Dirty Hand Tools 100171 User manual

-Ton, 7-Ton and 8-Ton

Vertical/Horizontal Log Splitters

is safety alert symbol identies important safety messages in

this manual. Failure to follow this important safety information

may result in serious injury or death.

MODEL #’s 100171 ( -Ton), 100408 ( 7-Ton), 10034 ( 8-Ton)

Operation Manual

!

Part # 10064 Rev A

1JFSDF"WFOVFt4VJUF#-PVJTWJMMF$0t'PS4FSWJDFPS2VFTUJPOTCall 1-877-487-8275

720-287-5182

www.dirtyhandtools.com

Dirty Hand Tools is a brand of

Table of Contents

Important Safety Information .....................................................4

Intended Use ..............................................................................4

Personal Protective Equipment ..................................................4

4BGFUZ%FDBMT..............................................................................5

(FOFSBM4BGFUZ............................................................................6

Preparation of the Log ...............................................................6

Work Area ................................................................................. 6

0QFSBUJPOPGUIF-PH4QMJUUFS.....................................................7

3FQBJSBOE.BJOUFOBODF4BGFUZ................................................8

)ZESBVMJD4BGFUZ.........................................................................8

Fire Prevention ...........................................................................9

5PXJOH4BGFUZ...........................................................................10

Assembly Instructions

1. Assembly Overview ..............................................................11

2. Unpacking the Container ......................................................12

3. Tank and Wheel Assembly ....................................................14

4. Tank and Tongue Assembly...................................................15

#FBN#SBDLFU"TTFNCMZ........................................................16

#FBNBOE5BOL"TTFNCMZ......................................................17

7. Hydraulic Line Connection...................................................18

8. Log Catcher Installation........................................................19

Operating Instructions

Operating Instructions ..............................................................20

Hydraulic Oil Recommendations .............................................20

Engine Oil Recommendations .................................................20

4UBSUJOH*OTUSVDUJPOT.................................................................21

Towing ..................................................................................... 23

Maintenance .............................................................................23

Assembly Details/Parts Lists

Tank/Engine Assembly ..............................................................24

Pump/Engine Assembly.............................................................25

#FBN"TTFNCMZ..........................................................................26

Tongue Assembly .......................................................................27

Warranty & Specications .........................................#BDL$PWFS3

Important Safety Information

WARNING: Read and understand the complete Operation

Manual before assembling or using this product! Failure

to comprehend and comply with warnings, cautions and

instructions for assembly and operation could result in serious

injury or death.

Do not permit children to operate this equipment at any time. Do

not permit others that have not read and understood the complete

Operation Manual to operate this equipment. Operation of power

equipment can be dangerous. It is the sole responsibility of the

operator to understand the assembly and safe operation of this

product.

Call our customer service department at 7 0- 87-518 ,

1-877-487-8 75, or visit www.dirtyhandtools.com if you have any

questions or concerns about the safe operation of this equipment.

INTENDED USE

Do Not Use the log splitter for any purpose other than splitting

wood, for which it was designed. Any other use is unauthorized

and may result in serious injury or death.

PERSONAL PROTECTIVE EQUIPMENT

When operating this log splitter it is essential that you wear safety

gear including goggles or safey glasses, steel toed shoes and tight

fitting gloves (no loose cuffs or draw strings). Always wear ear

plugs or sound deafening headphones to protect against hearing

loss when operating this log splitter.

Do Not wear loose clothing or jewelry that can be caught by

moving parts of the log splitter. Keep clothing and hair away

from all moving parts when operating this log splitter.

4

!

WARNING

!

DANGER

!

CAUTION

5

Important Safety Information

SAFETY DECALS

Make sure all safety warning decals are attached and in readable

condition. Replace missing or defaced decals. Contact Dirty Hand

Tools at 1-877-487-8 75 for replacement decals.

Operator Zone Decal Part # 100399

Oil Level Decal Part # 100 07

Operation Decal Part # 100 1

Warning Decal Part # 100 08

Pinch Point Decal Part # 100 04

6

Important Safety Information

GENERAL SAFETY

Failure to follow warnings, cautions, assembly and operation

instructions in the Operation Manual may result in serious

injury or death.

Read the Operation Manual before operation.

R55)5().5permit children to operate this equipment at any time.

Do not permit others that have not read and understood the

complete Operation Manual to operate this equipment.

