DIVEX DIVEX ULTRALITE 2 E12380 Operating instructions

OM111

P1972-OM-367 Rev 6

OPERATING AND MAINTENANCE MANUAL

for the

DIVEX ULTRALITE 2

OVERBOARD DUMP DIVING CHAMBER BREATHING

MASK

Standard without communications - Part No: E12380

Standard with communications, HTU - Part No: E13841

Standard with communications, Banana Plug - Part No: E15000

(Intentionally Blank)

OM111 i

P1972-OM-367 Rev 6 Preface

PREFACE

The following address should be used in all communications with the manufacturer:

National Approvals and Markings:

1. Product Marking: 0088

Divex Limited declares that this Personal Protective Equipment is in conformity with the

provisions of Articles 10 and 11 of the EUROPEAN DIRECTIVE 89/686/EEC as a

CATEGORY 3 DEVICE, and is manufactured under a Quality System approved by

Lloyd’s Register Q.A. (Notified Body No. 0088).

2. National Approvals

The Divex Limited Quality Management System has been approved by Lloyd’s

Register Quality Assurance Limited to BS EN ISO 9001.

Approval Certificate No. 0850495.

Divex Ltd

Enterprise Drive, Westhill, Aberdeen, AB32 6TQ, United Kingdom

Telephone: +44 (0)1224 740145

Fax +44 (0)1224 740172

Email [email protected]

Web www.divexglobal.com

EC Type Approval conducted by: Germanischer Lloyd AG,

D-20459,

Hamburg,

Vorsetzen 32/35,

Germany

Notified Body No. 0098

ii OM111

Preface P1972-OM-367 Rev 6

(Intentionally Blank)

