Dini Argeo DGT4X User manual

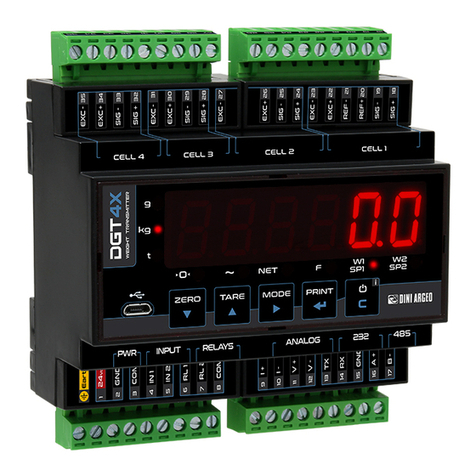

DGT4X

www.diniargeo.com

QUICK START GUIDE V1 ENGLISH

Digital weight Transmitter with 4 channels

2

LOAD CELL 1

+-

IN 2

IN 1

COM

COM

RL2

RL1

12 / 24 Vdc

6 7 83 4 51 2

33 3235 34 29 2831 30 25 2427 26 21 2023 22 19 18

E +

E -

+

+

-

-

S+ S-

SIG +

SIG -

REF +

REF -

EXC +

EXC -

LOAD CELL 2, 3, 4

LOAD CELL 4 LOAD CELL 3 LOAD CELL 2 LOAD CELL 1

E +

E -

+

+

-

-

S+

REF -

REF +

S-

SIG +

SIG -

EXC +

EXC -

11 12 16 179 10

RS485

B(-)

A(+)

J1

13 14 15

GND

RX

TX

RS232

JUMPER J1

QSG_ENG_DGT4X

1. Electrical scheme

Internal use

INPUT:

12÷48 Vdc,

OUTPUT:

48Vac or 60Vdc,

0,5 A max

CONSUMPTION:

4,5 W max.

For UL approved

models: equipment

to be powered by

12-24 Vdc LPS

or Class 2 power

source.

Load cells exitation: 5 V.

Load cells output: 6 mV/V max.

There’s a single SENSE circuit that

compensate all 4 load cells.

In LOAD CELL 2, 3, 4 connect:

SEN + to EXC +

SEN - to EXC -

3

CELL 4 CELL 3 CELL 2 CELL 1

PWR INPUT 485RELAYS ANALOG232

g

kg

lb

NET

0~

FW1

SP1 W2

SP2

35

EXC -

EXC +34

SIG - 29

SIG + 28

SIG - 25

SIG + 24

EXC - 23

REF -

21

REF 20

SIG - 19

SIG + 18

26

EXC +

22

EXC +

+

EXC +30

EXC -

31

SIG + 32

SIG - 33

EXC -27

24Vdc

Earth

1

RL 1

6

RL 2

7

5

IN 1

4

COM

3

2

COM

8

GND

IN 2

I -

10

I +

9

GND

15

A +

16

14

TX

13

V -

12

11

B -

17

V +

RX

ZERO TARE MODE PRINT

g

kg

lb

NET

0

~

FW1

SP1 W2

SP2

QSG_ENG_DGT4X

2. Key function in configuration menu and in weighing mode

Configuration menu

Decreases digit / Scroll down.

Increases digit / Scroll up.

Enter the setup.

Selects digit to modify.

Enters a step / Confirms.

Clears / Exits a step (no save).

Weighing mode

Clears the displayed gross weight.

With short pressing: executes semiautomatic tare.

With long pressing: allows to enter known tare.

With long pressing: allows to switch between scales

(only in Mode 2 “ind.Ch”).

With short pressing: execute a data transmission on

the printer serial port.

With long pressing: Setpoint configuration.

ON/Standby of the instrument.

0

Weight on zero.

~

Unstable weight.

NET

A tare is active.

F

A function is active.

W1

SP1

Digital output 1 is active.

W2

SP2

Digital output 2 is active.