55R55Keep all people and pets a minimum of 10 feet away from the

work area when operating this log splitter. Only the operator is

to be near the log splitter during use.

55R55)5().operate the log splitter when under the influence of

alcohol, drugs or medication.

55R55)5().allow a person who is tired or otherwise impaired or not

completely alert to operate the log splitter.

PREPARATION OF THE LOG

#PUIFOETPGUIFMPHTIPVMECFDVUBTTRVBSFBTQPTTJCMFUPQSFWFOUthe log from rotating out of the splitter during operation.

Do not split logs greater than 25 in. in length.

WORK AREA

R55)5().operate the log splitter on icy, wet, muddy or otherwise

slippery ground. ONLY operate your log splitter on level ground.

Operating on a slope could cause the log splitter to roll over or

logs to fall o of the equipment, which could result in injury.

55R55)5().operate the log splitter in an enclosed area. Exhaust

fumes from the engine contain carbon monoxide which can be

harmful or deadly when inhaled.

55R55)5().move the log splitter over hilly or uneven terrain without

a tow vehicle or adequate help.

55RUse a tire chock or block on the wheels to prevent movement of

the log splitter while in operation.

55ROperate the log splitter in daylight or under good artificial light.

55RKeep the work area free of clutter. Remove split wood from

around the log splitter immediately after each use to avoid

potential tripping.

!

DANGER

!

DANGER

7

Important Safety Information

OPERATION OF THE LOG SPLITTER

Operate the log splitter from within the operation zone as shown

in the diagrams below. e operator has the safest and most

efficient access to the control valve and the beam in these locations.

Failure to operate the log splitter in this position can result in

serious injury or death.

55R55%5-/,5."5)*,.),5%()1-5")15.)5-.)*5(5#-(!!5."5controls before operating.

55R55)5().5*&5"(-5),5 .5.1(5."5&)!5(5-*&#..#(!51!5/,#(!5 ),1,5),5,0,-5-.,)%85,#)/-5#($/,35),5."5)/&5result.

55R55)5().straddle or step over the log splitter during operation.

55R55)5().reach or bend over the log splitter to pick up a log.

55R5)5().attempt to split two logs on top of each other.

55R5)5().attempt to cross split a log.

55R55)5().attempt to load your log splitter when the ram or wedge

is in motion.

55RUse your hand to operate the control lever on the valve. Do not

use your foot, a rope or any extension device.

55R55)5().move the log splitter while the engine is running.

55R550,5&05."5+/#*'(.5/(..(51"#&5."5(!#(5#-5running. 4IVUPĊUIFFOHJOFFWFOJGZPVBSFMFBWJOHUIFMPHsplitter for a short period of time.

55RAvoid contact with the muffler and other hot areas of the engine

during operation or after running to prevent burns

!

DANGER

!

DANGER

8

Important Safety Information

REPAIR AND MAINTENANCE

55R55)5().5)*,.5."5&)!5-*&#..,51"(5#.5#-5#(5*)),5'"(#&5condition or in need of repair. Frequently check that all nuts,

bolts, screws, hydraulic fittings and hose clamps are tight.

55R55)5().alter the log splitter in any manner. Any alteration will

void the warranty and could cause the log splitter to be unsafe

to operate. Perform all recommended maintenance procedures

before using the log splitter. Replace all damaged or worn parts

immediately.

55R55)5().tamper with the engine to run it at excessive speeds.

e maximum engine speed is preset by the manufacturer and is

XJUIJOTBGFUZMJNJUT4FF,PIMFSFOHJOFNBOVBM55R5Remove the spark plug wire before performing any service or

repair on the log splitter.

55R55&13-5"%5."5&0&5) 5"3,/)#&5(5(!#(5)#&5 ),5operation.

55RReplacement parts must meet manufacturer’s specifications.

HYDRAULIC SAFETY

e hydraulic system of the log splitter requires careful inspection

BMPOHXJUIUIFNFDIBOJDBMQBSUT#FTVSFUPSFQMBDFGSBZFELJOLFEcracked or otherwise damaged hydraulic hoses or hydraulic

components.

55R55"%5 ),5"3,/ł/#5&%-5by passing a piece of paper or

cardboard underneath or over the area of the leak. )5().5"%5 ),5&%-51#."53)/,5"(85Fluid escaping from the smallest hole,

under pressure, can have enough force to penetrate the skin causing

serious injury or death.

