Direct-Lift PP9 Plus User manual

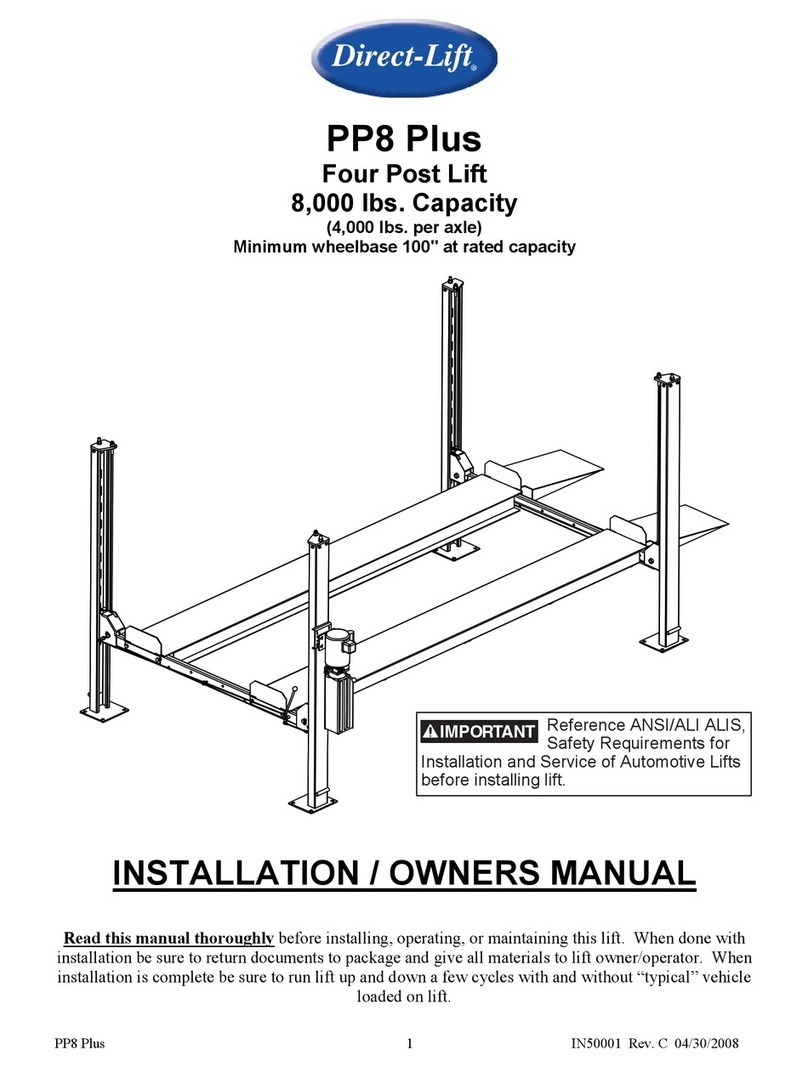

PP9 Plus

Four Post Lift

9,000 lbs. Capacity

(4,500 lbs. per axle)

Minimum wheelbase 101" at rated capacity

INSTALLATION / OWNERS MANUAL

Read this manual thoroughly before installing, operating, or maintaining this lift. When done with installation be

sure to return documents to package and give all materials to lift owner/operator. When installation is complete

be sure to run lift up and down a few cycles with and without “typical” vehicle loaded on lift.

© September 2010 by Vehicle Service Group. All rights reserved. CO7703.1 IN50004

Rev. E 07/19/2010

IMPORTANTReference ANSI/ALI ALIS,

Safety Requirements for

Installation and Service of Automotive Lifts

before installing lift.

2

TABLE OF CONTENTS

s )-0/24!.4).&/2-!4)/. .................................................................................................................. pg 2

s 4//,32%15)2%$ .................................................................................................................................... pg 4

s ,)&430%#)&)#!4)/.3 ............................................................................................................................. pg 4

s &LOOR0LAN ................................................................................................................................................. pg 5

s ).34!,,!4)/.).3425#4)/.3 ............................................................................................................ pg 6

s #!34%2+)4!33%-",9).34!,,!4)/. ........................................................................................... pg 8

s &/5.$!4)/.!.#(/2).'2%15)2%-%.43................................................................................. pg 9

s /7.%2%-0,/9%22%30/.3)"),)49.............................................................................................. pg 13

s ,/#+/544!'/54................................................................................................................................. pg 13

s 3!&%4902/#%$52%3 ............................................................................................................................ pg 15

3

s /0%2!4)/.).3425#4)/.3.................................................................................................................. pg 13

s 02%6%.4)6%-!).4%.!.#%3#(%$5,%........................................................................................... pg 15

s 42/5",%3(//4).' ............................................................................................................................... pg 17

s #!",%).30%#4)/.'5)$% ................................................................................................................... pg 19

s ),,5342!4%$0!243,)34...................................................................................................................... pg 26

IMPORTANT INFORMATION

Four Post Lifts

1. Always inspect the lift for damage and make note of any damage on the bill of lading.

2. In case of freight damage, call the truck line immediately and report the damage as a freight claim.

-AKESUREYOUHAVEEXTRAHELPORHEAVYDUTYLIFTINGEQUIPMENTWHENUNLOADINGANDASSEMBLINGTHELIFT

4. Please read the safety procedures and operating instructions in this manual before operating lift.

+EEPTHISMANUALNEARLIFTATALLTIMES-AKESUREALLOPERATORSREADTHISMANUAL

./4%!REYOUINSTALLINGINALEVELLOCATION,IFTMUSTBEANCHOREDINPLACEIFSLOPEISGREATERTHAN

1/8" per foot.)

-AKESUREYOUHAVEENOUGHROOMTOINSTALLTHELOCKRODS9OUWILLNEEDATLEASTOFCLEARANCEFROM

THEOPPOSITEENDOFTHEPOWERUNITENDOFTHELIFTANDATTHEPOWERUNITEND3EEmOORPLANONPAGE

4HEPOWERUNITMAYBEINSTALLEDONTHEDRIVERSFRONTORTHEPASSENGERREARCORNER

8. Never raise a car until you have double checked all bolts, nuts and hose fittings.

9. Always lock the lift before going under the vehicle or storing another vehicle underneath lift.

Never allow anyone to go under the lift when raising or lowering.

4

4HISISAVEHICLELIFTINSTALLATIONOPERATIONMANUALANDNOATTEMPTISMADEORIMPLIEDHEREINTOINSTRUCTTHEUSERIN

lifting methods particular to an individual application. Rather, the contents of this manual are intended as a basis

for operation and maintenance of the unit as it stands alone or as it is intended and anticipated to be used in

CONJUNCTIONWITHOTHEREQUIPMENT

0ROPERAPPLICATIONOFTHEEQUIPMENTDESCRIBEDHEREINISLIMITEDTOTHEPARAMETERSDETAILEDINTHESPECIlCATIONS

ANDTHEUSESSETFORTHINTHEDESCRIPTIVEPASSAGES!NYOTHERPROPOSEDAPPLICATIONOFTHISEQUIPMENTSHOULDBE

DOCUMENTEDANDSUBMITTEDINWRITINGTOTHEFACTORYFOREXAMINATION4HEUSERASSUMESFULLRESPONSIBILITYFORANY

EQUIPMENTDAMAGEPERSONALINJURYORALTERATIONOFTHEEQUIPMENTDESCRIBEDINTHISMANUALORANYSUBSEQUENT

damages.

