DITTING KF 804 User manual

Operating instructions

64420 A 98/16 page 1 - 17

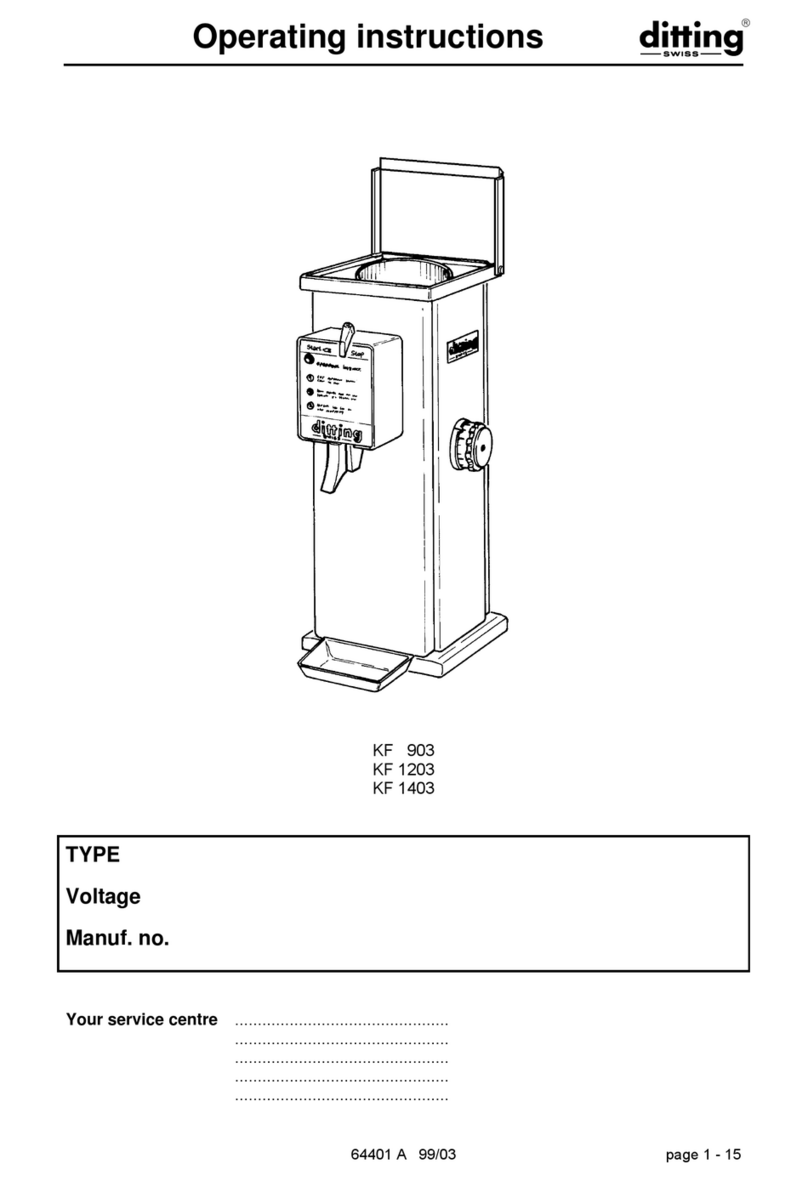

KF 804 KR 804

TYPE

Voltage /

Manuf. no.

Your service centre ...............................................

...............................................

...............................................

...............................................

...............................................

Operating instructions

64420 A 98/16 page 2 - 17

Contents

page

1 General

1.1 Warranty information 3

1.2 Transfer declaration 4

1.3 General safety instructions 5

1.3.1 Information and safety symbols 6

2 Installation of coffee grinder

2.1 Description and installation of unit 6

2.2 How to use the coffee grinder 7

3 Care / Maintenance / Adjustment

3.1 Care and cleaning of the coffee grinder 8

3.2 Maintenance 10

3.3 Setting the scale (adjustment) 10

3.3.1 Basic setting (calibration) 11

3.3.2 Changing the scale setting (customer setting) 12

3.4 Replacing the grinding discs 13

4 Faults / action

4.1 Action in event of a fault 14

4.1.1 Table with possible malfunctions 14

4.2 Repairs 15

4.2.1 Unblocking the discharge tube 15

4.2.2 Unblocking the grinding unit 15

4.2.3 Replacing the rubber bolt 16

4.2.4 Circuit breaker 16

5 Customer service 17

Operating instructions

64420 A 98/16 page 3 - 17

1 General

Dear Customer,

We congratulate and thank you for purchasing a DITTING quality product. These operating

instructions have been prepared to simplify your use of the coffee grinder. They contain

information, advice and instructions for the best use of your unit.