OM111 iii

P1972-OM-367 Rev 6 Approval Sheet

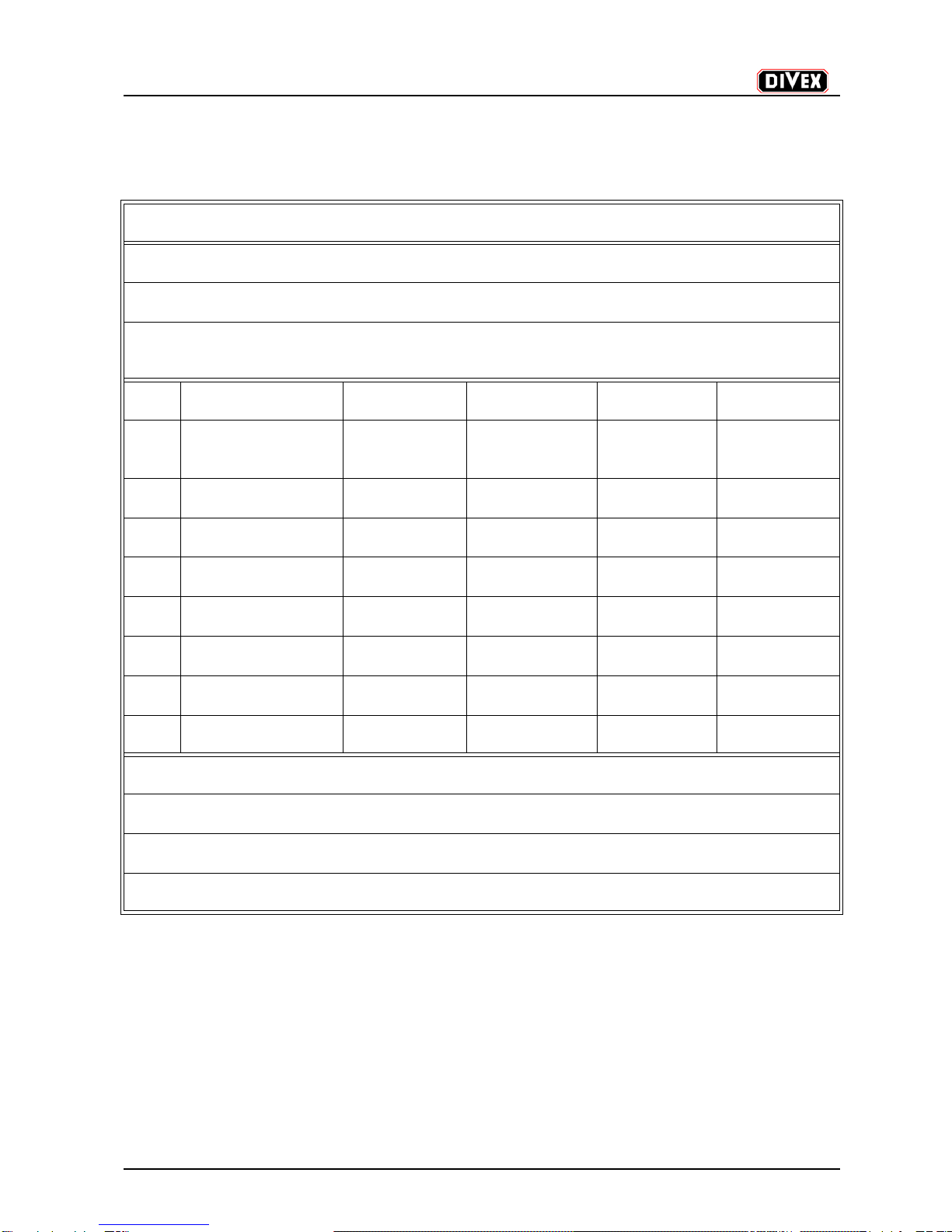

APPROVAL SHEET

DIVEX

MANUAL NUMBER: OM111

ADVITIUM NUMBER: P1972-OM-367

DOCUMENT TITLE: User Manual for the Ultralite 2 Overboard Dump Diving Chamber

Breathing Mask

REV DATE BY CHECK APP COMMENTS

0 01 November 1997 Hamish

Simpson Danny Gray Hamish

Simpson Original Issue

1 11 October 2000 PGB JR Ray Wylie ECN: 3302

2 18 July 2001 PGB Ray Wylie Ray Wylie ECN: 3493

3 19 June 2007 Christine Bain Jamie Massie Jamie Massie ECN: 9390

4 12 May 2010 Stewart Birnie Ray Wylie Ray Wylie ECN: 13504

5 20 May 2011 Debbie Allan Nick Graves Scott Waddell ECN: 14148

6 20 September 2012 Debbie Allan Alastair Naylor Mark Stevens ECN: 14955

7

ORIGINAL ISSUE DATE: 1 November 1997

ORIGINAL DOCUMENT BY: Hamish Simpson

CHECKED BY: Danny Gray

APPROVED BY: Hamish Simpson

iv OM111

Approval Sheet P1972-OM-367 Rev 6

(Intentionally Blank)

OM111 v

P1972-OM-367 Rev 6 Table of Contents

Page

PREFACE ........................................................................................................................................I

OPERATIONAL NOTICE ................................................................................................................1

CHAPTER 1 - WARNINGS ............................................................................................................3

CHAPTER 2 - INTRODUCTION .....................................................................................................5

CHAPTER 3 - OPERATION ...........................................................................................................7

CHAPTER 4 - CLEANING SOLUTIONS ........................................................................................9

CHAPTER 5 - FAULT FINDING ...................................................................................................11

CHAPTER 6 - PARTS LIST .........................................................................................................13

ANNEX A - BPR & RELIEF VALVE CONFIGURATIONS ............................................................19

ANNEX B - DRAWINGS & PARTS LISTS ....................................................................................21

TABLE OF CONTENTS

vi OM111

Table of Contents P1972-OM-367 Rev 6

(Intentionally Blank)

OM111 1

P1972-OM-367 Rev 6 Operational Notice

OPERATIONAL NOTICE

Only Divex approved spares shall be used on the Ultralite 2 in order to maintain CE PPE

approval of these products.

