2MN1641

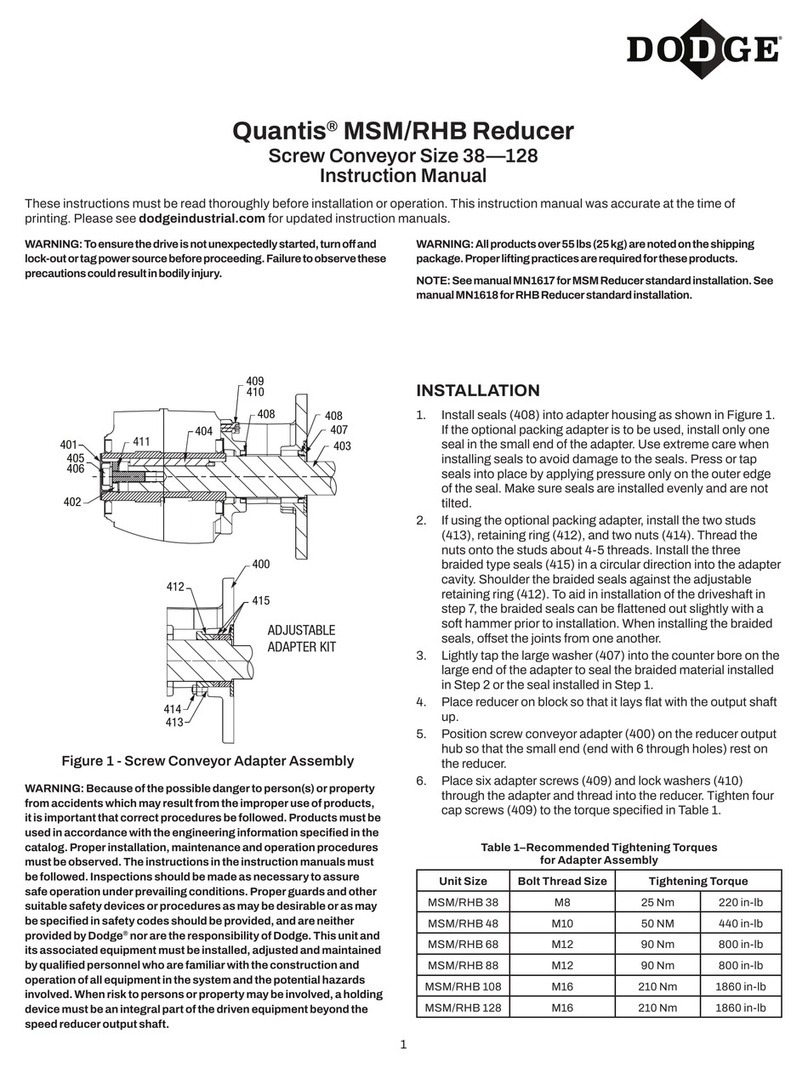

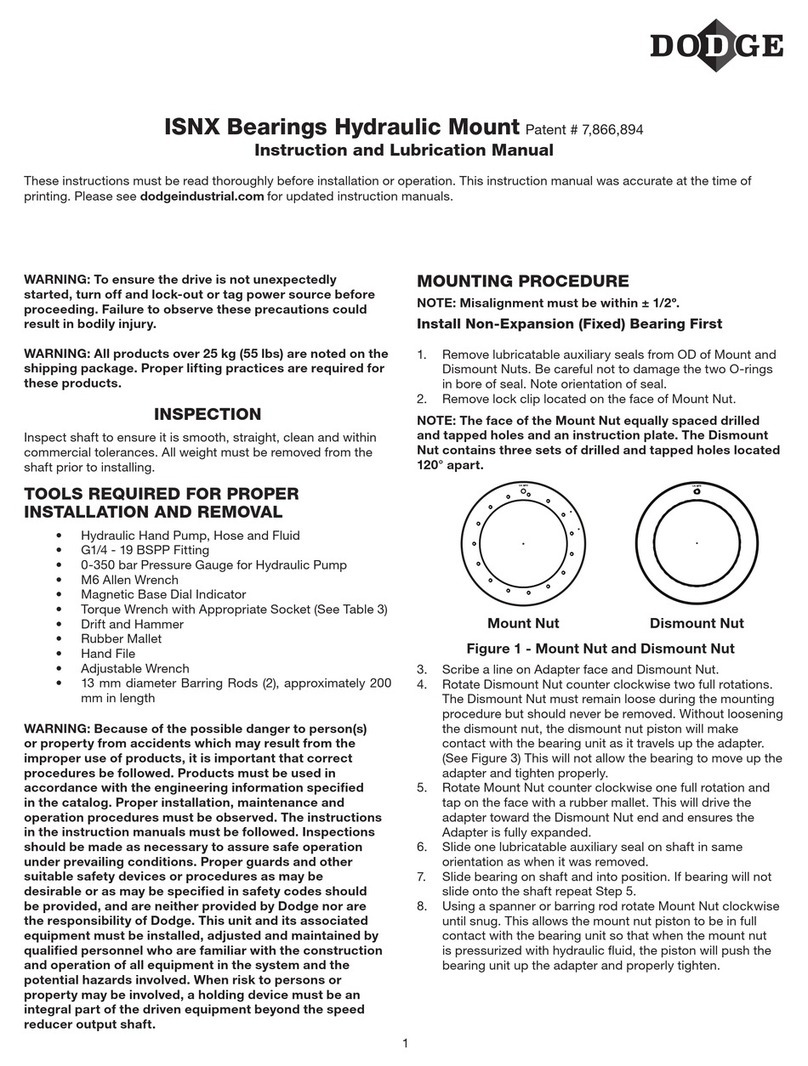

5. Mount the reducer on the driven shaft and align the shaft key

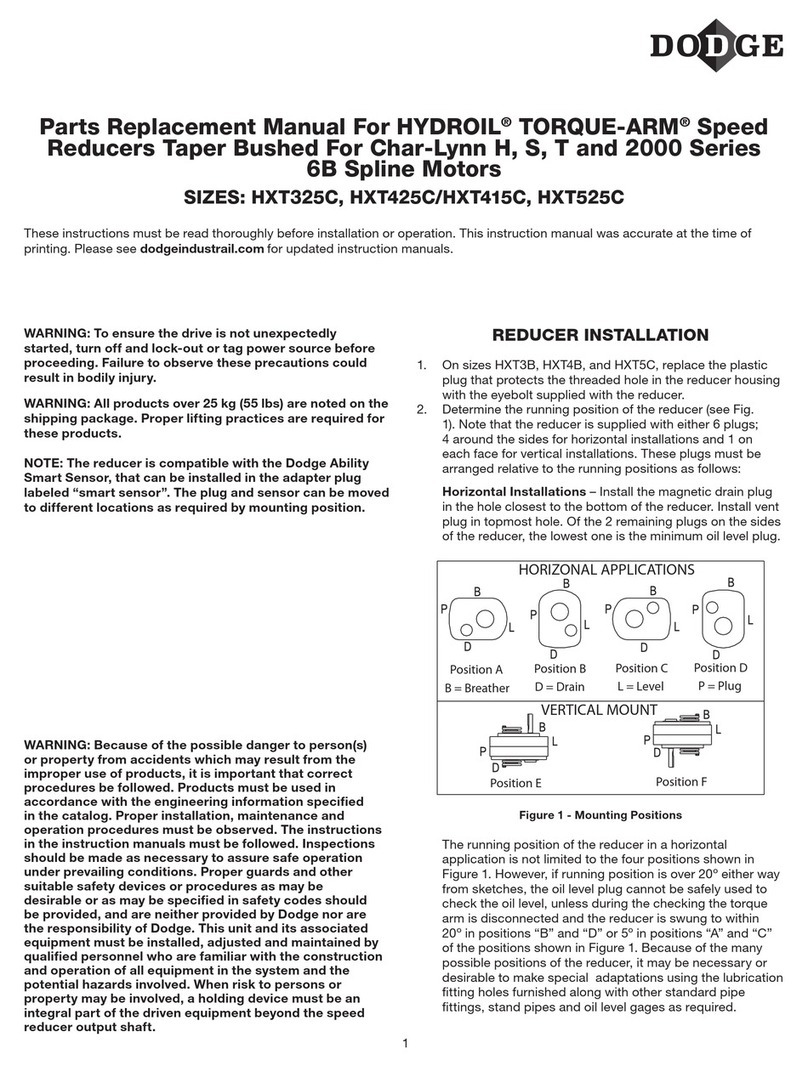

with the reducer hub keyway. Maintain the recommended

minimum distance “A” from the shaft bearing.

6. Insert the screws, with washers installed, in the unthreaded

holes in the bushing ange and align with the threaded holes

in the bushing backup plate. If necessary, rotate the bushing

backup plate to align with the bushing screws. Tighten the

screws lightly. If the reducer must be positioned closer than

dimension “A”, place the screws with washers installed, in the

unthreaded holes in the bushing before positioning reducer

making sure to maintain at least 1/8” between the screw

heads and the bearing.

7. Place the second tapered bushing in position on the shaft

and align the bushing keyway with the shaft key. Align the

unthreaded holes in the bushing with the threaded holes in

the bushing backup plate. If necessary, rotate the bushing

backup plate to align with the bushing holes. Insert bushing

screws, with washers installed in the unthreaded holes in the

bushing. Tighten screws lightly.

8. Alternately and evenly tighten the screws in the bushing

nearest the equipment to the recommended torque given in

Table 1. Repeat procedure on outer bushing.