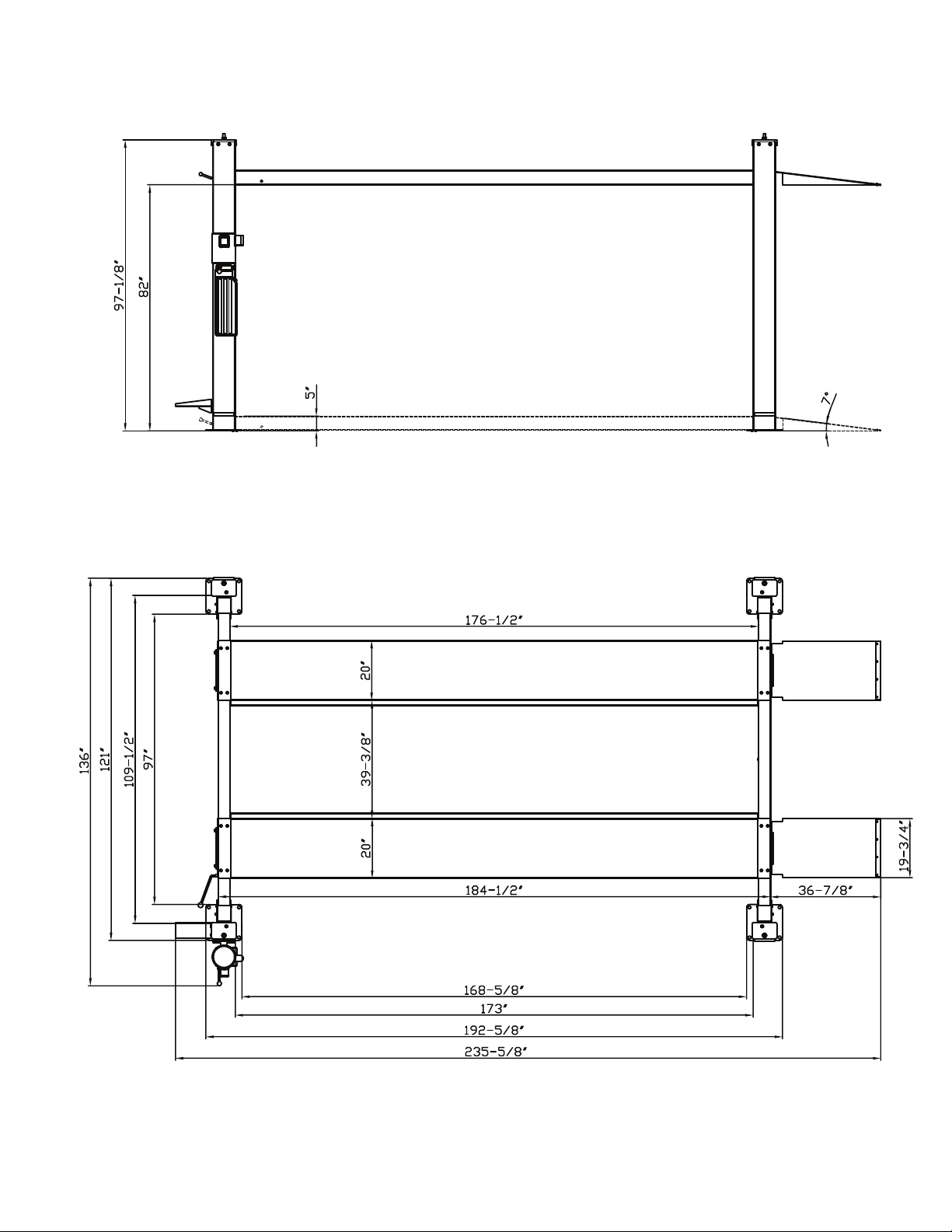

LIFT SPECIFICATIONS & FLOOR PLAN

Capacity 9,000 lbs

,IFTING(EIGHT vv

#EILING(EIGHTTOBEHEIGHTOFHIGHESTVEHICLETOBERAISEDPLUS vv

Overall Length w/ Ramps vv

Overall Length w/ no Ramps vv

Overall Width vv

Approach Ramp Length vv

Runway Width vv

Runway Length vv

2UNWAY(EIGHT 4-3/4”

(EIGHTOF#OLUMNS vv

Clearance between Columns vv

Clearance between Runways 39”

Outside Runway to Outside Runway vv

#LEARANCE5NDER2UNWAY vv

-OTORSPECS 6!#(0

Shipping Weight ,"3

5

6

TOOLS REQUIRED

s 3ETOFMETRICWRENCHESANDORSOCKETS

s !DJUSTABLEWRENCH

s ,OCKINGPLIERS

s 4APEMEASURE

s 3TEP,ADDER

s 'ALLONSOF(YDRAULIC/IL

2ECOMMENDED/IL)3/,IGHT(YDRAULIC/IL

INSTALLATION INSTRUCTIONS

2EMOVEPLASTICWRAPFROMTOPRUNWAYANDREMOVEALLHARDWARE4HISINCLUDESTHE0OWER5NIT$RIP

4RAYS4OOL"OXANDORANY*ACKS.OTE9OUSHOULDlNDTHISMANUALEITHERINTHETOPOFTHERUNWAYOR

INSIDETHE0OWER5NITBOX

7HILETHE-AINSIDE2UNWAY)TEM&IGURESISUPSIDEDOWNlNDTHEENDOFTHE(YDRAULIC(OSE

that is already connected to the cylinder. Locate the hole in the side of the runway and install the

DEGREE&ITTING)TEMSECURINGTORUNWAYWITH*AM.UT!LSOREMOVEALLOFTHEPLASTICTIESSECUR

INGTHECABLES%XTENDTHECABLEENDSTHROUGHTHERUNWAYENDS2EMOVECYLINDERRODSHIPPING

BLOCK4IGHTENHYDRAULIClTTINGS

%XTENDCYLINDERPISTONRODOUTBYPUSHINGORPULLINGONTHE#ABLE,OCK0LATE!)TEM&IGUREON

THEENDOFTHECYLINDER.OWUNBOLTTHETOPRUNWAYTAKINGTHENECESSARYSAFETYPRECAUTIONS.OTE5SING

SOMETYPEOFAHOISTISRECOMMENDEDTHISRUNWAYWILLNEEDTOBEmIPPEDOVERSOITISNOLONGER

upside down. Place this runway in your bay with the hydraulic fitting facing toward your

previously chosen corner for the power unit.

.EXTUNBOLTALLFOURCOLUMNSFROMTHESHIPPINGPACKAGEANDPLACETHECOLUMNWITHTHEPOWERUNITMOUNT

ing bracket in the above chosen corner. Arrange the other three columns in the remaining corners.

5NPACKTHE#ROSSBEAMS2AMPS3AFETY,ATCH,INKAGE2ODSAND,OCK,ADDERSFROMBOTTOM2UNWAY2E

MOVETHE3AFETY,ATCH#OVERS)TEMS&IGURE4HEYWILLBEREINSTALLEDLATER!RRANGETHE

#ROSSBEAMSSOTHATTHELOCKINGLINKAGEISFACINGOUTWARDANDTHE3HORT#ONNECTING2OD")TEM

&IGUREISCLOSESTTOTHEPOWERUNITCOLUMN!LSOREMOVE#ROSSBEAM#OVERS)TEMS

&IGUREIFNOTALREADYREMOVED

6. If you have means for securely lifting the Crossbeam, lower it into the tops of the columns. If you don't,

then the columns will have to be placed horizontal, and the crossbeams installed in the columns.

7

4HENTHEENTIREENDSTRUCTURETWOCOLUMNSANDCROSSBEAMWILLNEEDTOBESTOODUPASONE

5NPACKTHE,OCK,ADDERS)TEM&IGUREFROMTHEPACKAGEANDSLIDETHEMINTOTHEPRECUTSLOTON

THE2UB"LOCKS)TEM&IGUREINSIDEEACHCOLUMN!FTERREMOVINGTHETOPNUTFROMTHELOCK

LADDERYOUAREREADYTOINSTALLTHE4OP#APS!")TEMS&IGURESONTHECOLUMNS

"EAWAREOFTHEOFFSETHOLEINCOLUMN4OP#APS!RRANGETHEMSOTHATTHECABLEMOUNTINGHOLESARECLOS

ESTTOTHERUNWAYS5SEPROVIDEDBOLTSNUTSWASHERSANDLOCKWASHERSTOINSTALL4OP#APSASSHOWNIN

&IGURE

3ECURE4OP#APAND,OCK,ADDERASSEMBLIESTOGETHERWITH7ASHERAND.UT)TEMS&IGURE

Position the Crossbeams at the second lowest locking position on all columns.

3TANDUPANDARRANGETHETWOENDSTRUCTURES#OLUMNS#ROSSBEAMSSOTHATTHEOUTSIDEOFTHE#ROSS

beam rail to the outside of the other Crossbeam rail measure's 184.5”. Compare the measurements from

THELEFTANDTHERIGHTUNTILTHEYAREDIAGONALLYWITHINv4HEvVARIANCEWILLHELPINMOUNTING

the runways later.

,IFTANDPOSITIONEACH2UNWAYINTOPLACEANDSECUREWITHTHEPROVIDED(EX"OLTS,OCK7ASHER&LAT

7ASHERAND.UT)TEMSASSHOWNIN

&IGURE4HELIFTWILLSQUAREITSELFASYOUFURTHERASSEMBLEIT

.OTE)NSTALLTHE/FFSIDE2UNWAY)TEMOPPOSITEFROMTHE-AINSIDE2UNWAY)TEMAND0OWERUNIT

#OLUMNASSHOWNIN&IGURE

"EGINCABLEROUTINGINSTALLATIONBYREMOVINGTHE#ABLE3HEAVES3HAFTSAND3PACERSFROMALLFOURCORNERS

OFTHE-AINSIDE2UNWAYASSHOWNIN&IGURE

2OUTEANDMOUNTTHEAPPROPRIATE#ABLES)TEMSTOEACH#OLUMN4OP#APWHILEENSUR

INGTHATTHE0LASTIC#ABLE0ULLEY)TEMISBETWEENTHE#ABLEANDTHE,OCK,ADDERASSHOWNIN

&IGURES4HISWILLALLOWTHESECONDARYSLACKCABLELOCKTOFUNCTIONPROPERLY3EE&IGURE

for Cable routing installation.

