Page 7 of 100

WARNING

TO AVOID THE POSSIBILITY OF A

FIRE HAZARD, DO NOT STORE

ANYTHING OR ALLOW DEBRIS OF

ANY KIND TO ACCUMULATE IN

THE BOTTOM OF THE DOOR, IN

AND AROUND THE

REFRIGERATION COMPARTMENT

OF THE CABINET, OR IN FRONT

OF THE EVAPORATOR AND

CONDENSER COILS.

COIN CHANGERS & OTHER

ACCESSORIES

The vender must have an MDB coin changer

installed and can have an MDB bill acceptor

installed. If the MDB coin changer and other MDB

accessories are not factory installed, refer to the

instructions received from the manufacturer of the

MDB coin changer and other MDB accessories for

proper set-up and installation.

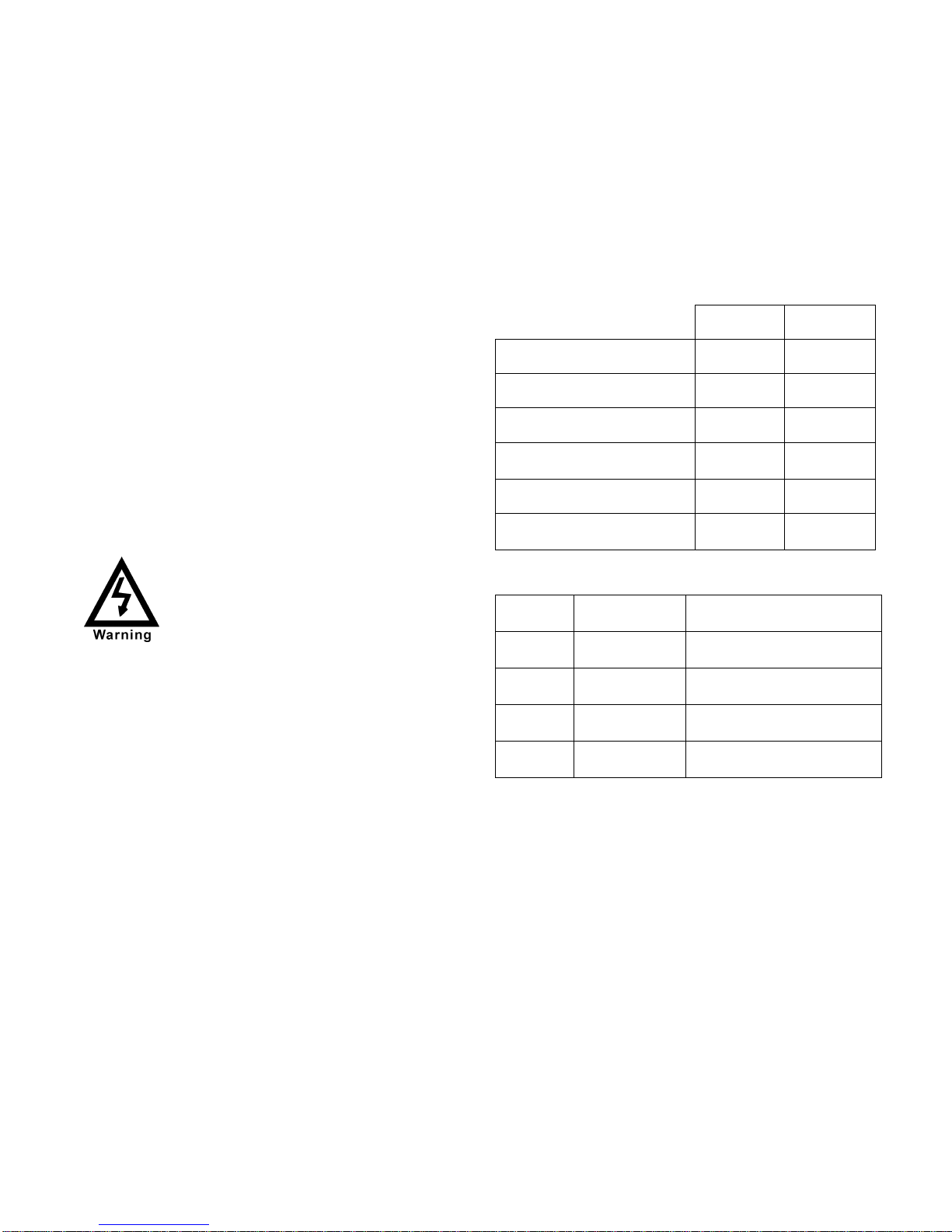

The vender will support the following MDB coin

changers:

Multi-Drop Coin Mech (Domestic)

Coinco 9302GX

Coinco USQ G700 Series

Conlux USLZ-101

Conlux CCM5G

Mars 4510

Mars 6512

The vender will support the following MDB bill

validators:

Multi-Drop Bill Validators (Domestic)

Coinco BA30B, BA50, MAG30, MAG50

Mars VN2512, VN2502, VN2312

Conlux NBU-2111-12, NBM 3000 Series

Ardac 5500 Series

The vender will support the following MDB card

readers:

At publication, card reader dispositions were

not available. Contact card reader

manufacturer for proper installation and

setup.