3. Indicator lights meaning

4

1

3

5

7

9

2

4

6

8

10

11

12

13 1

2

1

2

14

15

16

17

div.deC

TYPE

Cel.sen

span

i n P. 0 2

i n P. 0 1

oP

Cel.Cap

Chan

dead.ld

zero

0.Calib

adC.v

inPs

o . 0 1

o . 0 2

888888

CapaC

nChan

485

exCl.Ch

CloCk

QSG_ENG_DGT4X

4. Configuration menu

1. Reboot the weight transmitter

2. Press the key when display shows the 888888 message:

Theoretical calibration (ch. 7).

Zeroing of the deal load (pre-tare zeroing) (ch. 8).

Load cell exclusion (ch. 14).

Date and time setting (with optional card only).

RS485 port configuration (ch. 13).

Digital input configuration (ch. 11).

Digital output configuration (ch. 12).

HOW TO EXIT THE MENU AND STORE YOUR CONFIGURATION

1. Press key many times until save? message will appear; press to store or press to exit without storing.

Functioning mode (ch. 5).

Scale configuration: capacity, resolution and decimal point (ch. 6).

Calibration with sample weight (ch. 9).

Load cells diagnostic (ch. 10).

5

1 1

2

2

3

TYPE

888888

CELL 4 CELL 3 CELL 2 CELL 1

PWR INPUT 485RELAYS ANALOG232

g

kg

lb

NET

0

~

FW1

SP1 W2

SP2

35

EXC -

EXC+34

SIG - 29

SIG + 28

SIG - 25

SIG + 24

EXC - 23

REF -

21

REF 20

SIG - 19

SIG + 18

26

EXC+

22

EXC+

+

EXC+30

EXC -

31

SIG + 32

SIG - 33

EXC -27

24Vdc

Earth

1

RL 1

6

RL 2

7

5

IN 1

4

COM

3

2

COM

8

GND

IN 2

I -

10

I +

9

GND

15

A +

16

14

TX

13

V -

12

11

B -

17

V +

RX

ZERO TARE MODE PRINT

g

kg

lb

NET

0

~

FW1

SP1 W2

SP2

dep.Ch

Type

nChan

Chan

ind.Ch

n.Chan

CHAN

= dep.Ch

= 2÷ 4

Type

Chan

n.Chan

= ind.Ch

= 1÷ 4

= 1÷ 4

CELL 4 CELL 3 CELL 2 CELL 1

PWR INPUT 485RELAYS ANALOG232

g

kg

lb

NET

0

~

FW1

SP1 W2

SP2

35

EXC -

EXC+34

SIG -

29

SIG +

28

SIG -

25

SIG +

24

EXC -

23

REF -

21

REF

20

SIG - 19

SIG + 18

26

EXC+

22

EXC+

+

EXC+30

EXC -

31

SIG +

32

SIG -

33

EXC -

27

24Vdc

Earth

1

RL 1

6

RL 2

7

5

IN 1

4

COM

3

2

COM

8

GND

IN 2

I -

10

I +

9

GND

15

A +

16

14

TX

13

V -

12

11

B -

17

V +

RX

ZERO TARE MODE PRINT

g

kg

lb

NET

0

~

FW1

SP1 W2

SP2

QSG_ENG_DGT4X

5. Functioning mode

Digital equalisation box mode.

Multi-scale mode.

Set the number of active channels.

Select the channel to be programmed (for ind,Ch mode only).

MODE 1 “DEP.CH”

MODE 2 “IND.CH”

Allows to connect directly the load cells, equalize them (if necessary) and transmit each load cell data and the total weight through Fieldbus.

Allows to manage up to 4 indipendent scales and transmit all data of each scale through Fieldbus.

not visible

Load cell 1

Scale 1

Load cell 3

Scale 3

Load cell 2

Scale 2

Load cell 4

Scale 4

6

6

7

8

888888

888888 div.deC

div.deC

...

