9

Oil Maintenance Schedule

Drain, ush, and rell with oil after 2 to 3 weeks of initial break-

in operation. Since the satisfactory operation of the bearing

depends entirely on an oil lm being maintained between the

shaft and the bearing liner surface, it is recommended that an oil

analysis be performed at these regular intervals.

• Every 3 months for 24 hour/day service

• Every 6 months for 8 hour/day service

Acceptably of oil should be referred to the lubricant manufacturer.

If oil quality is acceptable then repeat this procedure in 3 month

intervals. Visually check oil for contamination between oil analysis

checks. Oil service life depends upon several factors such as

ambient conditions, operating temperature and frequency of

bearing starts and stops. It is recommended that the oil be

changed at least once per year for unltered static applications.

Removing contaminants through the use of either the OLF 2

(Oil Level and Filtration 2) Unit or a circulating oil system can

extend oil service life. Consult equipment manufacturer for more

information.

Any questions about installation, maintenance, and arrangement

of coolant or oil connections should be referred to the equipment

manufacturer.

NOTE: Isolators or Auxiliary Seals are recommended for

outdoor applications, contaminated atmospheres, and high

volume air flowing over the bearing.

Temperature

The bearing temperature will increase after start-up until its

normal operating point is reached. The normal operating

temperature should not exceed 180°F. Make sure to check

with the OEM for the specied normal operating temperature.

An alarm temperature should be set at 15°F above the normal

operating temperature. A shut-down temperature should be

set at 30°F above the normal operating temperature. Some

uctuation due to ambient temperature change is normal.

Low ambient and operating temperatures can be as harmful to

the bearing as high temperatures. The Dodge heater / thermostat

combo can be used in these low ambient conditions.

The Dodge heater / thermostat combo turns on at 70°F and

turn off at 100°F to ensure proper oil sump temperature during

operation.

NOTE: The recommended oil temperature at start-up is 70°F

MINIMUM.

CAUTION: If heaters are used, be sure heaters are off when

oil is removed from bearing.

WARNING: When installing heater and thermoswitch, follow

directions and safety procedures recommended by the

manufacturer. Install wiring in accordance with the National

Electrical Code and local codes. Failure to observe these

guidelines could result in electrical shock.

Vibration

Any signicant vibration or imbalance MUST be corrected.

Check with equipment manufacturer for acceptable conditions.

Pillow Block Material Details

Housing: Class 30 Gray Cast Iron

Liner: Class 30 Gray Cast Iron

Babbitt: Lead or Tin Based Babbitt

Oil Rings: Bronze

Aluminum Seal: Sand Cast Aluminum

O-ring: Elastomer Compound

Aux. Seal: HNBR with Stainless Steel Retainer

Grommet: Synthetic Rubber

Grommet Plate: Carbon Steel

Pipe Nipple: Carbon Steel

Oil Gauge: Stainless Steel, Polypropylene

Hardware: Carbon Steel

Plunger Screw: Carbon Steel

Gasket Eliminator: LOCTITE 515 Sealant

This Sleevoil pillow block could contain lead in the bearing

Babbitt material, please exercise proper precautions in the use,

installation, dismantling and recycling of this unit.

Other Notes:

CAUTION: This product is not to be used for person moving

applications.

NOTE: Care has been taken to keep instruction manuals

accurate and timely. The most recent version of the

instruction manual can be found on our website:

