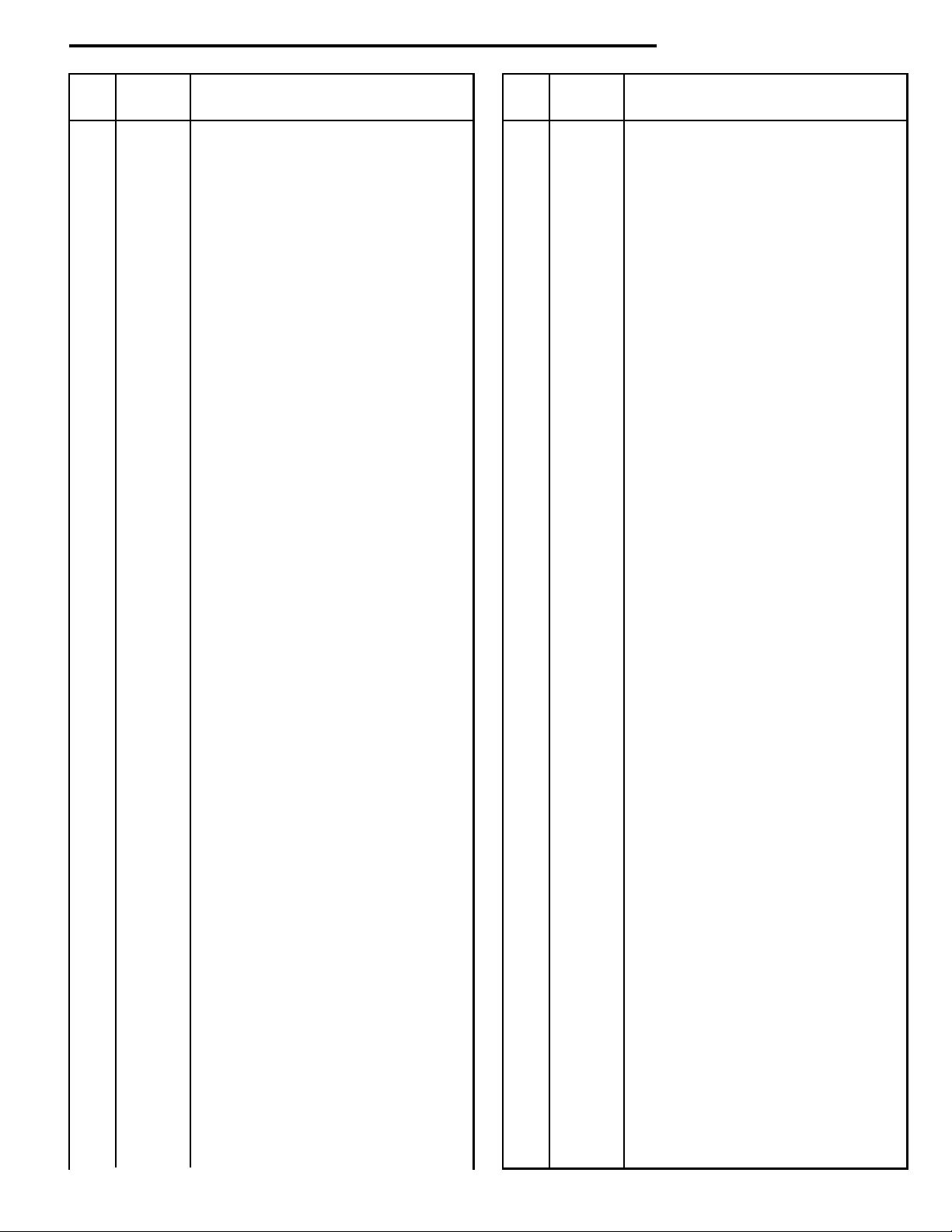

Item

No. Part No. Description

Item

No. Part No. Description

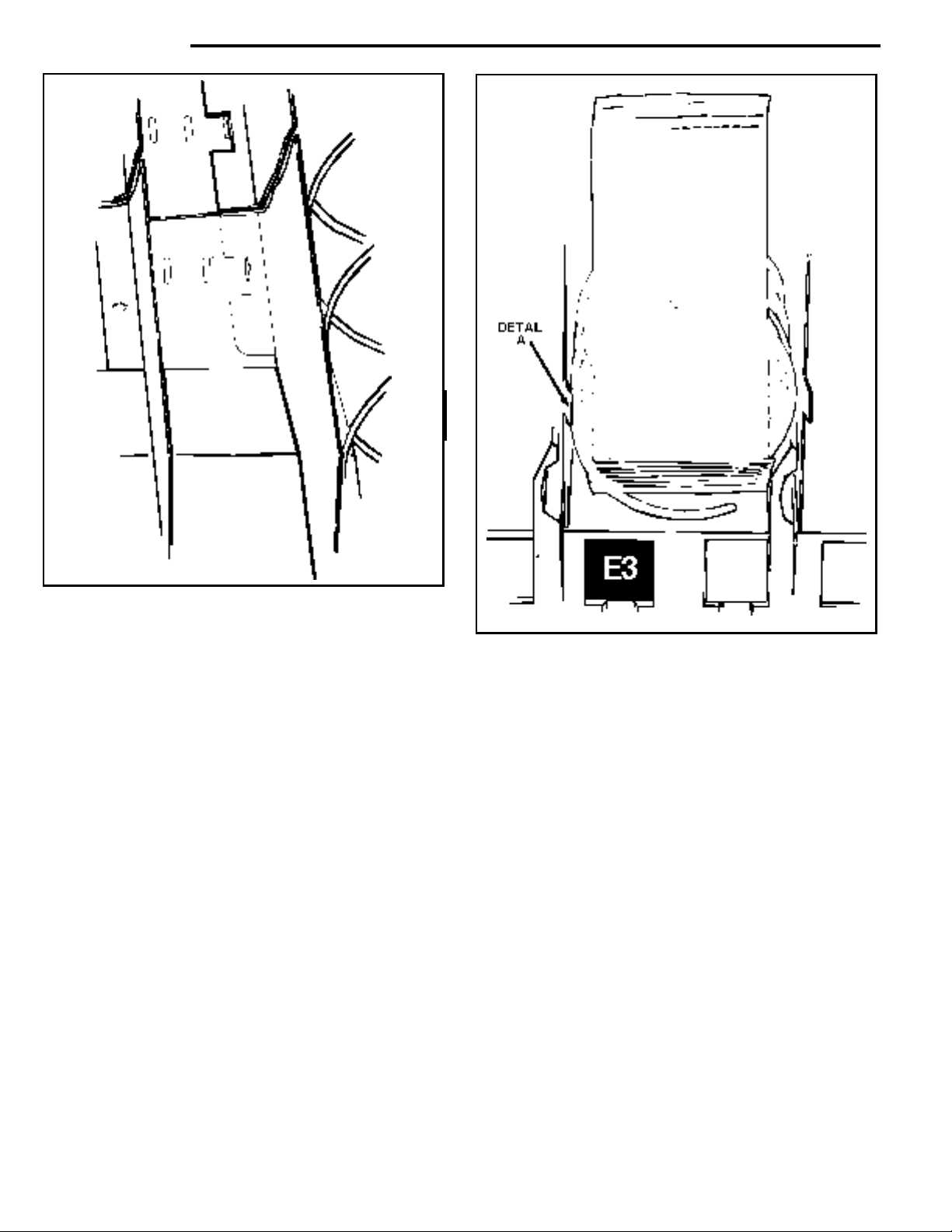

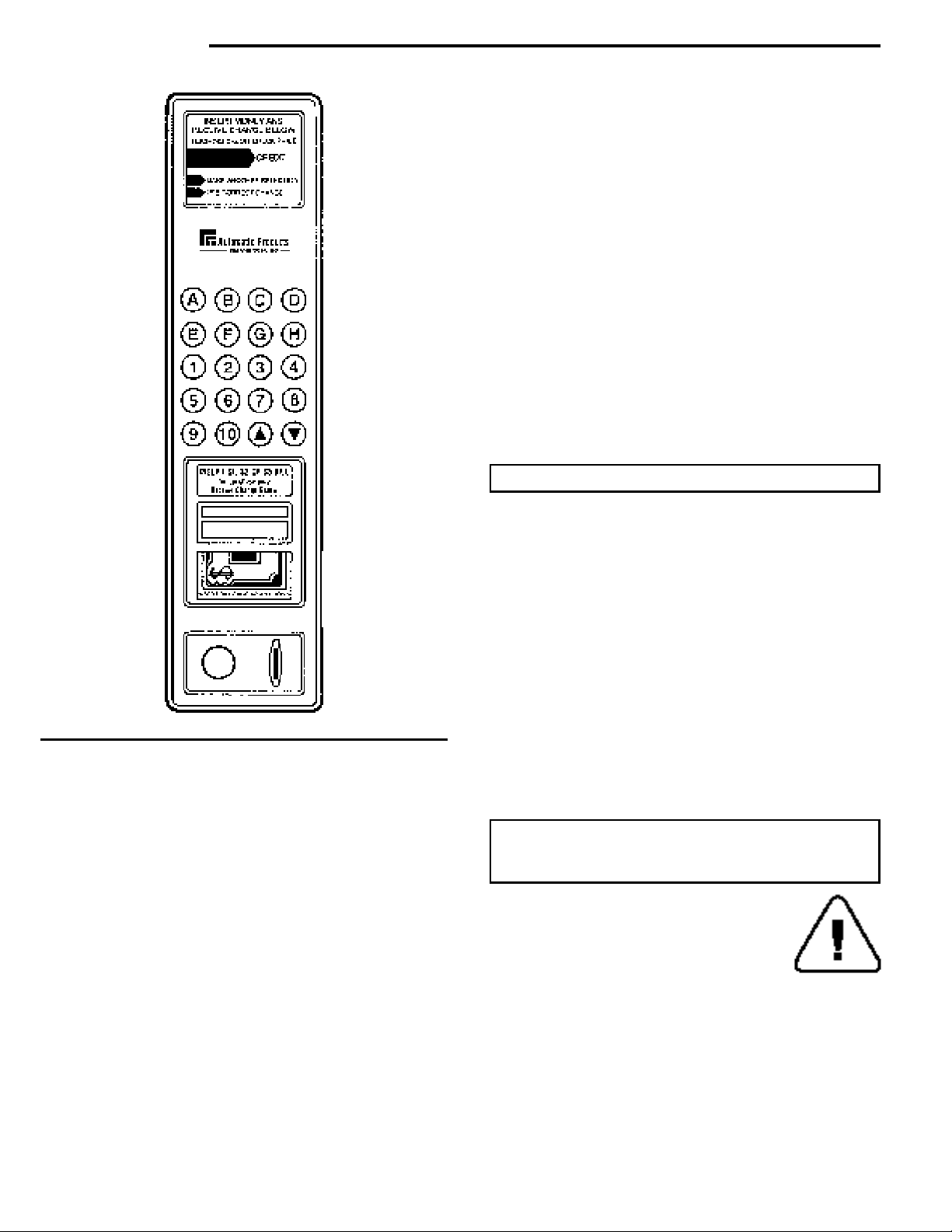

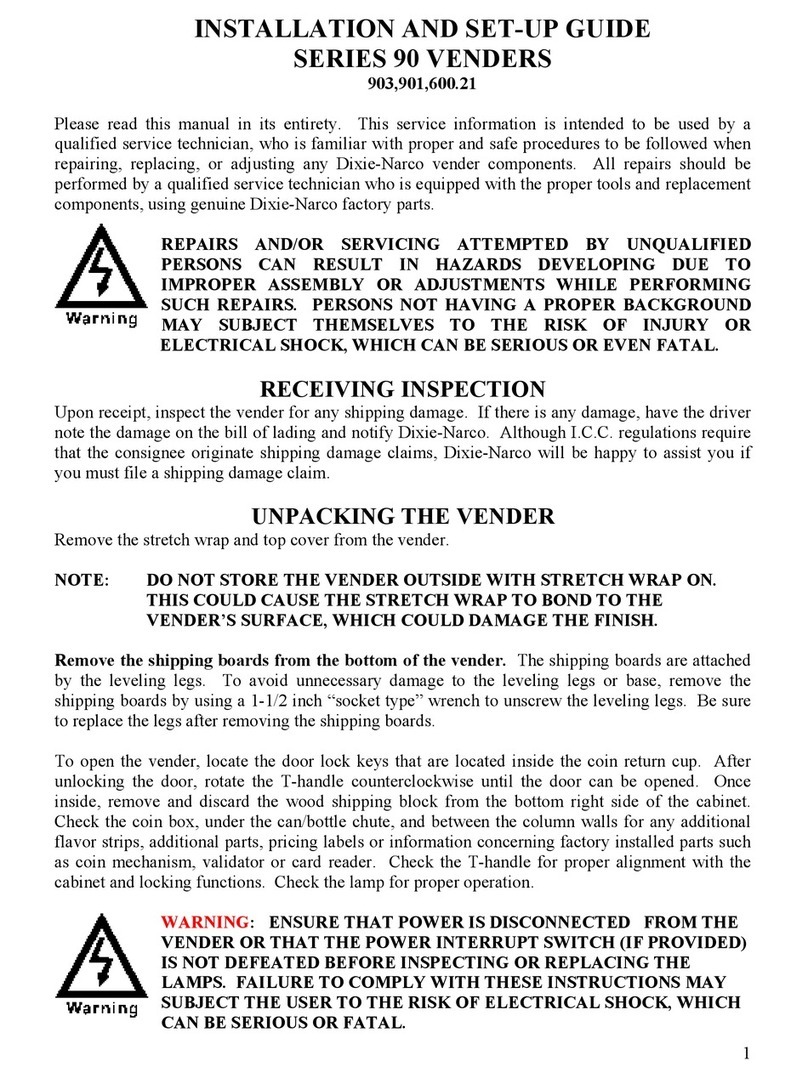

door - inside front

1 16000014 Door Only, Euro Style, Specify Color

16000018 Door Only, Standard, Specify Color

2 420303 Control Board Stand - Off

3 360206 Control Board w/MDB

(Requires Cover 202325)

4 680547 Harness Changer Plug-In

680567 Harness Changer Plug-In, Executive Export

680576 Harness MDB

5 202325 Control Board Cover Only

660528 Control Board Cover w/Decal

460628 Decal Only

460671 Decal, Dutch

6 201-6R7

Screw, Round Head, Phillips, Type B (6-18 x 7/16), Qty. 2

7 420062-1 Screw Round Hd.Slot Mach (4-36 x 3/4)