LOADING CHANGE TUBES

Open the main door and enter the “TUFL” TUBE

FILL ROUTINE mode in Programming (see Section

B – Programming).

Load the coin mechanism with coins by inserting

coins in the coin mech’s separator. The display will

show the total number of the coin type as they are

inserted.

Note: A low coin level in the coin tubes will

interfere with operation of the bill validator.

For additional information about coin mechanisms,

refer to the specific manufacturer’s instructions.

Loading Product

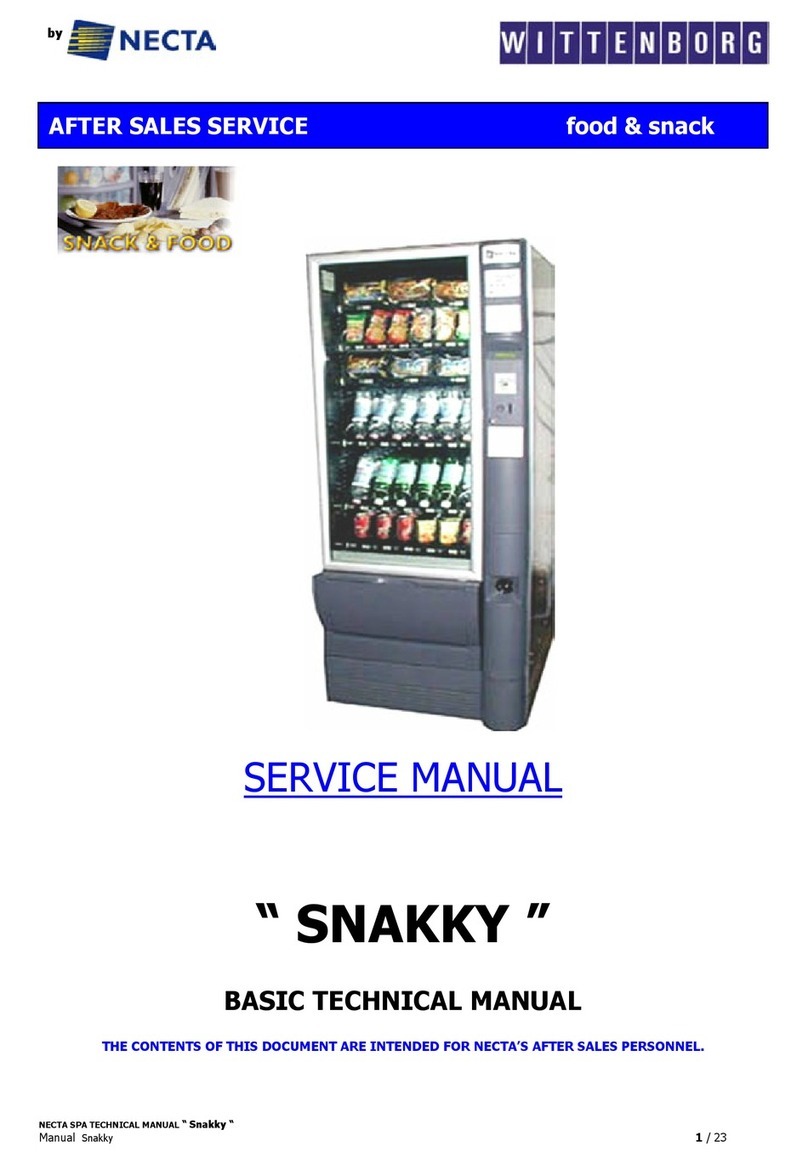

The P Series Vender is designed to vend a wide

range of packages internationally.

All P Series Venders are shipped ready to vend

packages according to customers orders. To vend

an alternative package in the P Series vender,

contact Dixie Narco Technical Service Dept. or your

Representative for assistance. You can also search

the package type you wish to vend at

www.dixienarco.com.

