAY 6 digits, h 13 mm.

SIGNALS 6 status indicator LED lights.

KEYPAD 5 keys.

TARE FUNCTION Subtraction possible over the entire range.

LOAD CELL POWER SUPPLY 5 Vdc ± 5%, 120 mA (max 8 cells of 350 ).

LOAD CELL CONNECTION 6 wires (CELL1) with sense, 4 wires (CELLS 2, 3, 4).

CONNECTABLE CELLS Up to 8 350 cells.

CASE Made of plastic, suitable for DIN rail or wall mounting.

SERIAL OUTPUTS 1 RS485 bidirectional port;

1 configurable RS232 bidirectional port for connection to printer;

1 PROFIBUS port (DGT4PB* version);

2 ETHERNET ports (versions DGT4ETHIP*, DGT4MODTCP*, DGT4ETHCAT*, DGT4PR-

ONET*);

1 CANOPEN port (DGT4CANOP* version);

1 DEVICENET port (DGT4DEVNET* version).

* Fieldbus models are not equipped with port 485.

OUTPUTS / INPUTS 2 fotomosfet outputs NO or NC, configurable as programmable weight thresholds:

48 Vac 0.15 A max (or 60 Vdc 0.15 A max);

2 configurable inputs (optocouplers): 12 - 48 Vdc;

Input reading and output update time: 1 msec;

Opto-isolated analog output with 16 bits, optionally 4 - 20 mA, 0 - 5 Vdc or 0 - 10 Vdc (DG-

T4AN version). The maximum applicable resistance on the current output is 350 while

the minimum applicable resistance on the voltage output is 10 k.

LOAD CELL SENSITIVITY Maximum sensitivity of the connectable load cells: 6 mV/V.

FIELDBUS UPDATE RATES Up to 16 Hz.

15

Optimized layout for A4 print.