Cel.Cap

div.deC

Cel.sen

dead.ld

CELL4 CELL 3 CELL2 CELL1

PWR INPUT 485RELAYS ANALOG232

g

kg

lb

NET

0

~

FW1

SP1 W2

SP2

35

EXC-

EXC+34

SIG- 29

SIG+ 28

SIG- 25

SIG+ 24

EXC- 23

REF-

21

REF 20

SIG- 19

SIG+ 18

26

EXC+

22

EXC+

+

EXC+30

EXC-

31

SIG+ 32

SIG- 33

EXC-27

24Vdc

Earth

1

RL1

6

RL2

7

5

IN1

4

COM

3

2

COM

8

GND

IN2

I-

10

I+

9

GND

15

A+

16

14

TX

13

V-

12

11

B-

17

V+

RX

ZERO TARE MODE PRINT

g

kg

lb

NET

0

~FW1

SP1 W2

SP2

CELL4 CELL 3 CELL2 CELL1

PWR INPUT 485RELAYS ANALOG232

g

kg

lb

NET

0

~

FW1

SP1 W2

SP2

35

EXC-

EXC+

34

SIG-

29

SIG+

28

SIG-

25

SIG+

24

EXC-

23

REF-

21

REF

20

SIG- 19

SIG+ 18

26

EXC+

22

EXC+

+

EXC+

30

EXC-

31

SIG+

32

SIG-

33

EXC-

27

24Vdc

Earth

1

RL1

6

RL2

7

5

IN1

4

COM

3

2

COM

8

GND

IN2

I-

10

I+

9

GND

15

A+

16

14

TX

13

V-

12

11

B-

17

V+

RX

ZERO TARE MODE PRINT

g

kg

lb

NET

0

~FW1

SP1 W2

SP2

6

7

div.deC

...

div.deC

div.deC

CapaC

QSG_ENG_DGT4X

Complete menu

at page 4

6. Maximum scale capacity, increment and decimal point setting

Set the decimal point position and the minimum scale increment*1

( 0,001 - 0,002 - 0,005 - 0,01 - 0,02 - 0,05 - 0,1 - 0,2 - 0,5 - 1- 2- 5- 10 - 20 - 50 ).

Set the maximum scale capacity*2(max 999999 ).

Examples:

7. Theoretical calibration

Set the total load cells capacity (up to 999999).

Set the load cells sensitivity (up to 999999).

(mV/V cell1) + (mV/V cell2) + (mV/V cell3) + (mV/V cell4)

(mV/V cell1) + (mV/V cell2) + ... + (mV/V celln)

n

Insert in Cel.sen parameter, the load cells sensitivity

sum value:

For each scale to calibrate, insert in Cel.sen parameter the

average sensitivity value of the load cells:

Dead load weight (from -9999.9 to 99999.9).

*1Increment = the amount that the scale will increment by as weight is added or removed.

*2Maximum capacity = the maximum weight that can be measured using the scale you are creating.

1. Set div.deC and CapaC

(ch. 4).

2. Set in Cel.Cap the total load cells

capacity (sum of the nominal load cell

capacities).

3. Set in Cel.sen the theoretical signal

value of the load cells.

4. Enter in dead.ld step. The display

shows the theoretical dead load

value. Modify the value and/or confirm

with .

5. Save calibration (Press key many

times until save? message will

appear, then press to confirm).

For a 60000 kg scale, with 2 kg

increment:

div.deC = 2

CapaC = 60000

For a 10000 g scale, with 0,1 g increment:

div.deC = 0,1

CapaC = 10000,0

For a 3000 kg scale, with 0,05 kg

increment:

div.deC = 0,05

CapaC = 3000,00

MODE 1 “DEP.CH” MODE 2 “IND.CH”

7

12

11

10

9

888888

888888

888888

i

div.deC

div.deC

...

0.Calib

div.deC

div.deC

...

zero

Span

div.deC

...

adC.v

QSG_ENG_DGT4X

Complete menu

at page 4

8. Zeroing of the mechanic tare (pre-tare zeroing)

Zeroing of the pre-tare (or mechanical tare).

This functionality allows to zero the weigh of the scale structure (e.g. empty silo, conveyor, etc.) without changing the calibration in

memory.