14. Reinstall the Cable Sheaves, Shafts, Spacers and hardware as shown in

&IGURES

.OTE-AKESUREALL#ABLESAREPROPERLYROUTEDAROUND#ABLE3HEAVES

)NSTALLALL,OCK2ODS,INKAGECOMPONENTSPERTHEDRAWINGON0AGE&IGURE!LSOINSTALLTHE

#ROSSBEAM"RACKET)TEMTOMIDDLEOUTSIDEOFEACH#ROSSBEAM3ECUREWITHTHEPROVIDED(ARD

WARE)TEMS&IGURE

-OUNTTHE0OWER5NIT)TEMTOTHE-AINSIDE#OLUMNWITHTHEATTACHEDMOUNTINGBRACKETUSINGTHE

(ARDWARE)TEMSPROVIDEDASSHOWNIN&IGURE/NCEMOUNTEDlLLTHE0OWER

5NITRESERVOIRTANKWITHHYDRAULICmUID.OWINSTALLTHEDEGREE(YDRAULIC&ITTING)TEM&IGURE

TOTHEHIGHPRESSUREPORTONTHE0OWER5NIT#ONNECTTHEELECTRICALPOWERTOTHE0OWER5NIT

)NSTALLTHEhBRADEDv(YDRAULIC(OSE)TEMTOTHE&ITTINGONTHESIDEOFTHE-AINSIDE2UNWAYANDAT

TACHTHEOTHERENDTOTHEDEGREE&ITTINGONTHE0OWER5NITASSHOWNIN&IGURE

.OWRAISETHECOMPLETEUNIT,IFTANDSETATONEOFTHEBOTTOMLOCKPOSITIONS0LACELEVELONCROSSBEAM

4IGHTEN,OCK,ADDER2OD.UTLOCATEDONTHETOPOFEACHPOSTS)TEM4HISWILLRAISETHECORNEROFTHE

8

lift to adjust for leveling. Each post has this adjustment. Adjust the proper columns to level the

lift. Place level on each runway and crossbeam and check for proper levelness.

./4%9/5-!9(!6%4/,//3%.4(%.545.$%24/00,!4%4/-!+%!$*534-%.43

!FTERLEVELINGISCOMPLETETIGHTENTHE.UTONTHE,OCK2ODUNDERNEATHTHE4OP#APONEACHPOST4HIS

will lock the Lock Ladder in position.

2AISELIFTOFFALLLOCKSUNTILCABLESARESUPPORTINGTHELIFT!DJUSTTHE#ABLE.YLON,OCK.UT)TEMLO

CATEDONTHETOPOFEACHPOSTUNTILLIFTISLEVELONCROSSBEAMSANDRUNWAYS4HISWILLENSURETHELIFTTRAVELS

up and down level.

./4%9/5-!9.%%$4/53%,/#+).'0,)%234/(/,$4(%#!",%&2/-452.).'7(%.!$*534).'4(%

.9,/..54-!+%352%4(!44(2%!$3%.'!'%4(2/5'(.9,/./.%!#(.9,/..54

2EINSTALL#ROSSBEAM#OVERS)TEMS&IGUREANDTHEBOTTOM2UNWAY#OVER)TEM

&IGUREONTOTHEUNDERSIDEOFTHE-AINSIDE2UNWAY

)NSTALLFRONT7HEEL3TOPS)TEMAND&OOT0LATE)TEMWITHPROVIDEDHARDWAREASSHOWNIN&IGURE

)NSTALLTHE$RIVE/N2AMPS)TEMWITH#ONNECTING&RAME)TEMASSHOWNIF&IGURE

./4%

"%352%4/,5"2)#!4%!,,#!",%3(%!6%3"%!2).'3!.$3(!&437)4(!'2%!3%'5.02)/24//0%2-

!4).'4(%,)&4

14

8

9 10

13

15

13

12

11

9

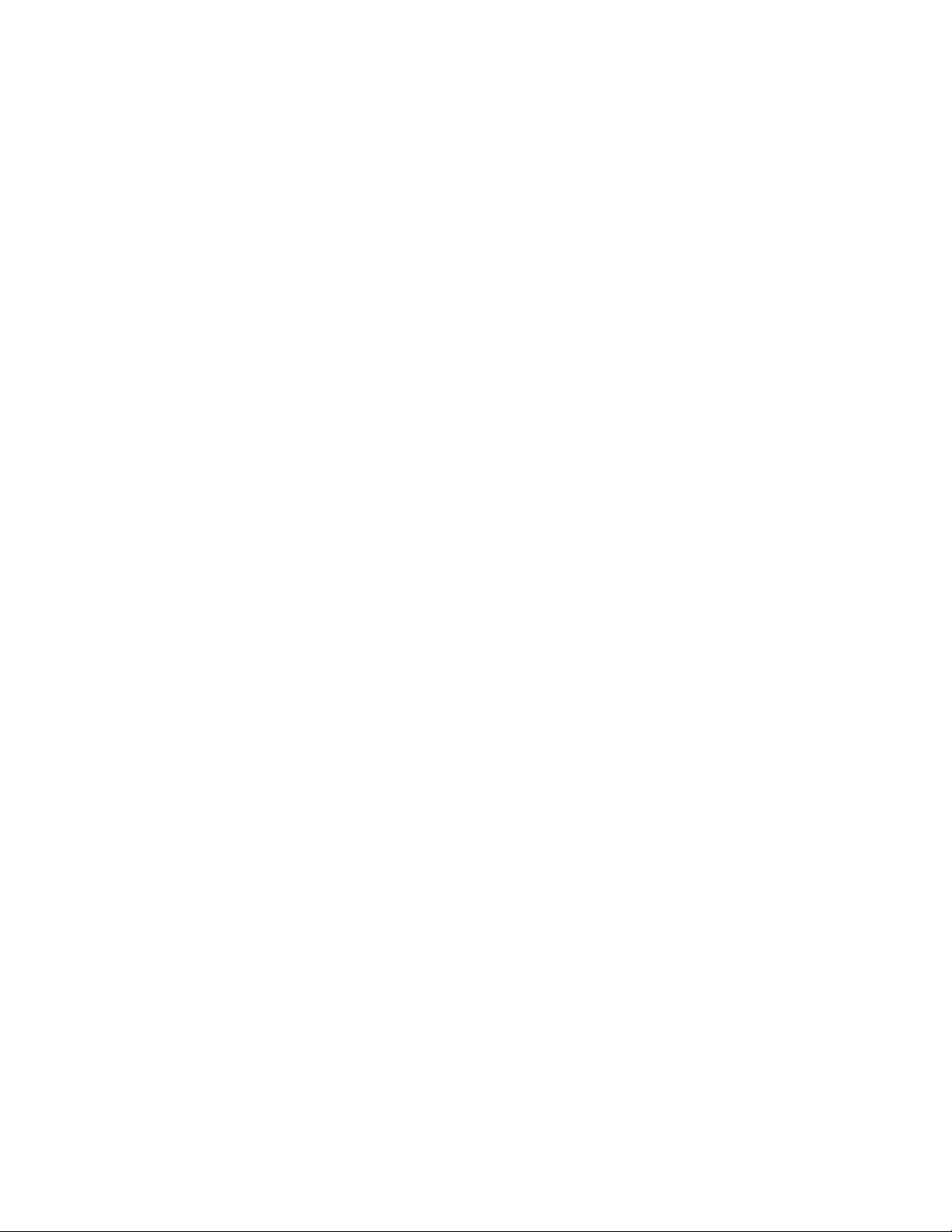

CASTER KIT INSTALLATION

1. Raise the Lift two to four feet high

0OSITIONEACHOFTHEFOUR#ASTERASSEMBLIESBELOWTHE#ROSSBEAMRAILSASSHOWNONPAGE&IGURE

and in below diagram.

3. Install the four Pivot pins and Cotter pins to secure assembly to each column as shown below.

4. Lower the Lift confirming that the Caster assemblies engage the Crossbeam rails and the four Columns

RISETOCLEARTHEmOOR

FOUNDATION REQUIREMENTS

Concrete shall have compression strength of at least 3,000 PSI and a minimum thickness of 4”.