34

SIG-

33

SIG+

32

EXC-

31

EXC+

30

EXC-

29

SIG+

28

SIG-

27

EXC+

26

EXC+

25

SIG+

24 23 22 21 20 19

CELL1CELL2CELL4 CELL3

35

EXC- SIG- EXC+

EXC- SIG+

SIG-SEN- SEN+

18

+24Vdc GND

3

COM

4

IN1

5

IN2

6

RL1

7

RL2

8

COM

15

TX RX

16 17

GND

POWER INPUT RELAYS RS232

1 2

FIELDBUS

34

SIG-

33

SIG+

32

EXC-

31

EXC+

30

EXC-

29

SIG+

28

SIG-

27

EXC+

26

EXC+

25

SIG+

24 23 22 21 20 19

CELL1CELL2CELL4 CELL3

35

EXC- SIG- EXC+

EXC- SIG+

SIG-SEN- SEN+

18

+24Vdc GND

3

COM

4

IN1

5

IN2

6

RL1

7

RL2

8

COM

15

TX RX

16 17

GND

POWER INPUT RELAYS RS232

1 2

FIELDBUS

34

SIG-

33

SIG+

32

EXC-

31

EXC+

30

EXC-

29

SIG+

28

SIG-

27

EXC+

26

EXC+

25

SIG+

24 23 22 21 20 19

CELL1CELL2CELL4 CELL3

35

EXC- SIG- EXC+

EXC- SIG+

SIG-SEN- SEN+

18

34

SIG-

33

SIG+

32

EXC-

31

EXC+

30

EXC-

29

SIG+

28

SIG-

27

EXC+

26

EXC+

25

SIG+

24 23 22 21 20 19

CELL1CELL2CELL4 CELL3

35

EXC- SIG- EXC+

EXC- SIG+

SIG-SEN- SEN+

18

+24Vdc GND

3

COM

4

IN1

5

IN2

6

RL1

7

RL2

8

COM

15

TX RX

16 17

GND

POWER INPUT RELAYS RS232

1 2

FIELDBUS

34

SIG-

33

SIG+

32

EXC-

31

EXC+

30

EXC-

29

SIG+

28

SIG-

27

EXC+

26

EXC+

25

SIG+

24 23 22 21 20 19

CELL1CELL2CELL4 CELL3

35

EXC- SIG- EXC+

EXC- SIG+

SIG-SEN- SEN+

18

+24Vdc GND

3

COM

4

IN1

5

IN2

6

RL1

7

RL2

8

COM

15

TX RX

16 17

GND

POWER INPUT RELAYS RS232

1 2

FIELDBUS

34

SIG-

33

SIG+

32

EXC-

31

EXC+

30

EXC-

29

SIG+

28

SIG-

27

EXC+

26

EXC+

25

SIG+

24 23 22 21 20 19

CELL1CELL2CELL4 CELL3

35

EXC- SIG- EXC+

EXC- SIG+

SIG-SEN- SEN+

18

+24Vdc GND

3

COM

4

IN1

5

IN2

6

RL1

7

RL2

8

COM

15

TX RX

16 17

GND

POWER INPUT RELAYS RS232

1 2

FIELDBUS

34

SIG-

33

SIG+

32

EXC-

31

EXC+

30

EXC-

29

SIG+

28

SIG-

27

EXC+

26

EXC+

25

SIG+

24 23 22 21 20 19

CELL1CELL2CELL4 CELL3

35

EXC- SIG- EXC+

EXC- SIG+

SIG-SEN- SEN+

18

34

SIG-

33

SIG+

32

EXC-

31

EXC+

30

EXC-

29

SIG+

28

SIG-

27

EXC+

26

EXC+

25

SIG+

24 23 22 21 20 19

CELL1CELL2CELL4 CELL3

35

EXC- SIG- EXC+

EXC- SIG+

SIG-SEN- SEN+

18

+24Vdc GND

3

COM

4

IN1

5

IN2

6

RL1

7

RL2

8

COM

15

TX RX

16 17

GND

POWER INPUT RELAYS RS232

1 2

FIELDBUS

34

SIG-

33

SIG+

32

EXC-

31

EXC+

30

EXC-

29

SIG+

28

SIG-

27

EXC+

26

EXC+

25

SIG+

24 23 22 21 20 19

CELL1CELL2CELL4 CELL3

35

EXC- SIG- EXC+

EXC- SIG+

SIG-SEN- SEN+

18

+24Vdc GND

3

COM

4

IN1

5

IN2

6

RL1

7

RL2

8

COM

15

TX RX

16 17

GND

POWER INPUT RELAYS RS232

1 2

FIELDBUS

34

SIG-

33

SIG+

32

EXC-

31

EXC+

