4

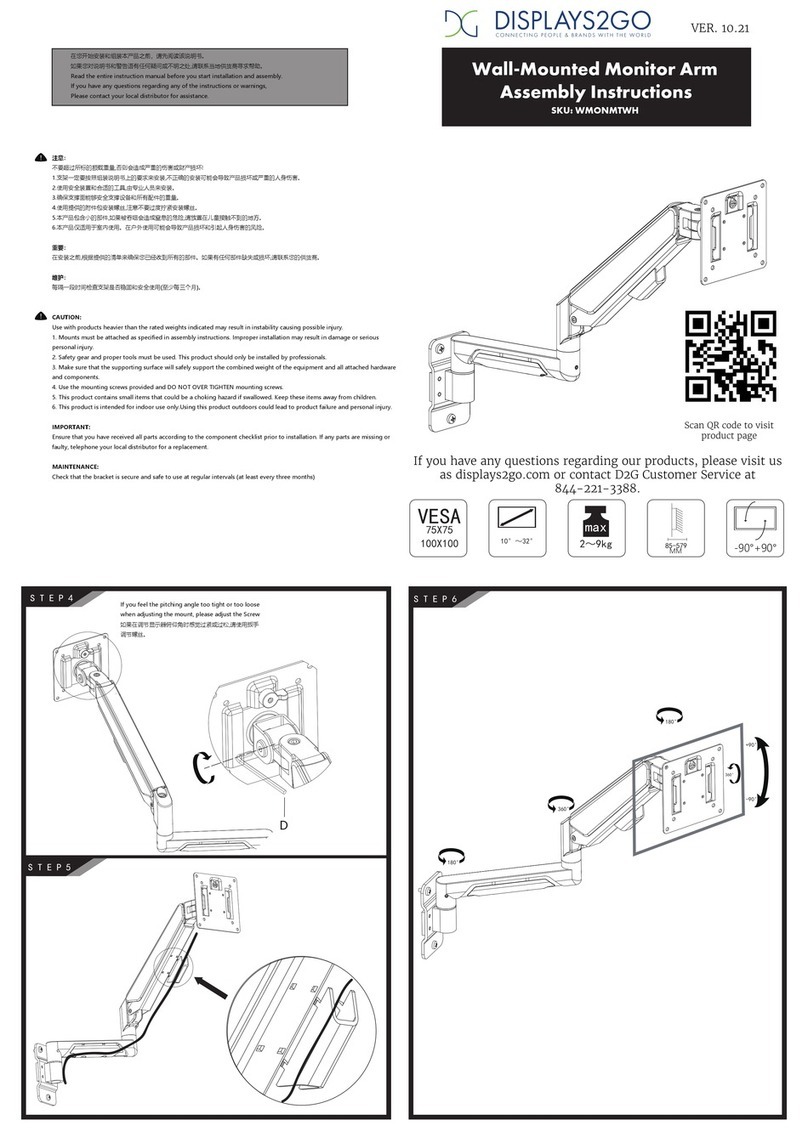

Step 4 - Using cable management (Fig. 6)

The HVAWM4290L includes a cable management system

where cable can be routed along the length of the arm

assembly.

Route the panel cable along the entrance of the cable

management slot.

NOTE: For optimal performance, route the AC power cable

separately from the audio and video cables

With all cables in place, pull the panel in and out to be

certain that the arm assembly moves freely, without

stretching or damaging the cables.

