NS3526S

GB-5

G

B

5. For safe operation

IMPORTANT

Check and follow the local regulations as to sound

level and hours of operations for the product.

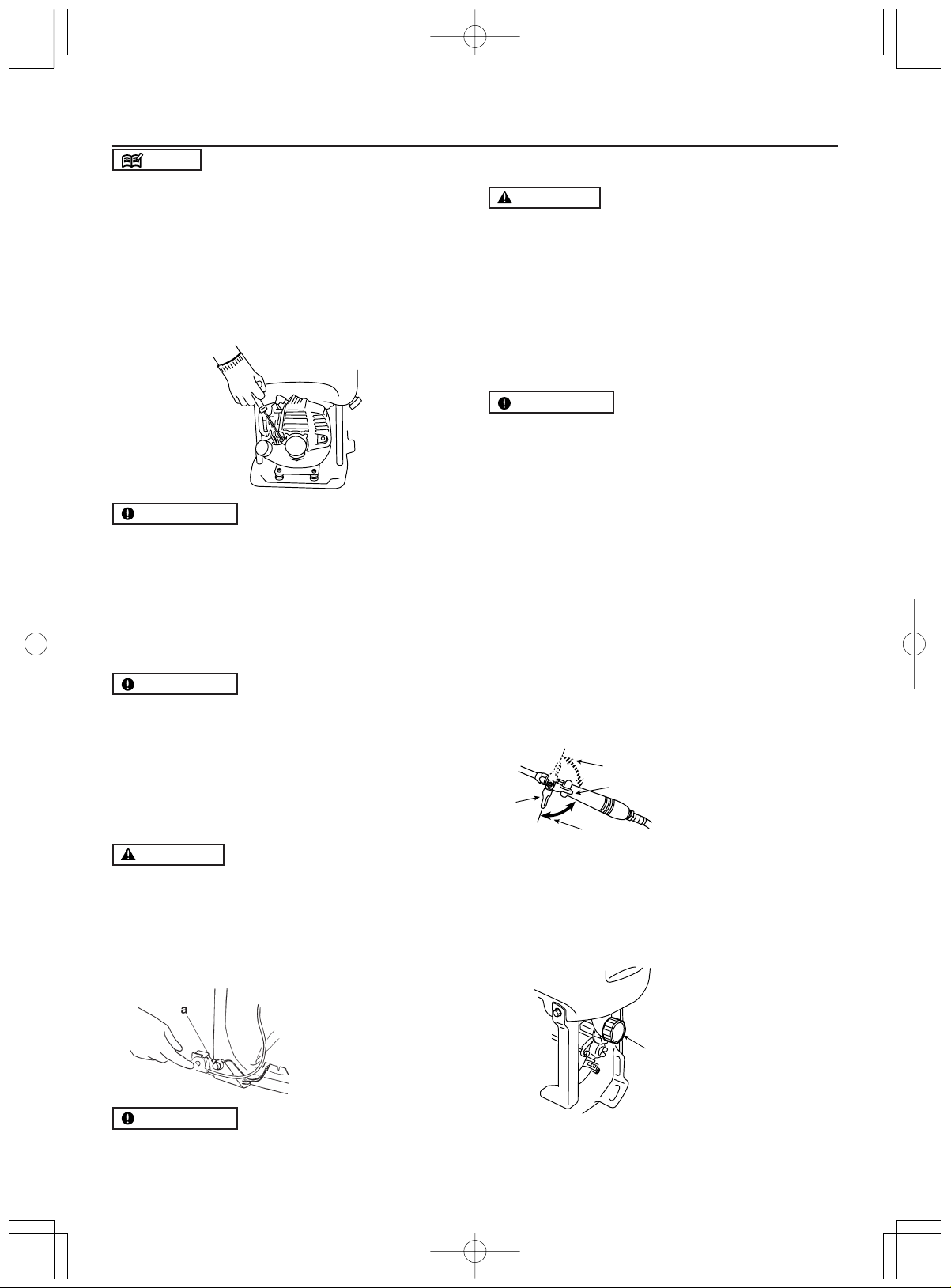

PRECAUTIONS BEFORE SPRAYING

•Make sure you have the correct protective clothing,

headgear, rubber gloves and boots, a protective

mask, goggles, a towel, protective cream, etc., to pre-

vent chemicals from coming into contact with your

skin or entering your lungs. When spraying, please

wear this protective gear to prevent any risk of injury.

