DOOSAN INFRACORE 2/36

2

SECTION

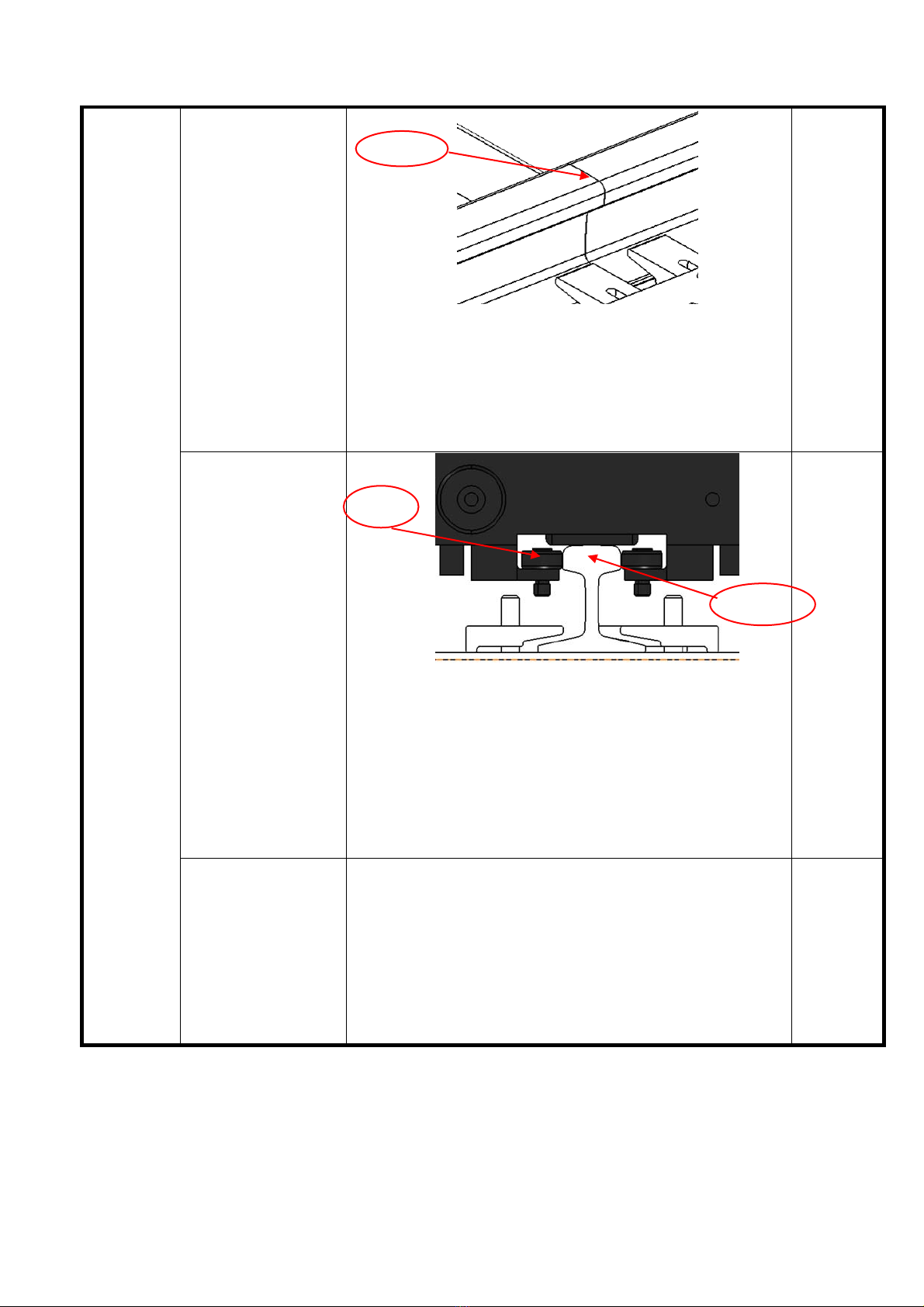

维护

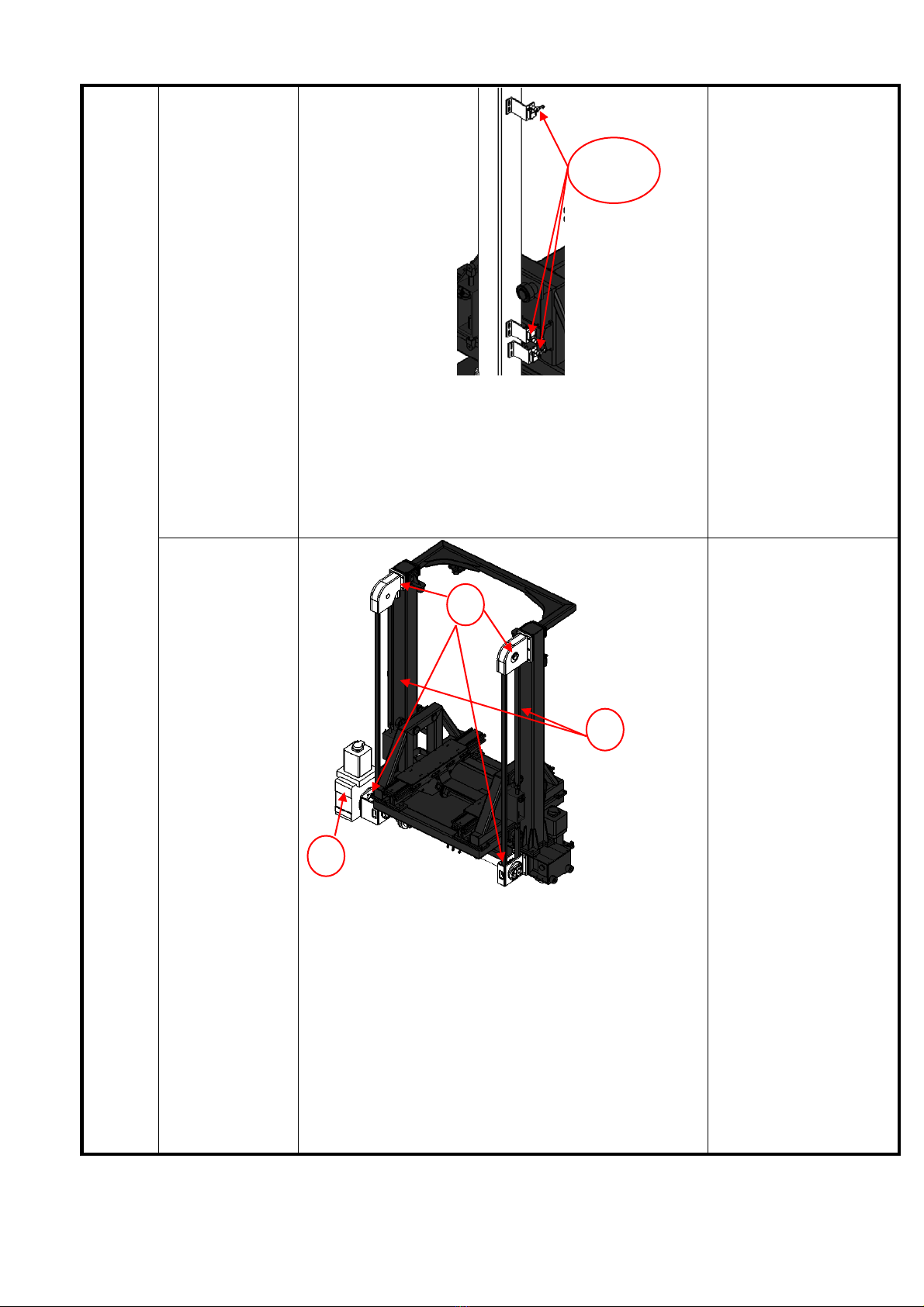

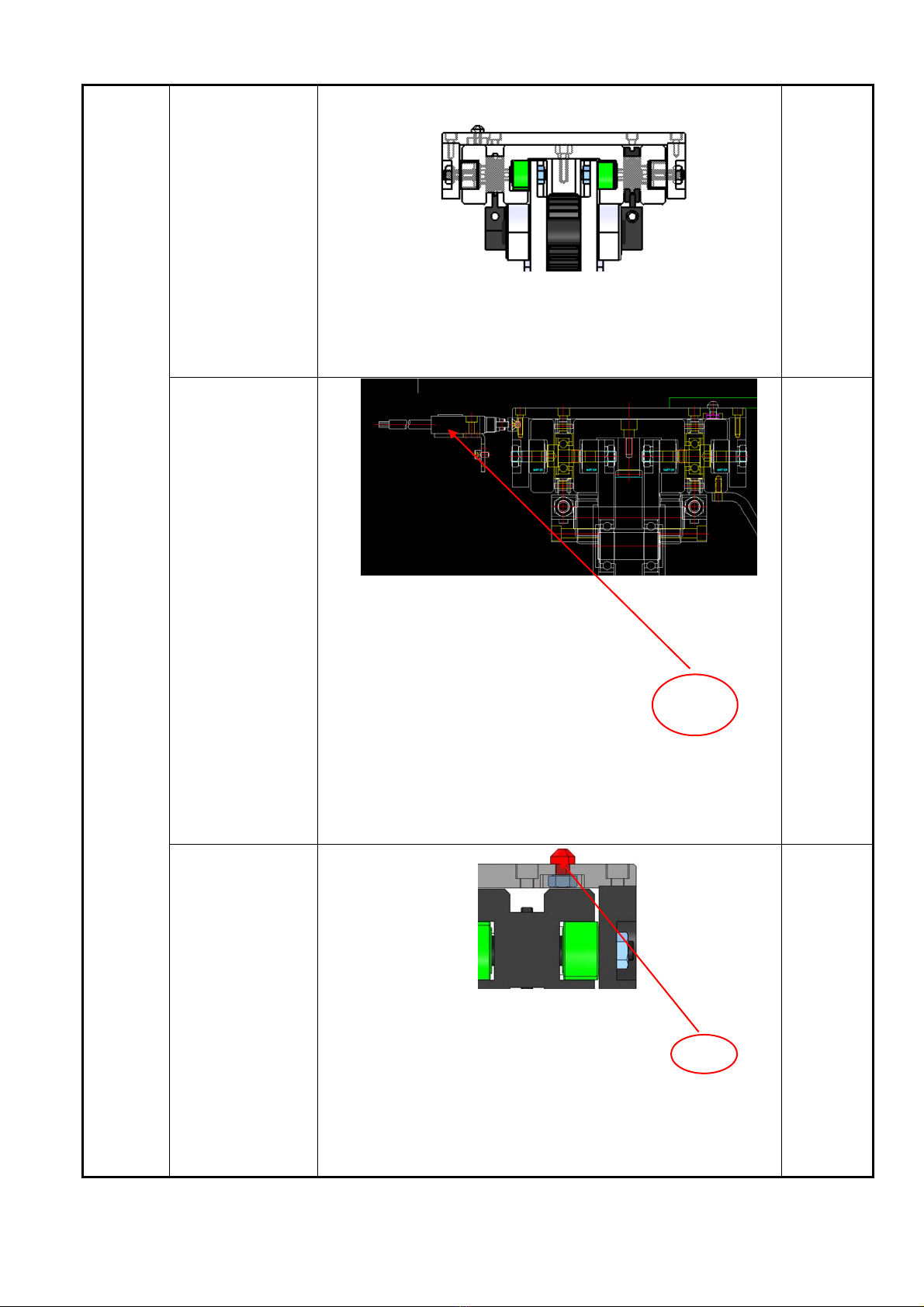

目录

1. 定期维护项目 ................................................................................................................................... 3

2. 检验基准 .......................................................................................................... 错误!未定义书签。

