Page 9 of 20

Assembly /disassembly

To be able to operate the lift, the operator must have

good knowledge of the lift, including assembly, dis-

assembly and preparation before use.

Assembly and use of charger

The battery charger shall be mounted on a vertical

wall surface close to a power outlet. The charger

shall be connected to the power outlet at all times.

Molift AS tests and charges all batteries be-

fore packing and shipment. However, all bat-

teries must be charged before use.

Unpacking

• The lifter comes in a cardboard box. Verify that

the box has no apparent damage. If damaged, -

check the contents and contact your dealer for as-

sistance if components are damaged.

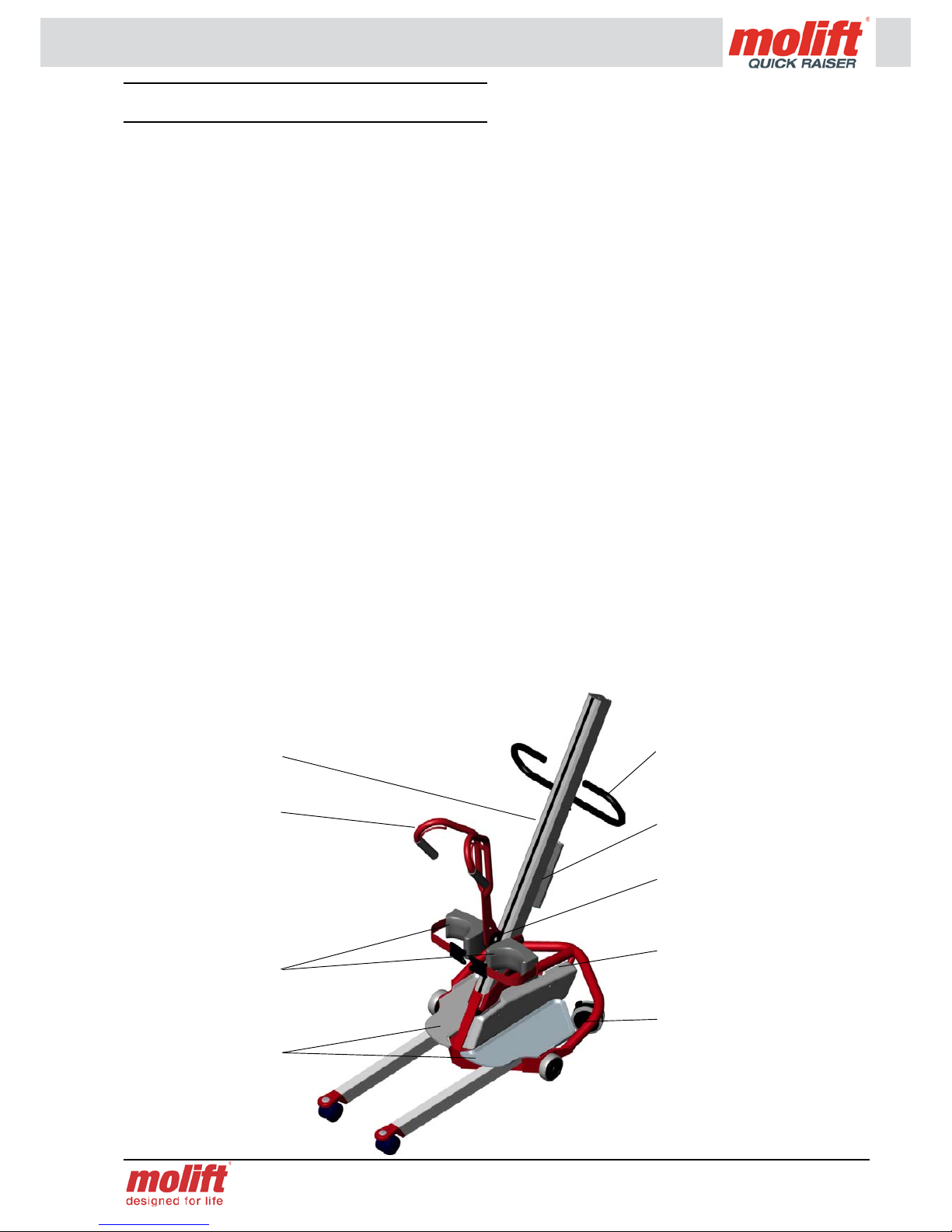

• The box contains chassis, lifting column, knee

support, lifting arm, drive handle, hand control,

battery, battery charger and documentation.

Make sure that the different parts have the

same lifting capacity. If in doubt, the part

with the lowest capacity is the ruling .

Assembly of lifter

The battery must not be in the battery holder

on the column during assembly!

• Assemble the kneepad bracket rst by sliding it

onto the lifting column. In order to do that, you

must rst remove the column xing bolts and -

plate. Guide the knee support bracket onto the

column with the head of the xing knob into the

T-groove on the column. Slide the bracket up the

column to the desired position and tighten the

knob.

• Retrieve the column xing bolts and -plate and

slide it into the T-groove at the base of the col-

umn and approx. 25mm up. Tighten one of the

screws slightly to x the plate. Insert the col-

umn into the chassis - the arrow on the column

side shall be exactly aligned with the edge of

the chassis. If the column stops before the arrow

has reached the edge, you will have to retract the

column and try turning the motor spline head to

align it with the connector at the base of the col-

umn. Do not use force to press the column down.

When the column is in place, release the column

xing bolt and let the plate with bolts slide into

the corresponding groove on the chassis. Tighten

the bolts rmly using the tool found at the top of

the column.

The QR2+ column has a pin in the bottom to

be fitted in the chassis.

• Slide the driving handle onto the top of the col-

umn by guiding the head of the xing knob into

the T-groove of the column. The handle shall be

pointing upwards. Tighten the knob rmly when

the handle is in the desired position.

• Guide the wire of the hand control through the

ring at the base of the drive handle and insert the

contact into the chassis connector. The hand con-

trol has a hook enabling it to hang on the handle.

• Attach the lifting arm.

QR2: Remove the security ring from the lifting

arm. Assemble the lifting arm by holding it ap-

prox. parallel to the column and guide the hook

of the arm onto the two bolts of the trolley. The

arm is now attached to the trolley. Mount the se-

curity ring.

QR2+: Place the lifting arm, install the bolt and at-

tach with the screws. Torque 28 Nm.

If the lifting arm appears wobbly in the trolley,

try tightening the bolts on each side of the trolley

to reduce the gap.

Be careful not to put fingers or similar under

the lifting arm between arm and trolley. Dan-

ger of personnel injury.

• Place the battery in the battery holder with the

connectors facing down. Run each function of

the lifter a couple of times without load to verify

proper function.

Molift AS tests all lifters with and without

load before shipment. The control is an extra

precaution to uncover any shipment damage

and/or incorrect assembly.