DIVERSITECH GREEN User manual

OWNER’S MANUAL

IMPORTANT

This manual contains specific cautionary statements relative to worker safety. Read this manual thoroughly and follow as directed. Hazards of

dust control equipment are not all listed in this manual. It is important that use of the equipment be discussed with a Diversi-tech

Representative. Persons involved with the equipment or systems should be instructed to operate the equipment in a safe manner.

1

D I V E R S I T E C H O M - G F C M

Page 1

Table of Contents

1.0 - Safety Precautions .................................................................................................................. 3

1.1 - Caution................................................................................................................................ 3

2.0 - Principles of Operation ........................................................................................................... 3

2.1 - Injection Cleaning System................................................................................................... 3

3.0 - Installation .............................................................................................................................. 5

3.1 - Upon Arrival ........................................................................................................................ 5

3.2 - Compressed Air Installation................................................................................................ 6

3.3 - Installation of the Barrel ..................................................................................................... 6

3.4 - Operation............................................................................................................................ 7

3.4.1 - Start Up ........................................................................................................................ 7

3.4.2 - Loading the filter.......................................................................................................... 7

3.5 - Engaging the System:........................................................................................................ 10

3.5.1 - LCD Readout .............................................................................................................. 10

3.5.2 - Menu.......................................................................................................................... 11

3.5.3 - Errors ......................................................................................................................... 13

3.5.4 - Reduce Time of operation......................................................................................... 13

3.5.5 - Dry Run ...................................................................................................................... 13

4.0 - Preventive Maintenance....................................................................................................... 14

5.0 - Troubleshooting List for Injection Cleaning System ............................................................. 15

5.1 - Debugging ......................................................................................................................... 15

6. 0 - WARRANTY Clauses ............................................................................................................. 17

7.0 - RETURN MATERIAL POLICY................................................................................................... 17

8.0 - REPLACEMENT PARTS ........................................................................................................... 18

APPENDIX:..................................................................................................................................... 19

WIRING SCHEMATIC: .................................................................................................................... 19

SPECIFICATIONS ............................................................................................................................ 20

2

D I V E R S I T E C H O M - G F C M

Page 2

WE APPRECIATE YOUR BUSINESS!

Congratulations on your new Diversi-tech product. We are proud to have you as our customer

and will strive to provide you with the best service and reliability in the industry. This Operating

Manual has been designed to instruct you on the correct use and operation of your Diversi-tech

Green Filter Cleaning Machine. Your satisfaction with this product and its safe operation is our

ultimate concern. Therefore please take the time to read the entire manual, especially the

Safety Precautions. They will help you to avoid potential hazards that may exist when working

with this product.

YOU ARE IN GOOD COMPANY!

We distinguish ourselves from our competition through market-leading, dependable products

that have stood the test of time. We pride ourselves on technical innovation, competitive

prices, excellent delivery, superior customer service and technical support, together with

excellence in sales and marketing expertise. Above all, we are committed to developing

technologically advanced products to achieve a safer working environment.

The Diversi-tech Green Filter Cleaning Machine is designed to clean air filters that are used to

collect dry particulate in both dust collectors and Diesel engines. The machine uses compressed

air to clean the filter and a high efficiency cyclone is used to collect the dislodged material.

Read and understand this entire Owner’s Manual and your employer’s safety practices before

installing, operating, or servicing the equipment. While the information contained in this

Owner’s Manual represents the Diversi-tech's best judgment, the Diversi-tech assumes no

liability for its use.

3

D I V E R S I T E C H O M - G F C M

Page 3

1.0 - Safety Precautions

1.1 - Caution

This indication refers to matters that have high risk of serious injuries if the system is

installed or operated incorrectly.

All users of Diversi-tech Equipment should comply with all National and Local Fire Codes and/or

other appropriate codes when determining the location and operation of dust control

equipment.