9. Calibration with sample weight

Zero point acquisition.

1. Unload the scale. 2. Enter the zero step to adjust the

zero point.

5. Save adjustment (Press key

many times until save? message will

appear, then press to confirm).

Sample weight acquisition.

3. Load the scale with span weight.

4. Enter the span step, type the span

weight value and press to adjust.

10. Diagnostic of the load cell V/V

It allows to verify signal of each channel. It must be included into the range 0 to 3 mV/V.

Signal have to be stable and it have to increase by increasing the weight on the scale.

With more channels connected, it’s possible to scroll between channels with keys and .

8

13 1

2 1

4

2

5

3

6

7

8

888888

C

none

are

mode

off

zero

prin

dis.key

div.deC

...

inps div.deCinp.01

inp.02

14 1

2 1

2 1

2

3

s.1 on

s.2 on

888888 div.deC

...

oUTPUT

no/nC

0 none

fnC

1 Gros

2 ne

div.deCo.01

o.02

QSG_ENG_DGT4X

Complete menu

at page 4

11. Input setting

See INP.02

Input disabled.

When input is active, transmitter keyboard is locked.

When input is active, transmitter reboots.

Emulation of key.

Emulation of key.

Emulation of key.

Emulation of key.

Emulation of key.

12. Output setting

See o.02.

Setpoint on gross weight.

Setpoint on net weight.

Output disabled.

Normally open / normally close.

12.1 HOW TO PROGRAM SETPOINTS

1. In weighing mode, press

for 3 second.

2. Select the setpoint to modify:

Set the output 1

setpoint value.

Set the output 2

setpoint value.

3. Press key to store and exit

the menu.

Please refer to the complete technical manual for more information.

9

15 1

2

888888 div.deC

...

485 div.deCse.add

bad

i

16 1

2

3

4

5

888888 div.deC

...

exCl.Ch div.deCnone

Ch 1

Ch 2

Ch 3

Ch 4

QSG_ENG_DGT4X

Complete menu

at page 4

13. RS485 port

485 address (01 ÷ 98).

Baud rate (1200, 2400, 4800, 9600, 19200, 38400, 57600, 115200).

The RS485 port is configured by default to communicate in Modbus RTU (ch. 18).

14. Broken laod cell exclusion (for dependent channels systems)

No channel excluded.

Channel 1 excluded.

Channel 2 excluded.

Channel 3 excluded.

Channel 4 excluded.

If a load cell is broken, it’s possible to temporarely exclude the channel where it is connected and continue to weigh, pending

replacement.

WARNING: this operation reduces the accuracy of the weighing system. We recommend use for liquid weighing or in applications

where the load is evenly distributed.

Visible only in DEP.Ch mode.

10

QSG_ENG_DGT4X

15. Programming errors

MESSAGE DESCRIPTION SOLUTION

preC. Calibration error First calibrate the zero point (zero), then proceed with the

sample weight acquisition (span) (ch. 9).

Err.pn Calibration error

Check the connection of the load cell. Check that the cell

signal is stable, valid and greater than that of the previously

acquired point.

Er 11 Calibration error Increase the calibration weight.

Er 12 Calibration error Check that the signal coming from the cell increases upon the

increasing of the weight loaded on the scale.

Er 37 Calibration error Repeat the calibration, checking that the capacity

and division have been correctly set.

Er 39 Instrument not configured Transmitter needs to be configurated.

C.e r. 36 Calibration error Check that the signal coming from the load cell is not negative.

C.e r. 37 Calibration error Check that the signal coming from the load cell is not negative.

Err.mo Weight unstable

Check in adC.v parameter that the signal is stable.

If the connection of the cells is with 4 wires, check that the sense

jumpers are inserted.

adC.err A/D converter error Converter failure. Reboot the instrument.

Cel.err Global load cell error Signal anomaly: check the load cells connection.

Er.Cel.1

...

Er.Cel.4

Load cell error Signal anomaly: check the indicated load cell connection.