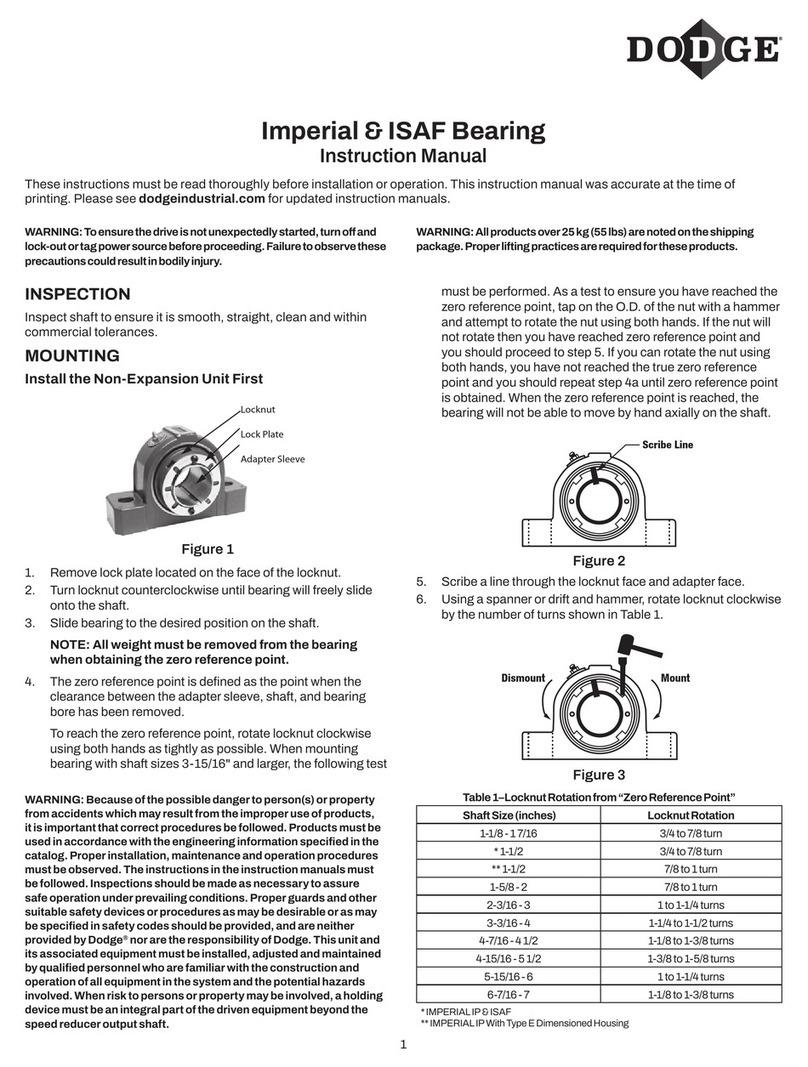

Short Shaft Bushings

1. One bushing assembly is required to mount the reducer on

the driven shaft. An assembly consists of one long tapered

bushing, one short tapered bushing, one tapered bushing

wedge, bushing screws and washers, two bushing backup

plates and retaining rings, and necessary shaft key or keys.

The driven shaft does not need to extend through the reducer

for the short shaft bushing to operate properly. The minimum

shaft length, as measured from the end of the shaft to the

outer edge of the bushing ange (see Figure 2), is given in

Table 1.

2. The long bushing is designed to be installed from the side of

the reducer opposite the driven equipment as shown in Figure

3. The long bushing when properly installed is designed to

capture the end of the customer shaft that does not extend

through the reducer. Normally the reducer would be mounted

such that the input shaft extends from the side of the reducer

opposite the driven equipment however the reducer design

allows installation of the reducer to be mounted in the

opposite direction.

3. Install the tapered bushing wedge into the hollow bore of

the reducer from the same side as the long bushing will be

installed. When installing the tapered bushing wedge into the

reducer hub, install the ange end rst so that the thin taper

is pointing outwards towards the long bushing as shown in

Figure 3. The wedge is properly installed when it snaps into

place in the reducer hub.

4. Align the tapered bushing wedge keyway with the reducer hub

keyway. The keyway in the wedge is slightly wider than the

keyway in the reducer hub allowing for easier installation.

NOTE: In most cases the keys that are supplied with the

bushing kit are NOT square keys, and the orientation of

the key is important. Install the key so that it ts snugly in

the width of the keyseat. The keys are marked with a part

number and some keys are also etched with “THIS SIDE

UP” – these markings should be showing on the top of the