30

EXC-

29

SIG+

28

SIG-

27

EXC+

26

EXC+

25

SIG+

24 23 22 21 20 19

CELL1CELL2CELL4 CELL3

35

EXC- SIG- EXC+

EXC- SIG+

SIG-SEN- SEN+

18

+24Vdc GND

3

COM

4

IN1

5

IN2

6

RL1

7

RL2

8

COM

15

TX RX

16 17

GND

POWER INPUT RELAYS RS232

1 2

FIELDBUS

34

SIG-

33

SIG+

32

EXC-

31

EXC+

30

EXC-

29

SIG+

28

SIG-

27

EXC+

26

EXC+

25

SIG+

24 23 22 21 20 19

CELL1CELL2CELL4 CELL3

35

EXC- SIG- EXC+

EXC- SIG+

SIG-SEN- SEN+

18

34

SIG-

33

SIG+

32

EXC-

31

EXC+

30

EXC-

29

SIG+

28

SIG-

27

EXC+

26

EXC+

25

SIG+

24 23 22 21 20 19

CELL1CELL2CELL4 CELL3

35

EXC- SIG- EXC+

EXC- SIG+

SIG-SEN- SEN+

18

+24Vdc GND

3

COM

4

IN1

5

IN2

6

RL1

7

RL2

8

COM

15

TX RX

16 17

GND

POWER INPUT RELAYS RS232

1 2

FIELDBUS

34

SIG-

33

SIG+

32

EXC-

31

EXC+

30

EXC-

29

SIG+

28

SIG-

27

EXC+

26

EXC+

25

SIG+

24 23 22 21 20 19

CELL1CELL2CELL4 CELL3

35

EXC- SIG- EXC+

EXC- SIG+

SIG-SEN- SEN+

18

+24Vdc GND

3

COM

4

IN1

5

IN2

6

RL1

7

RL2

8

COM

15

TX RX

16 17

GND

POWER INPUT RELAYS RS232

1 2

FIELDBUS

34

SIG-

33

SIG+

32

EXC-

31

EXC+

30

EXC-

29

SIG+

28

SIG-

27

EXC+

26

EXC+

25

SIG+

24 23 22 21 20 19

CELL1CELL2CELL4 CELL3

35

EXC- SIG- EXC+

EXC- SIG+

SIG-SEN- SEN+

18

+24Vdc GND

3

COM

4

IN1

5

IN2

6

RL1

7

RL2

8

COM

15

TX RX

16 17

GND

POWER INPUT RELAYS RS232

1 2

FIELDBUS

34

SIG-

33

SIG+

32

EXC-

31

EXC+

30

EXC-

29

SIG+

28

SIG-

27

EXC+

26

EXC+

25

SIG+

24 23 22 21 20 19

CELL1CELL2CELL4 CELL3

35

EXC- SIG- EXC+

EXC- SIG+

SIG-SEN- SEN+

18

34

SIG-

33

SIG+

32

EXC-

31

EXC+

30

EXC-

29

SIG+

28

SIG-

27

EXC+

26

EXC+

25

SIG+

24 23 22 21 20 19

CELL1CELL2CELL4 CELL3

35

EXC- SIG- EXC+

EXC- SIG+

SIG-SEN- SEN+

18

+24Vdc GND

3

COM

4

IN1

5

IN2

6

RL1

7

RL2

8

COM

15

TX RX

16 17

GND

POWER INPUT RELAYS RS232

1 2

FIELDBUS

TECH_MAN_ENG_DGT4_V8

Load cell installation

After carrying out the instructions for the platform or load receiver, the shielded cable from the cell(s) must be properly connected to the

terminal block(s) of the transmitter (from CELL1 to CELL4; see section “Wiring diagrams”).

The transmitter has one channel (CELL1) for 6-wire connection to load cells (using the SENSE), while for the remaining channels (CELL2,

CELL3, CELL4) only 4-wire connection is allowed.

The SENSE allows you to compensate for any voltage drop on the section of cable connecting the transmitter to the load receiver.

It is especially useful when the distance between the transmitter and the load receiver is more than 10 metres.