55R55%5*,) --#)(&5'#&5..(.#)(5#''#.&35# 5#($/,

35-*#(!5"3,/ł/#4FSJPVTJOGFDUJPOPSSFBDUJPODBOdevelop if medical treatment is not administered immediately.

55R55Relieve all pressure by shutting off the engine and moving the

valve control handle back and forth should it become necessary to

loosen or remove any hydraulic fitting.

55R55)5().5remove the cap from the hydraulic tank or reservoir while

the log splitter is running. e tank could contain hot oil under

pressure which could result in serious injury.

55R55)5().5adjust the hydraulic valve. e pressure relief valve on

the log splitter is preset at the factory. Only a qualied service

technician should perform this adjustment.

!

WARNING

9

Important Safety Information

FIRE PREVENTION

55R55)5().operate the log splitter near an open flame or spark.

Hydraulic oil and gasoline are ammable and can explode.

55R55)5().fill the gas tank while the engine is hot or running.

Allow the engine to cool before refueling.

55R55)5().5smoke while operating or refueling the log splitter. Gas

fumes can easily explode.

55R5Refuel the log splitter in a clear area with no gas fumes or spilled

gas. Use an approved fuel container. Replace the gas cap securely.

If gasoline has spilled, move the log splitter away from the area

of the spill and avoid creating any source of ignition until the

spilled gas has evaporated.

55R5,FFQB$MBTT#mSFFYUJOHVJTIFSPOIBOEXIFOPQFSBUJOHUIJTMPHsplitter in dry areas as a precautionary measure against possible

flying sparks.

55R5Drain the fuel tank prior to storage to avoid the potential fire

IB[BSE4UPSFHBTPMJOFJOBOBQQSPWFEUJHIUMZTFBMFEDPOUBJOFS4UPSFUIFDPOUBJOFSJOBDPPMESZQMBDF55RTurn the fuel shut off valve on the engine to the “OFF” position

before towing the log splitter. Failure to do so may result in

flooding the engine.

IMPORTANT NOTE:

is log splitter is equipped with an internal combustion engine

BOETIPVMEOPUCFVTFEPOPSOFBSBOZVOJNQSPWFEGPSFTUDPWFSFECSVTIDPWFSFEPSHSBTTDPWFSFEMBOEVOMFTTUIFFOHJOFTFYIBVTUsystem is equipped with a spark arrester meeting applicable

local or state laws (if any). If a spark arrester is used, it should be

maintained in effective working order by the operator. In the state

of California a spark arrester is required by law. Other states have

similar laws.

Federal laws apply on federal lands. A spark arrester muffler

(optional by manufacturer) is available as an accessory at your

nearest engine dealer. Always check the legal requirements in your

area.

!

CAUTION

!

CAUTION

10

Important Safety Information

TOWING SAFETY

RCheck all local and state regulations regarding towing, licensing,

and lights before towing your log splitter.

55RCheck before towing to make sure that the log splitter is

correctly and securely attached to the towing vehicle and that the

safety chains are secured to the hitch or bumper of the vehicle

with enough slack to allow turning. Always use a Class I, 2” ball

with this log splitter.

55R5)5().carry any cargo or wood on the log splitter.

55R5)5().allow anyone to sit or ride on the log splitter.

55RDisconnect the log splitter from the towing vehicle before

operating it.

55RUse care when backing up with the log splitter in tow to avoid

KBDLLOJmOH"MMPXGPSBEEFEMFOHUIPGUIFMPHTQMJUUFSXIFOturning, parking, crossing intersections and in all driving

situations.

55R55)5().exceed 45 mph when towing your log splitter. Towing

the log splitter at speeds higher than 45 mph could result in loss

of control, damage to the equipment, serious injury or death.

"EKVTUUPXJOHTQFFEGPSUFSSBJOBOEDPOEJUJPOT#FFYUSBDBVUJPVTwhen towing over rough terrain especially railroad crossings.

!

CAUTION

11

1. Assembly Overview

List of tools needed for assembly:

t)BNNFSt/FFEMFOPTFQMJFSTt#PYDVUUFSTt1IJMMJQTTDSFXESJWFStNNIFYLFZXSFODItNNESJWFStNNXSFODIPSTPDLFUXSFODItNNXSFODIPSTPDLFUXSFODItNNXSFODIPSTPDLFUXSFODItNNBOENNXSFODIFTPSDSFTFOUXSFODItNNTPDLFUXSFODI Item # Part # Description Qty.