Do not use any voltages other than the ones indicated

Do not cut or damage power cord. Damage to power cord may cause fire or electrical

shock

Flammable Objects-in the event a foreign object should happen to get inside the

cabinet, please take the following actions:

Turn Power Off

Unplug AC cords

Remove object

Resume Operation

Do not disassemble or modify the system –this may impact the warranty clauses

2.0 - Principles of Operation

2.1 - Injection Cleaning System

Principle of Operation:

The Injection Cleaning System (ICS) operates an air nozzle that cleans air filter cartridges. This is

accomplished by extreme compressed air originating from the inside-out through the filter. The

nozzle rotates 360° while moving up and down to insure cleaning of all the surface area of the

air filter.

The cleaning cycle is controlled by a microprocessor based Printed Circuit Board located in the

control box. The microprocessor has been programmed to turn on the cleaning system once

the filter is sealed (“Ready to Clean” appears on the LCD), the start button is pressed and

released. The nozzle will travel from its home position (located at the bottom) through the top

and then back down to home. The home and top positions are sensed by a limit switch and

proximity sensors. Simultaneously, when the gear motor is engaged, an in-line solenoid opens

and allows compressed air to reach the nozzle and the air pulse system. If for some reason the

Cabinet lid is open before the cleaning system has had a chance to terminate the cycle, the

system will shut itself down and resumes from where it left off once the lid is closed and the

filter is sealed.

4

D I V E R S I T E C H O M - G F C M

Page 4

Figure 1: Principle of Operation

Figure 2: GFCM Major Components

5

D I V E R S I T E C H O M - G F C M

Page 5

3.0 - Installation

3.1 - Upon Arrival

The Green Filter Cleaning Machine is shipped on a crated skid. The skid should be inspected for

any visible damage that may have occurred during shipment. Please advise the Transport

Company as soon as possible if the unit appears to have been damaged during shipping.

NOTE: Dust or debris in the machine or cyclone is due to factory testing. Each unit is tested

prior to shipping.

Always disconnect power supply before servicing the motor or working

with the unit for any reason. All electrical connections must be made

by a qualified electrician.

Use suitable floor anchors to securely bolt the machine to the floor.

Failure to anchor the machine may result in the machine tipping due to

the high center of gravity.

1. Bolt the four legs on the cyclone assembly.

2. Install the Cabinet Assembly and the Cyclone Assembly 12” apart. Using the supplied

flex hose, join the Cabinet to the Cyclone. Using hose clamps and silicone to seal the

interface between the flexible hose and the metal conduit.

Figure 3: Installation of GFCM

3. Connect the Dust Collector Cyclone Motor to the Control Panel using the Female

connector and the Male Plug.

Figure 4: Female Connector & Male

Plug

6

D I V E R S I T E C H O M - G F C M

Page 6

3.2 - Compressed Air Installation

NOTE: Only dry compressed air is to be used with the machine. The unit requires a minimum

of 80 CFM at 90 PSI to operate properly.

Connect compressed air (90 PSI) to the ½” inlet fitting located on the back of the unit. It is

recommended to install a cut-off valve on the line for safety purposes. A regulator will be

necessary to step down the supply air if the shop pressure is above 100 PSI. NOT complying

may result in damage to the unit’s components and reduce performance. A 1/2” NPT supply

line is required.

3.3 - Installation of the Barrel

Step 1: Slide barrel under cyclone cone.

Step 2: Apply liberal amounts of silicone sealant to the barrel inlet collar.

Step 3: Slide the flexible hose over the collar.

Step 4: Fasten the flexible hose to the collar using the provided hose clamp.

If Cyclone to Barrel connection is not fully sealed, the cyclone will not

operate properly.

7

D I V E R S I T E C H O M - G F C M

Page 7

3.4 - Operation

3.4.1 - Start Up

Before proceeding, one should note that all units have been tested at the factory before

shipping. The following steps are to insure proper functioning of the unit and nothing has been

damaged during transportation:

1. Check the pneumatic connections on the back of the unit.

2. Connect the air hose and make sure that the air fittings don’t leak air.

3. Check that nothing is jammed up against the mechanism.

PLEASE ENSURE THAT CYCLONE MOTOR IS PLUGGED INTO THE CONTROL BOX.

3.4.2 - Loading the filter

I. Measure the height of filter in inches. (Measuring tape on the side)

II. Refer to Filter Spacer Chart to select spacers required.

Step 1: Open the top of the Cabinet by releasing both latches.

