DITTING KS 3 User manual

Operating instructions

64426 A 03/35 page 1 - 14

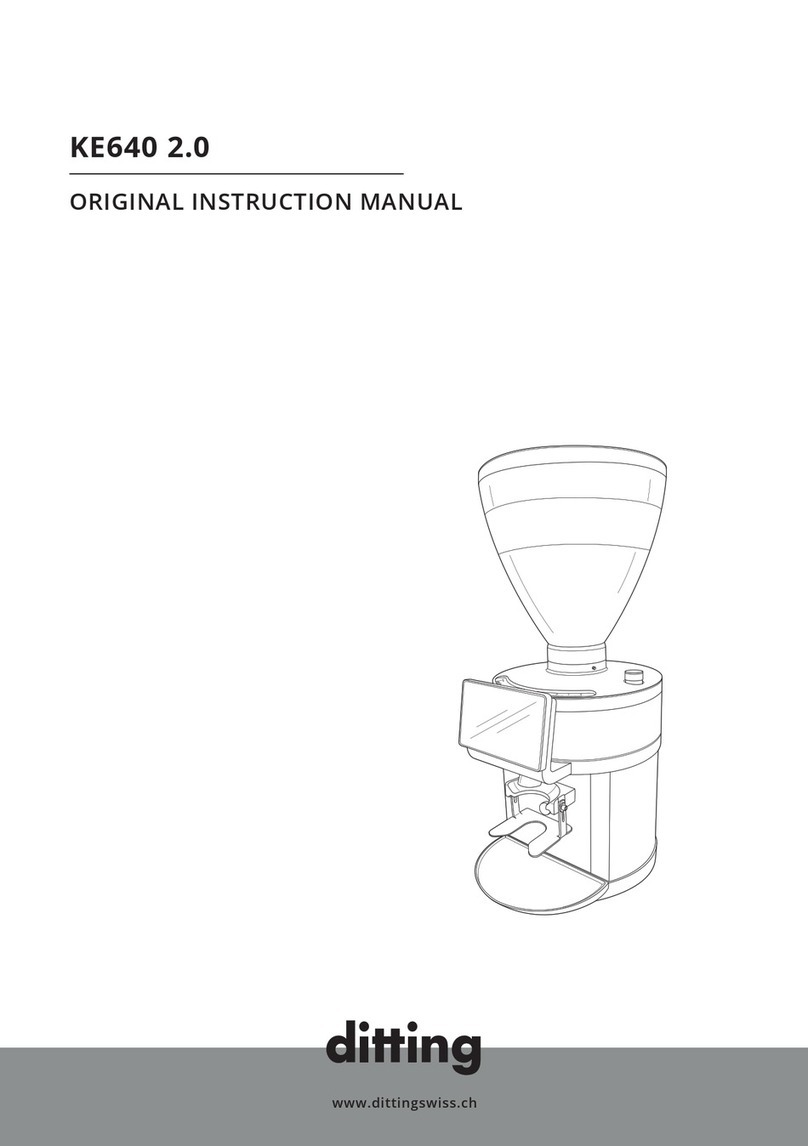

KS 1 / KS 3

TYPE

Voltage

Manuf. no.

Your service centre ...............................................

...............................................

...............................................

...............................................

...............................................

Operating instructions

64426 A 03/35 page 2 - 14

Contents

page

1 General

1.1 Warranty information 3

1.2 Transfer declaration 4

1.3 General safety instructions 5

1.3.1 Information and safety symbols 6

2 Description and Safety Device 6

2.1 Safety devices 6

3 Setting up and Basic Adjustment

3.1 Setting up area 7

3.2 Initial Set-up 7

3.3 Installation 7

3.4 Basic Setting 7

4 Operation

4.1 Operating controls 8

5 Care / Maintenance / Adjustment

5.1 Cleaning of the coffee grinder 9

5.2 Maintenance and repair 10

5.3 Spare parts 10

5.4.1 Setting scale (adjustment) 10

5.4.2 Changing the scale setting 11

5.5 Replacing the grinding discs 12

6 Faults / action

6.1 Action in event of a fault 13

6.2 Table with possible malfunctions 13

6.3 Thermal protector 14

7 Customer service 14

Operating instructions

64426 A 03/35 page 3 - 14

1 General

Dear Customer,

We congratulate and thank you for purchasing a quality product. These operating

instructions have been prepared to simplify your use of the coffee grinder. They contain

information, advice and instructions for the best use of your unit.

1.1 Warranty information

ALTHOUGH YOUR COFFEE GRINDER IS DISTINGUISHED BY A HIGH QUALITY AND

SAFETY STANDARD, DAMAGE TO MATERIAL OR RISK OF INJURY CANNOT BE

EXCLUDED IF OPERATED INCORRECTLY, USED IMPROPERLY OR MISUSED.