2OM111

Operational Notice P1972-OM-367 Rev 6

(Intentionally Blank)

OM111 3

P1972-OM-367 Rev 6 Chapter 1

CHAPTER 1 WARNINGS

The Divex Ultralite 2 is for use within a hyperbaric diving chamber and must NOT be used

underwater.

Pure oxygen and oxygen rich gases may be used to supply the mask. To reduce any risk of

combustion and / or explosion associated with the oxygen enriched environment, the mask

must be kept free from dust and dirt and free of any hydrocarbon greases, flammable

cleaning fluids, dust particles or other combustible materials.

4OM111

Chapter 1 P1972-OM-367 Rev 6

(Intentionally Blank)

OM111 5

P1972-OM-367 Rev 6 Chapter 2

CHAPTER 2 INTRODUCTION

The Divex Ultralite 2 mask is an anthropological oral/nasal based breathing system for use

by persons using a hyperbaric chamber. It is for use with breathable diving quality gases

such as pure oxygen, breathing quality oil free air and heliox (helium and oxygen) gas in a

hyperbaric diving chamber to depths down to 450 msw. The choice of gas to be breathed will

be dictated by diving table’s outwith the scope of this manual.

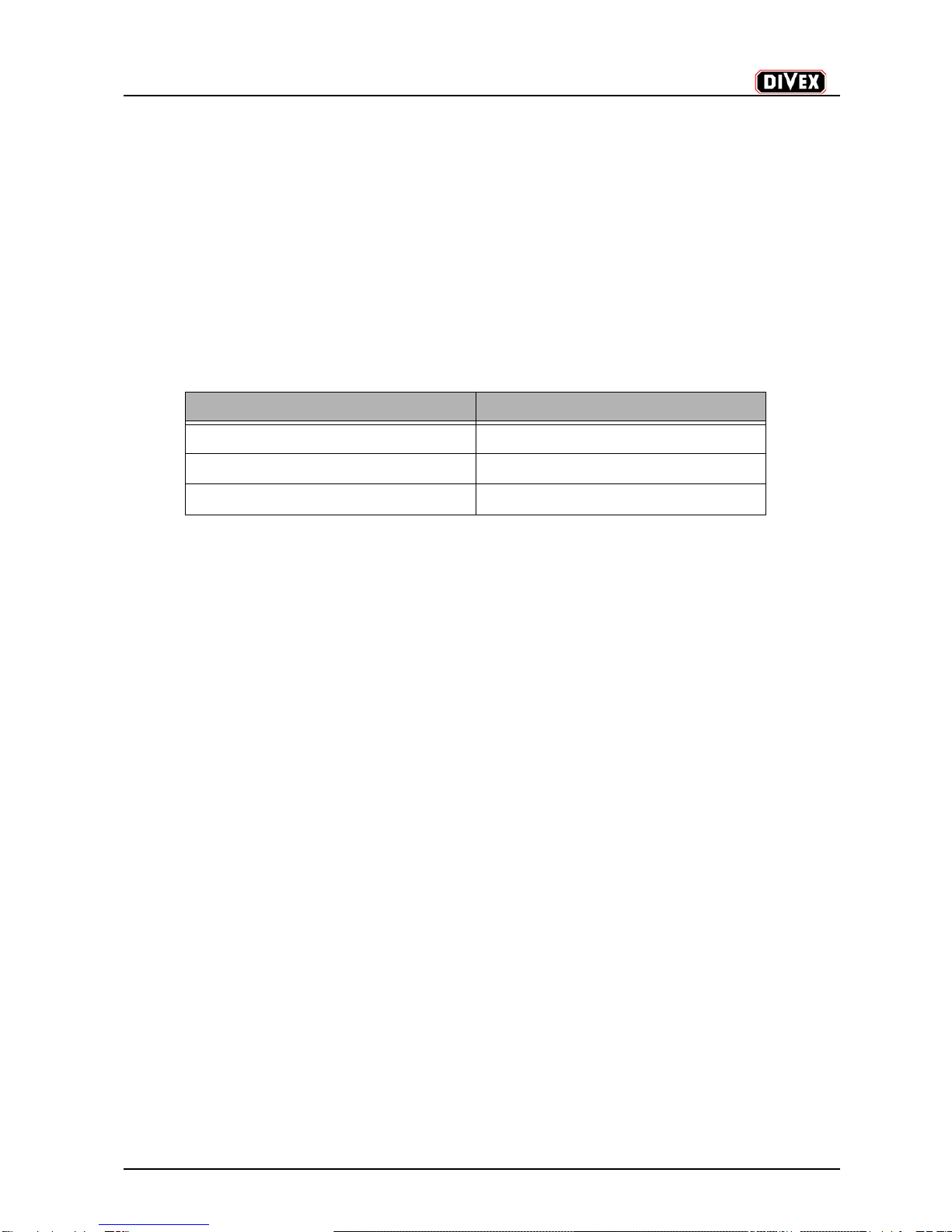

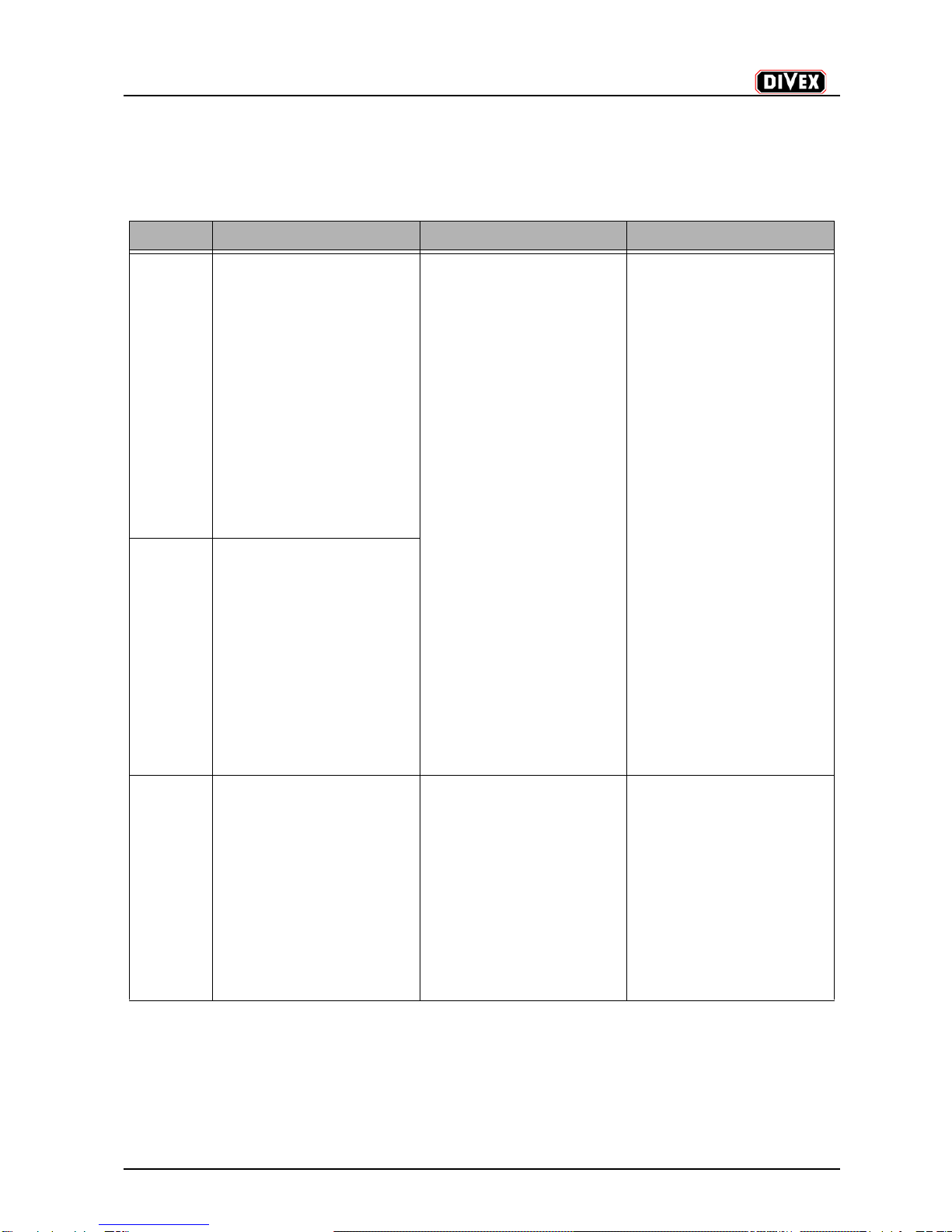

The following table shows which gases are technically acceptable for the mask at various

depths:

Heliox gas can be used at any working depth down to 450 msw, provided the partial pressure