1.1 Warranty information

ALTHOUGH YOUR COFFEE GRINDER IS DISTINGUISHED BY A HIGH QUALITY AND

SAFETY STANDARD, DAMAGE TO MATERIAL OR RISK OF INJURY CANNOT BE

EXCLUDED IF OPERATED INCORRECTLY, USED IMPROPERLY OR MISUSED.

THE OPERATING INSTRUCTIONS WILL THEREFORE FAMILIARISE YOU WITH

CORRECT USE OF THE COFFEE GRINDER AND ASSIST YOU TO AVOID WRONG

OPERATIONS. IF THE ENCLOSED INSTRUCTIONS ARE FOLLOWED EXACTLY, YOU

WILL AVOID DANGERS, REDUCE REPAIR AND STOPPAGE TIMES AND INCREASE

THE RELIABILITY AND SERVICE LIFE OF YOUR UNIT.

TO ENSURE THAT YOU AND YOUR EMPLOYEES TAKE NOTICE OF THE CONTENTS

OF THE OPERATING INSTRUCTIONS AND FOR YOUR OWN SAFETY, WE WOULD ASK

YOU TO COMPLETE THE TRANSFER DECLARATION PRINTED ON THE FOLLOWING

PAGE, DETACH THIS ALONG THE PERFORATION AND RETURN IT TO YOUR DEALER.

Operating instructions

64420 A 98/16 page 4 - 17

1.2 Transfer declaration

To ensure transfer of the operating instructions to final consumers

Note: The following declaration should be completed by the dealer and the purchaser. The

purchaser undertakes to return this declaration to the dealer. The purchaser thereby certifies

that the dealer has drawn his attention to the contents of operating instructions no. 64400, in

particular to the relevant safety instructions for use of the machine.

64420 A 97/34 page 4 - 15

Transfer declaration

(1) Type Machine no.

(2) Address of customer

(3) The machine specified in (1) was purchased by me. The complete operating

instructions were handed to me with transfer of the machine.

_______________________ _______________________

Signature of customer Place / date

(4) Date of transfer

(5) Address of dealer/importer

__________________________

Company stamp/signature

(6) The machine was handed to the customer in accordance with the guidelines of

the manufacturer.

Company stamp/signature if not identical with (5)

_____________________________ _______________________

Signature of customer service- Date

specialist

✂

✂✂

✂

Operating instructions

64420 A 98/16 page 5 - 17

1.3 General safety instructions

•The operating instructions must be kept permanently at the place of operation of

the machine and if possible attached at the point of installation in the immediate

vicinity of the machine.

•The competent sales and service personnel must have read the operating

instructions before putting the coffee grinder into operation and be familiar with all

functions including action in the event of a fault.

•If customers themselves operate the machine, a notice must be placed clearly

visible in the immediate vicinity of the machine that customers must immediately

call the service personnel responsible in the event of a fault and not try to eliminate

the fault themselves by tampering with the machine.

•The machine must be placed in the sales areas so that the sales personnel

responsible can be reached by the customer without difficulty.

•The model KF/KR 804 was developed and built for intermittent duty only and is

therfore not suitable for continuous operation. The max. grinding time, without

interruption, is 3 minutes. After 3 minutes, the grinder must be switched off and not

be operated for approx. 45 sec.

•Only original spare-parts must be used for repairs to the grinder. If spare-parts

from other manufacturers are used, the serviceability of the grinder may be

impaired. In addition, further injury to persons or material damage cannot be

excluded.

•The grinder should be installed out of reach of children. Children and users must

on no account reach into the openings or come into contact with electrical

components.

•Only original grinding discs sharpened by DITTING must be used.

•Never reach into the hopper opening while the machine is running.

•Never touch electrical components with conducting objects, such as needles, pins,

cutlery, etc. !

•The emission value referred to the workplace is 76 dB(A).

•The machine must be electrically protected by fuses according to the nameplate

and the local regulations.

Operating instructions

64420 A 98/16 page 6 - 17

3.1 Information and safety symbols

Two information symbols are used in these operating instructions to emphasise important

comments in the text:

Information

This symbol indicates information containing important data concerning

efficient use. Non-observance can lead to faults.