CAUTION! $/./4USEONASPHALTORSIMILARUNSTABLESURFACES

30%#)!,./4%

4HIS,IFTDOESNOTREQUIREBOLTINGTOTHEmOOR

"54

)FYOUCHOOSETHEOPTIONTOANCHORTHE,IFTTOTHEmOORPLEASEFOLLOWTHEDETAILEDINSTRUCTIONSANDCRITERIABELOW

FOUNDATION and ANCHORING REQUIREMENTS

1. Concrete shall have compression strength of at least 3,000 PSI and a minimum thickness of 4” in order

TOACHIEVEAMINIMUMANCHOREMBEDMENTOFv./4%7HENUSINGvXvLONGANCHORSIFTHETOP

OFTHEANCHOREXCEEDSvABOVETHEmOORGRADEYOU$/./4HAVEENOUGHEMBEDMENT

10

-AINTAINAvMINIMUMDISTANCEFROMANYSLABEDGEORSEAM(OLETOHOLESPACINGSHOULDBEAMINIMUM

vINANYDIRECTION(OLEDEPTHSHOULDBEAMINIMUMOFv

3HIMEACHCOLUMNBASEASREQUIREDUNTILEACHCOLUMNISPLUMB)FONECOLUMNHASTOBEELEVATEDTO

MATCHTHEPLANEOFTHEOTHERCOLUMNFULLSIZEBASESHIMPLATESSHOULDBEUSED4ORQUEANCHORSTO

FTLBS3HIMTHICKNESS-534./4EXCEEDvWHENUSINGTHEvLONGANCHORSWITHTHELIFT!DJUSTTHE

COLUMNEXTENSIONSPLUMB

)FANCHORSDONOTTIGHTENTOFTLBSINSTALLATIONTORQUEREPLACETHECONCRETEUNDEREACHCOLUMNBASE

WITHAXXvTHICK03)MINIMUMCONCRETEPADKEYEDUNDERANDmUSHWITHTHETOPOFEXISTING

mOOR!LLOWCONCRETETOCUREBEFOREINSTALLINGLIFTSANDANCHORSTYPICALLYTOWEEKS

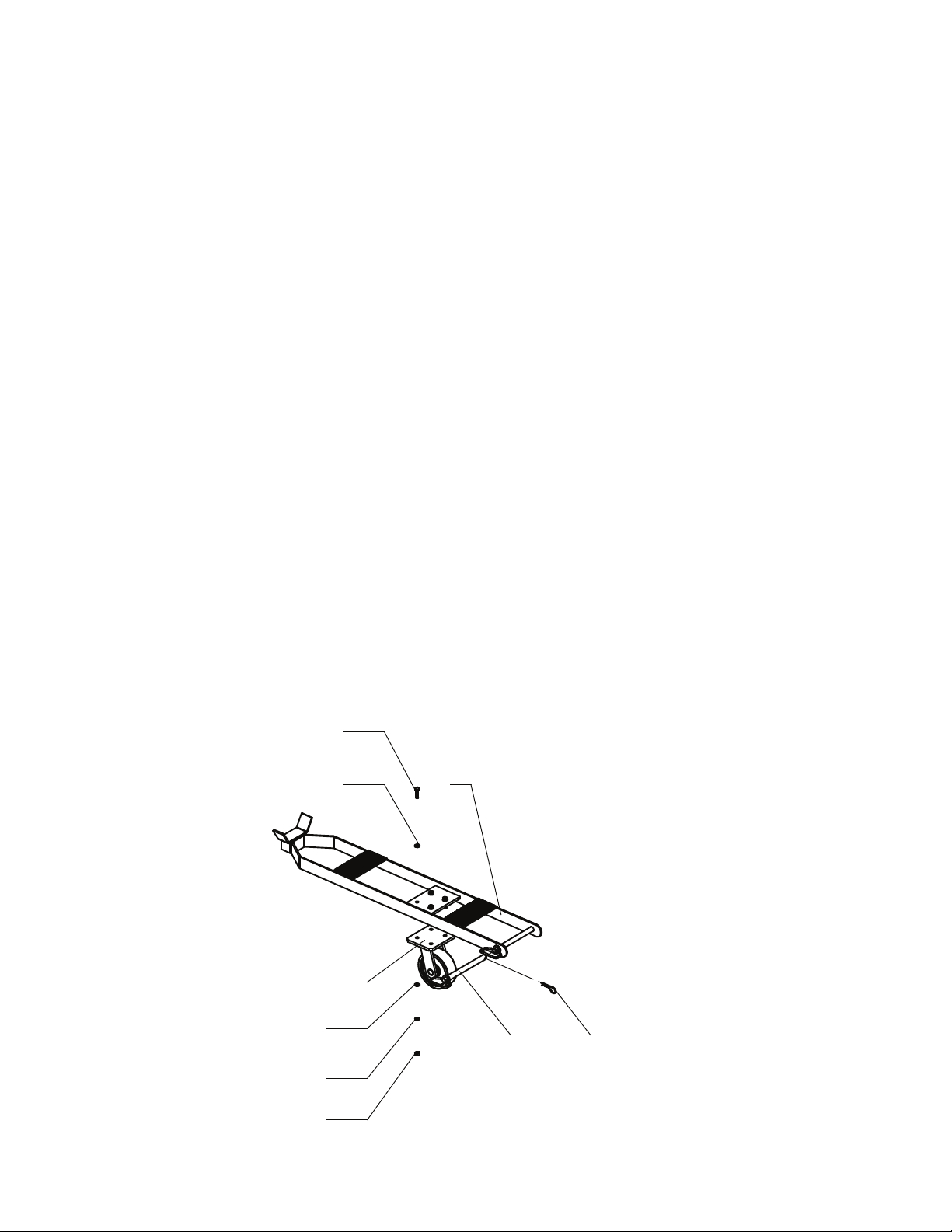

ANCHORING TIP INSTRUCTIONS

CAUTION!

Anchors must be at least 6” from the edge of the slab or any seam.

5SEACONCRETEHAMMERDRILLWITHACARBIDETIPSOLIDDRILLBITTHESAMEDIAMETERASTHEANCHORvTO

INCHESDIAMETER$ONOTUSEEXCESSIVELYWORNBITSORBITSWHICHHAVEBEENINCORRECTLYSHARPENED

+EEPTHEDRILLINAPERPENDICULARLINEWHILEDRILLING

,ETTHEDRILLDOTHEWORK$ONOTAPPLYEXCESSIVEPRESSURE,IFTTHEDRILLUPANDDOWNOCCASIONALLYTORE

move residue to reduce binding.

11

$RILLTHEHOLETODEPTHEQUALTOTHELENGTHOFANCHOR.OTE$RILLINGTHRUCONCRETERECOMMENDEDWILLAL

low the anchor to be driven thru the bottom of foundation if the threads are damaged or if the lift

will need to be relocated.

5. For better holding power blow dust from the hole.

0LACEAmATWASHERANDHEXNUTOVERTHREADEDENDOFANCHORLEAVINGAPPROXIMATELYINCHOFTHREAD

EXPOSEDCAREFULLYTAPANCHOR$ONOTDAMAGETHREADS4APANCHORINTOTHECONCRETEUNTILNUTAND

mATWASHERAREAGAINSTBASEPLATE$ONOTUSEANIMPACTWRENCHTOTIGHTEN4IGHTENTHE

NUTTWOORTHREETURNSONAVERAGECONCRETEDAYCURE)FTHECONCRETEISVERYHARDONLYONEOR

TWOTURNSMAYBEREQUIRED#HECKEACHANCHORBOLTWITHTORQUEWRENCHSETTOFOOTPOUNDS

OPERATION INSTRUCTIONS

./4%!,7!93#(/#+7(%%,3!.$3%40!2+).'"2!+%"%&/2%,)&4).'6%()#,%

Only authorized personnel are to operate lift. Read Operating and safety procedures Manual completely before

operating lift.