U-Cap cable management

Cable

Fig. 6

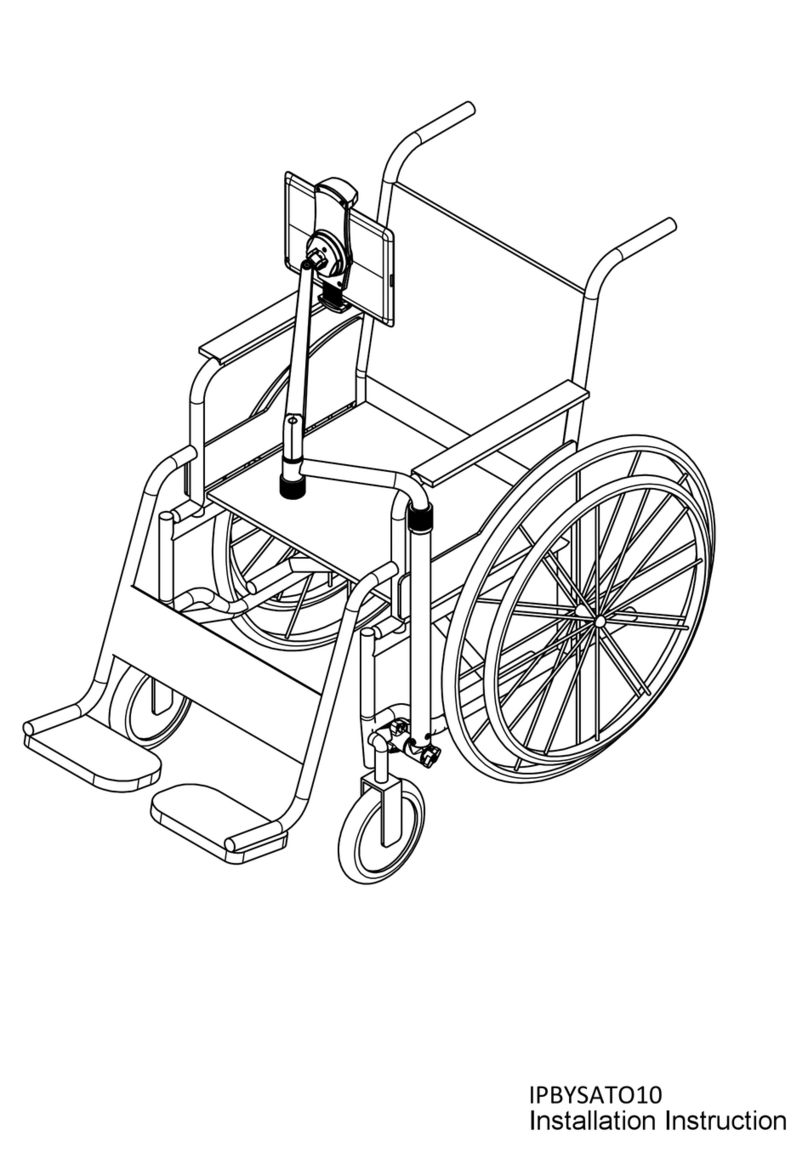

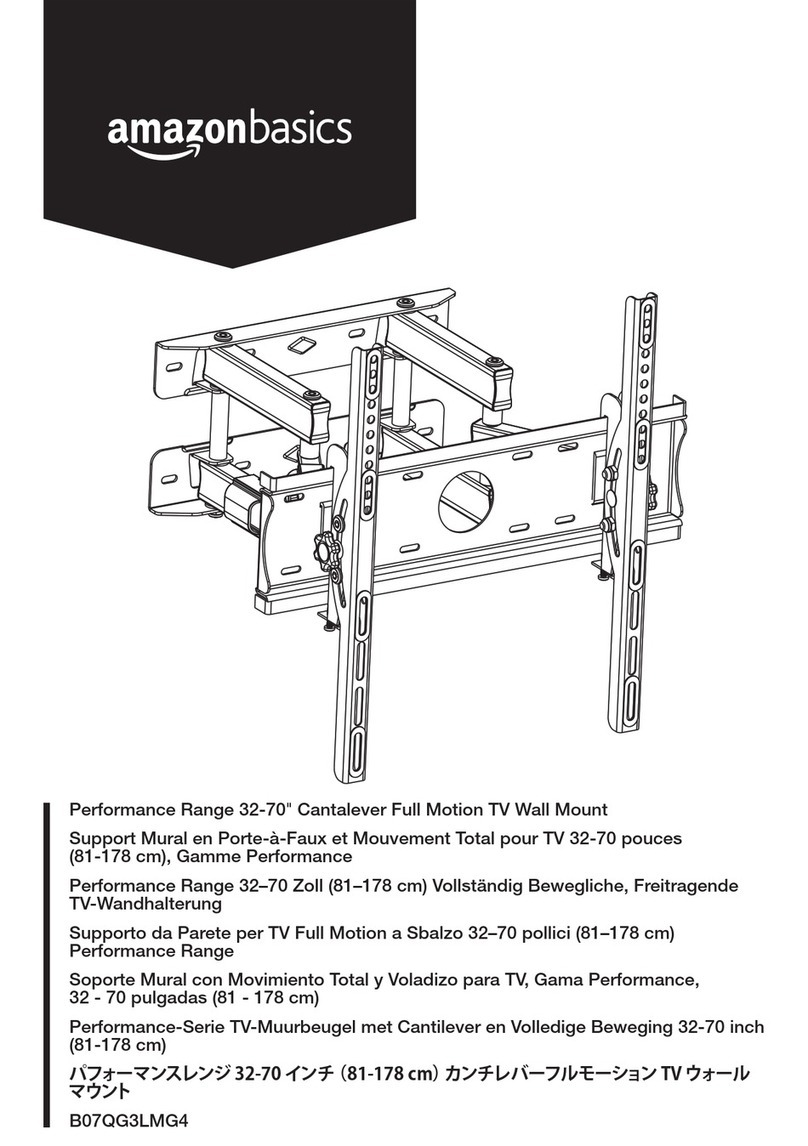

Step 5 - Adjusting the flat panel

The HVAWM4290L provides a wide range of adjustment possibilities

to suit your environment.

Roll Control - Horizontal levelling of the flat panel display.

Grasp the edge of the panel and roll it up or down into a level

position (Fig.7.1).

Loosen the screws as shown in Fig. 7.2 to allow roll control

adjustment. Tighten screws by hand when finished.

Tilt Adjustment - Raising or lowering the screen to improve

viewing angle. First release completely the tilt knob as shown

(Fig.9) Next, grasp the upper and lower edges of the panel,

and then turn it to the desired

tilt angle (Fig.8).

To lock the tilt angle, tighten

the tilt knob (Fig.10) securely.

NOTE : For heavier panels, never

fully release the tilt knob without

fully supporting the panel. The tilt

lever includes a ratchet function,

so that it can be lifted and

repositioned for the next turn. To

operate the ratchet, pull the lever

straight out, rotate it to an

unobstructed position, release the

lever, and then turn it in the

desired direction. Repeat as

necessary until the tilt tension is

set properly (Fig.10)

Fig. 7.1

Fig. 7.2

Fig. 8

Fig. 9

Fig. 10

a b

c d

Tilt knob Release tilt knob

Turn Tighten