www.dodgeindustrial.com

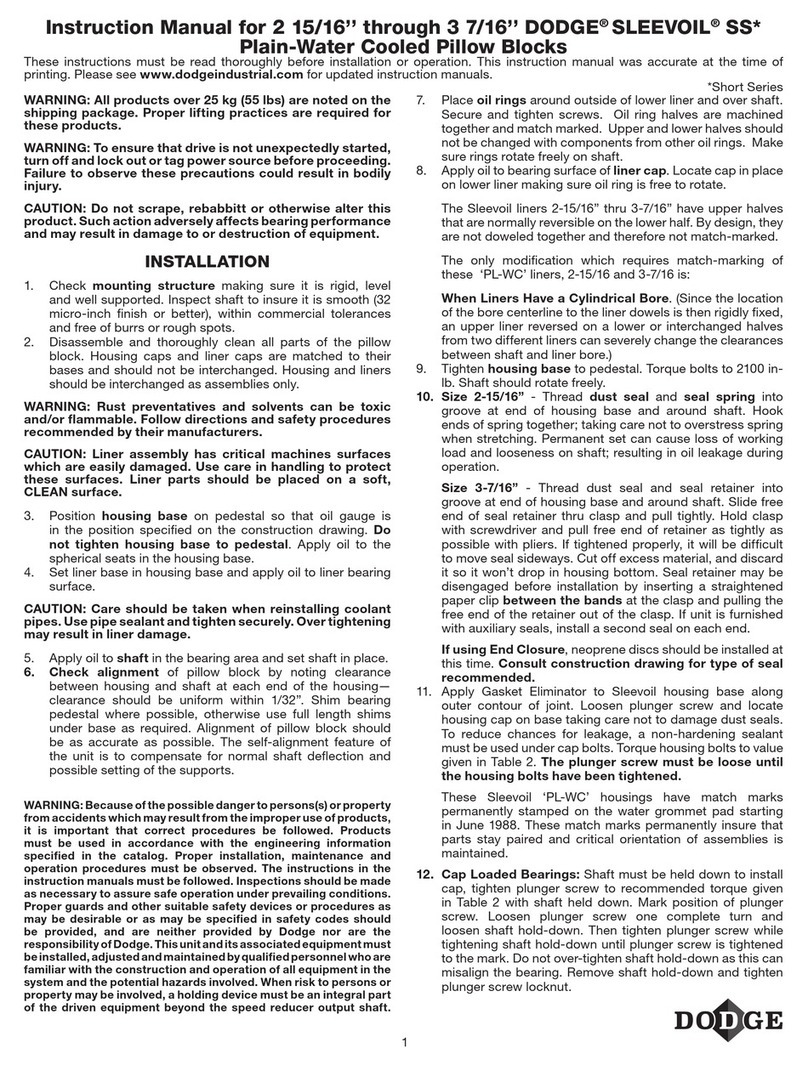

Weights:

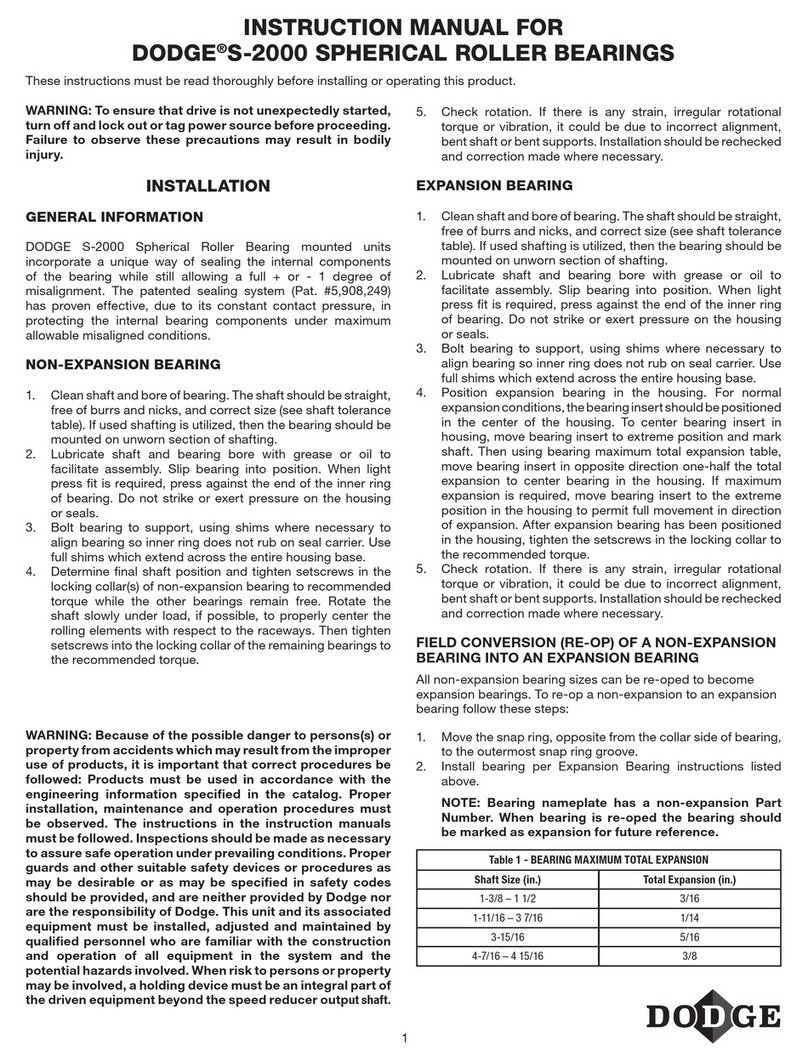

Table 7 - Weight of RTL Sleevoil

RTL SLEEVOIL

Size

Approximate Weights (lbs.)

Non-Expansion

Pillow Block

Expansion

Pillow Block

Liner Assembly

3-7/16 195 190 47

3-15/16 238 230 65

4-7/16 311 300 82

4-15/16 441 425 113

5-7/16 521 500 144

6854 825 182

71018 978 257

81368 1310 412

91738 1650 623

10 2262 2150 955

12 3670 3500 1405