s 0ROPERLYMAINTAINANDINSPECTLIFTINACCORDANCETOOWNERgMANUAL

s $ONOTOPERATEALIFTTHATISDAMAGEDORINNEEDOFREPAIR

s !LLOWONLYAUTHORIZEDPERSONNELINTHELIFTBAY

s 3TAYCLEAROFLIFTWHENRAISINGORLOWERINGNORIDERS

s +EEPHANDSANDFEETAWAYFROMPINCHPOINTSATALLTIMES

s .EVEROVERRIDETHELIFTOPERATINGANDSAFETYCONTROLS

s )FAVEHICLEISSUSPECTEDOFFALLINGCLEARAREAIMMEDIATELY

s $ONOTROCKVEHICLEWHILEPOSITIONEDONLIFT

s !LWAYSUSESAFETYJACKSTANDSWHENREMOVINGORINSTALLINGHEAVYCOMPONENTS

Vehicle Loading:

s 0OSITIONVEHICLEONLIFTRUNWAYSBYHAVINGANOTHERPERSONGUIDEYOUONTOTHERUNWAYS#HECKFORPROPER

WEIGHTDISTRIBUTIONCENTEROFGRAVITYSHOULDBEEVENLYDISTRIBUTEDBETWEENCOLUMNS

s 3ETVEHICLEPARKINGBRAKEANDCHOCKTIRESTOPREVENTVEHICLEMOVEMENT

s 5SECAUTIONBEFORELIFTINGPICKUPTRUCKSSUVgSANDOTHERVEHICLES4HEINDIVIDUALAXLEWEIGHTCAPACITY

SHOULDNOTEXCEEDOFLIFTCAPACITY

s -AKESUREVEHICLEISNEITHERFRONTNORREARHEAVY

Raising Lift:

s 0USHUPSWITCHTORAISELIFTUNTILPLATFORMRUNWAYSCLEARmOOR

s 3TOPANDCHECKFORVEHICLEMOVEMENTANDVEHICLEWEIGHTDISTRIBUTION)FSECURERAISETODESIREDHEIGHT

s !LWAYSLOWERTHELIFTTOTHENEARESTLOCKPOSITIONBYPRESSINGTHELOWERLEVERTORELIEVETHEHYDRAULICPRES

sure and let the latch set tight in a lock position.

s .EVERWORKUNDERALIFTTHATISNOTINTHELOCKEDPOSITION

Lowering Lift:

s #LEARALLOBSTACLESFROMUNDERLIFTANDVEHICLEANDENSUREONLYLIFTOPERATORISINTHELIFTAREA

s 3TAYCLEAROFLIFTANDRAISETHELIFTOFFTHESAFETYLOCKS

12

s 0ULLSAFETYLATCHRELEASESANDPRESSTHELOWERLEVERTOBEGINDESCENT

13

s %NSURELIFTISFULLYLOWEREDANDHAVINGANOTHERPERSONGUIDEYOUCAREFULLYUNLOADTHELIFTBYDRIVINGOFFOF

the lift runways.

#!54)/.

0!9!44%.4)/.4/4(%,/7%2).'30%%$/&!,,&/52#/2.%23-!+%352%4(%9!2%-/6).'$/7.

!44(%3!-%30%%$34/0,/7%2).'4(%,)&4"92%,%!3).'4(%,/7%2).',%6%2/.4(%0/7%25.)4

!.$-/6).'4(%,/#+,%6%24/4(%,/#+0/3)4)/.)&!.9#/2.%234/03-/6).'/2)33,/7%2).$%-

3#%.4!,7!93,/#+4(%,)&4"%&/2%'/).'5.$%24(%6%()#,%.%6%2!,,/7!.9/.%4/'/5.$%2

4(%,)&47(%.2!)3).'/2,/7%2).'

./4%)TISNORMALFORANEMPTYLIFTTOLOWERSLOWLYITMAYBENECESSARYTOADDWEIGHT

OWNER / EMPLOYER RESPONSIBILITIES

The Owner / Employer:

s 3HALLENSURETHATLIFTOPERATORSAREQUALIlEDANDTHATTHEYARETRAINEDINTHESAFEUSEANDOPERATIONOFTHE

LIFTUSINGTHEMANUFACTURERSOPERATINGINSTRUCTIONS!,)3-!,),IFTINGIT2IGHTSAFETYMANUAL

!,)34!,)3AFETY4IPSCARD!.3)!,)!,/)-!MERICAN.ATIONAL3TANDARDFOR!UTOMO

TIVE,IFTS3AFETY2EQUIREMENTSFOR/PERATION)NSPECTIONAND-AINTENANCE!,)7,3ERIES!,)

5NIFORM7ARNING,ABEL$ECALS0LACARDSANDINTHECASEOFFRAMEENGAGINGLIFTS!,),0'5)$%6EHICLE

,IFTING0OINTS1UICK2EFERENCE'UIDEFOR&RAME%NGAGING,IFTS

s 3HALLESTABLISHPROCEDURESTOPERIODICALLYINSPECTTHELIFTINACCORDANCEWITHTHELIFTMANUFACTURERS

INSTRUCTIONSOR!.3)!,)!,/)-!MERICAN.ATIONAL3TANDARDFOR!UTOMOTIVE,IFTS3AFETY

2EQUIREMENTSFOR/PERATION)NSPECTIONAND-AINTENANCEAND4HE%MPLOYER3HALLENSURETHATLIFT

INSPECTORSAREQUALIlEDANDTHATTHEYAREADEQUATELYTRAINEDINTHEINSPECTIONOFTHELIFT

s 3HALLESTABLISHPROCEDURESTOPERIODICALLYMAINTAINTHELIFTINACCORDANCEWITHTHELIFTMANUFACTURERS

INSTRUCTIONSOR!.3)!,)!,/)-!MERICAN.ATIONAL3TANDARDFOR!UTOMOTIVE,IFTS3AFETY

2EQUIREMENTSFOR/PERATION)NSPECTIONAND-AINTENANCEAND4HE%MPLOYER3HALLENSURETHATLIFT

MAINTENANCEPERSONNELAREQUALIlEDANDTHATTHEYAREADEQUATELYTRAINEDINTHEMAINTENANCEOFTHELIFT

s 3HALLMAINTAINTHEPERIODICINSPECTIONANDMAINTENANCERECORDSRECOMMENDEDBYTHEMANUFACTUREROR

!.3)!,)!,/)-!MERICAN.ATIONAL3TANDARDFOR!UTOMOTIVE,IFTS3AFETY2EQUIREMENTSFOR/PERA

TION)NSPECTIONAND-AINTENANCE

s 3HALLDISPLAYTHELIFTMANUFACTURERSOPERATINGINSTRUCTIONS!,)3-!,),IFTINGIT2IGHTSAFETYMANUAL

!,)34!,)3AFETY4IPSCARD!.3)!,)!,/)-!MERICAN.ATIONAL3TANDARDFOR!UTOMOTIVE,IFTS

3AFETY2EQUIREMENTSFOR/PERATION)NSPECTIONAND-AINTENANCEANDINTHECASEOFFRAMEENGAGINGLIFTS

!,),0'5)$%6EHICLE,IFTING0OINTS1UICK2EFERENCE'UIDEFOR&RAME%NGAGING,IFTSINACONSPICUOUS

location in the lift area convenient to the operator.

s 3HALLNOTMODIFYTHELIFTINANYMANNERWITHOUTTHEPRIORWRITTENCONSENTOFTHEMANUFACTURER

s 3HALLPROVIDENECESSARYLOCKOUTTAGOUTMEANSFORENERGYSOURCESPER!.3):23AFETY

2EQUIREMENTSFORTHE,OCKOUT4AGOUTOF%NERGY3OURCESBEFOREBEGINNINGANYLIFTREPAIRS

Lift Lockout/Tagout Procedure

Purpose

14

4HISPROCEDUREESTABLISHESTHEMINIMUMREQUIREMENTSFORTHELOCKOUTOFENERGYTHATCOULDCAUSEINJURYTOPER-

sonnel by the operation of lifts in need of repair or being serviced. All employees shall comply with this proce-

dure.

Responsibility

4HERESPONSIBILITYFORASSURINGTHATTHISPROCEDUREISFOLLOWEDISBINDINGUPONALLEMPLOYEESANDSERVICEPERSON-

NELFROMOUTSIDESERVICECOMPANIESIE!UTHORIZED)NSTALLERSCONTACTORSETC!LLEMPLOYEESSHALLBEINSTRUCT-

ed in the safety significance of the lockout procedure by the facility owner/manager. Each new or transferred

EMPLOYEEALONGWITHVISITINGOUTSIDESERVICEPERSONNELSHALLBEINSTRUCTEDBYTHEOWNERMANAGERORASSIGNED

designee) in the purpose and use of the lockout procedure.

Preparation

%MPLOYEESAUTHORIZEDTOPERFORMLOCKOUTSHALLENSURETHATTHEAPPROPRIATEENERGYISOLATINGDEVICEIECIRCUIT

BREAKERFUSEDISCONNECTETCISIDENTIlEDFORTHELIFTBEINGLOCKEDOUT/THERSUCHDEVICESFOROTHEREQUIPMENT

MAYBELOCATEDINCLOSEPROXIMITYOFTHEAPPROPRIATEENERGYISOLATINGDEVICE)FTHEIDENTITYOFTHEDEVICEISIN

QUESTIONSEETHESHOPSUPERVISORFORRESOLUTION!SSURETHATPROPERAUTHORIZATIONISRECEIVEDPRIORTOPERFORMING

the lockout procedure.