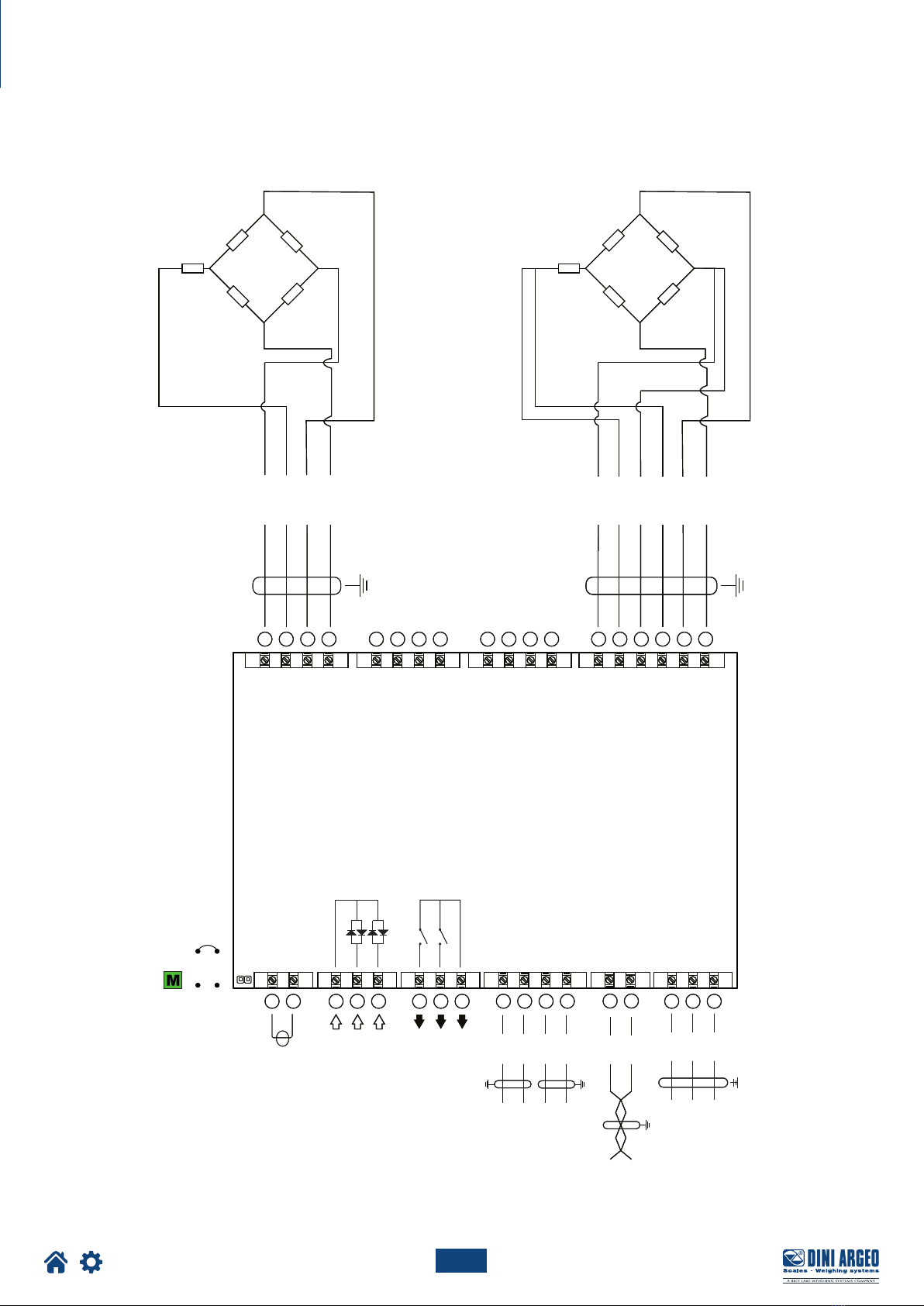

4-WIRE CONNECTION

CELL2 / CELL3 / CELL4

6-WIRE CONNECTION

CELL2 / CELL3 / CELL4

6-WIRE CONNECTION

CELL1

4-WIRE CONNECTION

CELL1

16

Optimized layout for A4 print.

LOAD CELL 1

IN 2

IN 1

COM

COM

RL2

RL1

12 / 24 Vdc

15 16 176 7 83 4 51 2

33 3235 34 29 2831 30 25 2427 26 21 2023 22 19 18

E +

E -

+

+

-

-

S+ S-

SIG +

SIG -

REF +

REF -

EXC +

EXC -

LOAD CELL 2, 3, 4

LOAD CELL 4 LOAD CELL 3 LOAD CELL 2 LOAD CELL 1

E +

E -

+

+

-

-

S+ S-

SIG +

SIG -

EXC +

EXC -

GND

RX

TX

RS232

11 12 13 149 10

RS485

B(-)

A(+)

J1

+

-

TECH_MAN_ENG_DGT4_V8

Wiring diagrams

DGT4

Internal use

17

Optimized layout for A4 print.