Step 2: Install required spacers (refer to Filter Spacer Chart)

Step 3: Load the filter, then close and secure the latches

Important Note:

DO NOT OPEN LID DURING OPERATION. The cabinet is fitted with a compression

mechanism that seals the top of the filter. If the filter is not sealed properly the

machine will not operate. Opening the cabinet should only be done after cycle is

completed.

The unit is equipped with a high efficiency cyclone. Any air leaks in the suction or

exhaust line (connection to the barrel) may result in some debris accumulating in the

exhaust filter. Periodically check the exhaust filter for debris, replace if necessary. DO

NOT PLACE THE EXHAUST FILTER IN THE MACHINE.

8

D I V E R S I T E C H O M - G F C M

Page 8

Open Both End Filters

CAUTION: Add Spacers –as required

Please note that the machine only accepts filters within the following size range:

10”-to-32”of height

A minimum of 6.5” of inner diameter

A maximum of 20” of outer diameter

Filter Spacer Chart

Height

of Filter

to be

Cleaned

in

inches

# of

Spacers

Required

1" Spacer

2" Spacer

3" Spacer

4" Spacer

5" Spacer

6" Spacer

32

0

31

1

1

30

1

1

29

1

1

28

1

1

27

1

1

26

1

1

25

2

1

1

24

2

1

1

23

2

1

1

22

2

1

1

21

2

1

1

20

2

2

19

3

1

2

18

3

1

2

17

3

1

2

16

3

1

2

15

3

1

2

14

4

1

1

2

13

4

1

1

2

12

4

1

1

2

11

4

1

1

2

10

5

1

1

1

2

9

D I V E R S I T E C H O M - G F C M

Page 9

Closed One End Filters

CAUTION: Add Spacers –as required

Please note that the machine only accepts filters within the following size range:

10”-to-32”of height

A minimum of 6.5” of inner diameter

A maximum of 20” of outer diameter

Step 1: Measure the height of filter in inches.

(See left figure)

Step 2: Refer to Filter Spacer Chart. (Previous

page)

Step 3: Install required spacers + 1” Spacer

10

D I V E R S I T E C H O M - G F C M

Page 10

3.5 - Engaging the System:

The control box includes an LCD screen with a Power rotary switch and a Start, Abort Cycle,

Menu/Select & Scroll buttons. A single cleaning cycle is defined as the traveling of the nozzle up and

down the filter.

3.5.1 - LCD Readout

LCD Reading

Description

Diversi-Tech

GFCM REV 3.0

You are operating Version 3

Going Home 2.5A

The GFCM is resetting itself

"Going Home": Machine is resetting itself by returning to home position

located at the bottom of the mechanism

"2.5A": Amperage reading of the 24V DC Motor operating the mechanism

Ready to Clean

8 Cycle 23-32"

This is the Home Reading

"Ready to Clean": GFCM is ready to clean a dirty filter

"8 Cycle": GFCM will run for 8 cycles

"23-32"": The height range of the dirty filter

Clean UP 2.5A

288 Sec CYC 6/8

The GFCM is in operation

"Clean UP": The nozzle is rotating while moving upwards

"2.5A": Amperage reading of the 24V DC Motor operating the mechanism

"288 Sec": Indicates the remaining time of the cleaning cycle in seconds

"CYC 6/8": GFCM is at its 6th cycle out of 8th

Clean DOWN

2.5A

288 Sec CYC 6/8

The GFCM is in operation

"Clean DOWN": The nozzle is rotating while moving downwards

"2.5A": Amperage reading of the 24V DC Motor operating the mechanism

"288 Sec": Indicates the remaining time of the cleaning cycle in seconds

"CYC 6/8": GFCM is at its 6th cycle out of 8th

Air Jet ON

045 Sec

Air Pulse system is activated

"Air Jet ON": Air pulse system to clean the cabinet

"045 Sec": Time left to terminate the Air pulse system

Clean Finished

8 Cycle 23-32"

Cycle has ended

"Clean Finished": Cleaning cycles has ended

"8 Cycle": GFCM has cleaned the filter for 8 consecutive cycles

"23-32"": The height range of the dirty filter.