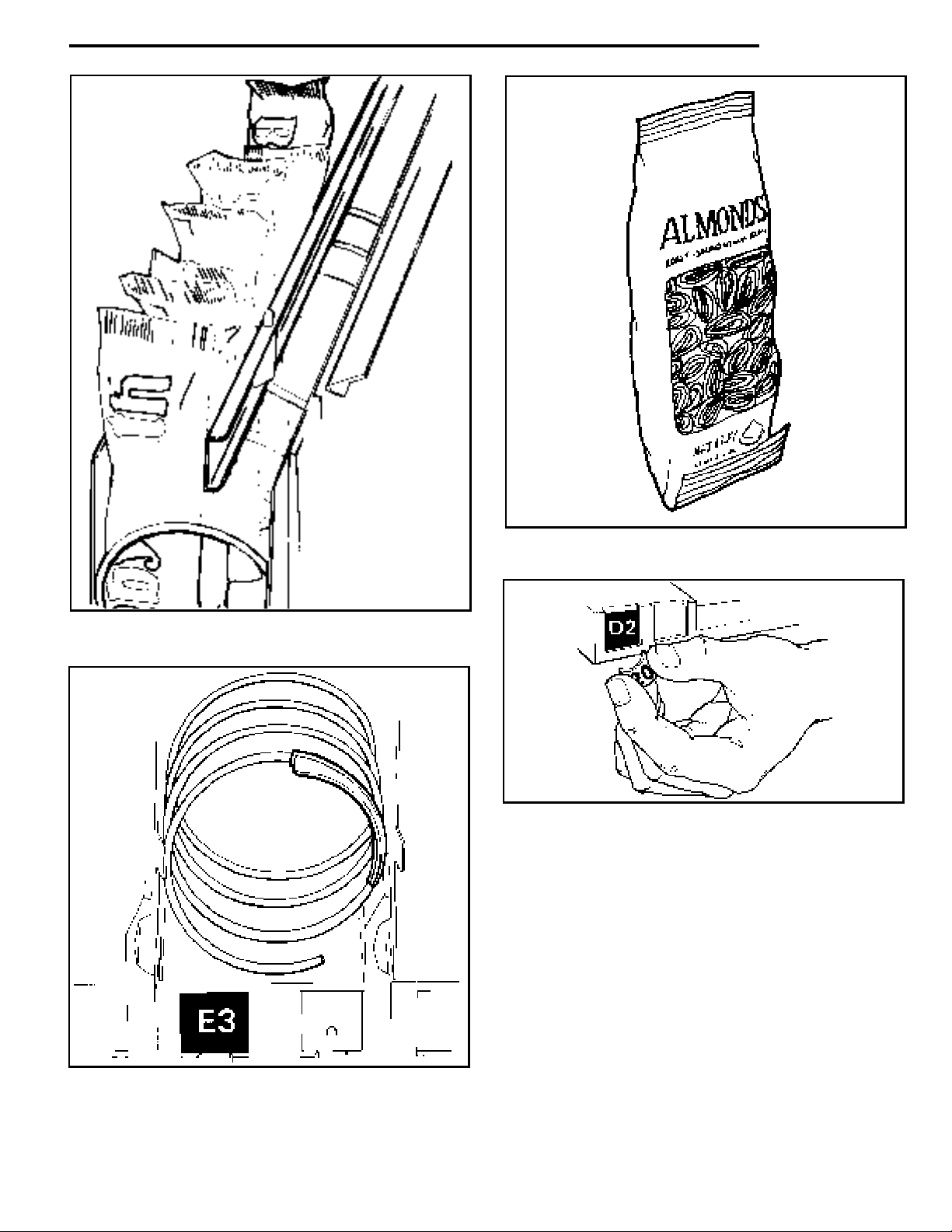

8 460436 Insulation, Rubber, 143’’ (Order length needed)

9 380022-5 Lamp, Fluorescent (F18T8 CW-24)

10 750141 Window, Front (44-5/8 x 26-7/8 x 1/8)

NOTE: Replacement Glass Must Be Hard

Tempered or Lexan Only.

460570 Decal, “Cool-Cool” (not shown)

11 201-6R11

Screw, Round Head, Phillips, Type B (6-20 x 11/16)

12 201381 -3 Shield & Window Clamp

13 201384 Window Clamp, Bottom

14 114-41-8 Screw, Hex Head, Machine (1/4-20 x 1/2)

15 420010 Washer

16 300156 Nut, Special, Door Stop Anchor

17 400192 Door Stop

18 200906 Delivery Bin Anchor Strap

19 217-8R10 Screw, Pan Head, Phillips, Type A (8 x 5/8)

20 210-8R6 Screw, (8-32 x 3/8)

21 Assembly Complete, Delivery Bin (See page

31 for itemized parts)

22 600179-1 Cash Box

12000088 Cash Box Stop (Not Shown)

23 600714 Cash Box Mounting Bracket

24 400180 Cash Box Retainer

25 420003-1 Screw, Flat Head (1/4-20 x 1/2)

26 420003 Screw, Flat Head (1/4-20 x 3/4)