THE OPERATING INSTRUCTIONS WILL THEREFORE FAMILIARISE YOU WITH

CORRECT USE OF THE COFFEE GRINDER AND ASSIST YOU TO AVOID WRONG

OPERATIONS. IF THE ENCLOSED INSTRUCTIONS ARE FOLLOWED EXACTLY, YOU

WILL AVOID DANGERS, REDUCE REPAIR AND STOPPAGE TIMES AND INCREASE

THE RELIABILITY AND SERVICE LIFE OF YOUR UNIT.

TO ENSURE THAT YOU AND YOUR EMPLOYEES TAKE NOTICE OF THE CONTENTS

OF THE OPERATING INSTRUCTIONS AND FOR YOUR OWN SAFETY, WE WOULD ASK

YOU TO COMPLETE THE TRANSFER DECLARATION PRINTED ON THE FOLLOWING

PAGE, DETACH THIS ALONG THE PERFORATION AND RETURN IT TO YOUR DEALER.

Operating instructions

64426 A 03/35 page 4 - 14

1.2 Transfer declaration

To ensure transfer of the operating instructions to final consumers

Note: The following declaration should be completed by the dealer and the purchaser. The

purchaser undertakes to return this declaration to the dealer. The purchaser thereby certifies

that the dealer has drawn his attention to the contents of operating instructions no. 64426, in

particular to the relevant safety instructions for use of the machine.

64426 A 03/35 page 4 - 14

Transfer declaration

(1) Type Machine no.

(2) Address of customer

(3) The machine specified in (1) was purchased by me. The complete operating

instructions were handed to me with transfer of the machine.

_______________________ _______________________

Signature of customer Place / date

(4) Date of transfer

(5) Address of dealer/importer

__________________________

Company stamp/signature

(6) The machine was handed to the customer in accordance with the guidelines of

the manufacturer.

Company stamp/signature if not identical with (5)

_____________________________ _______________________

Signature of customer service- Date

specialist

✂

✂✂

✂

Operating instructions

64426 A 03/35 page 5 - 14

1.3 General safety instructions

•The operating instructions must be kept permanently at the place of operation of

the machine and if possible attached at the point of installation in the immediate

vicinity of the machine.

•The competent sales and service personnel must have read the operating

instructions before putting the coffee grinder into operation and be familiar with all

functions including action in the event of a fault.

•If customers themselves operate the machine, a notice must be placed clearly

visible in the immediate vicinity of the machine that customers must immediately

call the service personnel responsible in the event of a fault and not try to eliminate

the fault themselves by tampering with the machine.

•The machine must be placed in the sales areas so that the sales personnel

responsible can be reached by the customer without difficulty.

•The model KS 1 / KS 3 was developed and built for intermittent duty only and is

therefore not suitable for continuous operation. The max. grinding time, without

interruption, is 40 minutes. After 40 minutes, the grinder must be switched off and

not be operated for approx. 30 min.

•Only original spare-parts must be used for repairs to the grinder. If spare-parts

from other manufacturers are used, the serviceability of the grinder may be

impaired. In addition, further injury to persons or material damage cannot be

excluded.

•The grinder should be installed out of reach of children. Children and users must

on no account reach into the openings or come into contact with electrical

components.

•Never reach into the hopper opening while the machine is running.

•Never touch electrical components with conducting objects, such as needles, pins,

cutlery, etc. !

•The emission value referred to the workplace is 76 dB(A).

•The machine must be electrically protected by fuses according to the nameplate

and the local regulations.

Operating instructions

64426 A 03/35 page 6 - 14

1.3.1 Information and safety symbols

Two information symbols are used in these operating instructions to emphasise important

comments in the text:

Information

This symbol indicates information containing important data concerning

efficient use. Non-observance can lead to faults.

Safety

This symbol indicates information which if not observed can lead to danger to

persons and/or substantial material damage. The safety instructions must be

followed without fail.

