5

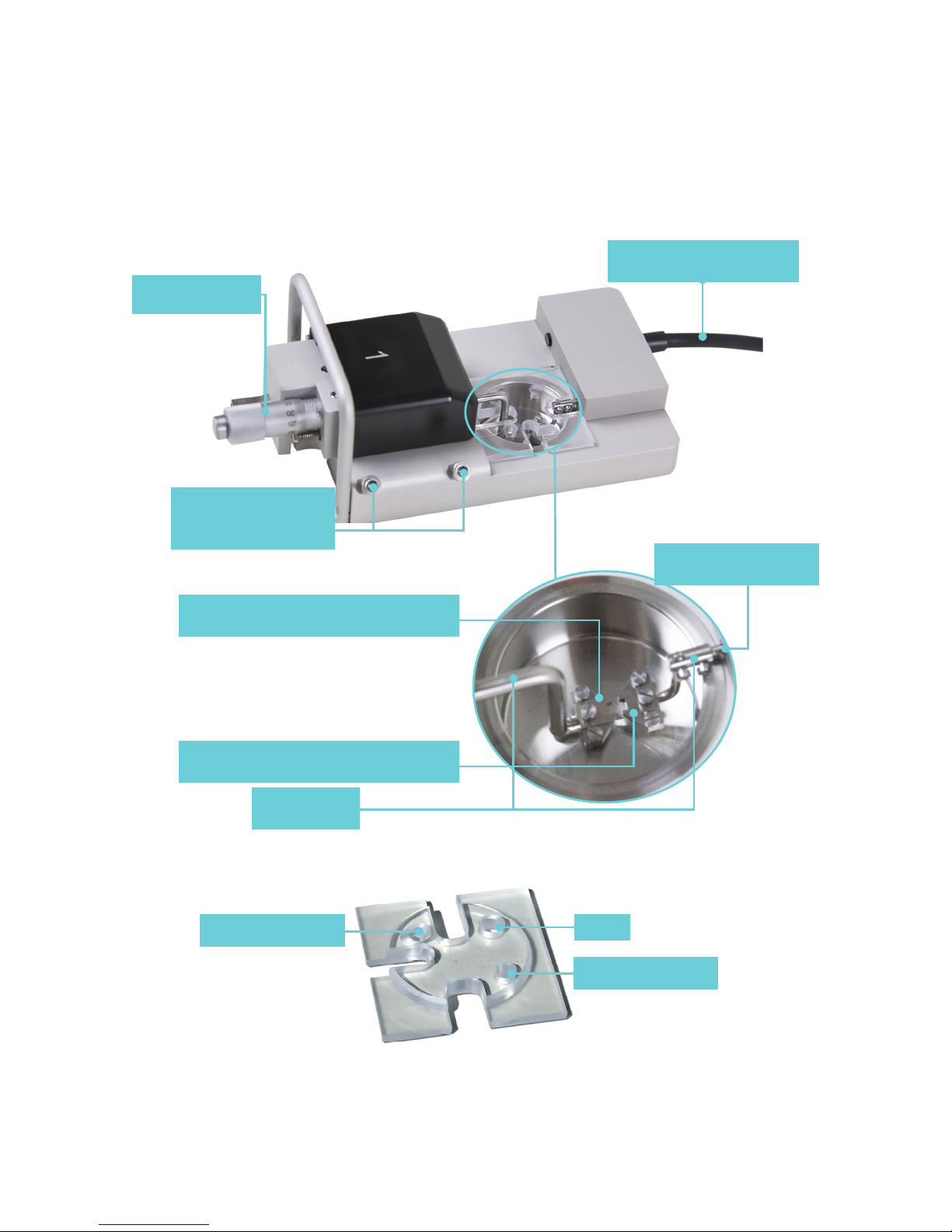

CHAPTER 2 - THE MULTI WIRE MYOGRAPH UNIT

2.1 CHANGING AND ADJUSTING THE MOUNTING SUPPORTS

NOTE: The transducers are fragile and sensitive to mechanical strain. Be very careful

when changing or adjusting the mounting supports!