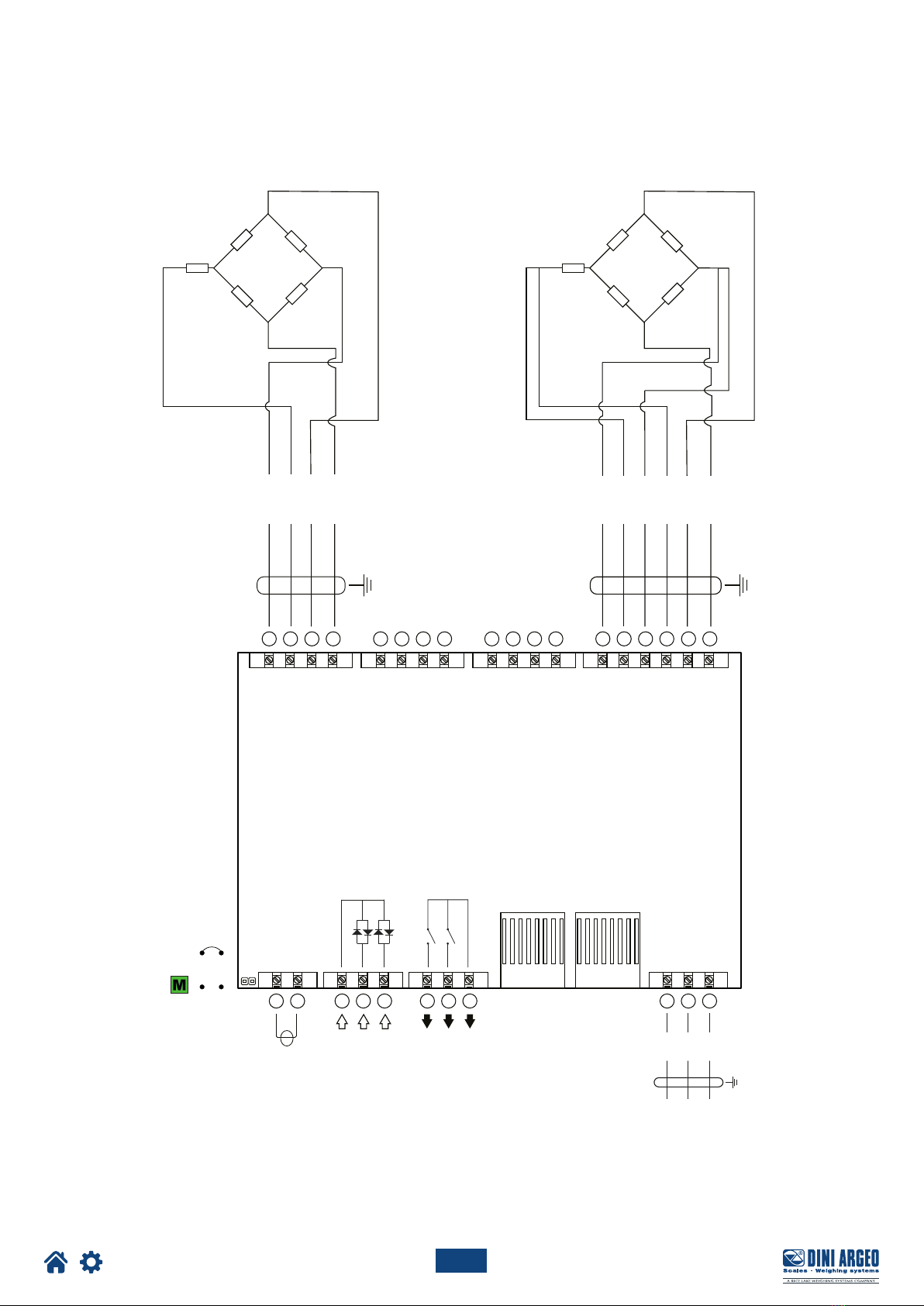

LOAD CELL 1

IN 2

IN 1

COM

COM

RL2

RL1

12 / 24 Vdc

15 16 176 7 83 4 51 2

33 3235 34 29 2831 30 25 2427 26 21 2023 22 19 18

E +

E -

+

+

-

-

S+ S-

SIG +

SIG -

REF +

REF -

EXC +

EXC -

LOAD CELL 2, 3, 4

LOAD CELL 4 LOAD CELL 3 LOAD CELL 2 LOAD CELL 1

E +

E -

+

+

-

-

S+ S-

SIG +

SIG -

EXC +

EXC -

GND

RX

TX

RS232

13 14

RS485

B(-)

A(+)