Sequence of Lockout Procedure

1) Notify all affected employees that a lockout is being performed and the reason for it.

5NLOADTHESUBJECTLIFT3HUTITDOWNANDASSURETHEDISCONNECTSWITCHISh/&&vIFONEISPROVIDEDONTHE

lift.

4HEAUTHORIZEDLOCKOUTPERSONOPERATESTHEMAINENERGYISOLATIONDEVICEREMOVINGPOWERTOTHESUBJECT

lift.

s )FTHISISALOCKABLEDEVICETHEAUTHORIZEDLOCKOUTPERSONPLACESTHEASSIGNEDPADLOCKONTHEDEVICETO

PREVENTITSUNINTENTIONALREACTIVATION!NAPPROPRIATETAGISAPPLIEDSTATINGTHEPERSONSNAMEATLEASTv

XvINSIZEANEASILYNOTICEABLYCOLORANDSTATESNOTTOOPERATEDEVICEORREMOVETAG

s )FTHISDEVICEISANONLOCKABLECIRCUITBREAKERORFUSEREPLACEWITHAhDUMMYvDEVICEANDTAGITAPPRO

priately as mentioned above.

!TTEMPTTOOPERATELIFTTOASSURETHELOCKOUTISWORKING"ESURETORETURNANYSWITCHESTOTHEh/&&vPOSI

tion.

4HEEQUIPMENTISNOWLOCKEDOUTANDREADYFORTHEREQUIREDMAINTENANCEORSERVICE

Restoring Equipment to Service

1) Assure the work on the lift is complete and the area is clear of tools, vehicles, and personnel.

!TTHISPOINTTHEAUTHORIZEDPERSONCANREMOVETHELOCKORDUMMYCIRCUITBREAKERORFUSETAGAND

activate the energy isolating device so that the lift may again be placed into operation.

Rules for Using Lockout Procedure

5SETHE,OCKOUT0ROCEDUREWHENEVERTHELIFTISBEINGREPAIREDORSERVICEDWAITINGFORREPAIRWHENCURRENT

operation could cause possible injury to personnel, or for any other situation when unintentional operation could

injure personnel. No attempt shall be made to operate the lift when the energy isolating device is locked out.

Operating Conditions

15

Lift is not intended for outdoor use and has an operating ambient temperature range

OF&#

)-0/24!.43!&%49).3425#4)/.3

7HENUSINGYOURGARAGEEQUIPMENTBASICSAFETYPRECAUTIONSSHOULDALWAYSBEFOLLOWEDINCLUDINGTHEFOLLOW-

ING

1. Read all instructions

2. Care must be taken as burns can occur from touching hot parts.

$ONOTOPERATEEQUIPMENTWITHADAMAGEDCORDORIFTHEEQUIPMENTHASBEENDROPPEDORDAMAGEDUNTIL

ITHASBEENEXAMINEDBYAQUALIlEDSERVICEPERSON

$ONOTLETACORDHANGOVERTHEEDGEOFTHETABLEBENCHORCOUNTERORCOMEINCONTACTWITHHOTMANI

folds or moving fan blades.

)FANEXTENSIONCORDISNECESSARYACORDWITHACURRENTRATINGEQUALTOORMORETHANTHATOFTHEEQUIP

MENTSHOULDBEUSED#ORDSRATEDFORLESSCURRENTTHANTHEEQUIPMENTMAYOVERHEAT

!LWAYSUNPLUGEQUIPMENTFROMELECTRICALOUTLETWHENNOTINUSE.EVERUSETHECORDTOPULLTHEPLUGFROM

the outlet. Grasp plug and pull to disconnect.

,ETEQUIPMENTCOOLCOMPLETELYBEFOREPUTTINGAWAY,OOPCORDLOOSELYAROUNDEQUIPMENTWHENSTORING

4OREDUCETHERISKOFlREDONOTOPERATEEQUIPMENTINTHEVICINITYOFOPENCONTAINERSOFmAMMABLELIQUIDS

GASOLINE

!DEQUATEVENTILATIONSHOULDBEPROVIDEDWHENWORKINGONOPERATINGINTERNALCOMBUSTIONENGINES

+EEPHAIRLOOSECLOTHINGlNGERSANDALLPARTSOFBODYAWAYFROMMOVINGPARTS

4OREDUCETHERISKOFELECTRICSHOCKDONOTUSEONWETSURFACESOREXPOSETORAIN

5SEONLYASDESCRIBEDINTHISMANUAL5SEONLYMANUFACTURERgSRECOMMENDEDATTACHMENTS

!,7!937%!23!&%49',!33%3%VERYDAYEYEGLASSESONLYHAVEIMPACTRESISTANTLENSESTHEYARENOT

safety glasses.

SAVE THESE INSTRUCTIONS

SAFETY PROCEDURES

s .EVERALLOWUNAUTHORIZEDPERSONSTOOPERATELIFT4HOROUGHLYTRAINNEWEMPLOYEESINTHEUSEANDCAREOF

lift.

s #AUTIONTHEPOWERUNITOPERATESATHIGHPRESSURE

s 2EMOVEPASSENGERSBEFORERAISINGVEHICLE

s 0ROHIBITUNAUTHORIZEDPERSONSFROMBEINGINSHOPAREAWHILELIFTISINUSE

s 4OTALLIFTCAPACITYISLBS$ONOTEXCEEDTHISCAPACITY

s 0RIORTOLIFTINGVEHICLEWALKAROUNDTHELIFTANDCHECKFORANYOBJECTSTHATMIGHTINTERFEREWITHTHEOPERA

TIONOFLIFTANDSAFETYLATCHESTOOLSAIRHOSESSHOPEQUIPMENT

s 7HENAPPROACHINGTHELIFTWITHAVEHICLEMAKESURETOCENTERTHEVEHICLEBETWEENTHECOLUMNS3LOWLY

drive the vehicle up with some one outside the vehicle guiding the driver.

s 0RIORTOLOWERINGVEHICLEWALKAROUNDTHELIFTANDCHECKFORANYOBJECTSTHATMIGHTINTERFEREWITHTHE

OPERATIONOFLIFTANDSAFETYLATCHESTOOLSAIRHOSESSHOPEQUIPMENT

s 3LOWLYDRIVETHEVEHICLEONANDOFFOFTHELIFT(AVESOMEONEOUTSIDETHEVEHICLEGUIDETHEDRIVER

16

#!54)/../4%

,5"2)#!4%!,,#!",%3(%!6%3"%!2).'3!.$3(!&437)4('2%!3%02)/24//0%2!4).'4(%,)&4

,5"2)#!4%!,,/.!.!..5!,"!3)3

-OTORSANDALLELECTRICALCOMPONENTSARENOTSEALEDAGAINSTTHEWEATHERANDMOISTURE)NSTALLTHISLIFTINAPRO-

tected indoor location. Failure by the owner to provide the recommended shelter could result in unsatisfactory

lift performance, property damage, or personal injury.

2EADANDHEEDALL7!2.).'#!54)/.AND3!&%49).3425#4)/.LABELSONLIFT

PREVENTIVE MAINTENANCE SCHEDULE

4HEPERIODIC0REVENTIVE-AINTENANCE3CHEDULEGIVENISTHESUGGESTEDMINIMUMREQUIREMENTSANDMINIMUM

INTERVALSACCUMULATEDHOURSORMONTHLYPERIODWHICHEVERCOMESSOONER

Periodic maintenance is to be performed on a daily, weekly, and yearly basis as given in the following para-

graphs.

)NTHEEVENTYOUNEEDREPLACEMENTPARTSUSEONLY$IRECT,IFTREPLACEMENTPARTSAVAILABLEFROMYOURLOCAL$IRECT

Lift distributor.

$ONOTMODIFYTHELIFTINANYMANNERWITHOUTTHEPRIORWRITTENCONSENTOFTHEMANUFACTURER

7!2.).'

/CCUPATIONAL3AFETYAND(EALTH!DMINISTRATION/3(!ANDTHE!MERICAN.ATIONAL3TANDARDS)NSTITUTE!.3)

REQUIRESUSERSTOINSPECTLIFTINGEQUIPMENTATTHESTARTOFEVERYSHIFT4HESEANDOTHERPERIODICINSPECTIONSARE

the responsibility of the user.