key when it is installed in the shaft keyseat, see Figure 4

below.

5. Install one bushing backup plate on the end of the hub and

secure with the supplied retaining ring. Repeat procedure for

other side.

6. Install the short bushing; ange rst, on the driven shaft and

position per dimension “A”, as shown in Table 1. This will allow

the bolts to be threaded into the bushing for future bushing

and reducer removal.

7. Insert the output key in the shaft and bushing. For ease of

installation, rotate the driven shaft so that the shaft keyseat is

at the top position.

8. Mount the reducer on the driven shaft and align the shaft key

with the reducer hub keyway. Maintain the recommended

minimum distance “A” from the shaft bearing.

9. Insert the screws, with washers installed, in the unthreaded

holes in the bushing ange and align with the threaded holes

in the bushing backup plate. If necessary, rotate the bushing

backup plate to align with the bushing screws. Tighten the

screws lightly. If the reducer must be positioned closer than

dimension “A”, place the screws with washers installed, in the

unthreaded holes in the bushing before positioning reducer

making sure to maintain at least 1/8” between the screw

heads and the bearing.

10. Place the long bushing in position on the shaft and align the

bushing keyway with the shaft key. Use care to locate the

long bushing with the tapered bushing wedge installed earlier.

Align the unthreaded holes in the bushing with the threaded

holes in the bushing backup plate. If necessary, rotate the

bushing backup plate to align with the bushing holes. Insert

bushing screws, with washers installed in the unthreaded

holes in the bushing. Tighten screws lightly.

11. Alternately and evenly tighten the screws in the bushing

nearest the equipment to the recommended torque given in

Table 1. Repeat procedure on outer bushing.

A

Figure 2 - Minimum Recommended Dimensions

Figure 3 - Short Shaft Bushing and

Output Assembly

Figure 4 - Key Marking

AND MARKING