27 420040-9 Hole Plug

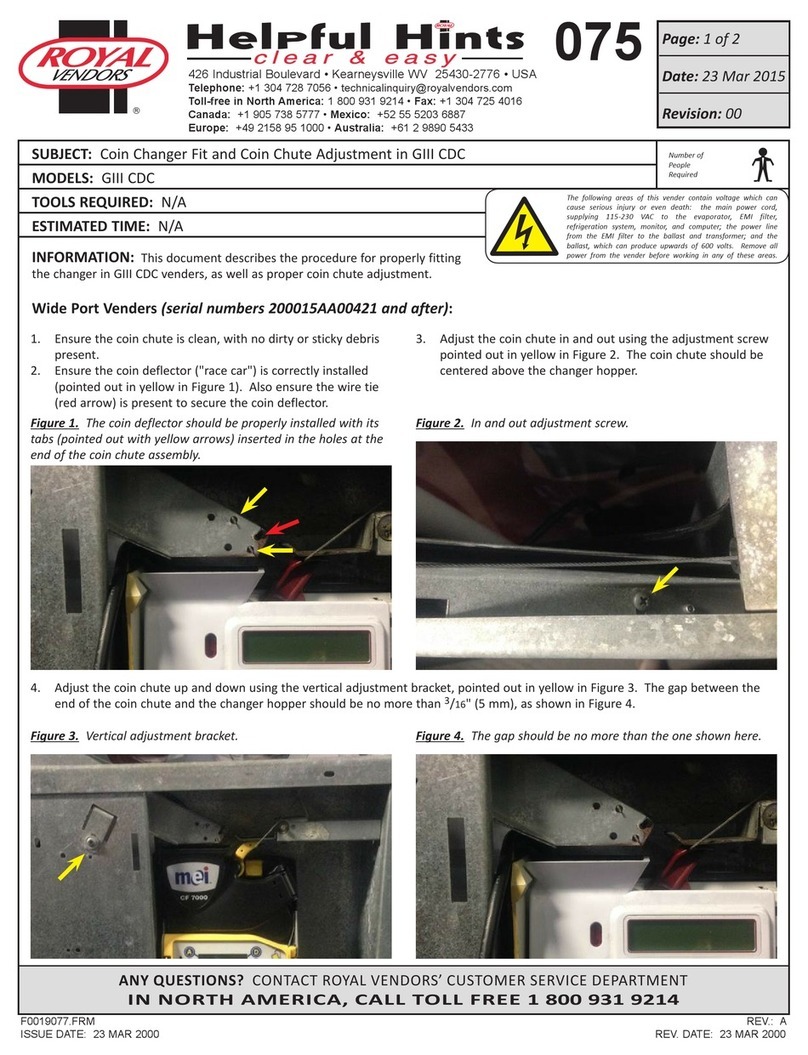

28 640154 Lower Hinge Plate

29 420010-18 Washer

31 202024 Changer Socket Bracket

202775 Loading Barricade Closer (Not Shown)

32 305-7R8 Screw, Pan Hd.Plastite Phillips (#7 x 1/2)

33 400112 Spring Locking Bar

34 600432-3 Locking Bar Only

35 201660 Coin Return Bracket

36 440289 Coin Return Button, Gray

440289-3 Coin Return Button, Black

37 660370 Assembly, Validator Filler, Black

660370-3 Assembly, Validator Filler, Gray

38 420144 Ferrule

39 660519 Assembly, Selector Switch Panel

40 440304 Selector Buttons, Quantity - 20

41 440390 Instruction Glass

440401 Instruction Glass, French

440400 Instruction Glass, Mexico

440402 Instruction Glass, Dutch

440403 Instruction Glass, German

440440 Instruction Glass, Italian

17400005 Instruction Glass, Russian

17400007 Instruction Glass, Hungary

42 660517 Assembly Complete, Selector Bezel, Gray

660517-1 Assembly Complete, Selector Bezel, Black

440389-1 Selector Bezel Only, Gray

440389 Selector Bezel Only, Black

43 404-8 Nut, Hex Head (8-32)

44 118-10-8 Bolt, Carriage (10-24 x 1/2)

45 660319 Assembly Complete, Lock Handle w/Lock

Arm & Nut

46 201712 Coin Chute Bracket

47 440311 Coin Chute, Plastic

48 660488 Assembly, Coin Chute, Plastic

49 660367 Assembly Complete, Coin Return

640152 Assembly, Coin Return Bracket