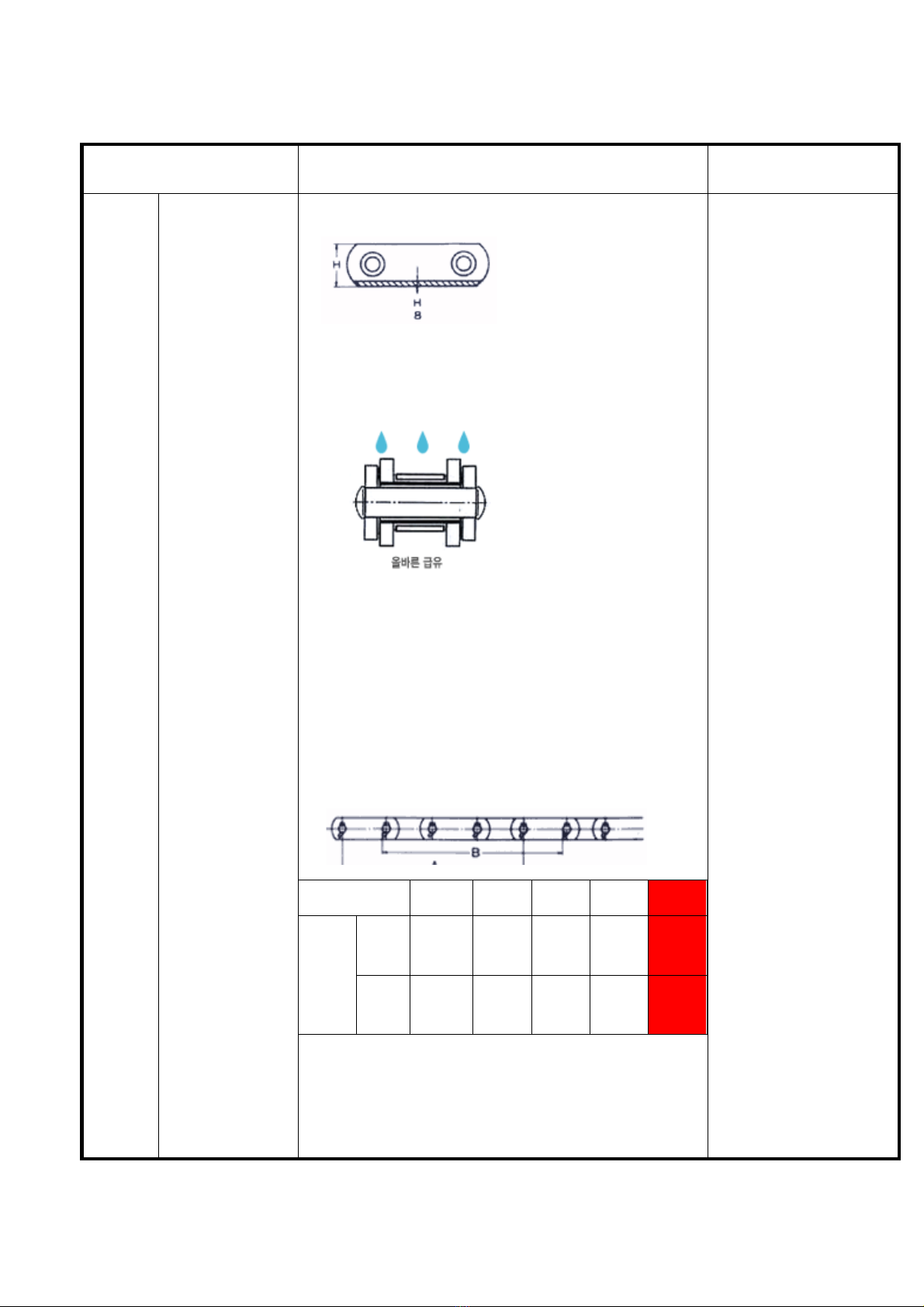

3. 检查链要点 ....................................................................................................... 错误!未定义书签。

4. 伺服电机检查要点 ........................................................................................................................ 20

5. 期检查及更换 ................................................................................................... 错误!未定义书签。

6. 使用润滑油 ....................................................................................................... 错误!未定义书签。

7. 正常运转 .......................................................................................................... 错误!未定义书签。

8. 随着报警故障措施要点 ................................................................................... 错误!未定义书签。

10. RETURN TO HOME POSITION FROM AN ERROR SITUATION ............................................ 28

11. 在STACKER CRANE 内有托盘状态时紧急停止 ....................................... 错误!未定义书签。

12. 发生门开着状态时措施要点 ......................................................................... 错误!未定义书签。

13. 定期检查表 .................................................................................................... 错误!未定义书签。