•Please store chemicals in a locked storage box, locker,

or other safe place out of the reach of children.

•Carefully read the instructions for using the chemi-

cals, and familiarize yourself with the level of toxicity,

method of use, etc.

•Please pay all due consideration to the area in which

you will be spraying, to ensure that you do not pollute

the water supply, rivers, lakes, ponds, etc., or cause

any damage to residents, passers-by, livestock, etc.

•Prepare yourself physically on the day before spray-

ing, by for example cutting down on alcoholic bever-

ages or late-night work.

•Do not allow children, animals, etc., to enter the

chemical spraying area.

•Before spraying, please prepare fully by inspecting

sprayer nozzles and checking for abnormalities such

as loose screws or spray hose connections, fuel leaks,

defective or broken fluid gaskets, or damage to the

carrying band.

PRECAUTIONS WHEN TRANSPORTING CHEMI-

CALS

•When transporting chemicals, please handle with care

to ensure that there is no spillage of chemicals from

torn bags, broken bottles, or loose stoppers.

•Do not carry chemicals in the same container as food.

PRECAUTIONS WHEN TRANSPORTING THE

SPRAYER

•Do not transport the sprayer while it has chemicals or

fuel in the tank, as these could leak out as a result of

impact during transportation.

•When transporting in a vehicle, please use a rope or

similar to fix the sprayer firmly to the cargo trailer in

an upright position. Please do not transport by bicycle

or motorbike, as this is dangerous.

PRECAUTIONS CONCERNING FUEL

•The engine of this product is fueled by "mixed gaso-

line" that includes highly combustible fuel. Do not re-

fuel or store fuel containers where there is any risk of

combustion from incinerators, burners, bonfires,

kitchen stoves, electric sparks, welding sparks, etc.

•Smoking while spraying or refueling is dangerous.

Please avoid this at all costs.

•When refueling during use, always stop the engine

and make sure there are no naked flames in the vicin-

ity before refilling.

•Any fuel spilt during refueling should be wiped off com-

pletely with a rag or similar before starting the engine.

•After refueling, seal the fuel container, tightly close the fuel

tank cap, and start the engine at least 3 meters away.

PRECAUTIONS WHEN REFILLING CHEMICALS

•Before filling the tank with chemicals, please make

sure that the spray lever is completely at rest.

•After chemical refilling, firmly tighten the tank cap. If

not fully tightened the cap may become loose during

spraying, with the risk of physical exposure to the

chemicals.

PRECAUTION WHEN STARTING THE ENGINE

•Please keep children, animals, etc. well away when

starting the engine and spraying.

PRECAUTIONS WHEN SPRAYING

•Since protective clothing generally offers poor venti-

lation and thus places stress on the body, there is a

risk of contracting heatstroke or other illness when

operating for long periods under high temperatures.

Please avoid spraying on hot days, aiming instead

for early morning and late afternoon times when tem-

peratures are relatively cool and winds are low.

•When starting work, please pay all due consideration

to the spraying time, wind direction, etc., to ensure

that no noise disturbance or chemical hazard is

caused to nearby residents, passers-by, farm crops,

and so on.

•While spraying please hold the grip firmly at all times

and be careful not to point the nozzle in the direction

of people or animals.

1. Protective headgear

2. Protective goggles

3. Protective mask

4. Rubber boots

5. Ear muffs

6. Neck covering

7. Protective clothing

8. Rubber gloves

9. Protective clothing

1NS3526SGB三 15.8.26, 1:49 PMPage 5 AdobePageMaker6.5J/PPC