of oxygen (PPO2) within the Heliox mixture, is within acceptable limits.

The mask has been designed to provide “overboard dump” i.e. exhausting the exhaled

breath to the outside of the chamber at atmospheric pressure and has been designed to

safely accept exhaust below chamber ambient pressure on its exhaust hose equivalent to –4

barg. It’s nominal design working suction, however, is –2 barg and hence at depths deeper

than 20 msw, the chamber system should be fitted with a back pressure regulator (BPR)

capable of maintaining the –2 barg suction at the required exhaled flowrate.

To prevent exhaust hose from collapsing when not in use, an inward relieving 3 barg relief

valve should be fitted between the exhaust hose and the BPR. Examples of setup

configurations are shown in ANNEX A (page 19).

The design supply pressure for the mask can range from 6 barg to 16 barg over the chamber

ambient pressure.

The Ultralite 2 mask has been designed to meet the Norwegian Petroleum Directorate’s

(NPD) work of breathing and respiratory pressures at all breathing rates to 62.5 litre/min

RMV from 3 msw to 450 msw. The mask can be used on the surface where it meets NPD

requirements up to 22.5 litre/min RMV and up to 40 litre/min RMV at 2 msw.

The Ultralite 2 mask can be supplied with or without diver communications.

The only difference between these variants is the communications cable assembly attached

to the supply hose. This manual details both variants.