11 129 10

ANALOG

V-

V+

I-

I+

J1

+

-

TECH_MAN_ENG_DGT4_V8

LOAD CELL 1

IN 2

IN 1

COM

COM

RL2

RL1

12 / 24 Vdc

15 16 176 7 83 4 51 2

33 3235 34 29 2831 30 25 2427 26 21 2023 22 19 18

E +

E -

+

+

-

-

S+ S-

SIG +

SIG -

REF +

REF -

EXC +

EXC -

LOAD CELL 2, 3, 4

LOAD CELL 4 LOAD CELL 3 LOAD CELL 2 LOAD CELL 1

E +

E -

+

+

-

-

S+ S-

SIG +

SIG -

EXC +

EXC -

GND

RX

TX

RS232

13 14

RS485

B(-)

A(+)

11 129 10

ANALOG

V-

V+

I-

I+

J1

+

-

Internal use

DGT4AN

18

Optimized layout for A4 print.

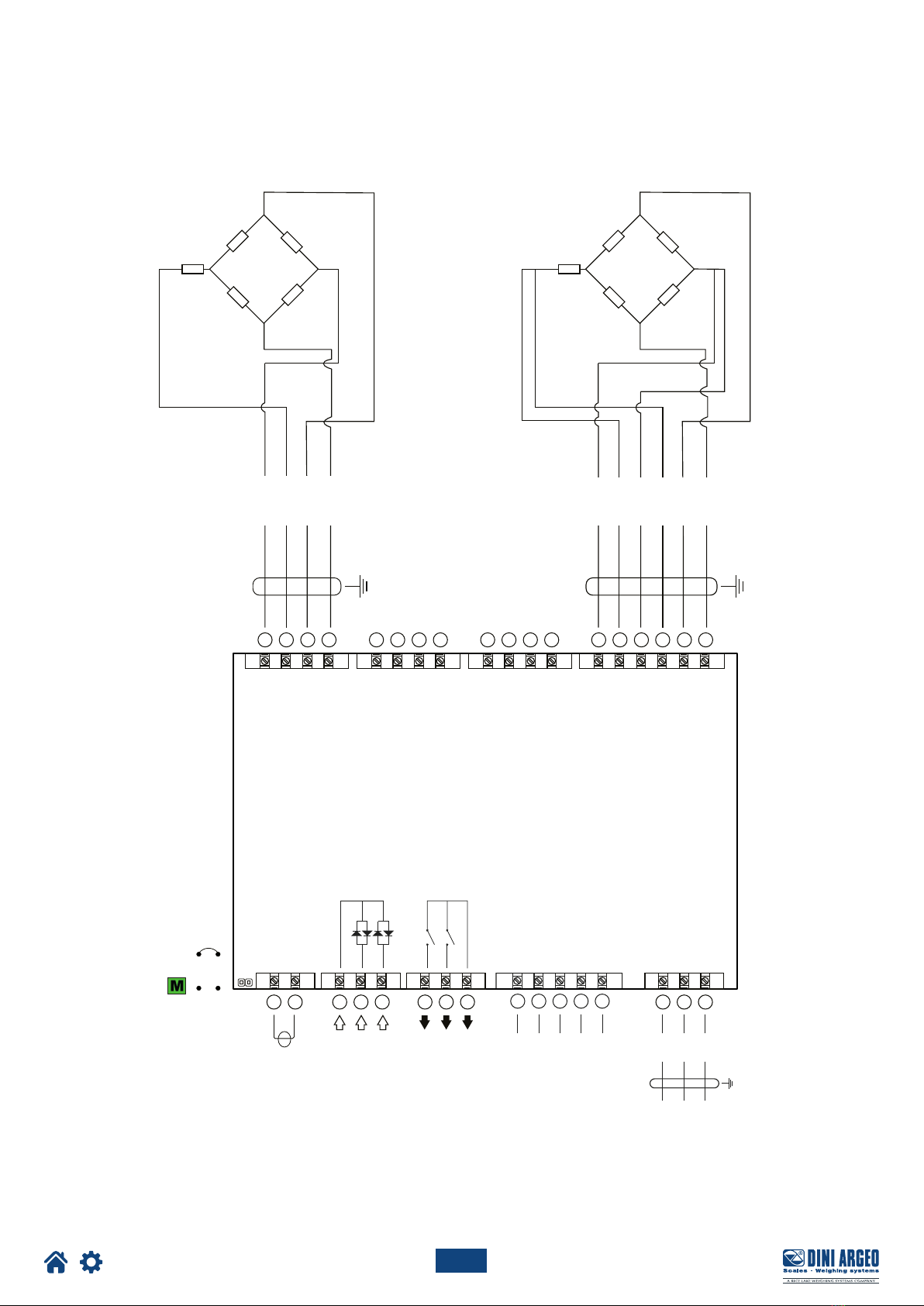

LOAD CELL 1

IN 2

IN 1

COM

COM

RL2

RL1

12 / 24 Vdc

15 16 176 7 83 4 51 2

33 3235 34 29 2831 30 25 2427 26 21 2023 22 19 18

E +

E -

+

+

-

-

S+ S-

SIG +

SIG -

REF +

REF -

EXC +

EXC -

LOAD CELL 2, 3, 4

LOAD CELL 4 LOAD CELL 3 LOAD CELL 2 LOAD CELL 1

E +

E -

+

+

-

-

S+ S-

SIG +

SIG -

EXC +

EXC -

PROFIBUS

PORT

GND

RX

TX

RS232

J1

+

-

TECH_MAN_ENG_DGT4_V8

DGT4PB

Internal use

19

Optimized layout for A4 print.

LOAD CELL 1

+

-

IN 2

IN 1

COM

COM

RL2

RL1

12 / 24 Vdc

15 16 176 7 83 4 51 2

33 3235 34 29 2831 30 25 2427 26 21 2023 22 19 18

E +

E -

+

+

-

-

S+ S-

SIG +

SIG -

REF +

REF -

EXC +

EXC -

LOAD CELL 2, 3, 4

LOAD CELL 4 LOAD CELL 3 LOAD CELL 2 LOAD CELL 1

E +

E -

+

+

-

-

S+ S-

SIG +

SIG -

EXC +

EXC -

ETHERNET I/O PORT 1

