5 090085 Rev 23

DISASSEMBLY –PART I

CAUTION! THE POPPET IS HELD UNDER CONSIDERABLE SPRING TENSION. WHENEVER

THE NOSE RING (2) OR POPPET (9) ARE REMOVED OR REASSEMBLED, THE

VALVE MUST BE LATCHED IN THE OPEN POSITION OR THE POPPET

OTHERWISE RESTRAINED (LOAD ONLY). PERSONAL INJURIES MAY RESULT IF

THIS PRECAUTION IS NOT TAKEN.

ATTENTION! WHERE POLISHING IS INDICATED, USE NOT LESS THAN 600 GRIT POLISHING

CLOTHS.

Inspect nose ring (2) for scratches on sealing surface. If there are any scratches on the sealing

surface, the nose ring (2) should be replaced to avoid valve leakage. Faces without hard coating

should be polished around the bore and only in circumferential direction.

Poppet (9) should be inspected for scoring or raised metal on the stem. Any raised metal on the

poppet stem should be removed with a fine flat file and polished in axial direction.

Inspect poppet bearing (10) for intrusion of any foreign material on the inside diameter. Any foreign

material on the inside diameter should be carefully removed with a sharp tool and polished.

On completion of poppet (9) and poppet bearing (10) inspection, test the bearing (10) on the poppet (9)

without the spring (27) to make sure that the bearing (10) smoothly slides along the poppet (9) stem. If

this is not the case, the bearing should be replaced.

Test rotation of the poppet roller (13) around the pin (20). If the rotation is difficult, the roller bearing

should be replaced. To access the roller bearing, support the poppet (9) and release the pin (20) using

a ¼” pin punch.

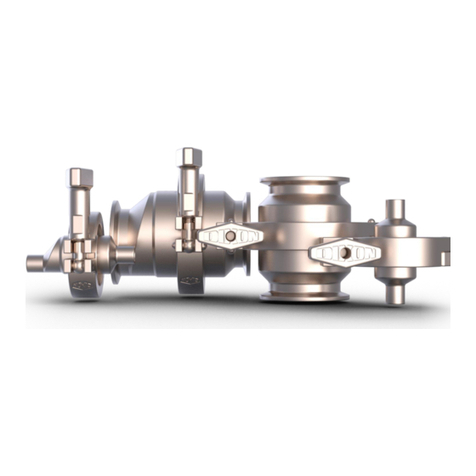

Check the handle (8) for free and easy movement of the opening and closing cycle. Operation of the

handle (8) normally requires limited effort. If operating the handle (8) involves stronger force, it implies

the need to clean and possibly replace the shaft bearing (6) and the shaft (3).

Poppet o’ring (16) and main o’ring (17) should be inspected for cracks, scratches, missing material,

unusual hardness, softness, roughness, and other signs of chemical damage. Do not remove poppet

o’ring from the poppet at this stage.

At this point it may be decided to replace the main o’ring (17) and reassemble the valve if the first part

of the inspection did not reveal any damage or malfunction of the parts, or to continue with Part II of

disassembly and replace all the o’rings if there are any additional concerns regarding the performance

of the valve. Steps 5 through 8 of the Assembly section describe how to assemble the valve from this

point.

DISASSEMBLY –PART II

To remove two roll pins (19), turn the handle until the pin is accessible and drive out each pin in turn

using ¼” pin punch. If this is done with the valve attached to the tank, take precautions to ensure that

the pins (19) do not enter upstream piping. To remove the cam arm roll pin (19), ensure that the

handle is rotated to a position such that the roll pin will be clear of the deflector cone (valve body) as it

is driven out. If the roll pin appears not to drive further than approximately ¼”, check for contact

between the roll pin and deflector cone and slightly adjust the rotation of the handle to allow sufficient

clearance.

Take out handle (8) with shaft assembly, shaft spacer (5) and cam (11).