This manual provides information for the user only, servicing and routine maintenance is

covered in detail in the “Service Manual for the Ultralite 2 Overboard Dump Diving Chamber

Breathing Mask” – document number OM079.

GAS DEPTH RANGE (MSW)

Oxygen 0-20

Breathing Quality Oil Free Air 0-50

Heliox 0-450

6OM111

Chapter 2 P1972-OM-367 Rev 6

(Intentionally Blank)

OM111 7

P1972-OM-367 Rev 6 Chapter 3

CHAPTER 3 OPERATION

Set the supply pressure to the following guidelines:

If a BPR is fitted, set the exhaust pressure to 2-4 bar suction, relative to chamber ambient

pressure.

When the Ultralite 2 mask is used it should be adjusted to the optimum breathing resistance

using the free flow control knob and set at the point where free flow on the inlet valve has just

stopped.

When the mask is initially donned, the head harness can be adjusted by pulling each strap

leg through the buckle for individual user comfort.

0-150 msw 6 - 12 bar Over chamber pressure

200 msw 8 - 12 bar Over chamber pressure

250 msw 10 - 12 bar Over chamber pressure

300 msw 11 - 12 bar Over chamber pressure

350 - 450 msw 12 bar Over chamber pressure

8OM111

Chapter 3 P1972-OM-367 Rev 6

(Intentionally Blank)

OM111 9

P1972-OM-367 Rev 6 Chapter 4

CHAPTER 4 CLEANING SOLUTIONS

4.1 Soapy Water

A solution of domestic soapy clean warm water will remove dirt and stains from the

mask and harness.