ETHERNET I/O PORT 2

GND

RX

TX

RS232

J1

TECH_MAN_ENG_DGT4_V8

DGT4ETHIP, DGT4ETHCAT, DGT4PRONET, DGT4MODTCP

Internal use

20

Optimized layout for A4 print.

EDCBA

NC

CANL

NC

CANH

GND

LOAD CELL 1

IN 2

IN 1

COM

COM

RL2

RL1

12 / 24 Vdc

15 16 176 7 83 4 51 2

33 3235 34 29 2831 30 25 2427 26 21 2023 22 19 18

E +

E -

+

+

-

-

S+ S-

SIG +

SIG -

REF +

REF -

EXC +

EXC -

LOAD CELL 2, 3, 4

LOAD CELL 4 LOAD CELL 3 LOAD CELL 2 LOAD CELL 1

E +

E -

+

+

-

-

S+ S-

SIG +

SIG -

EXC +

EXC -

GND

RX

TX

RS232

J1

+

-

TECH_MAN_ENG_DGT4_V8

DGT4CANOP

Internal use

Other manuals for DGT4

1

Table of contents

Other Dini Argeo Transmitter manuals

Dini Argeo

Dini Argeo DGT4X User manual

Dini Argeo

Dini Argeo DGT1SX User manual

Dini Argeo

Dini Argeo DGT1S User manual

Dini Argeo

Dini Argeo DGT4X User manual

Dini Argeo

Dini Argeo DGT4XAN User manual

Dini Argeo

Dini Argeo DGT1SP User manual

Dini Argeo

Dini Argeo DGT1P User manual

Dini Argeo

Dini Argeo DGT1S User manual

Popular Transmitter manuals by other brands

Velleman

Velleman AVMOD17 quick guide

Zamel

Zamel RTN-01 Manual instruction

Dräger

Dräger Polytron 3000 Instructions for use

Magnetrol

Magnetrol Pulsar R86 manual

DB Elettronica Telecomunicazioni

DB Elettronica Telecomunicazioni CTX 5 user manual

Absolute Process Instruments

Absolute Process Instruments APD 1401 quick start guide