11

QSG_ENG_DGT4X

Data Register DESCRIPTION

Gross weight

30001

Gross Weight value.

30002

Net weight

30003

Net Weight value.

30004

Input status

register

30005

Bit 15

(msb)

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8 (lsb)

Active channel.

Active channel.

No function.

No function.

No function.

No function.

Status of input n. 2.

Status of input n. 1.

Bit 7(msb)

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0 (lsb)

1 = Scale unloaded (gross weight = 0).

Tare PT (1 = PT tare is active).

Tare (1 = Tare is active).

Overload condition (0 = No; 1 = Overload).

Underload condition (0 = No; 1 = Underload).

Weight Stability (0 = Unstable; 1 = Stable).

Gross Weight Polarity (0 = “+”; 1 = “-”).

Net Weight Polarity (0 = “+”; 1 = “-”).

Command status

register

30006

Last received command.

Bit 7(msb)

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0 (lsb)

Last command result.

Last command result.

Last command result.

Last command result.

Counting of processed commands.

Counting of processed commands.

Counting of processed commands.

Counting of processed commands.

Output status

register

30007

No Function.

Bit 7(msb)

...

Bit 2

Bit 1

Bit 0(lsb)

No function.

...

No function.

Digital output 2 status (0 = OFF; 1 = ON).

Digital output 1 status (0 = OFF; 1 = ON).

µV Channel 1

30111 µV value of the channel 1.

µV Channel 2

30112 µV value of the channel 2.

µV Channel 3

30113 µV value of the channel 3.

µV Channel 4

30114 µV value of the channel 4.

Bit 15

Bit 14

Active Channel

0 0 Channel 1

0 1 Channel 2

1 0 Channel 3

1 1 Channel 4

16. Modbus

16.1 MODBUS REGISTERS dep.CH /ind.ch (1 SCALE)

This manual contains the main registers for reading data / sending commands.

Refer to the Modbus protocol manual for the complete list of available registers.

12

QSG_ENG_DGT4X

Data Register DESCRIPTION

Status register

scale 1

40202

Bit 15

(msb)

...

Bit 8 (lsb)

No function.

Bit 7(msb)

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0 (lsb)

Tare PT (1 = PT tare is active).

Tare (1 = Tare is active).

Net Weight Polarity (0 = “+”; 1 = “-”).

1 = Scale unloaded (gross weight = 0).

Overload condition (0 = No; 1 = overload).

Underload condition (0 = No; 1 = underload).

Stability (0 = “unstable”; 1 = “stable”).

Gross Weight Polarity (0 = “+”; 1= “-”).

Gross weight

scale 1

40203

Gross Weight of scale 1.

40204

Status register

scale 2

40205 Same as Status register scale 1.

Gross weight

scale 2

40206

Gross Weight of scale 2.

40207

Status register

scale 3

40208 Same as Status register scale 1.

Gross weight

scale 3

40209

Gross Weight of scale 3.

40210

Status register

scale 4

40211 Same as Status register scale 1.

Gross weight

scale 4

40212

Gross Weight of scale 4.

40213

Net weight

scale 1

40214

Net Weight of scale 1.

40215

Net weight

scale 2

40216

Net Weight of scale 2.

40217

Net weight

scale 3

40218

Net Weight of scale 3.

40219

Net weight

scale 4

40220

Net Weight of scale 4.

40221

Data Register DESCRIPTION

Status register

scale 1

40202

Bit 15

(msb)

...

Bit 8 (lsb)

No function.

Bit 7(msb)

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0 (lsb)

Tare PT (1 = PT tare is active).

Tare (1 = Tare is active).

Net Weight Polarity (0 = “+”; 1 = “-”).

1 = Scale unloaded (gross weight = 0).

Overload condition (0 = No; 1 = overload).

Underload condition (0 = No; 1 = underload).

Stability (0 = “unstable”; 1 = “stable”).

Gross Weight Polarity (0 = “+”; 1= “-”).

Gross weight

scale 1

40203

Gross Weight of scale 1.