1 100104 Tank & Engine Assembly 1

5BOL&OHJOF"TTFNCMZ5PO5POHVF4UBOE"TTFNCMZ#FBN$ZMJOEFS"TTFNCMZ5PO#FBN$ZMJOEFS"TTFNCMZ5PO#FBN$ZMJOEFS"TTFNCMZ5PO4 100062 Wheel/Tire Assembly, 4.80 x 8 in. 2

#FBN-PDL#SBDLFU#FBN1JWPU#SBDLFU7 100173 Log Catcher Assembly. 1

h85(*%#(!5."5)(.#(,Step 1: Remove top and sides of crate

Use a #2 phillips head and 8mm driver to remove hardware from

the plywood shipping crate (shown above). Due to the use of wood

staples, it may be necessary to use a hammer and/or a crow bar to

fully remove the packaging top and sides.

Step : Remove the log catcher box, wheels and hardware box

from the crate. en SFNPWFUIF5POHVF4UBOE"TTFNCMZGSPNthe crate.

1

h85(*%#(!5."5)(.#(,5(continued)

Step 3: Remove restraining bolts (tee nut bolts) from the beam

(5.(%5--'&#-85Use a 13mm wrench or socket to

remove the two hex bolts that are securing the beam to the

crate bottom (as shown below). Please note that the two

hex bolts are located diagonally opposed to each other.

13

Step 5: Remove Tank & Engine Assembly from crate, then

SFNPWFUIF#FBN$ZMJOEFS"TTFNCMZ-JGU#FBNCylinder Assembly to its vertical position standing on the

footplate.

Step 4: Use a 13mm wrench or socket to remove the single hex

bolt that is securing the tank assembly to the crate bottom

(as shown below).

Item # Part # Description Qty.

1 100104 Tank & Engine Assembly 1

2 100062 Wheel/Tire Assembly, 4.80 x 8 in. 2

3 100142 Flat Washer, 3/4 in. 2

$BTUMF/VU$MFBS;JOD$PUUFS1JOJOYJO6 100063 Hub Cap 2

7 100162 Hub Cap Tool 1

i85(%5(5"&5--'&3Installing the wheels:

1. Remove disposable spindle covers and wheel bearing covers.

4MJEFWheel/Tire Assembly

on to the spindle with valve stem

of tire facing outwards.

3. Install the Flat Washer, 3/4 in.

onto the spindle.

4. read the slotted Castle Nut, ¾ in.

onto the spindle. e

slotted nut should be driven down with a 28mm socket only

UJHIUMZFOPVHIUPFMJNJOBUFUIFGSFFQMBZPGUIFXIFFMBTTFNCMZand not tighter. Make sure that the wheels can freely rotate.e

Castle Nut needs to be oriented to allow for the installation of the

Cotter Pin, 1/8 in.

.

5. Install the Cotter Pin, 1/8 in. 5 through the Castle Nut, ¾ in.

BOETQJOEMF#FOEQJOFOETBSPVOETQJOEMFUPTFDVSFJUTQPTJUJPO6. Install the Hub Cap

using the Hub Cap Tool

. Gently tap on

the hub cap tool with a hammer to drive the hub cap into place.

7. Repeat these steps to install the 2nd wheel.

14

j85(%5;5)(!/5--'&31. Attach the Tongue & Stand Assembly

to the (%5;5Cylinder Assembly

XJUI)FY#PMU.YYNN

;

Flat Washer, M12

; Lock Washer, M12

; and Hex Nut, M12

x 1.75

in two places. Tighten securely using 19mm socket

wrenches.

Item # Part # Description Qty

1 100104 Tank & Engine Assembly 1

5BOL&OHJOF"TTFNCMZ5PO5POHVF4UBOE"TTFNCMZ5POHVF4UBOE"TTFNCMZ5PO)FY#PMU.YYNN(4 100181 Flat Washer, M12 10

5 100023 Lock Washer, M12 8

6 100022 Hex Nut, M12 x 1.75, G8.8 8

15

16

k85'5,%.5--'&31. Attach the5'5)%5,%.

to the Beam & Cylinder

Assembly

XJUI)FY#PMU.YYNN

; Flat Washer,

M12

; Lock Washer, M12

; and Hex Nut, M12 x 1.75

in

two places. Tighten securely using 19mm socket wrenches.