50 400007 Spring

51 201703 Coin Return Link

52 751-25 Retaining Ring (1/4)

53 660581 Coin Cup Front Assembly, Black

660581-1 Coin Cup Front Assembly, Gray

440411 Trim, Coin Cup, Black

440411-1 Trim, Coin Cup, Gray

440412 Coin Cup Door (not shown)

54 400108 Spring (Not Shown)

440413 Coin Return Cup, LCM All - No Striker

660570 Assembly Coin Cup w/Striker Export

202432 Striker Door Switch Export

300184 Shoulder Bushing (2) Export

276-8R6 Screw Pan Hd Self Tap (8-32x3/8)(2)

400188 Spring Striker Door Switch Export

55 460041 Insulation, Foam (Order length needed)

56 12000010 Window, Side Shield, Lock Side

57 640131 Lock Arm Only

58 404-10 Nut, Hex Head (10-24)

59 680548 Harness, Bill Validator Hook-Up

680641 Harness Mars MDB 24 Volt

680613 Harness, MDB/Fan Cross Flow

60 440414 Coin Cup Chute

61 680512 Harness, Lamp

680456-1 Harness, Lamp (not shown)

62 380023 Starter, FS-25

380023-4 Starter, FS-11, 240V

63 750097 Lock and Cam for Cash Box. w/2 keys.

Specify Number.

420020 Lock w/1 key. Specify Number.

13100005-01

Cam Cash Box Locking only.

64 460629 Decal Mode Instructions, English

460672 Decal Mode Instructions, Dutch

460679 Decal Mode Instructions, Italian

460680 Decal Mode Instructions, Spain

460685 Decal Mode Instructions, German

460645 Decal Mode Instructions, French

65 300206 Window Screw (Not Shown)

16