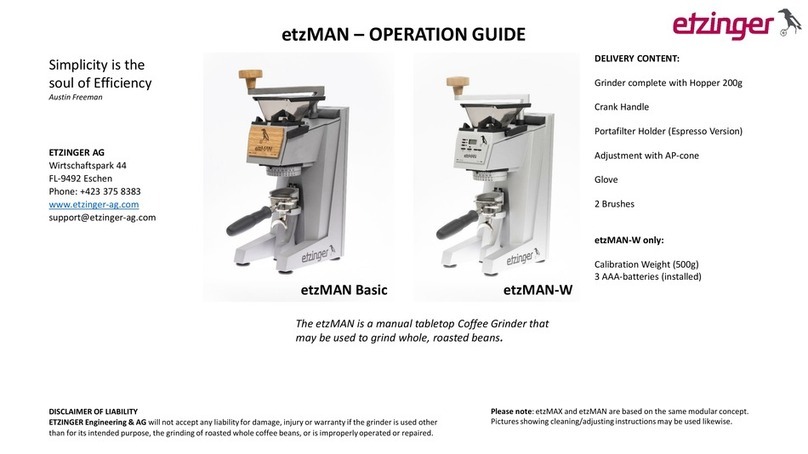

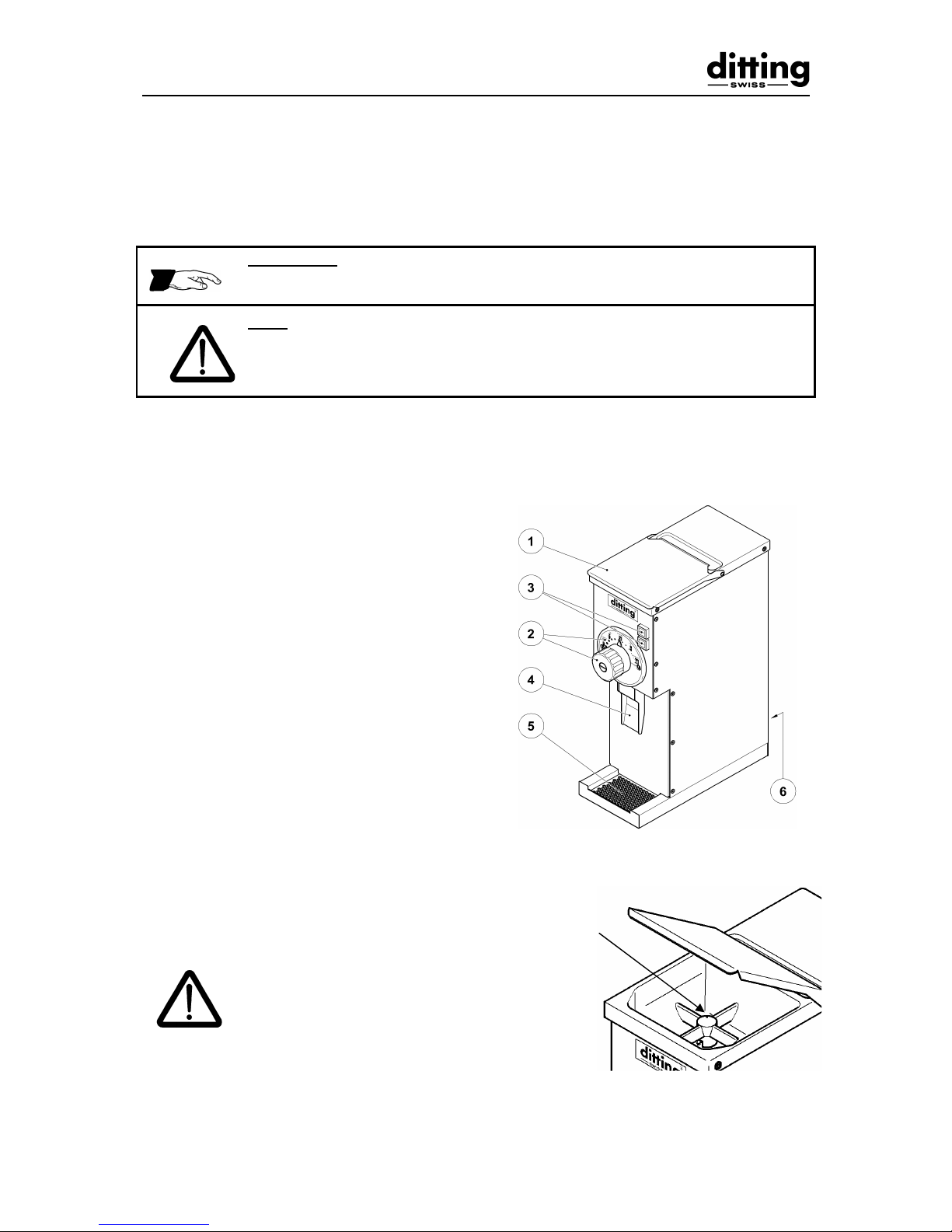

2 Description and Safety Devices

Main Components and Operating Elements

The main components and operating elements

are shown in the Figure.

1. Lid for hopper

2. Grinding degree setting

3. START / STOP

4. Spout with bag detector

5. Bag shaker

6. Rating / Serial no. plate

2.1 Safety Devices

Finger protector / magnet holder

A combined finger protector/magnet holder is

fitted in the hopper of the grinder. It is sup-

posed to prevent the user from reaching into

the running grinding mechanism. At the same

time, it also prevents ferrous objects

from getting into the grinding mechanism.

Every now and then you should clean the

magnet since adhering ferrous objects could

be hanging from the magnet.

Operating instructions

64426 A 03/35 page 7 - 14

3 Setting Up and Basic Adjustment

The KS 1 / KS 3 coffee grinders are suitable for grinding various kinds of coffee. The

grinding fineness can be set from "Turkish fine" to "percolator" with an adjusting knob

provided with a scale. The KS 1 / KS 3 coffee grinders are suitable for use in small food

stores, coffee shops. The simple method of operation enables customers to use the grinder

themselves in self-service stores.