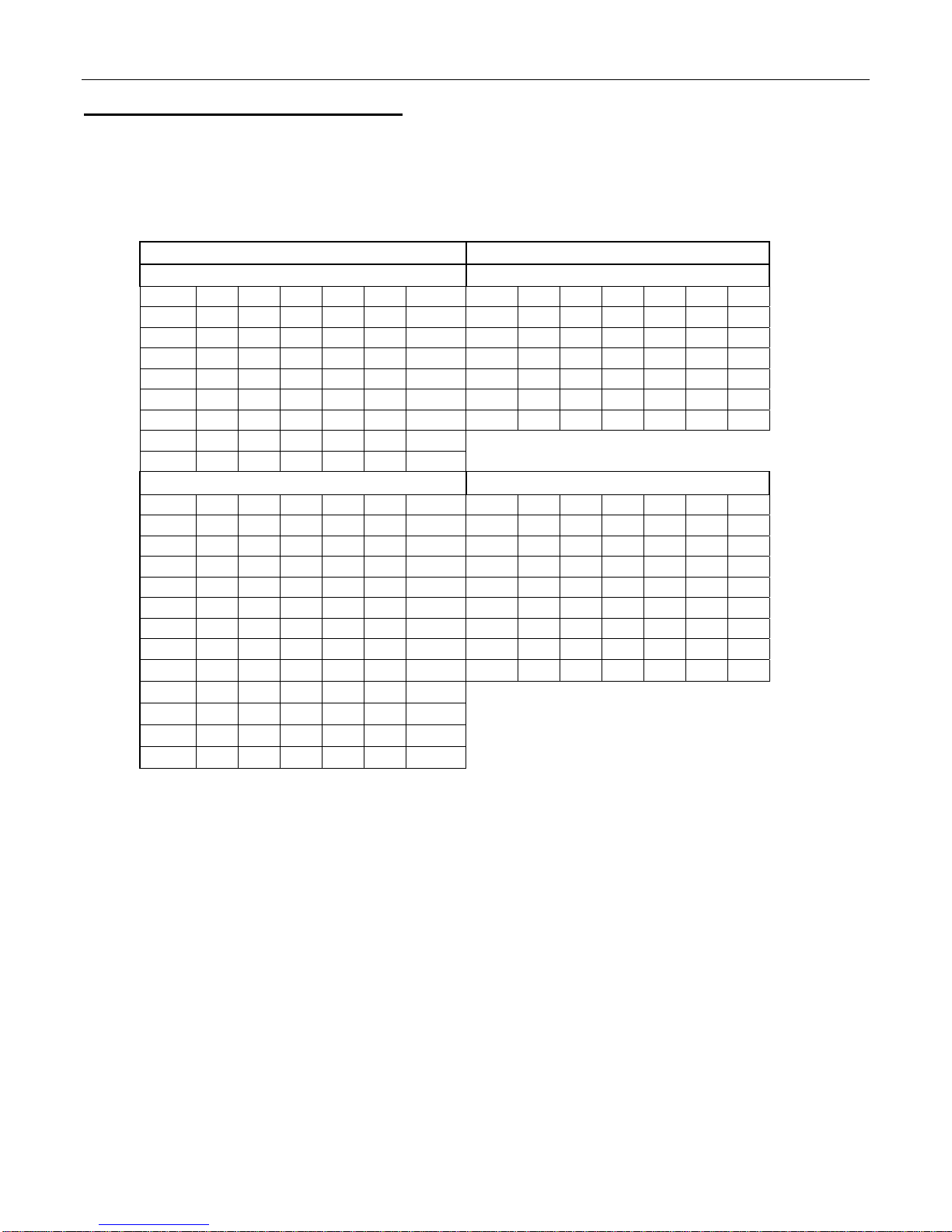

INITIAL LOADING

To ensure proper vending, make sure columns are

set to vend the proper packages. When loading the

narrow columns, lay the first row of packages on the

Load Bar.

Correct loading will prevent service calls and ensure

proper vending.

After loading the vender for the first time, ensure the

vender is loaded and primed. Priming is done in

programming. The depth must also be

programmed depending on the package to be

vended. 12oz Cans may be programmed up to 4

deep.

NOTE: To ensure proper airflow through the

evaporator and the proper operation of the

Vend Sensor, DO NOT place packages (or

other foreign objects) in the bottom of the

tank.

SERVICE NOTE

Battery Backup (SBC)

The Single Board Controller is equipped with a battery

backup which is used to retain information programmed in

the system (pricing, time, date, etc.) in case of power

interruptions or any time the main power is off. When the

vender is shipped, the battery is connected and memory is

being maintained.

Disconnect the battery if the vender will be stored for a

long period of time. The following steps will guide you

through this procedure.

¾Remove power from the vender by unplugging

the main power cord from the wall receptacle.

¾Locate the Control Board on the main door.

Remove the battery from its holder (B1).