Rotary Switch

Functionality

Power

Turn rotary switch ON to power the controller

Buttons

Functionality

Start

Push Start to begin cleaning cycle

Menu/Select

Push and Hold Menu/Select for one second to enter the Menu

< > (Scroll)

Push < > to scroll over the choices

Abort Cycle

Push Abort Cycle to skip pre-set number of cycles and complete

current cycle.

11

D I V E R S I T E C H O M - G F C M

Page 11

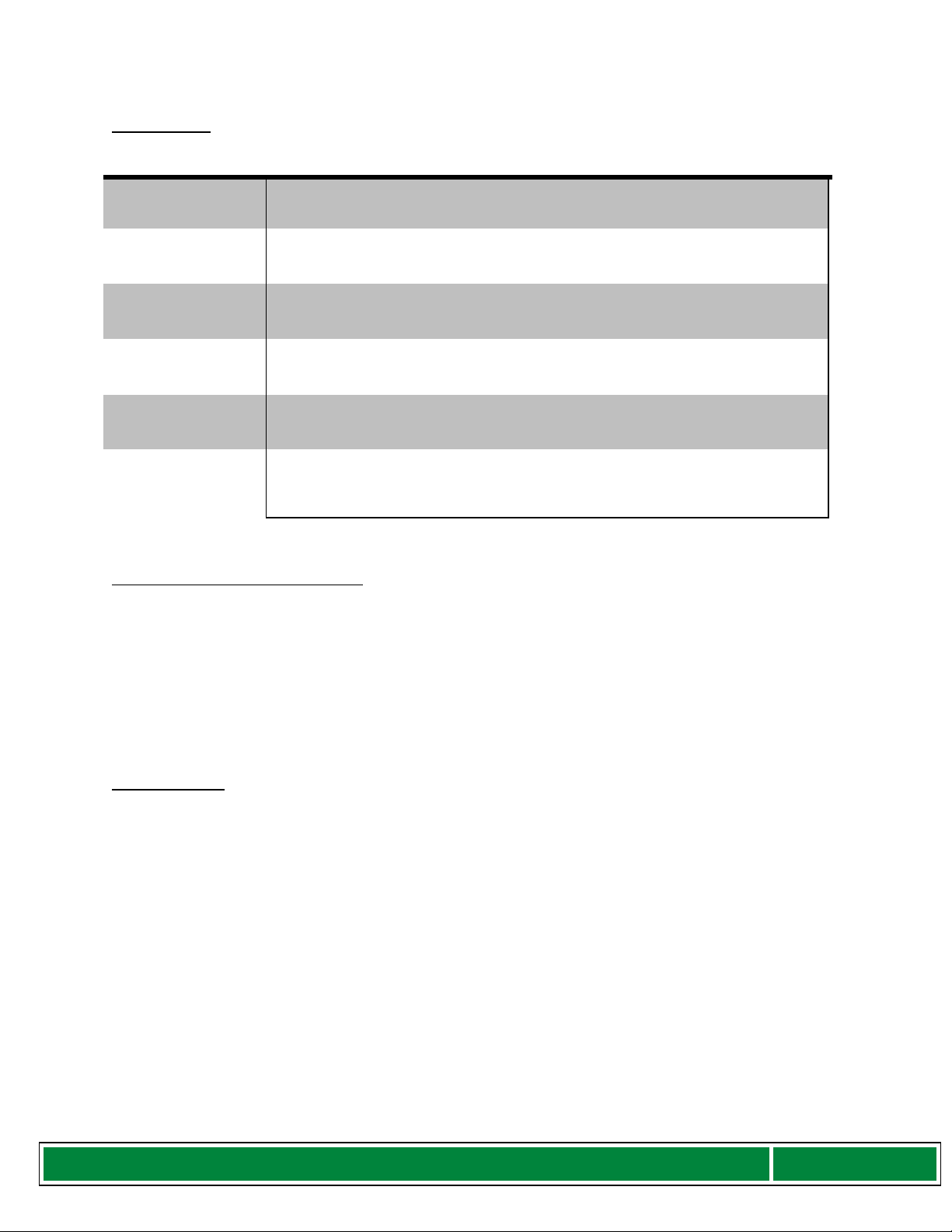

3.5.2 - Menu

To enter the Menu: Press and hold Menu/Select Button for 1 second

LCD Reading

Description

Change # Cycles?