A grinding test run is carried out on each grinder in the manufacturer's factory. This is why

you may find ground material residue in the grinding mechanism!

3.1 Setting-up area

Place the grinder on a level surface free from vibration.

Never operate the grinder in moist, or even worse, in wet surroundings.

3.2 Initial Set-up

Open the top lid. Clear all foreign objects and shipping materials from the hopper

compartment and the entrance to the grind chamber.

3.3 Installation

You have received your grinder in operating condition. Now you only need to connect it to a

power supply system. Proceed as follows:

Determine whether the mains voltage and frequency correspond to the information on

the rating plate.

Protect your grinder with a separate pre-fuse (not included in the scope

of supplies) according to the information provided under Item 2

"Technical data". Make sure that the pre-fuse is not overloaded by other

consuming machines (e.g. fan-forced heaters, deep freezers).

Insert the plug into the available grounded outlet.

3.4 Basic Setting

A grinding test can be conducted when the grinder is ready for

operation.

The basic setting has been set in the factory and the grinding degree is already

set to the finest grind.

For this reason please make no alterations, as this could lead to damage

of the appliance.

Operating instructions

64426 A 03/35 page 8 - 14

4 Operation

Use the KS 1 or KS 3 grinder only in accordance with the instructions listed

under 1.3.

Never place fingers or objects into the grinding gears!

Never exceed the maximum allowable operating time of 40 minutes.

Afterwards, allow the motor to cool off for around 30-40 minutes prior to

switching the grinder on again.

4.1 Operating Controls

Start/Stop Switch

START Pressing the START button initiates grinding only when a bag is in place

behind the spout. The switch will return to this position after a grind cycle has

begun and will remain in this position after grinding has ceased.

STOP pressing the STOP button stops the operation of the grinder.

Grind Selector

Allows the user to vary the grind for each bag of coffee. The grind ranges indicated on the

label allow a very precise grind control. The grinding results may very substantially for

different types and roasts of coffee.

Bag Detector

Prevents the grinder from operating unless the back of a bag is in place behind the spout.

This is also a safety device. Please do not attempt to by-pass the bag detector (not visible).

The grinder must only be installed in dry areas!

Place the coffee grinder on a firm, level and non-slip base. Danger of tipping

and slipping on unstable surfaces. Before connecting the coffee grinder to the

mains supply, ensure that this supply corresponds with the data on the unit

nameplate.

Operating instructions

64426 A 03/35 page 9 - 14

5 Care / maintenance / adjustment

5.1 Cleaning of coffee grinder

The coffee grinder must only be cleaned with a paper towel.

If necessary use suitable mild dish washer detergent.

Do not use an alkaline cleaning agent.

Do not spray coffee grinder with water and/or steam.

Reason: 1- It can result in a short-circuit and therefore damage the unit.

2- The use of alkalis can affect the flavor of the coffee.

The coffee grinder should be cleaned at least once a week and always if soiled.

Before cleaning the coffee grinder, switch off motor AND REMOVE THE

POWER CABLE FROM THE OUTLET.

Always remove the electrical plug from the outlet before conducting

cleaning or repair work on the appliance!

Observe the safety instructions under 1.3!

Avoid allowing foreign objects to fall into the grinding gears!

The use of damp cloth rinsed in any mild, non-abrasive, liquid detergent is recommended for

cleaning all surfaces and interior parts. Regular cleaning is essential to keep your grinder in

a hygienic and workable condition.

Cleaning of grinding discs and grinding chamber

Cleaning of the grinding chamber and grinding discs must only be performed

by persons familiar with the unit after carefully reading the following

instructions.

The grinding discs and grinding chamber should be cleaned at least

once a week.

Operating instructions

64426 A 03/35 page 10 - 14

5.2 Maintenance and Repair

Always pull the plug out of the socket before you perform any

maintenance or clean the grinder.

Always check the grinder regularly for damage, especially damage to the

power cord, plug, finger protector etc.

Any repairs necessary may only be performed by an authorised

specialist. Please contact an authorised service centre or your dealer.

5.3 Spare Parts

Spare parts are usually ordered from your customer service centre or your local dealer. To

ensure quick, correct processing of your order, the following information is absolutely

required:

1. Type designation and serial number of the grinder

(on the rating plate on the rear side of the grinder).

2. An exact description of the part to be replaced or the article number.

Periodic checking of the grinding quality and grinding discs must only be

performed by competent specialists and/or service personnel.

5.4.1 Setting the scale (adjustment)

Setting of the scale (with the adjusting knob) makes the fineness of the ground coffee

correspond with the fineness set on the scale (marked).

Setting of the scale must only be performed by persons familiar with the unit

after carefully reading the following instructions.

Checking the setting:

When turning the adjusting knob from scale position Turkish to French Press

there must on no account be a sound of metal parts rubbing together.

There must be no sound of grinding discs rubbing together at scale position

Turkish = excessive wear of grinding discs.