2. Attach the #0).5,%.

to the Beam & Cylinder Assembly

VTJOHUIFGPVSCPUUPNIPMFTXJUI)FY#PMU.YYNN

; Flat Washer, M12

; Lock Washer, M12

; and Hex Nut,

M12 x 1.75

in four places. Tighten securely using 19mm socket

wrenches.

Item # Part # Description Qty.

#FBN$ZMJOEFS"TTFNCMZ#FBN-PDL#SBDLFU#FBN1JWPU#SBDLFU)FY#PMU.YYNN(5 100181 Flat Washer, M12 10

6 100023 Lock Washer, M12 8

7 100022 Hex Nut, M12 x 1.75, G8.8 8

17

l85'5;5(%5--'&33PUBUFUIF+BDL4UBOEBUUBDIFEUPUIFTJEFPGUIF5POHVFAssembly downwards into position by releasing the pin and

then securing the release pin.

2. Remove the Retaining Clip, 1/8 in.

and Hitch Pin, 5/8 in. x

JO

from the assembled unit (as shown below).

4MPXMZCBDLUIFBTTFNCMFEVOJUVQUPUIF#FBN$ZMJOEFS"TTFNCMZ"MJHOUIF5POHVF#SBDLFUPGUIFBTTFNCMFEVOJUUPUIF1JWPU#SBDLFUPGUIF#FBN"TTFNCMZ4. Once the brackets are aligned, install the Hitch Pin

through

the brackets then install the Retaining Clip

into the

Hitch Pin.

Item # Part # Description Qty.

1 100131 Hitch pin, 5/8 in. x 6 1/4 in. 1

3$MJQJO'JUTJOUPJO

18

7. Hydraulic Line Connection

1. Apply teflon tape or pipe sealant on to the hose fitting threads.

Install the ends of the two Hydraulic Hoses

and

to the

ValveBTTIPXOJOEFUBJMESBXJOH4FDVSFMZUJHIUFOUIFmUUJOHconnections using 22mm and 24mm wrenches.

Item # Part # Description Qty.

1 100136 Hydraulic Hose, 1/2 in. x 56 in. 1

2 100137 Hydraulic Hose, 1/2 in. x 38 in. 1

19

8. Log Catcher Installation

3PUBUF#FBN$ZMJOEFS"TTFNCMZEPXOGSPNVQSJHIUposition and lock in place with the release pin.

2. Install the Log Catcher Assembly

XJUI)FY#PMUT.Y1.5 x 30mm

; Flat Washer, M10

; Lock Washer, M10

;

Hex Nut, M10 x 1.5

BOE#VUUPO4DSFX.YYNN

; in 2 places. Tighten hex nuts securely with a 17mm socket

wrench and tighten button screws with 6mm hex key wrench.

Item # Part # Description Qty.

1 100173 Log Catcher Assembly 1

)FY#PMU.YYNN(3 100161 Flat Washer, M10 6

4 100089 Lock Washer, M10 4

5 100009 Hex Nut, M1 x 1.5, G8.8 4

#VUUPO4DSFXM10 x 1.5 x 30mm, G8.8

o85#(&5(-.&&.#)(5"%Check tightness of all fittings, nuts and bolts prior to filling the

log splitter with fluids.

0

Operating Instructions

WARNING: Read and understand the complete Operation

Manual before assembling or using this product! Failure

to comprehend and comply with warnings, cautions and

instructions for assembly and operation could result in serious

injury or death.

Do not permit children to operate this equipment at any time.

Do not permit others that have not read and understood

the complete Operation Manual to operate this equipment.

Operation of power equipment can be dangerous. It is the sole

responsibility of the operator to understand the assembly and safe

operation of this product.

Call our customer service department at 7 0- 87-518 ,

1-877-487-8 75, or visit www.dirtyhandtools.com if you have

any questions or concerns about the safe operation of this

equipment.

CAUTION: Oil must be added to the hydraulic reservoir and

the engine before starting or operation.

STEP 1: Fill the hydraulic reservoir with oil. AW32 hydraulic oil

is recommended. Automatic transmission fluid can be substituted

used instead of hydraulic oil when temperatures are below 32°F.