Safety

This symbol indicates information which if not observed can lead to danger to

persons and/or substantial material damage. The safety instructions must be

followed without fail.

2 Installation of coffee grinder

2.1 Description and installation of unit

The KF/R 804 coffee grinders are suitable for grinding various kinds of coffee. The grinding

fineness can be set from "Turkish fine" to "coarse" with an adjusting knob provided with a

scale. The KF/R 804 coffee grinders are suitable for use in small food stores, cafés,

restaurants and hotels. The simple method of operation enables customers to use the

grinder themselves in self-service stores. Operation of the machine can differ slightly from

the description in these operating instructions depending on the version KF or KR.

Hopper Filling cover

Adjusting knob

Bag holding lever

Discharge tube

Bag vibrating plate Name plate

(KR only)

ON/OFF switch Circuit breaker

The grinder must only be installed in dry areas!

Place the coffee grinder on a firm, level and non-slip base. Danger of tipping

and slipping on unstable surfaces. Before connecting the coffee grinder to the

mains supply, ensure that this supply corresponds with the data on the unit

nameplate.

Operating instructions

64420 A 98/16 page 7 - 17

2.2 How to use the coffee grinder

- Set the required grinding fineness on the

scale with adjusting knob (1).

- Open the filling cover (2) and place coffee

beans in hopper (3).

- Clamp empty paper bag over discharge

tube (5) with bag holding lever (4) and

release bag.

Please ensure that the bag is opened fully before clamping with bag holding

lever (4) for grinding.

Reason: If the bag is not fully open, the ground coffee cannot run out

properly, which can result in a build-up and malfunction of the unit.

- Switch on motor with the ON/OFF switch

(6).

- After the end of grinding switch off the

motor (6).

- Hold the bag tightly in the hand and tap the

discharge tube clean by pulling and

releasing the bag holding lever (4), then

remove the bag.

Only grind whole coffee beans!

Coffee already ground must not be ground again!

1

4

5

6

4

2

3

Operating instructions

64420 A 98/16 page 8 - 17

3 Care / maintenance / adjustment

3.1 Care and cleaning of coffee grinder

The coffee grinder must only be cleaned with a paper towel.

If necessary use suitable mild dish washer detergent.

Do not use an alkaline cleaning agent.

Do not spray coffee grinder with water and/or steam.

Reason:1- It can result in a short-circuit and therefore damage the unit.

2- The use of alkalis can affect the flavor of the coffee.

The coffee grinder should be cleaned at least once a week and always if soiled.

Before cleaning the coffee grinder, switch off motor AND REMOVE THE

POWER CABLE FROM THE OUTLET.

Cleaning of body shell

Use a paper towel along with a mild dish washer

detergent to clean the body shell, cover lid and

the inside of the hopper.

Cleaning of discharge tube

Use a brush and paper towel to clean in and

outside of discharge tube (1) from any coffee

particles.

Cleaning of grinding discs and grinding chamber

Cleaning of the grinding chamber and grinding discs must only be performed

by persons familiar with the unit after carefully reading the following

instructions.

1

Operating instructions

64420 A 98/16 page 9 - 17

The grinding discs and grinding chamber should be cleaned at least once a

week.

a UNPLUG THE COFFEE GRINDER

b Dismantle hopper according to 4.2.2

1 Use a paper towel and/or a brush to clear the hopper and built-in magnet from any

coffee particles. If necessary, use mild dish washer detergent along with towel.

c Remove the screws that hold the top stationary disc flange.

1 Pull out the stationary disc and set it aside.

2 Use paper towel and brush to clear the grinding chamber and grinding discs from

any coffee particles. If necessary, use mild dish washer detergent along with

towel.

d Loosen the screw in the center of the adjusting knob (on the right side of the machine)

and slowly remove the screw, the aluminum backing plate, and the spring behind it.

1 Unscrew (counter-clockwise) the adjusting gear/cone and set it aside.

e Remove the center bolt holding the lower rotating disc. You need to place the soft

handle of a pair of pliers in the opening chamber where the coffee goes out to the

discharge tube to prevent the rotating disc from moving.

1 Take out the washer behind the bolt and replace the bolt in the hole (finger tight).

f Take a wood dowel (or a piece of hard wood) , place it on the head of the center bolt

and hit it with a hammer to push away the cone tipped shaft from the lower rotating

plate. The rotating disc is press fit on the motor shaft.

g Lift up and remove the rotating plate.