Operating instructions

64426 A 03/35 page 11 - 14

5.4.2 Changing the scale setting (adjustment

for customer settings)

The purpose of setting the scale on the rotary knob is to ensure that the fineness

of the ground coffee matches the fineness setting shown on the scale. The

machine is supplied complete with a factory setting and is ready for operation.

Alter the scale setting:

if the fineness of the coffee after grinding does not match the scale and is

therefore not as required.

if a setting for a particular grinding fineness is needed.

IMPORTANT

Only the maintenance staff should be allowed to adjust the scale settings!

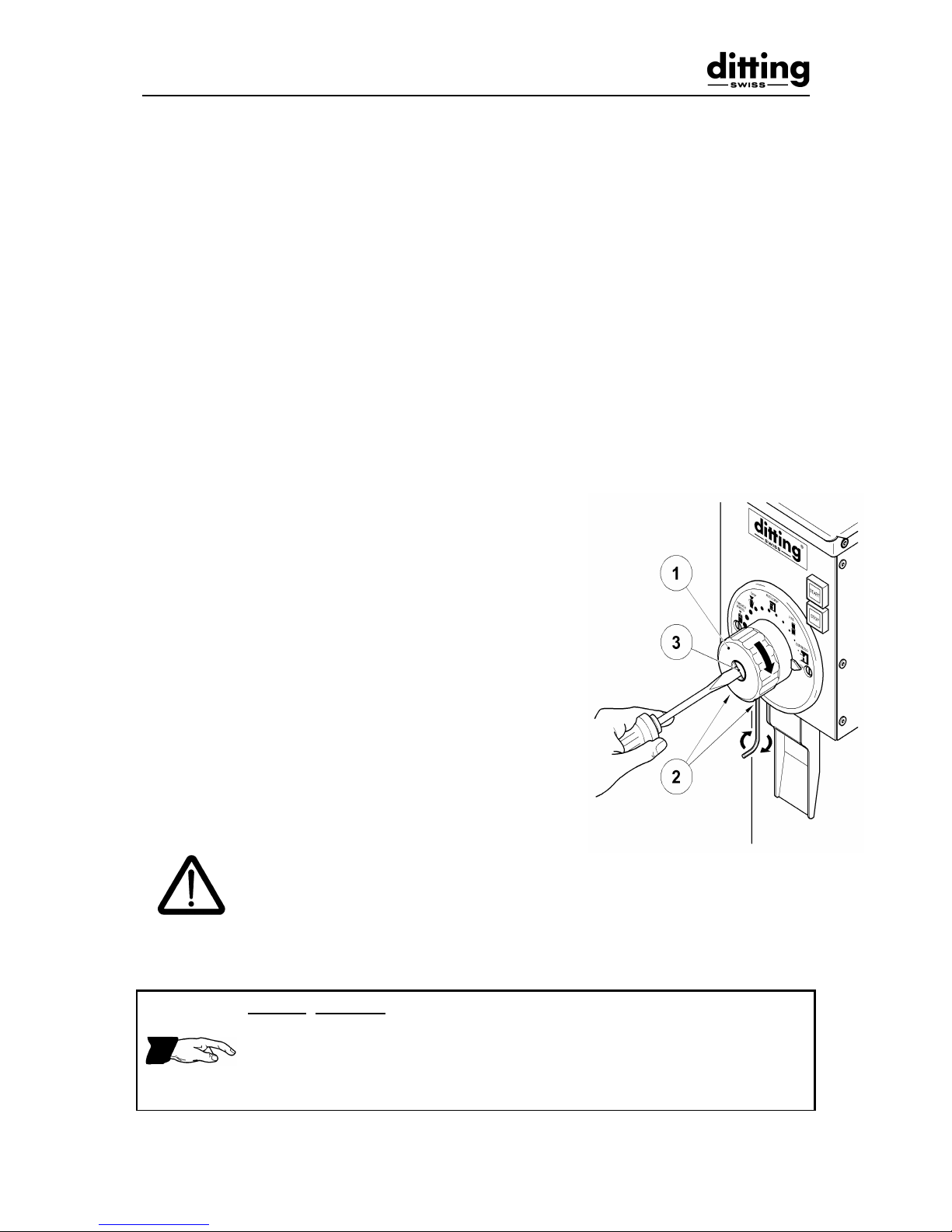

Procedure

1. Place a bag under the delivery tube for the

ground coffee.

2. Switch the machine on.

3. Turn the rotary knob (1) in a clockwise

direction as far as the catch point.

4. Use the hexagonal Allen key (approx. 3

turns) to release the studs (2).

5. Turn the centre screw head (3)

- for greater grinding fineness:

clockwise

- for coarser grinding: anti-clockwise.

CAUTION

If you hear a slight sound (grinding discs in contact with each other), this

means that the gap between the grinding discs is too small and must be

increased! (Correct by turning anti-clockwise!)