&AILURETOPERFORMTHEDAILYPREOPERATIONALCHECKCANRESULTINEXPENSIVEPROPERTYDAMAGELOSTPRODUCTIONTIME

SERIOUSPERSONALINJURYANDEVENDEATH4HESAFETYLATCHSYSTEMMUSTBECHECKEDANDWORKINGPROPERLYBEFORE

the lift is put to use.

&AILURETOHEEDTHISWARNINGCANRESULTINDEATHORSERIOUSINJURYORDAMAGETOEQUIPMENT)FYOUHEARANOISENOT

ASSOCIATEDWITHNORMALLIFTOPERATIONORIFTHEREISANYINDICATIONSOFIMPENDINGLIFTFAILURE#%!3%/0%2!4)/.

)--%$)!4%,9)NSPECTCORRECTANDORREPLACEPARTSASREQUIRED5SEONLY$IRECT,IFTREPLACEMENTPARTSAVAIL-

ABLEFROMYOURLOCAL$IRECT,IFTDISTRIBUTOR

Daily Pre-Operation Check (8-Hours)

s #HECKSAFETYLOCKAUDIBLYANDVISUALLYWHILEINOPERATION

s #HECKSAFETYLATCHESFORFREEMOVEMENTANDFULLENGAGEMENTWITHRACK

s #HECKHYDRAULICCONNECTIONSANDHOSESFORLEAKAGE

s #HECKCABLESCONNECTIONSBENDSCRACKSANDFORLOOSElTTINGS

17

s #HECKFORFRAYEDCABLESINBOTHRAISEDANDLOWEREDPOSITION

s #HECKSNAPRINGSATALLROLLERSANDSHEAVES

s #HECKBOLTSNUTSANDSCREWSANDTIGHTENIFNEEDED

s #HECKWIRINGSWITCHESFORDAMAGE

s #HECKmOORFORSTRESSCRACKSNEARCOLUMNS

s #HECK,UBRICATIONSONCABLESHEAVESANDSHAFTS

Weekly Maintenance (every 40-Hours)

s )&,)&4)3!.#(/2%$4/&,//2#HECKANCHORBOLTSTORQUETOFTLBSFORTHEINANCHORBOLTS$ONOT

use an impact wrench to tighten anchor bolts.

s #HECKmOORFORSTRESSCRACKSNEARCOLUMNS

s #HECKHYDRAULICOILLEVEL

s #HECKANDTIGHTENBOLTSNUTSANDSCREWS

s #HECKALLCABLESHEAVESASSEMBLYFORFREEMOVEMENTOREXCESSIVEWEARONCABLESHEAVESHAFT

Yearly Maintenance

s ,UBRICATETHECABLESHEAVESHAFTBYUSINGGREASEGUNATLEASEONCEAYEARAFTERTHELIFTISINSERVICE

s #HECKFOREXCESSIVEWEAROFCABLE2EPLACETHEMIFNECESSARY

s #HANGETHEHYDRAULICmUIDGOODMAINTENANCEPROCEDUREMAKESITMANDATORYTOKEEPHYDRAULICmUID

CLEAN.OHARDFASTRULESCANBEESTABLISHEDOPERATINGTEMPERATURETYPEOFSERVICECONTAMINATIONLEV

ELSlLTRATIONANDCHEMICALCOMPOSITIONOFmUIDSHOULDBECONSIDERED)FOPERATINGINDUSTYENVIRONMENT

SHORTERINTERVALMAYBEREQUIRED

Special Maintenance Tasks

./4%4HEFOLLOWINGITEMSSHOULDONLYBEPERFORMEDBYATRAINEDMAINTENANCEEXPERT

s 2EPLACEMENTOFHYDRAULICHOSES

s 2EPLACEMENTOFCABLESANDSHEAVES

18

s 2EPLACEMENTORREBUILDINGAIRANDHYDRAULICCYLINDERSASREQUIRED

s 2EPLACEMENTORREBUILDINGPUMPSMOTORSASREQUIRED

s #HECKINGOFHYDRAULICCYLINDERRODANDRODENDTHREADSFORDEFORMATIONORDAMAGE

#!54)/.

2ELOCATINGORCHANGINGCOMPONENTSMAYCAUSEPROBLEMS%ACHCOMPONENTINTHESYSTEMMUSTBECOMPATIBLE

an undersized or restricted line will cause a drop in pressure. All valve, pump, and hose connections should be

SEALEDANDORCAPPEDUNTILJUSTPRIORTOUSE!IRHOSESCANBEUSEDTOCLEANlTTINGSANDOTHERCOMPONENTS(OW-

EVERTHEAIRSUPPLYMUSTBElLTEREDANDDRYTOPREVENTCONTAMINATION-OSTIMPORTANTISCLEANLINESS#ONTAMINA-

TIONISTHEMOSTFREQUENTCAUSEOFMALFUNCTIONORFAILUREOFHYDRAULICEQUIPMENT

TROUBLESHOOTING

4HECOMMONPROBLEMSTHATMAYBEENCOUNTEREDANDTHEIRPROBABLECAUSESARECOVEREDINTHEFOLLOWINGPARA-

GRAPHS

s Motor Does Not Operate

&AILUREOFTHEMOTORTOOPERATEISNORMALLYCAUSEDBYONEOFTHEFOLLOWING

"REAKERORFUSEBLOWN

&AULTYWIRINGCONNECTIONSCALLELECTRICIAN

$EFECTIVEUPBUTTONCALLELECTRICIANFORSERVICE

s Motor Functions but Lift Will Not Rise

)FTHEMOTORISFUNCTIONINGBUTTHELIFTWILLNOTRISEDOTHEFOLLOWINGINTHEORDERGIVEN

!PIECEOFTRASHISUNDERCHECKVALVE0USHHANDLEDOWNANDPUSHTHEUPBUTTONATTHESAMETIME(OLD

FORSECONDS4HISSHOULDmUSHTHESYSTEM

#HECKTHECLEARANCEBETWEENTHEPLUNGERVALVEOFTHELOWERINGHANDLE4HERESHOULDBEvCLEAR

ance.

3. Remove the check valve cover and clean ball and seat.

7!2.).'

&AILURETOPROPERLYRELIEVEPRESSUREINTHEFOLLOWINGSTEPCANCAUSEINJURYTOPERSONNEL4HISLIFTUSES)3/'RADE

OROTHERGOODGRADENONDETERGENTHYDRAULICOILATAHIGHHYDRAULICPRESSURE"EFAMILIARWITHITSTOXICOLOGI-

19

cal properties, precautionary measures to take, and first aid measures as stated in the Safety Summary before

performing any maintenance with the hydraulic system.

4. Oil level too low. Oil level should be just under the vent cap port when the lift is down. Relieve all hydrau

LICPRESSUREANDADDOILASREQUIRED

s Oil Blows out Breather of Power Unit

)FOILBLOWSOUTOFTHEBREATHEROFTHEPOWERUNITTAKETHEFOLLOWINGACTIONS

/ILRESERVOIROVERlLLED2ELIEVEALLPRESSUREANDSIPHONOUTHYDRAULICmUIDUNTILATAPROPERLEVEL

,IFTLOWEREDTOOQUICKLYWHILEUNDERAHEAVYLOAD,OWERTHELIFTSLOWLYUNDERHEAVYLOADS

s Motor Hums and Will Not Run

)FTHEMOTORHUMSBUTFAILSTORUNTAKETHEFOLLOWINGACTIONS

,IFTOVERLOADED2EMOVEEXCESSIVEWEIGHTFROMLIFT

7!2.).'

4HEVOLTAGESUSEDINTHELIFTCANCAUSEDEATHORINJURYTOPERSONNEL)NTHEFOLLOWINGSTEPSMAKESURETHATA

QUALIlEDELECTRICIANISUSEDTOPERFORMMAINTENANCE

2. Faulty wiring..….... Call electrician

"ADCAPACITORx#ALLELECTRICIAN

4. Low voltage........... Call electrician

s ,IFT*ERKS'OING5PAND$OWN

1. If the lift jerks while going up and down, it is usually a sign of air in the hydraulic system. Raise lift all the

WAYTOTOPANDRETURNTOmOOR2EPEATTIMES$ONOTLETTHISOVERHEATPOWERUNIT

s /IL,EAKS

/ILLEAKCAUSESATTHEPOWERUNITANDCYLINDERSARENORMALLYCAUSEDBYTHEFOLLOWING

0OWERUNITIFTHEPOWERUNITLEAKSHYDRAULICOILAROUNDTHETANKMOUNTINGmANGECHECKTHEOILLEVELINTHE

20

TANK4HELEVELSHOULDBETWOINCHESBELOWTHEmANGEOFTHETANK!SCREWDRIVERCAN

be used as a “dipstick”.