1 Remove the felt gasket.

2 Use paper towel and/or brush to clear the rotating disc from any coffee particles. If

necessary, use mild dish detergent along with towel.

3 Insert the new felt gasket. Guide the disc carefully into the housing.

4 Gently guide the rotating disc over the shaft.

h Remove the center bolt. Replace the washer that you had taken out and tighten the

bolt back in place. Place the handle of the pliers back into the outlet hole, and tighten

the center bolt tightly.

i Re-install the adjusting gear/cone in the grinder and turn it clockwise until the rotating

plate’s wings clear the grinding housing and the lower plate spins freely.

Operating instructions

64420 A 98/16 page 10 - 17

1 Place the spring over the gear cone, followed by the Aluminum backing plat and

screw. Turn the screw only 3 full turn ( you will tighten the after calibration of step

3.3.1).

j Clean the mating surfaces free from dirt and coffee, and install the top stationary disc

and install and tighten the screws

k Install the hopper.

l Plug in the grinder into the power outlet.

m Perform basic calibration according to 3.3.1.

The coffee grinder should be cleaned at least once weekly and always if soiled.

3.2 Maintenance

If the grinding quality is no longer of the required standard, the grinding discs must be

replaced.

The grinding discs should be inspected for wear after not longer than 12 months.

Periodic checking of the grinding quality and grinding discs must only be

performed by competent specialists and/or service personnel.

3.3 Setting the scale (adjustment)

Setting of the scale (with the adjusting knob) makes the fineness of the ground coffee

correspond with the fineness set on the scale (marked).

Setting of the scale must only be performed by persons familiar with the unit

after carefully reading the following instructions.

The basic setting according to 3.3.1 should be made:

- following change of grinding discs

- following inadvertent displacement of the scale

setting

Change of scale setting as 3.3.2 should be performed:

- if the desired grinding fineness does not

correspond with the scale (adjusting knob)

- if an individual setting of the grinding fineness is

desired (customer setting)