6. Tighten the studs (2) once more.

Checking the setting:

When turning the adjusting knob from scale position Turkish to French Press

there must on no account be a sound of metal parts rubbing together.

There must be no sound of grinding discs rubbing together at scale position

Turkish = excessive wear of grinding discs. If there is a sound, grinding must

be set more coarsely (see 5.5).

Operating instructions

64426 A 03/35 page 12 - 14

5.5 Replacing the grinding discs

Cleaning the grinding mechanism

CAUTION

The grinding discs must not be removed until the machine is completely at

rest! Before beginning this task, switch off the main switch (if fitted), ensure

the machine cannot be switched on by accident and pull out the mains plug

from the mains socket.

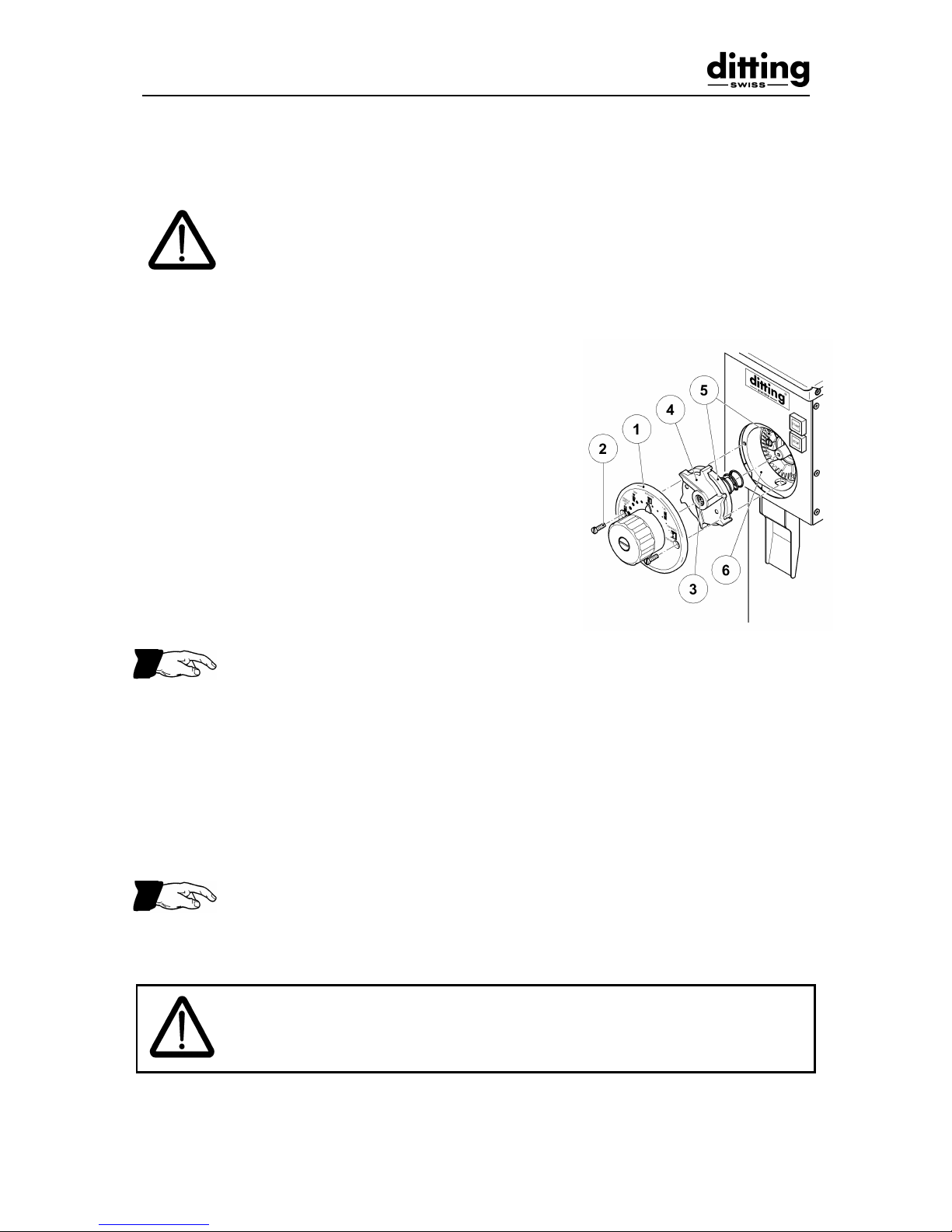

1. Remove the adjustment unit (1) by

unscrewing both screws (2).

2. To push off the rotary disc flange, open

the centre screw (3).

3. Pull out the rotary disc flange (4) from

the grinder body chamber (6).

4. Remove any foreign matter that may be

present.

5. Check the grinding discs (5), the rotary

disc flange (4) and the grinder body

chamber (6) for possible damage and

replace faulty parts.

IMPORTANT

All the contact surfaces of the grinding discs (5), the rotary disc flange (4)

and the grinder body chamber (6) must be absolutely clean when

reassembled! This is the only way to ensure completely trouble-free grinding.