#YLINDER0ISTON2ODTHERODSEALOFTHECYLINDERISOUT2EBUILDORREPLACETHECYLINDER

#YLINDER6ENTTHEPISTONSEALOFTHECYLINDERISOUT2EBUILDORREPLACETHECYLINDER

s Lift makes excessive noise / vibrates

%XCESSIVENOISEFROMTHELIFTISNORMALLYCAUSEDBYTHEFOLLOWING

1. Cross beam ends are rubbing the columns. Readjustment needed.

2. Cylinder too tight, load lift half capacity and cycle up and down a few times to break in.

-AYHAVEEXCESSIVEWEARONCABLESHEAVESORSHAFTS2EPLACETHEM

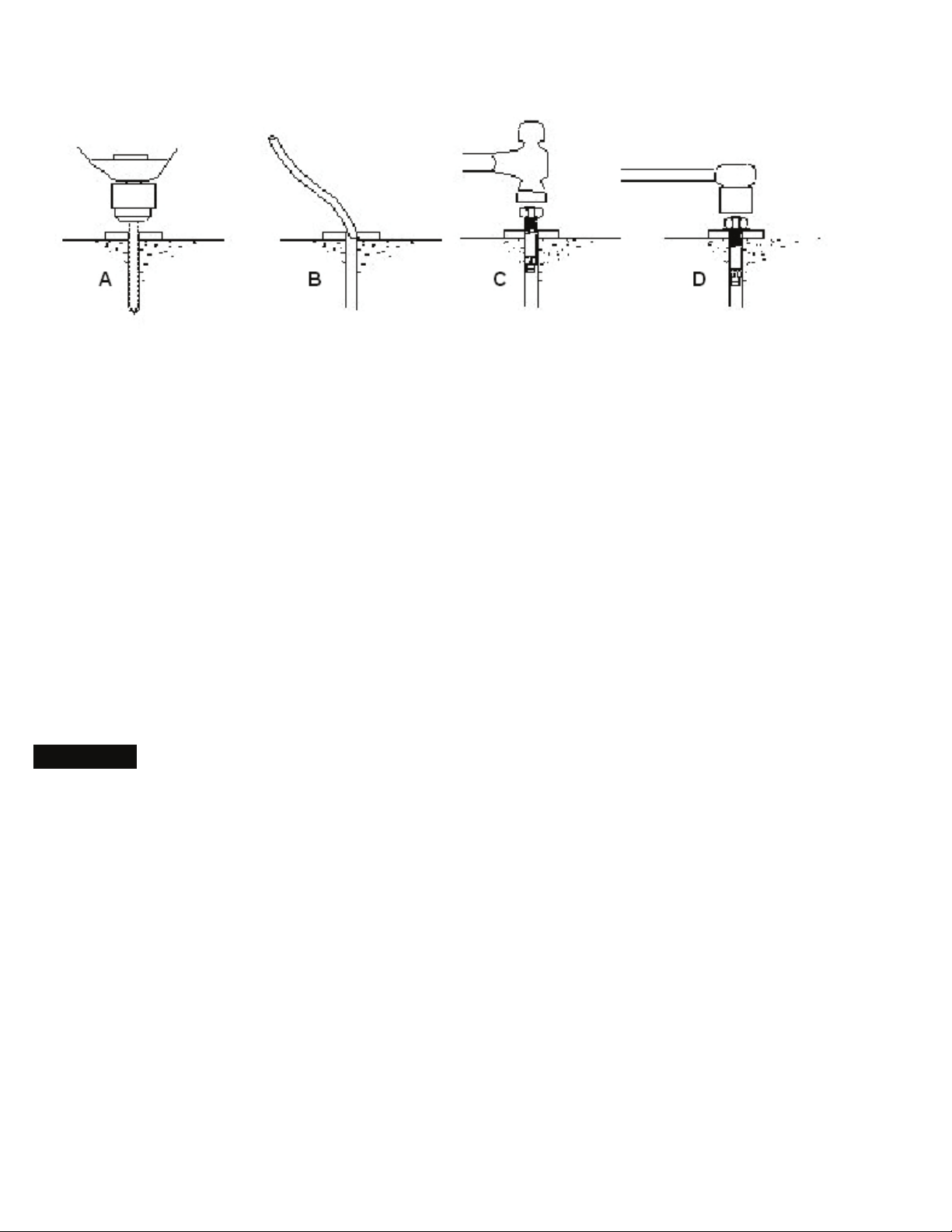

Cable Inspection Guide

-AXIMUM!LLOWABLE#ABLE.ECKING

.OM#ABLE$IAMETERS-AX2EDUCTIONIN$IAMETER

5PTOv v

3/8” to 1/2” 1/32”

9/16” to 3/4” 3/64”

7/8” to 1-1/8” 1/16”

1-1/4” to1-1/2” 3/32”

4YPICAL'OOD#ABLE #ABLE7ITH"ROKEN7IRES

Cable With Severe Corrosion Cable With Necking

Table of contents

Other Direct-Lift Lifting System manuals

Popular Lifting System manuals by other brands

Invacare

Invacare Aquatec Disk Assembly instructions

Basta Boatlifts

Basta Boatlifts Over-Center 10k53 manual

Yale

Yale UNOplus 750 operating instructions

Molift

Molift QUICK RAISER Operation manual

Venset

Venset TS700 installation instructions

AMGO Hydraulics

AMGO Hydraulics 408-P Installation and service manual

Sinoboom

Sinoboom GTJZ1023D Operation manual

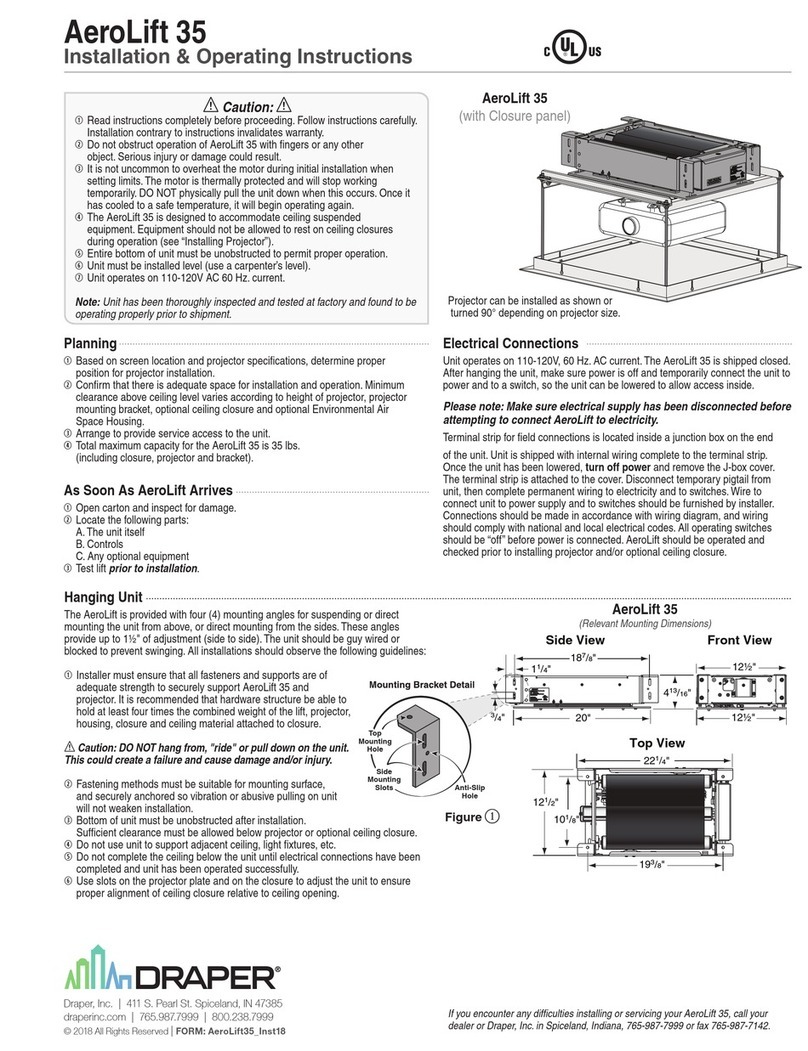

Draper

Draper AeroLift 35 Installation & operating instructions

Valx

Valx WSM DRUM Workshop manual

Lippert Components

Lippert Components Schwintek TV Lift OEM INSTALLATION MANUAL

Mec

Mec SMART Series manual

Garage Smart

Garage Smart Universal XL HD Lifter user guide