Operating instructions

64420 A 98/16 page 11 - 17

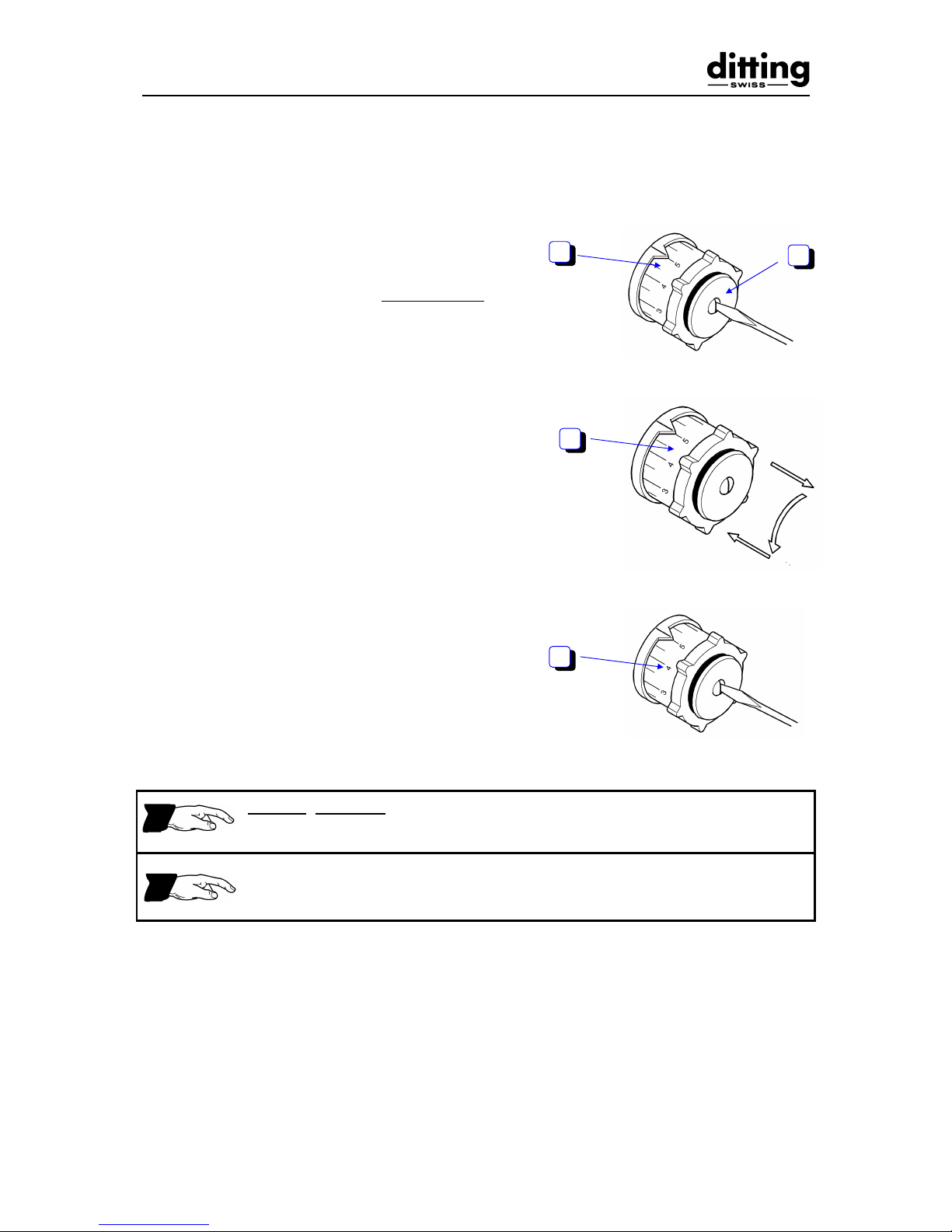

3.3.1 Basic setting (calibration)

If the basic setting is incorrect, friction can occur between the grinding discs,

resulting in excessive wear.

- Switch on motor.

- Unscrew screw (1) at centre of adjusting

knob (2) approx. 3 - 5 mm, do not remove.

- Pull out (3) adjusting knob (2) and turn 1/4

of a revolution anti-clockwise (4). Release

and engage (5) adjusting knob (2). (1

division corresponds to approx. 3 - 4 mm

on the scale.) Turn adjusting knob (2)

slowly clockwise to scale position 1 until

there is a sound of grinding discs rubbing

together (6).

- When the sound of grinding discs rubbing

together is heard, turn back while locked

10 mm anti-clockwise (7). Pull out (8)

adjusting knob (2) and turn clockwise to

scale position 1 (9). Release adjusting

knob (2) and engage (10).

- Retighten screw at centre of adjusting knob

(2).

Checking the setting:

When turning the adjusting knob from scale position 1 - 9 there must on no

account be a sound of metal parts rubbing together.

There must be no sound of grinding discs rubbing together at scale position 1

= excessive wear of grinding discs.

- Switch off motor.