6. Reassemble all the parts using the same steps in reverse order.

7. After reassembly, reconnect the machine to the mains.

8. Switch the machine on briefly.

IMPORTANT

If the grinding mechanism jams or if you hear the sound of metal parts

rubbing against each other, you must reset the scale. For this, read the

chapter entitled “Setting the scale”.

Before changing grinding discs switch off motor without fail and disconnect

power cable !

The grinding discs must only be replaced by persons familiar with operation of

the machine according to the following instructions.

- Switch off motor and pull out power cable. Set adjusting knob

(2) to coarse grinding scale position percolator.

Operating instructions

64426 A 03/35 page 13 - 14

6 Faults / action

6.1 Action in event of a fault

When operated by customers, it must be ensured that personnel are notified

in the event of a fault and that customers do not try to repair the machine

themselves.

The grinder must only be opened, inspected and dismantled by persons

familiar with the method of operation of the machine, who have previously

read these operating instructions through carefully.

6.2 Table with possible malfunctions

Fault Result Action (information text) Re.

Grinder cannot be

switched on

Grinder will not shut

off

Grinder starts, but

is not dispensing

Failure of power supply

Circuit breaker

Bag detector

Start/Stop switch

Start/Stop switch

Bag detector

Hopper

Entrance to grind

chamber

Plug-in the grinder, check voltage

at the fuse

The receiving bag must be placed

correctly

Press the switch to the “Start”

position

Press Stop switch

Refer to service – Start/Stop switch

for testing procedures

Remove bag from the dispense

spout

Refer to service – Bag detector for

testing procedures

Coffee must be filled into the

hopper before grinding

Material different than coffee might

be cleared from the grinding

chamber

3.3

4.1

4.1

4.1

4.1

4.1

3

5.5

Grinder jams, motor

does not start

Unblock discharge tube

Unblock grinding unit

5.5

5.5

Irregular grinding Check grinding discs for wear and

replace if necessary

5.5

Increased amount

of dust

Check grinding discs for wear and

replace if necessary

5.5

Operating instructions

64426 A 03/35 page 14 - 14

6.3 Thermal protector

- If the grinder is overheated, the integrated thermal

protector prevents the motor from running

- Let the grinder cool off for half an hour and the coffee

grinder is again ready for operation.

7 Customer service

If it is found during maintenance that the grinding discs must be resharpened/replaced or

other repairs must be made, the nearest service centre (see page 1) should be contacted or

direct connection made with the sales offices mentioned below.

New grinding discs, spare-parts and accessories (also at intermediate times) can be ordered

from our customer service or the relevant agent.

The grinding discs can be resharpened

once or twice

Data such as manufacturing number and type of power supply as specified on the

rating/serial no. plate of the coffee grinder should be stated on orders for grinding discs,

spare-parts and accessories to ensure rapid and efficient advice and delivery.

Subject to technical modification.

