English (GB)

5

English (GB) Installation and operating instructions

Original installation and operating instructions.

CONTENTS

Page

1. Symbols used in this document

2. General information

These installation and operating instructions are a supplement to

installation and operating instructions for the corresponding

standard pumps TP, TPD, NK, NKG and NB, NBG. For

instructions not mentioned specifically here, please see

installation and operating instructions for the standard pump.

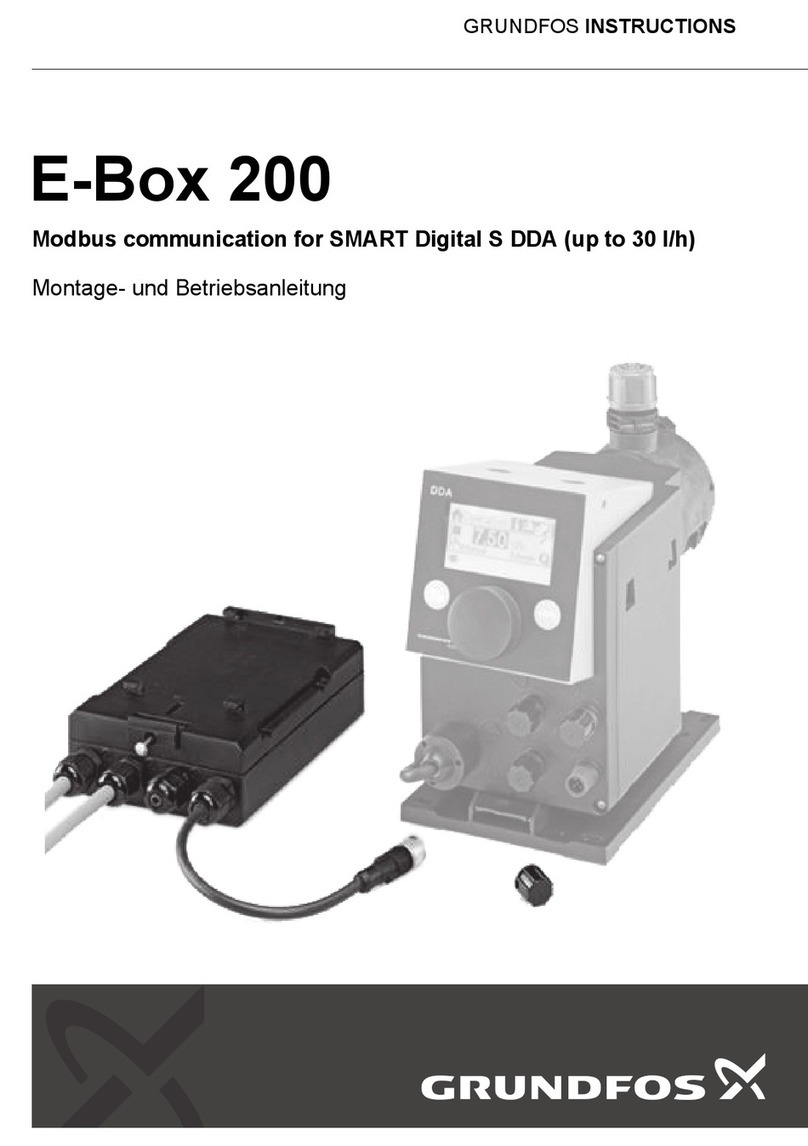

3. General description

Grundfos E-pumps have standard motors with integrated

frequency converter. The pumps are for single-phase or three-

phase mains connection.

The pumps have a built-in PI controller and can be set up for an

external sensor enabling control of the following parameters:

•pressure

• differential pressure

•temperature

• differential temperature

•flow.

From factory, the pumps have been set to control mode

uncontrolled. The PI controller can be activated by means of

R100.

The pumps are typically used as circulator pumps in large heating

or cooling water systems with variable demands.

3.1 Settings

The desired setpoint, can be set in three different ways:

• directly on the pump control panel

• via an input for external setpoint signal

• by means of the Grundfos wireless remote control R100.

All other settings are made by means of the R100.

Important parameters such as actual value of control parameter,

power consumption, etc. can be read via the R100.

3.2 Twin-head pumps

Twin-head pumps do not require any external controller.

1. Symbols used in this document 5

2. General information 5

3. General description 5

3.1 Settings 5

3.2 Twin-head pumps 5

4. Mechanical installation 6

4.1 Motor cooling 6

4.2 Outdoor installation 6

5. Electrical connection 6

5.1 Cable requirements 6

5.2 Electrical connection - single-phase pumps 6

5.3 Electrical connection - three-phase pumps up to 7.5

kW 8

5.4 Electrical connection - three-phase pumps, 11-22 kW 10

5.5 Signal cables 13

5.6 Bus connection cable 13

5.7 Communication cable for TPED pumps 13

6. Modes 14

6.1 Overview of modes 14

6.2 Operating mode 14

6.3 Control mode 15

6.4 Factory setting 15

7. Setting by means of control panel 15

7.1 Setpoint setting 16

7.2 Setting to max. curve duty 16

7.3 Setting to min. curve duty 16

7.4 Start/stop of pump 16

8. Setting by means of R100 16

8.1 Menu OPERATION 18

8.2 Menu STATUS 19

8.3 Menu INSTALLATION 20

9. Setting by means of PC Tool E-products 23

10. Priority of settings 23

11. External forced-control signals 24

11.1 Start/stop input 24

11.2 Digital input 24

12. External setpoint signal 24

13. Bus signal 25

14. Other bus standards 25

15. Indicator lights and signal relay 25

16. Insulation resistance 26

17. Emergency operation (only 11-22 kW) 27

18. Maintenance and service 28

18.1 Cleaning of the motor 28

18.2 Relubrication of motor bearings 28

18.3 Replacement of motor bearings 28

18.4 Replacement of varistor (only 11-22 kW) 28

18.5 Service parts and service kits 28

19. Technical data - single-phase pumps 28

19.1 Supply voltage 28

19.2 Overload protection 28

19.3 Leakage current 28

19.4 Inputs/outputs 28

20. Technical data - three-phase pumps up to 7.5 kW 29

20.1 Supply voltage 29

20.2 Overload protection 29

20.3 Leakage current 29

20.4 Inputs/output 29

21. Technical data - three-phase pumps, 11-22 kW 29

21.1 Supply voltage 29

21.2 Overload protection 29

21.3 Leakage current 29

21.4 Inputs/output 30

22. Other technical data 30

23. Disposal 32

Warning

Prior to installation, read these installation and

operating instructions. Installation and operation

must comply with local regulations and accepted

codes of good practice.

Warning

If these safety instructions are not observed, it may

result in personal injury!

Warning

The surface of the product may be so hot that it may

cause burns or personal injury.

If these safety instructions are not observed, it may

result in malfunction or damage to the equipment.

Notes or instructions that make the job easier and

ensure safe operation.