3

6

5

4

21

2

28

7

10

9

Operating instructions

64420 A 98/16 page 12 - 17

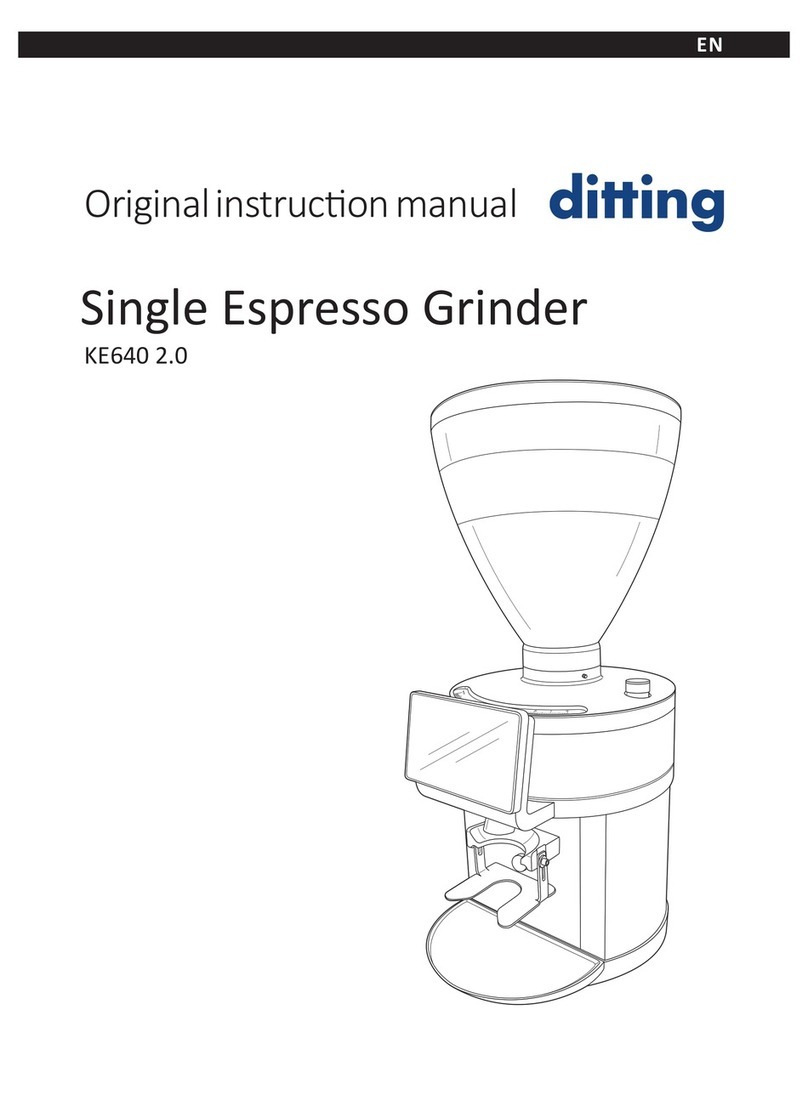

3.3.2 Changing the scale setting (adjustment

for customer settings)

- Switch off motor.

- Unscrew screw (1) at centre of adjusting

knob (2) approx. 3 - 5 mm, do not remove.

- Set required number of divisions by pulling

out adjusting knob (2), turning in the

corresponding direction and re-engaging.

(1 division corresponds to approx. 3 - 4 mm

on the scale.)

•adjustment clockwise = coarser grinding

•adjustment anti-clockwise = finer

grinding

- Switch on motor.

- Retighten screw at centre of adjusting knob

(2).

Checking the setting:

When turning the adjusting knob from scale position 1 - 9 there must on no

account be a sound of metal parts rubbing together.

There must be no sound of grinding discs rubbing together at scale position 1

= excessive wear of grinding discs. If there is a sound, grinding must be set

more coarsely (see 3.3.1).

- Switch off motor.

21

2

2

Operating instructions

64420 A 98/16 page 13 - 17

3.4 Replacing the grinding discs

Before changing grinding discs switch off motor without fail and disconnect

power cable !

The grinding discs must only be replaced by persons familiar with operation of

the machine according to the following instructions.

- Switch off motor and pull out power cable.

Set adjusting knob (2) to coarse grinding

scale position 9.

- Release left-hand hopper lock (3) only, but

do not remove.

Turn hopper (4) counter-clockwise through

approx. 15°and remove.

- Remove stationary disc flange (5) by

releasing screws (6) (see illustration) and

dismantle grinding discs. Dismantle lower

grinding disc from rotating disc flange

(rotary flange 7).

All supporting (mating) surfaces of stationary disc

flange, rotating disc flange, grinding discs and

grinding case must be absolutely clean before

assembly.

Only in this way can perfect grinding be guaranteed.

- Screw new grinding discs to the cleaned

stationary and rotating disc flanges (5 + 7).

- For resharpened grinding discs the

shims if supplied should be inserted

between grinding disc and flange.

- Then re-assemble parts in reverse

sequence.

2

4

3

5

6

7

Operating instructions

64420 A 98/16 page 14 - 17

- Plug in power cable, switch on coffee

grinder briefly. If it blocks or there is a

sound of metal parts rubbing together, the

scale setting must be adjusted according to

3.3.2.

- Retighten screws (6) of the stationary disc

flange. For this purpose the hopper (4)

must be removed again and then re-fitted.

Retighten hopper lock (3) after reassembly (see illustration page 11).

- Perform basic setting (calibration)

according to 3.3.1.

4 Faults / action

4.1 Action in event of a fault

When operated by customers, it must be ensured that personnel are notified

in the event of a fault and that customers do not try to repair the machine

themselves.

The grinder must only be opened, inspected and dismantled by persons

familiar with the method of operation of the machine, who have previously

read these operating instructions through carefully.

4.1.1 Table with possible malfunctions

Fault Result Action (information text) Re.