Ditting Maschinen AG

Bramenstrasse 11

CH-8184 Bachenbülach

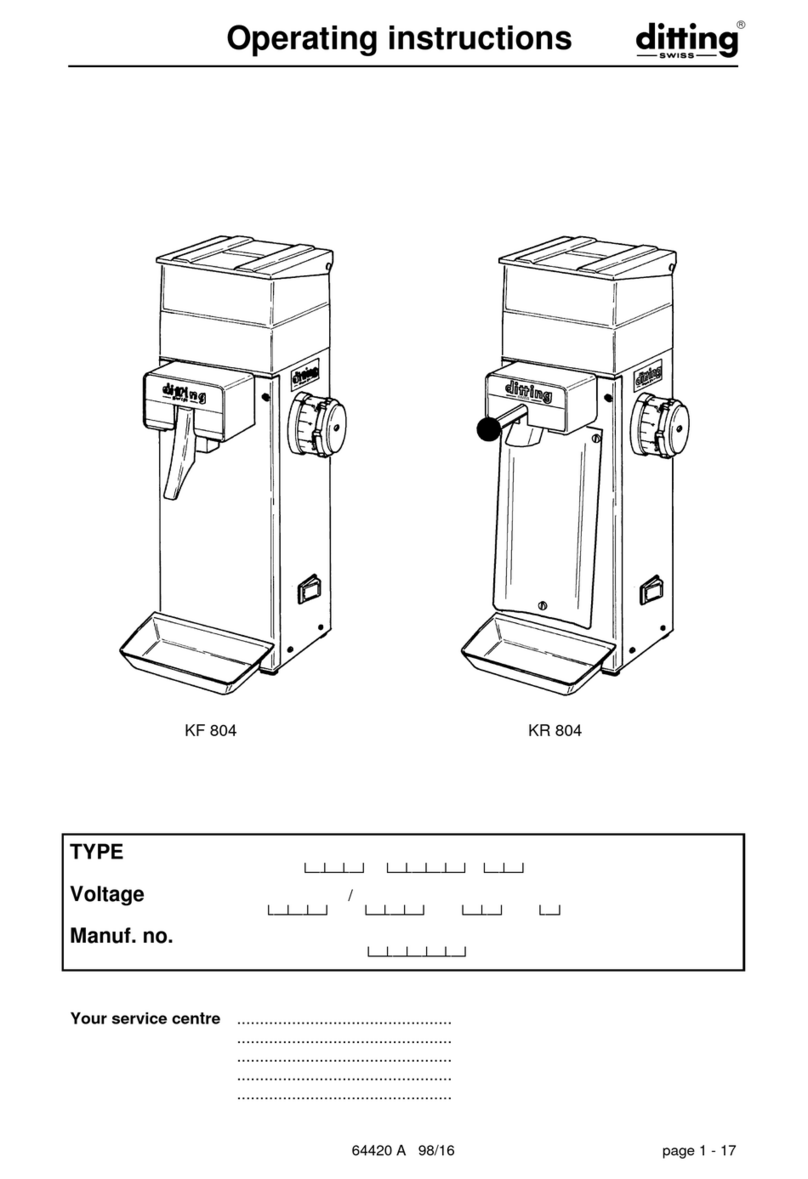

This manual suits for next models

1

Table of contents

Other DITTING Coffee Grinder manuals

DITTING

DITTING ProD User manual

DITTING

DITTING KR 805 User manual

DITTING

DITTING KE640 2.0 User guide

DITTING

DITTING 807 User manual

DITTING

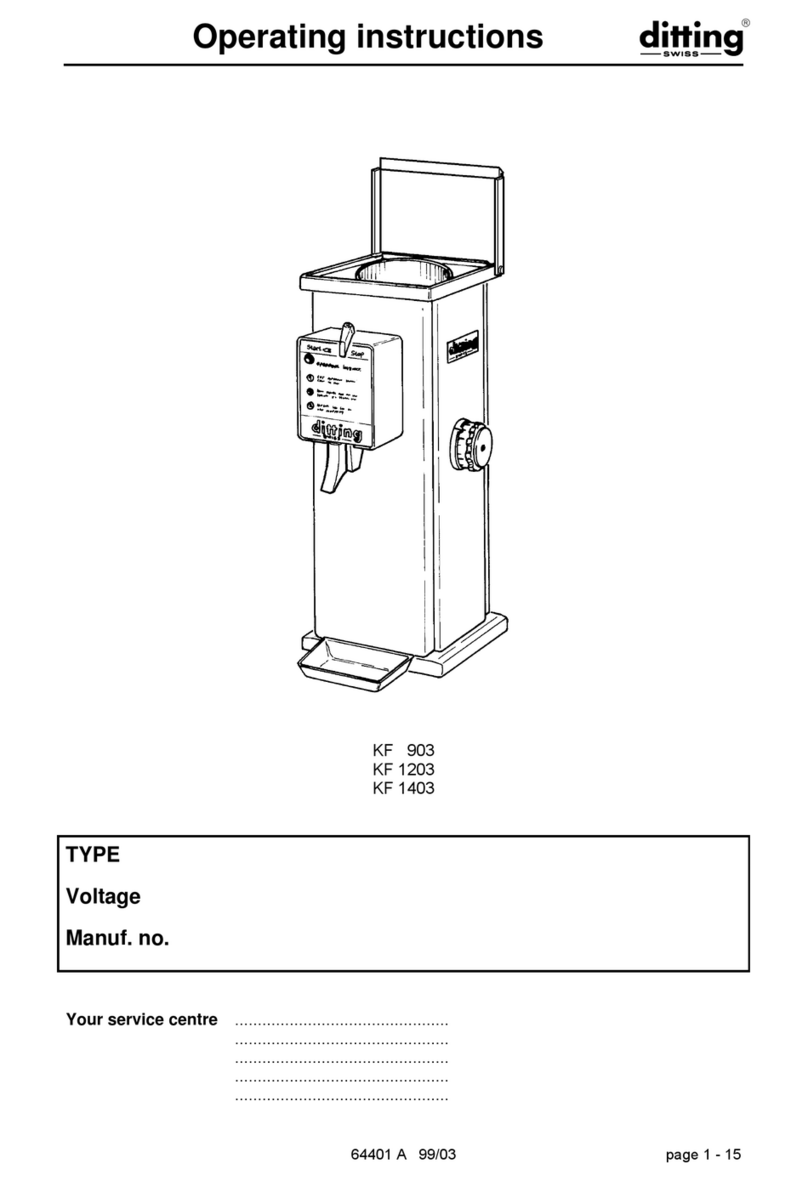

DITTING KR 1203 User manual

DITTING

DITTING KF 804 User manual

DITTING

DITTING KE640 ES User manual

DITTING

DITTING KE640 VARIO User manual

DITTING

DITTING 804 Series Assembly instructions

DITTING

DITTING KF 903 User manual