40204

Status register

scale 2

40205 Same as Status register scale 1.

Gross weight

scale 2

40206

Gross Weight of scale 2.

40207

Status register

scale 3

40208 Same as Status register scale 1.

Gross weight

scale 3

40209

Gross Weight of scale 3.

40210

Status register

scale 4

40211 Same as Status register scale 1.

Gross weight

scale 4

40212

Gross Weight of scale 4.

40213

Net weight

scale 1

40214

Net Weight of scale 1.

40215

Net weight

scale 2

40216

Net Weight of scale 2.

40217

Net weight

scale 3

40218

Net Weight of scale 3.

40219

Net weight

scale 4

40220

Net Weight of scale 4.

40221

16.2 MODBUS REGISTERS ind.ch (4 SCALES)

This manual contains the main registers for reading data / sending commands.

Refer to the Modbus protocol manual for the complete list of available registers.

Data Register DESCRIPTION

Command

40001

Main available commands:

Value

Command

00 Hex

No command

01 Hex

Scale zeroing

02 Hex

Tare

03 Hex

Preset Tare

0A Hex

Setpoint 1 setting

0B Hex

Setpoint 2 setting

19 Hex

Digital output setting

22 Hex

Reboot the weight transmitter

Parameter 1

40002

First parameter of the command.

Parameter is always expressed in absolute mode (no decimals, no sign).

40003

Parameter 2

40004

Second parameter of the command.

Parameter is always expressed in absolute mode (no decimals, no sign).

40005

EXAMPLE 1

For zeroing the weight on the scale:

2. Set the command in byte 2

Byte

Value

100 Hex

201 Hex

EXAMPLE 2

For setting a preset tare of 1000 kg:

1. Set the tare value in parameter 1 (byte 3, 4, 5, 6)

2. Set the command in byte 2

Byte

Value

100 Hex

203 Hex

3(MSB) 00 Hex

400 Hex

503 Hex

6(LSB) E8 Hex

This manual contains the main registers for reading data / sending commands.

Refer to the Modbus protocol manual for the complete list of available registers.

16.3 MODBUS REGISTERS FOR COMMAND SENDING

Notes

This publication, or portions thereof, may not be duplicated without written permission from the Manufacturer. All information contained in this manual is based

on the data available at the time of its publication; the Manufacturer reserves the right to make changes to its products at any time without notice and without incurring

any penalty. We therefore recommend that you always check for any updates.

The individual in charge of the scale operation must ensure that all safety regulations in force in the country of use are applied, ensuring that the appliance is used

in accordance with the purpose it is intended for and to avoid any danger for the user.

The Manufacturer declines any liability arising from any weighing operation errors.

The information in this document is approximate and can be subject to variations without prior notice by Dini Argeo, with respect of the norms in force. The ocial

technical data is available in the updated version on the www.diniargeo.com website or by contacting the Dini Argeo Customer Service.

Rev. 30.01.2020

HEAD OFFICE

Via Della Fisica, 20

41042 Spezzano di Fiorano, Modena - Italy

Tel. +39 0536 843418 - Fax +39 0536 843521

SERVICE ASSISTANCE

Via Dell’Elettronica, 15

41042 Spezzano di Fiorano, Modena - Italy

Tel. +39 0536 921784 - Fax +39 0536 926654

www.diniargeo.com

Authorized service center stamp

QSG_ENG_ DGT4X

Other manuals for DGT4X

1

This manual suits for next models

8

Table of contents

Other Dini Argeo Transmitter manuals

Dini Argeo

Dini Argeo DGT4XAN User manual

Dini Argeo

Dini Argeo DGT1P User manual

Dini Argeo

Dini Argeo DGT4 User manual

Dini Argeo

Dini Argeo DGT4X User manual

Dini Argeo

Dini Argeo DGT1SX User manual

Dini Argeo

Dini Argeo DGT1S User manual

Dini Argeo

Dini Argeo DGT1SP User manual

Dini Argeo

Dini Argeo DGT1S User manual