1

WARNING: To ensure the drive is not unexpectedly started,

turn off, lock out and tag power source before proceeding.

Failure to observe thisprecautions could result in bodily

injury.

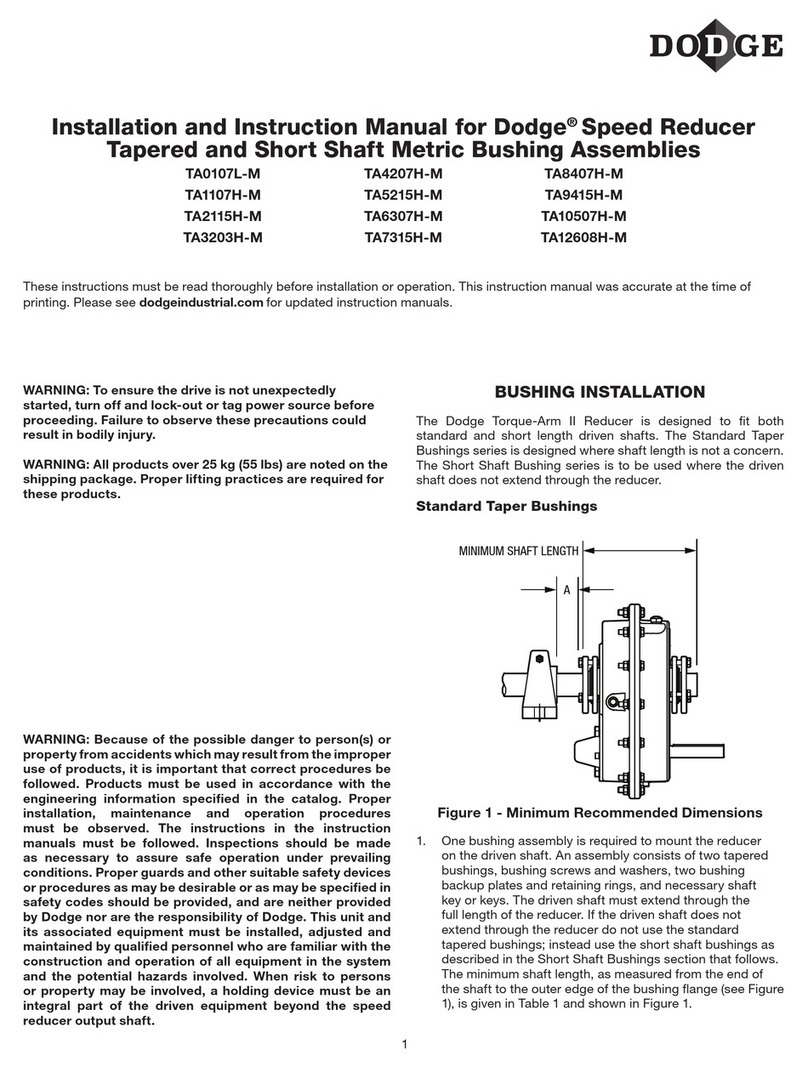

1. The take-up frame will arrive in two pieces, the frame and

screw assembly. (WSTU housing and bearing are sold

separately.)

332221 1

628406 2 8 4 0

0000000000

0000000000

2. Stand the frame up on feet and remove the hex bolt and

hex nut from the end.

3. Remove Upper Guide located to the left of the Load

Indicator Plate by removing the bolts holding it in place.

WARNING Because of the possible Danger to persons or

property from accidents which may result from the improper

use of products, it is important that correct procedures be

followed: Products must be used in accordance with the

engineering information specified in the catalog. Proper

installation, maintenance and operational procedures

must be observed. The instructions in the instruction

manual must be followed. Inspections should be made

as necessary to assure safe operation under prevailing

conditions. Proper guards and other suitable safety devices

or procedures as may be desirable or as may be specified in

safety codes should be provided, and are neither provided

by Dodge nor are the responsibility of Dodge. This unit and

its associated equipment must be installed, adjusted and

maintained by qualified personnel who are familiar with the

construction and operation of all equipment in the system

and the potential hazards involved. When risk to persons

or property may be involved, a holding device must be an

integral part of the driven equipment beyond the speed

reducer and output shaft.

DODGE Load Indicated Take-Up Frame Instruction Manual

These instructions must be read thoroughly before installing or operating this product.

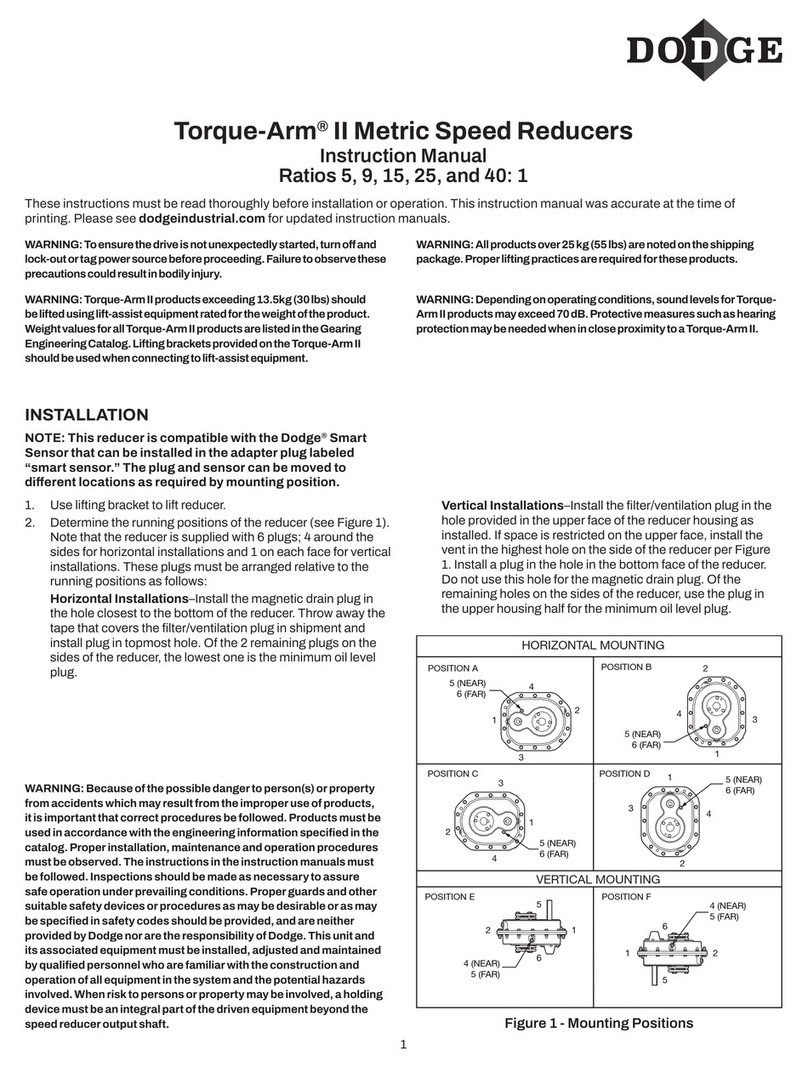

4. Slide the Deection Indicator Plate so the Cone Point

Setscrew is over the 0 on the Load Indicator Plate.

3 3 2 2 2 1 1

6 2 8 4 0 6 2 8 4 0

0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0

5. Reattach the Upper Guide using ¼-20NC X 1” screws

(included).

6. Lift the top to insert the bearing and screw assembly.

3

3

2

2

2

1 1

6

2

8

4

0

6 2 8 4

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0