Y N

Press the Scroll Button to the desired selection

Press Menu/Select Button to select Yes or No

Select # Cycles

1 2 4 8

Number of Cycles

Press the Scroll Button to the desired selection

Press Menu/Select Button to select 1,2,4 or 8 cycles

Change Filter

Height? Y N

Press the Scroll Button to the desired selection

Press Menu/Select Button to select Yes or No

Filter Height (")

0-16 17-22 23-32

Filter Height Range

Press the Scroll Button to the desired selection

Press Menu/Select Button to select the range of filter that

needs to be cleaned 0-16", 17"-22" or 23"-32"

Cycles to Date

65535

The number of cycles the machine has performed up to date.

Press Menu/Select to return to Home Reading or wait 3 seconds

12

D I V E R S I T E C H O M - G F C M

Page 12

Figure 5: Menu

Change # Cycles?

Yes

No

Select # Cycles

1

2

4

8

Change Filter Height?

Yes

No

Filter Height (”)

0-16”

17”-22”

23”-32”

Cycles to Date

Press & Hold Menu/Select

13

D I V E R S I T E C H O M - G F C M

Page 13

3.5.3 - Errors

Contact us for additional support: 1-800-361-3733

3.5.4 - Reduce Time of operation

A full 23”-32” cycle takes approximately 5 minutes to end. The cycle time could be reduced by 25-to-

50% if and only if the filter is open on both ends and the height of filter is equal or less than 22”.

This could be accomplished by setting the filter height (Figure 5) to 0-16” or 17”-22”. One should

note that loading the filter defers from the usual procedure. (Read procedure below)

Step 1: Install the filter

Step 2: Add the required spacers on top of the filter (Rather than adding them at the bottom)

3.5.5 - Dry Run

Dry Run is to operate the GFCM without any air supply. This is only to observe any

malfunctioning components or to trouble shoot issues that the GFCM may encounter.

LCD Reading

Description

Filter is not

sealed properly

Spacers not installed / Incorrect Spacer Height

Cabinet Lid not secured properly

Clean UP 2.5A

Counter Error

Proximity Sensor Failure while cleaning upwards –Replace it

with the one provided in the bottom of the Cabinet

Clean DOWN 2.5A

Counter Error

Proximity Sensor Failure while cleaning downwards - Replace it

with the one provided in the bottom of the Cabinet

Clean UP 8.5A

Overcurrent STOP

Nozzle is jammed while cleaning upwards - Verify that the

nozzle is not jammed up against an obstruction

Clean DOWN 8.5A

Overcurrent STOP

Nozzle is jammed while cleaning downwards - Verify that the

nozzle is not jammed up against an obstruction

Clean DOWN 0.0A

Home SW ERROR

Home position is misplaced. Manually turn tube CCW for the

nozzle to move upwards. Remove Maintenance panel and

adjust Limit Switch to the correct position.

14

D I V E R S I T E C H O M - G F C M

Page 14

4.0 - Preventive Maintenance

1. Injection Cleaning System

Regular checklist:

a) Inspect the Limit switch at the bottom of the assembly for any debris

b) Ensure that the Nozzle Assembly disc properly aligns with the Limit switch

to ensure that contact occurs. This can be achieved doing a “Dry Run”.

Step 1: Open the top by releasing both latches.

Step 2: Remove filters/spacers inside the Cabinet.

Step 3: Cut air supply to the unit.

Step 4: There is a Maintenance switch on the side of the Cabinet below

the Control Box, turn this switch on.

Step 5: Once the LCD reads “Ready to Clean”

Step 6: Press the start button

Step 7: Let the unit run up & down.

Once this checklist is verified, please turn OFF the switch on the side of the Cabinet

below the Control Box. This switch is for maintenance only.