4.2 Disinfectants

TriGene II (concentrate supplied in multiples of 5 litres, Part No. SM039) is the only

disinfectant recommended by Divex for use with the Ultralite II BIBS mask.

4.3 Ultrasonic Cleaning

If, for any reason, hydrocarbon grease or metal filings have contaminated the mask,

the complete assembly and hoses should be striped down and cleaned in an

ultrasonic bath using an approved oxygen cleaning procedure.

4.4 Material Compatibility

Extensive tests by Divex have resulted in the recommendation in section 4.2

(page 9). It is wholly the responsibility of the user to verify compatibility with the

materials used within the construction of the mask. These materials are noted in

“Service Manual for the Ultralite 2 Overboard Dump Diving Chamber Breathing

Mask” – document number OM079 Chapter 10.

4.5 Cleaning Procedure

4.5.1 Remove Oral Nasal Assembly Part No: E15846.

4.5.2 Remove Head Harness Part No: E12366 from the buckles at each side of the mask

body.

4.5.3 Remove the Rear Panel Assembly Part No: E13837.

4.5.4 Remove Inlet and Exhaust Hoses from the mask banjos, Part No: E13160.

4.5.5 For disinfecting the parts, immerse the Mask Body Part No: E12364, the Oral Nasal

Part No: E15846 and the Rear Panel Part No: E13837 in a solution of 1 part Tri-

Gene II to 50 parts warm water for 15 minutes.

4.5.6 Rinse the parts in fresh water and allow to dry.

10 OM111

Chapter 4 P1972-OM-367 Rev 6

4.5.7 Connect Inlet and Exhaust hoses Part No: E13160 to the mask banjos.

4.5.8 Fit Oral Nasal Part No: E15846 and Rear Panel Assembly Part No: E13837.

4.5.9 Connect to gas supply and turn Freeflow Knob clockwise to blow any remaining

droplets of water from the inlet banjo before breathing the mask.

OM111 11

P1972-OM-367 Rev 6 Chapter 5

CHAPTER 5 FAULT FINDING

FAULT PROBABLE CAUSE REMEDY

5.1 Mask free flowing on inlet

side. Free flow control knob

screwed too far in. Back off free flow control

knob.

Inlet gas supply pressure

set too high. Reduce gas supply

pressure (6-12 bar over

chamber depth).

Inlet valve diaphragm

levers incorrectly set after

maintenance.

Reset diaphragm inlet

levers.

Damage to inlet valve

seat. Replace inlet valve stem

assembly.

Damage to inlet valve

nipple. Replace inlet valve nipple.

5.2 Mask continually sucking

chamber gas on exhaust

side.

Exhaust valve diaphragm

levers incorrectly set after

maintenance.

Reset diaphragm exhaust

levers.

Damage to exhaust valve

seat. Replace exhaust valve

stem assembly.

Damage to exhaust valve

nipple. Replace exhaust valve

nipple.

Mask positioned face

downwhilstremovedfrom

diver.

Position mask with oral

nasal facing downward.

5.3 Difficulty inhaling. Free flow control knob

incorrectly set. Adjust free flow control

knob clockwise for easy

breathing.

Inlet valve diaphragm

levers incorrectly set after

maintenance.

Reset diaphragm inlet

levers.

Incorrect supply pressure. Reset supply pressure to

recommended pressures

for depth (6-12 bar over

chamber).