Grinder cannot be

switched on

ON/OFF switch does

not light

Circuit breaker

Check power cable, connection

and building fuses

Reset circuit breaker

4.2.4

Grinder jams, motor

does not start ON/OFF switch lights

Unblock discharge tube

Unblock grinding unit

4.2.1

4.2.2

Irregular grinding Check grinding discs for wear and

replace if necessary

3.4

Increased amount

of dust

Check grinding discs for wear and

replace if necessary

3.4

Bag slips or is no

longer held properly

Replace rubber bolt 4.2.3

6

Operating instructions

64420 A 98/16 page 15 - 17

4.2 Repairs

Switch off motor and pull out power cable before all major repairs requiring

work inside the machine, in order to avoid danger of injury while working on

motor while running and electric shock !

The electrical wiring diagram for this unit can be found inside the front panel.

4.2.1 Unblocking the discharge tube

- Switch off motor and pull out power cable.

- Unblock discharge tube from outside as far

as possible.

- Set adjusting knob (1) to coarse grinding

scale position 9 and switch motor on again.

This frequently unblocks the grinder and

extracts any foreign bodies in the grinding

unit.

- If the motor still does not run, continue

according to 4.2.2.

4.2.2 Unblocking the grinding unit

- Switch off motor and pull out power cable.

- Remove coffee beans from hopper (4) (use

a vacuum cleaner if necessary).

- Release left-hand hopper lock (3) only, but

do not remove.

Turn hopper (4) counter-clockwise through

approx. 15°and remove.

- Remove stationary disc flange (5) by

releasing screws (6) (see illustration).

1

4

3

5

6

Operating instructions

64420 A 98/16 page 16 - 17

- Remove foreign bodies. Check grinding

discs, rotating and stationary disc flange,

etc. for damage.

All supporting surfaces of stationary disc flange, rotating disc flange, grinding

discs and grinding case must be absolutely clean before assembly.

Only in this way can perfect grinding be guaranteed.

- Then re-assemble parts in reverse

sequence.

- Plug in power cable, switch on coffee

grinder briefly.

If the coffee grinder should block or there is a sound of metal parts rubbing

together, the scale setting must be adjusted according to 3.3.2.

- Retighten screws (6) of the stationary disc

flange. For this purpose the hopper (4)

must be removed again and then re-fitted

(see illustration page 13).

Retighten hopper lock (3) after reassembly (see illustration page 13).

- Perform basic setting (calibration)

according to 3.3.1.

4.2.3 Replacing the rubber bolt (KF only)

- Pull bag holding lever (1).

- Remove sleeve screw (2) with adequate

wrench (no. 17).

- Replace old rubber tube (3) with new one.

- Re-tighten sleeve screw (2) with adequate

wrench and release bag holding lever.

4.2.4 Circuit breaker

- Set ON/OFF switch to position 0.

- Close overcurrent release by pressing red

button underneath bottom plate.

- The coffee grinder is again ready for

operation.

1

2

3

Operating instructions

64420 A 98/16 page 17 - 17

5 Customer service

If it is found during maintenance that the grinding discs must be resharpened/replaced or

other repairs must be made, the nearest service centre (see page 1) should be contacted or

direct connection made with the factory.

New grinding discs, spare-parts and accessories (also at intermediate times) can be ordered

from our customer service or the relevant agent.

The grinding discs can be resharpened

once or twice at the factory.

Data such as manufacturing number and type of power supply as specified on the

nameplate of the coffee grinder should be stated on orders for grinding discs, spare-parts

and accessories to ensure rapid and efficient advice and delivery.

DITTING MASCHINEN LTD.

Bramenstrasse 11

P.O. Box 241

CH-8184 Bachenbülach

Switzerland

Phone: (41) 1 860 5421

Fax: (41) 1 860 8238

E-mail: ditting@dittingswiss.ch

www.dittingswiss.ch

ditting

®

U.S.A.

1000 Air Way

Glendale, CA 91201

Tel: 800-835-5992

Fax: 818-247-9722

www.ditting.com

Subject to technical modification.

This manual suits for next models

1

Table of contents

Other DITTING Coffee Grinder manuals

DITTING

DITTING KE640 2.0 User guide

DITTING

DITTING KE640 2.0 User guide

DITTING

DITTING KR 805 User manual

DITTING

DITTING ProD User manual

DITTING

DITTING KR 1203 User manual

DITTING

DITTING KF 903 User manual

DITTING

DITTING KE 640 Vario User manual

DITTING

DITTING KE 640 Original operating manual

DITTING

DITTING 804 Series Assembly instructions

DITTING

DITTING KE640 VARIO User manual