Use only clean oil and take care to prevent dirt from entering the

hydraulic reservoir. Fill the hydraulic tank with approximately 5

to 4 gallons of hydraulic oil. Remaining fluid is added at a later

step.

ENGINE OIL RECOMMENDATIONS

6TFTUSPLFBVUPNPUJWFEFUFSHFOUPJM4"&8JTSFDPNNFOEFEGPSHFOFSBMVTF3FGFSUPUIF4"&7JTDPTJUZGrades chart in your engine owner’s manual for average

temperature ranges. e engine manufacturer recommends using

"1*4&37*$&$BUFHPSZ4&PS4'PJMɩFFOHJOFPJMDBQBDJUZJTP[GPS,PIMFS4)5PO5POBOEP[GPS,PIMFS$)5PO"MXBZTDIFDLPJMMFWFMCFGPSFTUBSUJOHUIFengine and keep level full.

!

DANGER

!

CAUTION

Other manuals for 100171

1

This manual suits for next models

2

Table of contents

Popular Industrial Equipment manuals by other brands

UnionSpecial

UnionSpecial 3000M Instructions and illustrated parts list

ISC

ISC RP037 General Instructions for Use

Eriez

Eriez HS36 Installation, operation and maintenance instructions

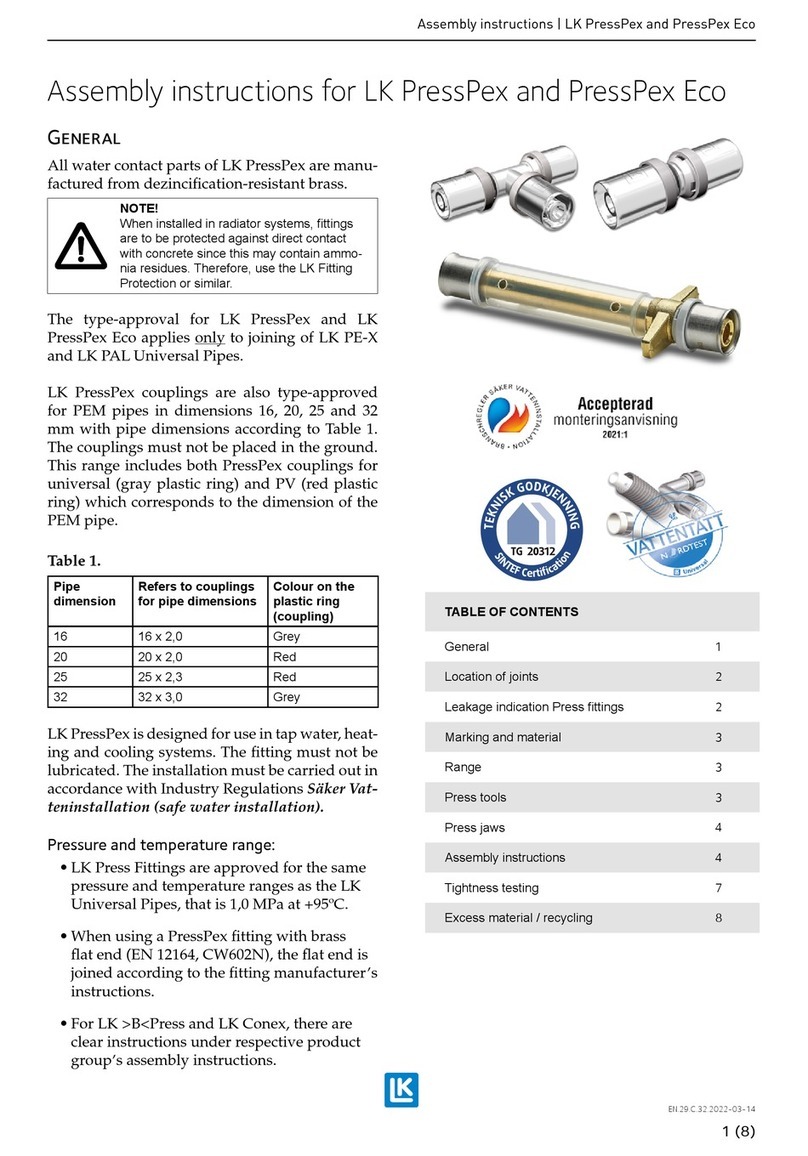

LK

LK PressPex Eco 188 26 68 Assembly instructions

Grundfos

Grundfos TPE Series Installation and operating instructions

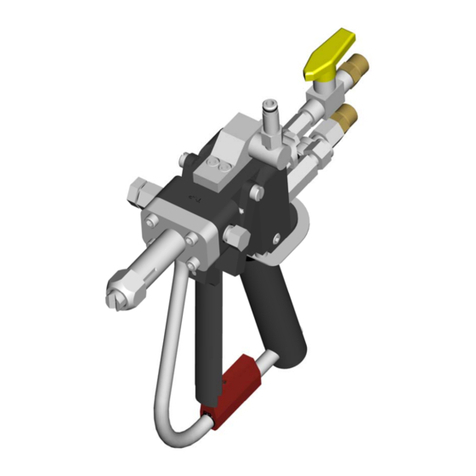

Graco

Graco GLASCRAFT Indy Operation

Panasonic

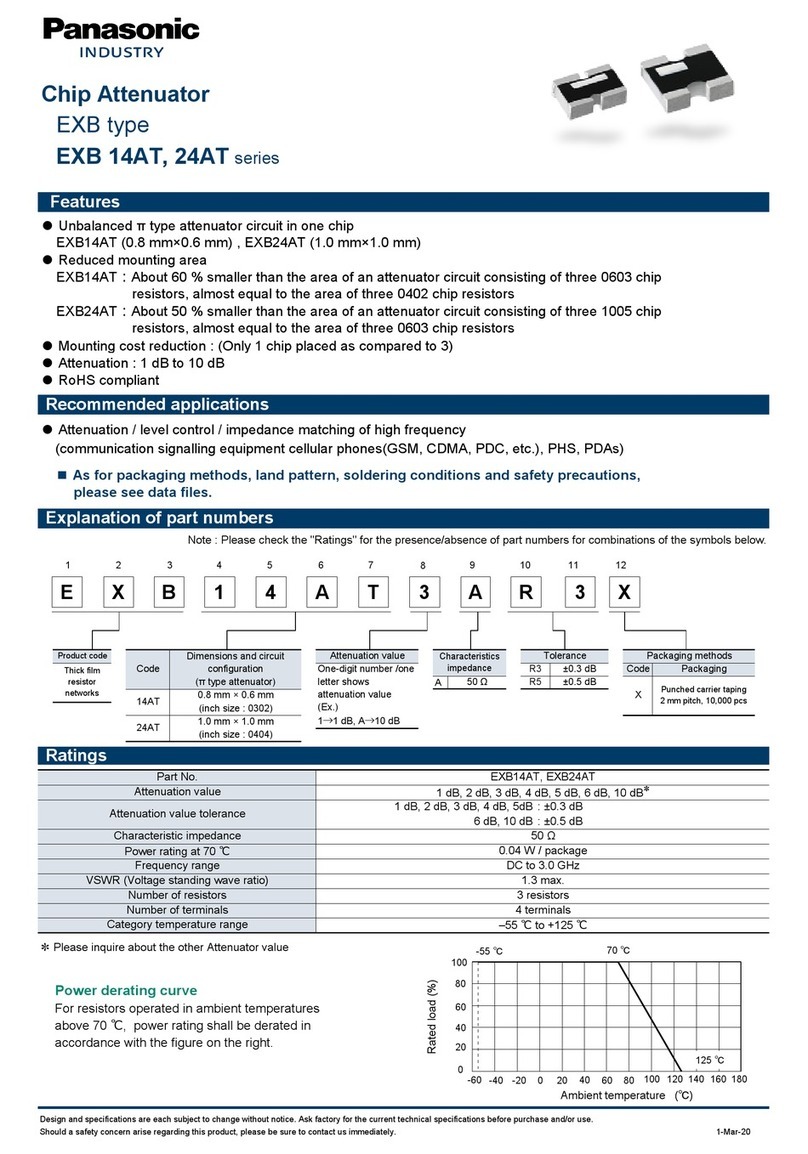

Panasonic EXB 14AT Series manual

Powermatic

Powermatic 72A Instruction manual & parts list

ENOTOSCANA

ENOTOSCANA MINI VIRGILIO 6 user manual

CRH

CRH Leviat HALFEN DEHA HA-N Assembly instructions

Edwards

Edwards Drystar GV80-EH250 instruction manual

Gervall

Gervall Overspeed Governor ALJO 2129 Assembly and maintenance instructions