12 OM111

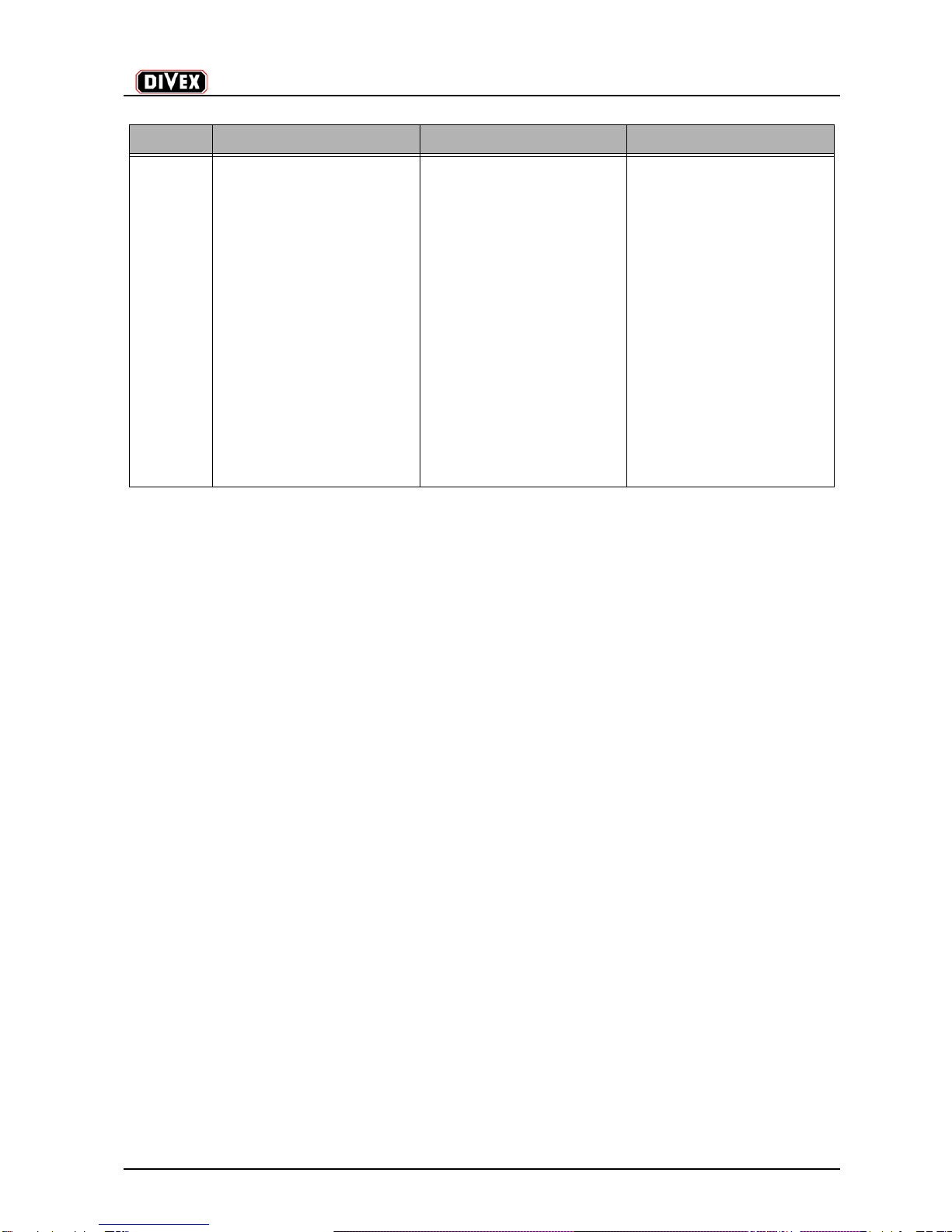

Chapter 5 P1972-OM-367 Rev 6

5.4 Difficulty exhausting. Diving depth too shallow. Open by-pass valve

around diving system

backpressureregulator(if

fitted) or enlarge diving

system exhaust pipework.

Exhaust valve diaphragm

levers incorrectly set after

maintenance.

Reset diaphragm exhaust

levers.

Diving system exhaust

valve closed. Open diving system

exhaust valve.

Diving depth too deep

causing difficulty in

opening exhaust valve.

Ensure a Divex Back

Pressure Regulator is

fitted to the exhaust side

of the mask and is set to -

2 barg.

FAULT PROBABLE CAUSE REMEDY

This manual suits for next models

2

Table of contents

Other DIVEX Diving Instrument manuals