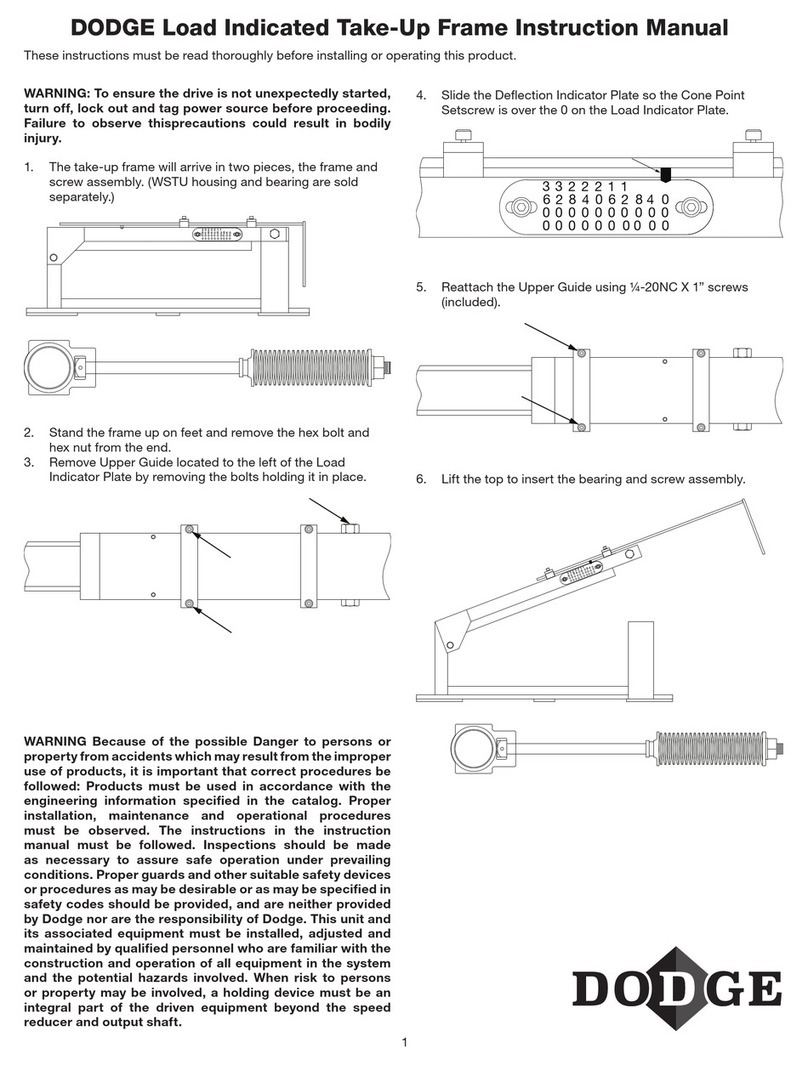

1

WARNING: Because of the possible danger to person(s)

or property from accidents which may result from the

improper use of products, it is important that correct

procedures be followed. Products must be used in

accordance with the engineering information specified

in the catalog. Proper installation, maintenance and

operation procedures must be observed. The instructions

in the instruction manuals must be followed. Inspections

should be made as necessary to assure safe operation

under prevailing conditions. Proper guards and other

suitable safety devices or procedures as may be

desirable or as may be specified in safety codes should

be provided, and are neither provided by Dodge nor are

the responsibility of Dodge. This unit and its associated

equipment must be installed, adjusted and maintained by

qualified personnel who are familiar with the construction

and operation of all equipment in the system and the

potential hazards involved. When risk to persons or

property may be involved, a holding device must be an

integral part of the driven equipment beyond the speed

reducer output shaft.

WARNING: To ensure the drive is not unexpectedly

started, turn off and lock-out or tag power source before

proceeding. Failure to observe these precautions could

result in bodily injury.

WARNING: All products over 25 kg (55 lbs) are noted on the

shipping package. Proper lifting practices are required for

these products.

ISNX Bearings Hydraulic Mount Patent # 7,866,894

Instruction and Lubrication Manual

These instructions must be read thoroughly before installation or operation. This instruction manual was accurate at the time of

printing. Please see dodgeindustrial.com for updated instruction manuals.

INSPECTION

Inspect shaft to ensure it is smooth, straight, clean and within

commercial tolerances. All weight must be removed from the

shaft prior to installing.

TOOLS REQUIRED FOR PROPER

INSTALLATION AND REMOVAL

• Hydraulic Hand Pump, Hose and Fluid

• G1/4 - 19 BSPP Fitting

• 0-350 bar Pressure Gauge for Hydraulic Pump

• M6 Allen Wrench

• Magnetic Base Dial Indicator

• Torque Wrench with Appropriate Socket (See Table 3)

• Drift and Hammer

• Rubber Mallet

• Hand File

• Adjustable Wrench

• 13 mm diameter Barring Rods (2), approximately 200

mm in length

MOUNTING PROCEDURE

NOTE: Misalignment must be within ± 1/2º.

Install Non-Expansion (Fixed) Bearing First

1. Remove lubricatable auxiliary seals from OD of Mount and

Dismount Nuts. Be careful not to damage the two O-rings

in bore of seal. Note orientation of seal.

2. Remove lock clip located on the face of Mount Nut.

NOTE: The face of the Mount Nut equally spaced drilled

and tapped holes and an instruction plate. The Dismount

Nut contains three sets of drilled and tapped holes located

120° apart.

1/4 NPTF 1/4 NPTF

Mount Nut Dismount Nut

Figure 1 - Mount Nut and Dismount Nut

3. Scribe a line on Adapter face and Dismount Nut.

4. Rotate Dismount Nut counter clockwise two full rotations.

The Dismount Nut must remain loose during the mounting

procedure but should never be removed. Without loosening

the dismount nut, the dismount nut piston will make

contact with the bearing unit as it travels up the adapter.

(See Figure 3) This will not allow the bearing to move up the

adapter and tighten properly.

5. Rotate Mount Nut counter clockwise one full rotation and

tap on the face with a rubber mallet. This will drive the

adapter toward the Dismount Nut end and ensures the

Adapter is fully expanded.

6. Slide one lubricatable auxiliary seal on shaft in same

orientation as when it was removed.

7. Slide bearing on shaft and into position. If bearing will not

slide onto the shaft repeat Step 5.

8. Using a spanner or barring rod rotate Mount Nut clockwise

until snug. This allows the mount nut piston to be in full

contact with the bearing unit so that when the mount nut

is pressurized with hydraulic uid, the piston will push the

bearing unit up the adapter and properly tighten.