2. Hardware

Bolts and nuts should be checked periodically and tightened.

3. Dust Barrel

Empty out the contents of the dust barrel periodically. Please ensure that the

materials are disposed of properly in accordance with local disposal laws.

Important Note: Barrel should not be more than ¾ full.

4. Exhaust Filter

After cleaning filters visually inspect the exhaust filter located behind the cyclone.

Replace the filter when necessary.

Important Note: Do not place Exhaust filter into the machine.

5. Cabinet debris

After every 24 filters cleaned remove panel in front of the Cabinet, inspect and

vacuum (if necessary) around the cleaning mechanism base.

Figure 6: Front Panel, Limit Switch and Nozzle Assembly

15

D I V E R S I T E C H O M - G F C M

Page 15

5.0 - Troubleshooting List for Injection Cleaning System

PROBLEM

CAUSE

SOLUTION

System is NOT turning

Power is not supplied to PC board.

Ensure the unit is plugged in; ensure there is no loose or short

wiring between primary & secondary of transformer and the

24VAC power inlets of PC Board.

Filter is not sealed properly

Check the compression mechanism on top of the inner chamber

lid. Insert appropriate Spacer. (Refer to Filter Spacer Chart)

Loose connection between PC board

and motor.

Check motor connection. When the “UP” light is ON, the motor

should be rotating the nozzle upwards; and downwards when

the “DOWN” light is ON. (Refer to the electrical diagram)

This could be a result of the nozzle

being jammed, or of something

restricting free movement of the

nozzle.

Locate and repair the cause of the physical restriction before

operating the system.

Limit switch needs alignment

Push limit switch forward or backwards to align with the Nozzle

Assembly switch disc

System is NOT turning and no air

comes out of the nozzle.

Solenoid is not opening.

Upon a cleaning cycle, the “SOLN1” light turns ON indicating

power is being supplied to the solenoid.

Check the wiring between the PC board and the solenoid for

any possible bad connections.

Check if solenoid is operational. This can be done by jumping

the solenoid leads to the secondary side of the transformer.

(24VAC)

If both wiring and solenoid are in order, the PC board might

need to be changed.

System turns but no air comes out

of the nozzle.

Low air supply pressure.

Ensure that air pressure is 80-100psi and Minimum 80CFM

The nozzle is blocked by dirt or

other contaminant.

Remove blockage from the nozzle.

Check if pneumatic filter is filtering air properly. Its filter unit

might need to be replaced.

Not enough air coming out of the

nozzle.

There is an air leak in the pneumatic

system.

Verify pneumatic system for leaks and tighten or change hose

clamps or hoses.

For any other inquiry, please contact Diversi-tech at 1-800-361-3733.

5.1 - Debugging

Things to check

When the machine is first plugged in, the mechanism will move to a “home” position. Once the nozzle is at home

position, the system is ready. The cleaning cycle is controlled by a microprocessor based PC board located in the

control box. The microprocessor has been programmed to turn on the cleaning system once the start button is

pressed and released, and the filter is sealed. The nozzle will travel from its home position (located at the bottom)

through the top and back down to home. The home and top positions are sensed by Limit Switch and Proximity

Sensor respectively. Simultaneously, when the gear motor is engaged, an in-line solenoid opens and allows

compressed air to reach the nozzle or the pneumatic vibrator motor. If for some reason the lid is open before the

cleaning system has had a chance to terminate the cycle, the system will shut itself and the unit will resume from

where it left off once the Cabinet lid is closed.

16

D I V E R S I T E C H O M - G F C M

Page 16

1. Cyclone Assembly

a. Dust Collector Motor 5HP

i. Depending on the voltage used the running amperage differs on every machine

ii. Look for Maximum Amperage (Max. AMP.) on Serial Number Sticker located on left side

of the Control box. (e.g. For a 460V/3P/60Hz the maximum amperage is 6.1A)

iii. Hook an Amperage meter to the T1 in the control box. The running amperage readout

should be below the Maximum Amperage. (e.g. For a 460V/3P/60Hz the running

amperage is around 5-to-5.5A). If the amperage is higher, shut down the power and

invert the L1 with L2.

iv. Rotation of Motor is Clockwise from the top view.

b. Dust Collector Motor 5HP is not starting

i. Verify the Male and Female connector plug. Insure they are

well connected.