Each chamber can accommodate mounting

supports for either small vessels (>30µm) or

larger segments (>500µm). Because the mounting

supports can be changed easily, experiments can

be performed with dierent vessels of varying

internal diameter. Continuous use and repeated

greasing of the transducer pin holes will cause

some misalignment of the mounting supports.

The mounting supports, therefore, whether

they are the jaws for wires or the pins, will need

occasional adjustments.

Changing and adjustment of the supports is

performed using the following step-by-step

procedure.

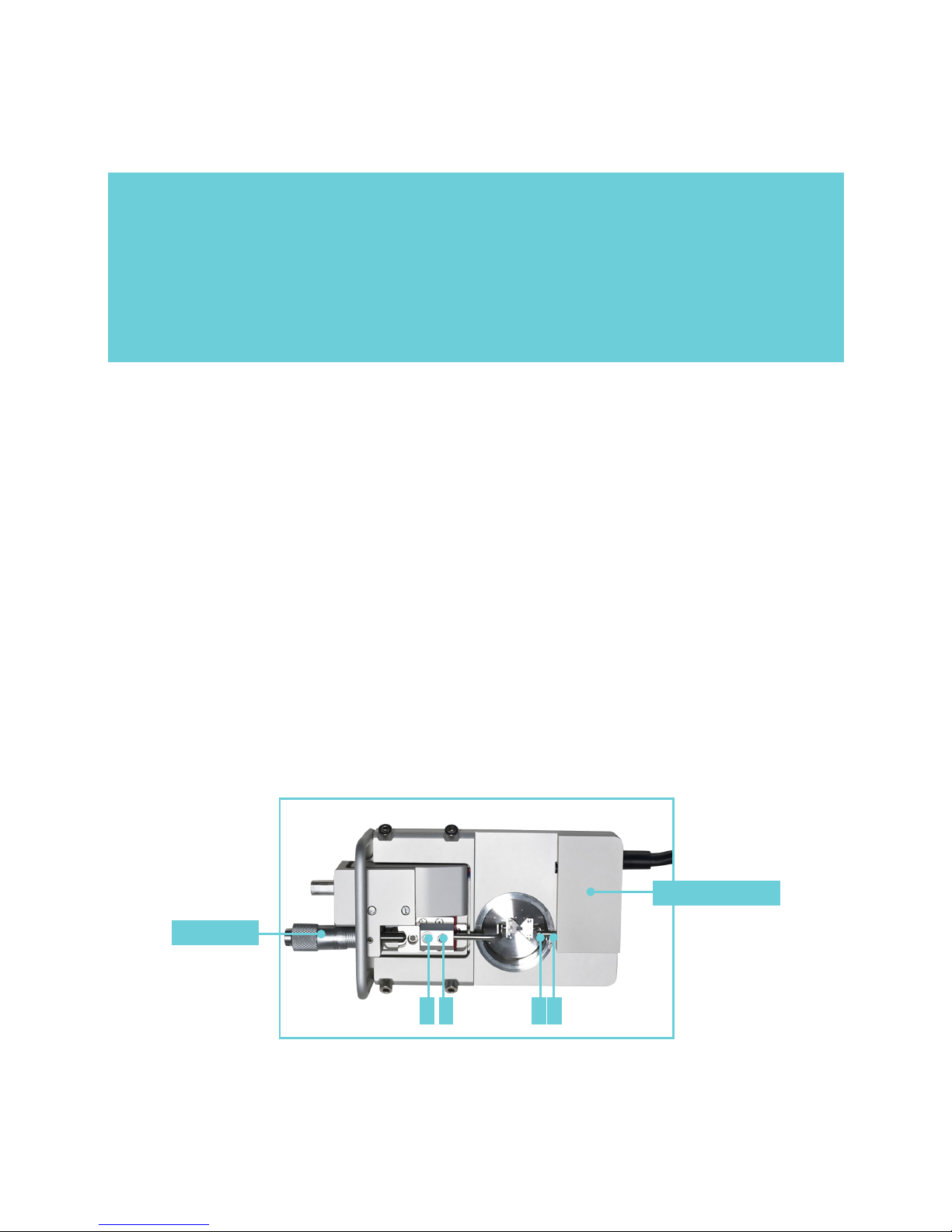

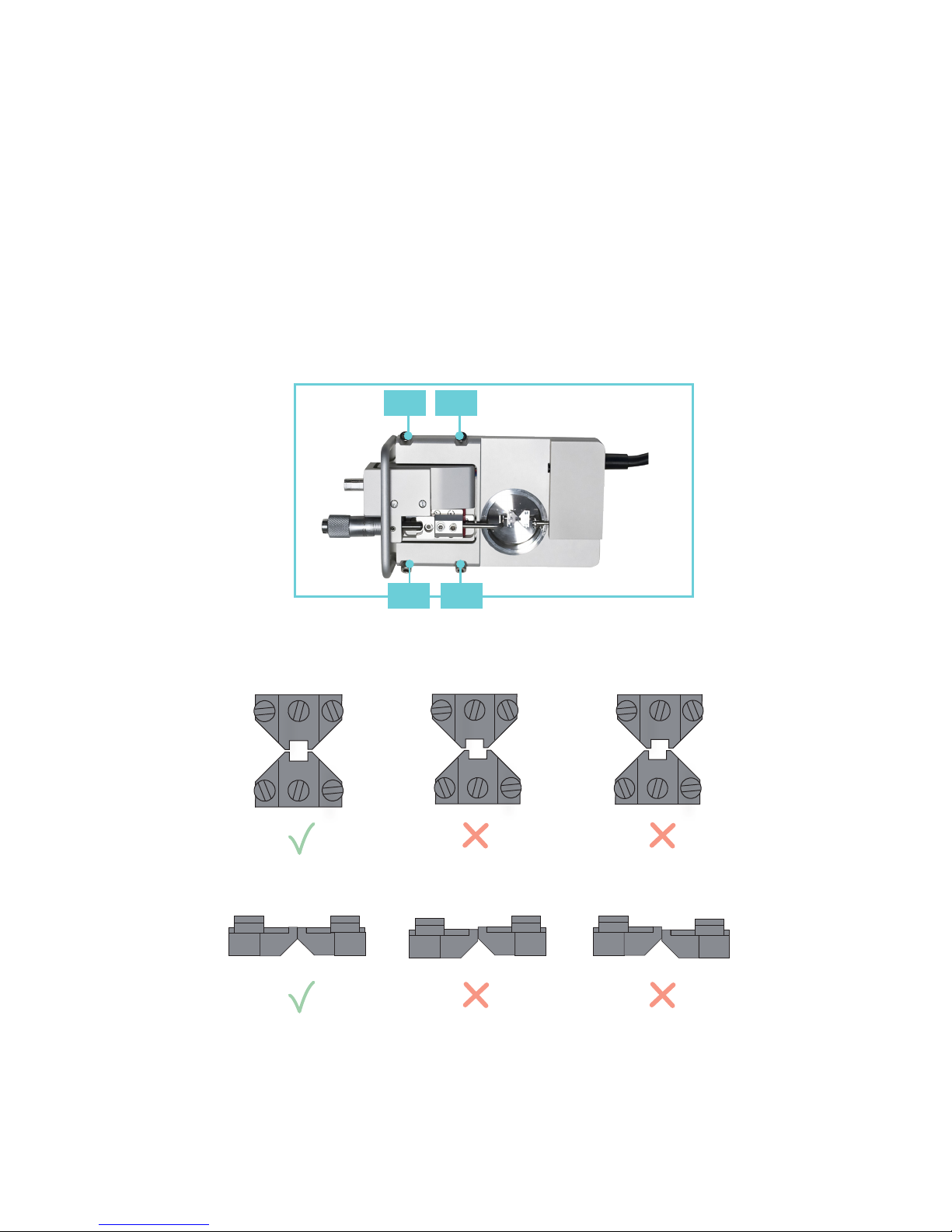

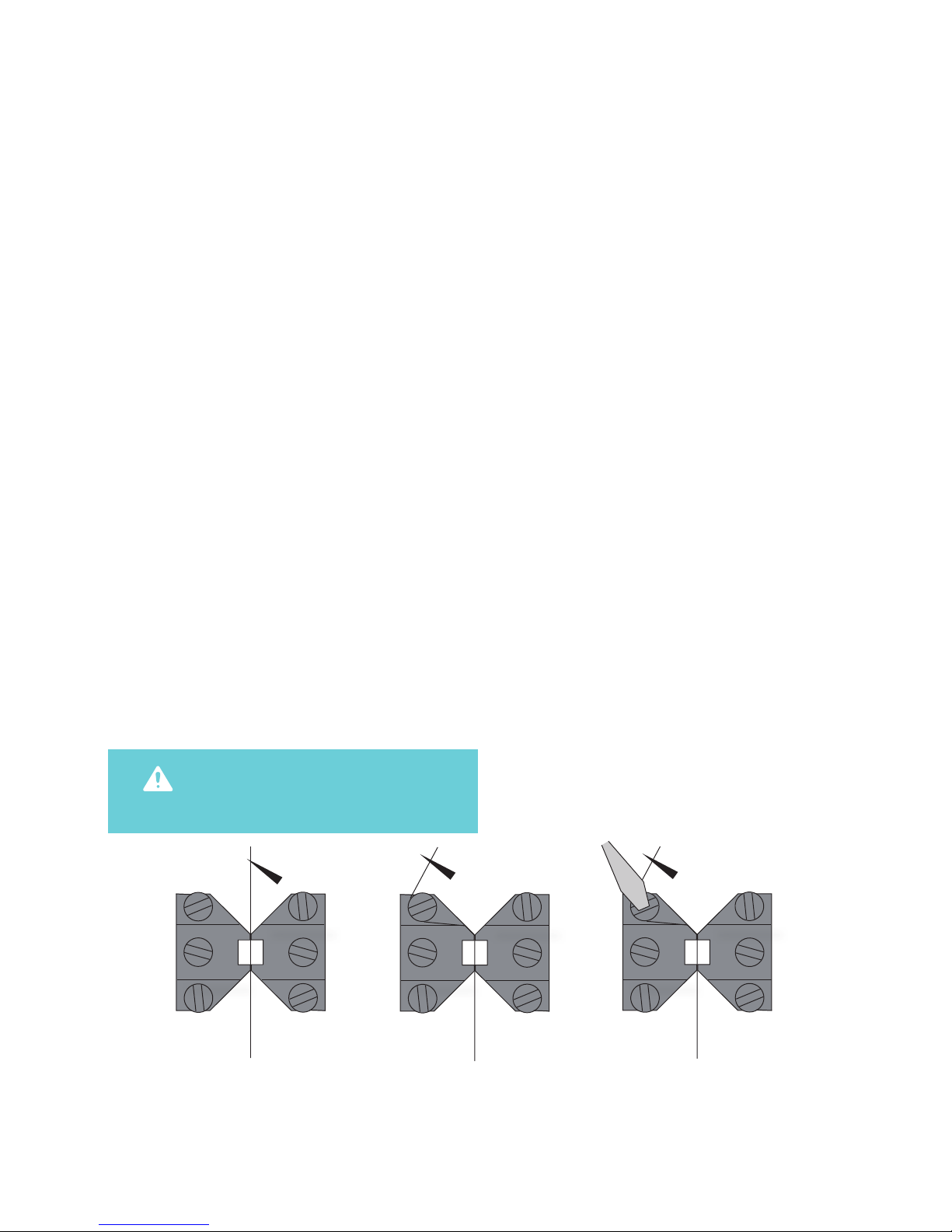

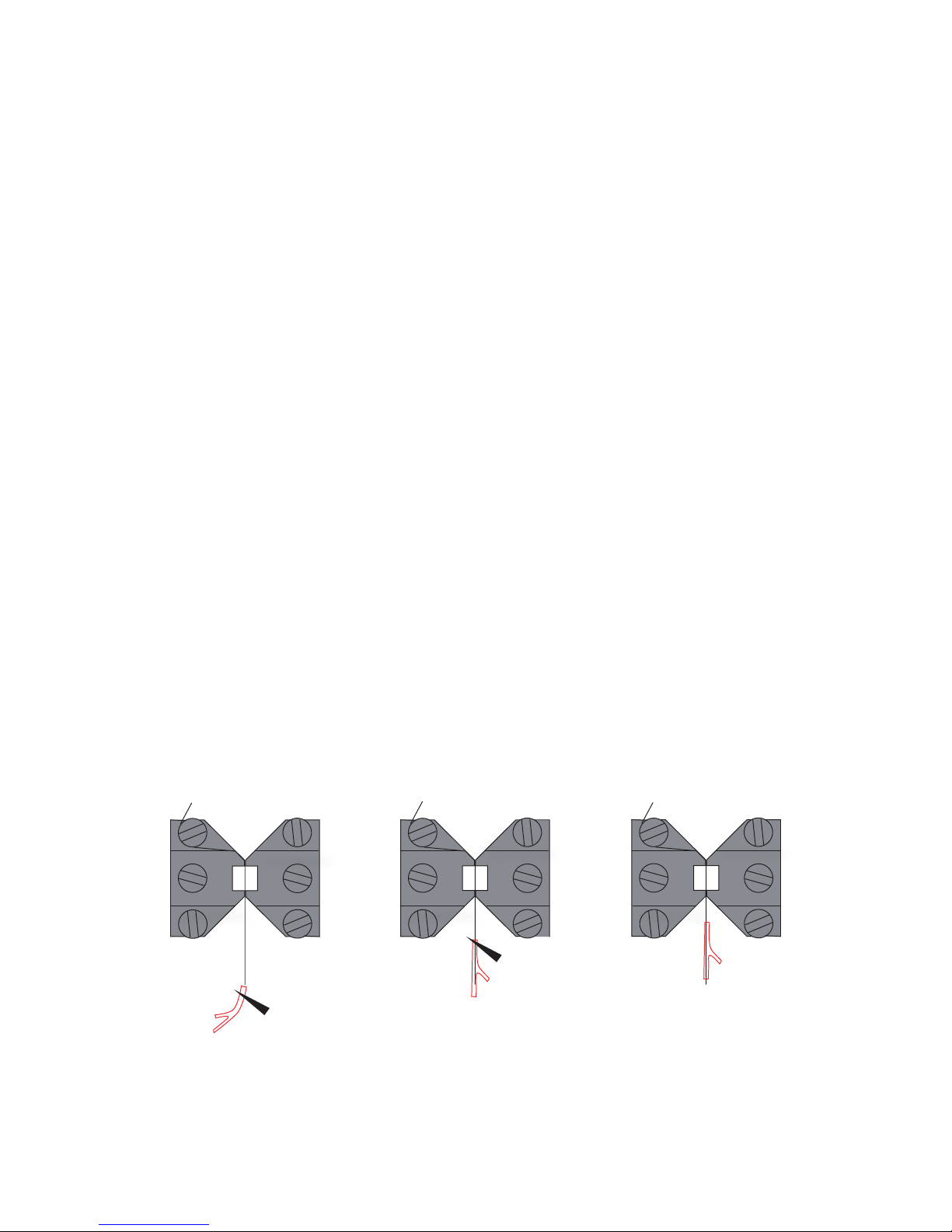

2.1.1 CHANGING THE MOUNTING SUPPORTS (FIGURE 2.1)

1. Use the micrometer to separate the supports

as far apart as possible.

2. Use the small screwdriver provided to gently

loosen screw D on the support attached on the

transducer side using the small screwdriver.

Screw D is the screw on the transducer-side

support closest to the transducer.

3. Gently pull the support away from the

transducer pin.

4. Loosen screw B on the micrometer side with

the appropriate tting allen key.

5. Pull the support away. Note: Number the

supports with the chamber number they

were removed from using some kind of

permanent marker. Store the supports in

the provided plastic case. Numbering the

supports will save time when the sup ports

are changed again, limiting the amount of

adjustments needed after each change.