10

(see overleaf)

2

13

xxxxx

xx

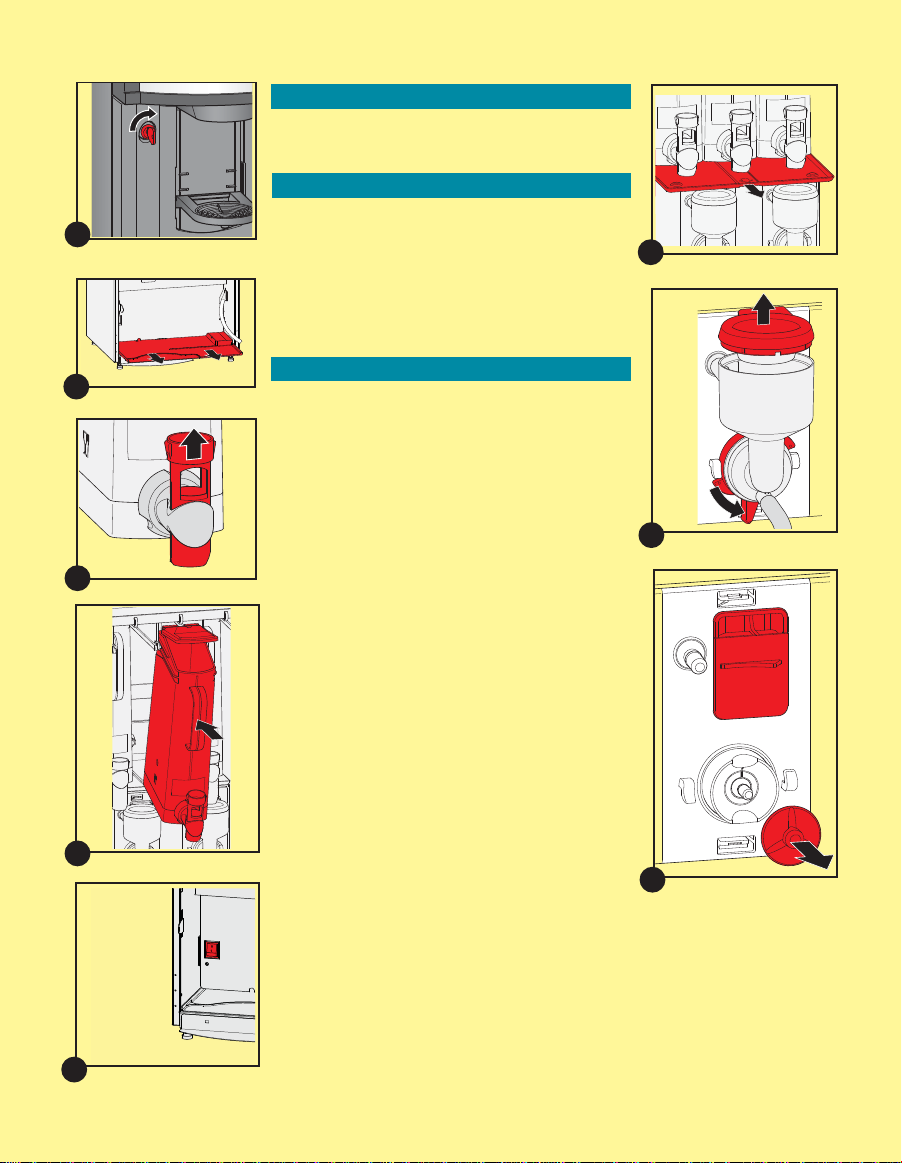

Ingredient

HACCP Guidelines

Directives

• For correct operation of the machine, at least the

mentioned guidelines must be taken into

consideration. The operator is held responsible for

the correct operation.

HACCP guidelines

Handling of ingredients

• Ensure hygienic handling:

- wash hands, preferably with a disinfectant

(1)

- use hygienic gloves

- after cleaning, do not touch surfaces of parts that

may come into contact with food

- always use a clean cloth when cleaning

- keep the working area tidy.

• Check the package for integrity and damage

(2)

.

• Store the ingredients dry, cool and dark.

• Use the packages within the recommended time

period (see the "best before"-date on the package).