2. Mechanism check

a. During operation verify that the Amperage readout on the LCD is

not higher than 5Amps. The machine must be shut down and

maintenance clean up should be performed on cleaning mechanism

of the GFCM.

b. Maintenance Switch located under the Control Box. Cut air supply

to the GFCM and turn on the maintenance switch. Observe the

cleaning mechanism while it goes up and down. If an error appears

see section 3.5.3 Errors

17

D I V E R S I T E C H O M - G F C M

Page 17

6. 0 - WARRANTY Clauses

Effective immediately

, the following policy will apply to all equipment.

LIMITED EQUIPMENT WARRANTY

All Diversi-Tech units are warranted to be free from defects in material and workmanship for

a period of two years from the date of purchase. Diversi-Tech Inc. will repair or replace, at

our option, any defective parts returned to the manufacturer

’

s plant in Montreal - Quebec

freight

prepaid- which fail during the warranty period. This warranty is limited to

replacement parts

and labor ONL

Y,

subject to on site or in house evaluation of defective

materials and does

not apply to any personal liability or property loss that occurs due to the

use or installation of this equipment.

FREIGHT CLAIMS

All Diversi-T

ech units are sold ex-plant, Montreal, Qc., Canada. Therefore, it is the user

’

s

responsibility to file any freight claims for obvious or concealed damages which

developed in transit from Montreal to your location or when drop shipped.

7.0 - RETURN MATERIAL POLICY

1.

Prior to the return of material, for whatever reason, a return manufacturing

authorization

number (RMA#) is required from the Diversi-T

ech production

control department.

This procedure is necessary for proper control and handling of

returned materials. Fax us or call to obtain the RMA.

Phone:#

Fax: #

2.

All material must be returned prepaid. Credit will be given for returns for

warranty repair or

replacement. Freight collect shipments will not be accepted. It

is the shipper

’

s responsibility

to insure that material being returned to Diversi-

Tech is adequately packaged for shipment to preclude damages.

1200 55th Avenue

Montreal, Quebec H8T 3J8

Toll-free: (800) 361-3733

Fax: (514) 631-9480

E-mail: [email protected]

www.diversitech.ca

18

D I V E R S I T E C H O M - G F C M

Page 18

8.0 - REPLACEMENT PARTS

REPLACEMENT PARTS

GFCM-001

PAPER CARTRIDGE FILTER EXHAUST

GFCM-001P

POLYESTER CARTRIDGE FILTER EXHAUST-STANDARD

GFCM-001NF

NANOFIBER CARTRIDGE FILTER EXHAUST

GFCM-002

SPUNBOND INTAKE PANEL FILTER 12X12X2

GFCM-004

24 VDC GEARMOTOR

GFCM-005

GEARMOTOR CABLE

GFCM-006

SENSOR CABLE

GFCM-008

5 HP/230-380-460-600V/3/50-60Hz MOTOR

GFCM-009

5 BI CCW BLOWER WHEEL

GFCM-010

5 BLOWER CONE

GFCM-011

BARREL PLUGS

GFCM-012

BARREL KNOBS

GFCM-013

CYCLONE

GFCM-014

LIMIT SWITCH

GFCM-015

PROXIMITY SENSOR

GFCM-016

RECOIL HOSE

GFCM-017

AIR NOZZLE

GFCM-018

RARE EARTH MAGNETS

GFCM-019

MOTOR STARTER

GFCM-020

230/380/460/600 –24 VAC TRANSFORMER

GFCM-021

PC-BOARD

GFCM-022

FUSE

GFCM-024

24VAC SOLENOID VALVE

GFCM-026

6"dia FLEXHOSE (SPECIFY LENGTH WHEN ORDERING)

GFCM-027

CYCLONE EXHAUST BARREL

APPENDIX:

WIRING SCHEMATIC:

Table of contents

Other DIVERSITECH Cleaning Equipment manuals