• Always use packages according to the "first-in-first-

out"-principle.

• Thoroughly close an opened package to keep the

quality and preventing contamination.

• Ingredients should be stored separated from

cleaning products.

• The ingredient container should be cleaned

occasionally (see operating instructions).

• Do not fill more ingredients than needed until the

next cleaning.

Cleaning the machine

• Observe the cleaning instructions.

• Clean the machine preferably at the end of the day

• After cleaning, dispense and check a drink (see

"Last check").

• Fill in the cleaning record card.

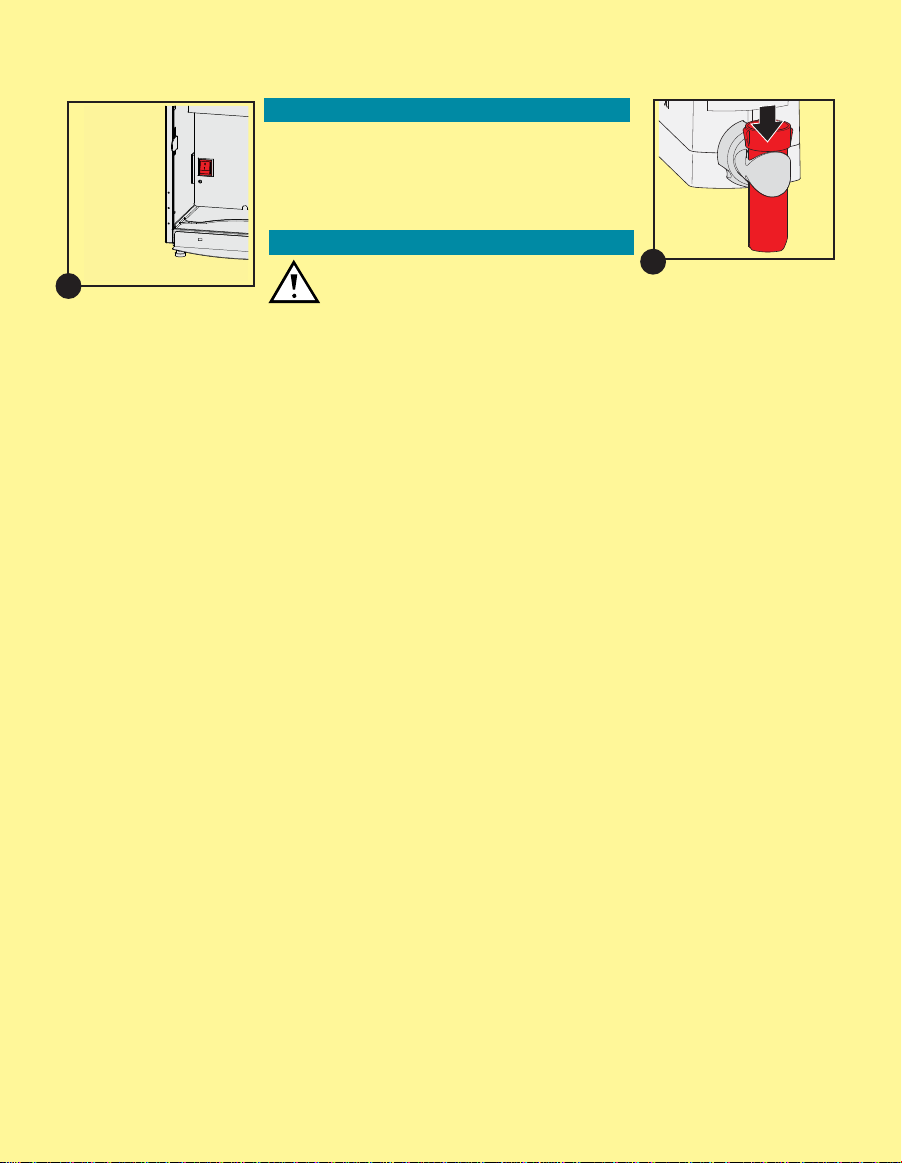

• When the display indicates an error message

(3)

,

observe the display messages on the reference

card.

• Only use the recommended cleaning agents that

have been approved for the food industry (slightly

disinfecting, preferably liquids, tabs, possibly grains.

Avoid powders).