WARNING: Because of the possible danger to person(s) or property from accidents which may result

from the improper use of products, it is important that correct procedures be followed. Products must

be used in accordance with the engineering information specified in the catalog. Proper installation,

maintenance and operation procedures must be observed. The instructions in the instruction manuals

must be followed. Inspections should be made as necessary to assure safe operation under prevailing

conditions. Proper guards and other suitable safety devices or procedures as may be desirable or

as may be specified in safety codes should be provided, and are neither provided by Dodge nor are

the responsibility of Dodge. This unit and its associated equipment must be installed, adjusted and

maintained by qualified personnel who are familiar with the construction and operation of all equipment

in the system and the potential hazards involved. When risk to persons or property may be involved, a

holding device must be an integral part of the driven equipment beyond the speed reducer output shaft.

ASSEMBLY OF USAF, USDAF, SAFS & SAF-XT BEARINGS

These instructions must be read thoroughly before installation or operation. This instruction manual was

accurate at the time of printing. Please see dodgeindustrial.com for updated instruction manuals.

WARNING: To ensure the drive is not

unexpectedly started, turn off and lock-out

or tag power source before proceeding.

Failure to observe these precautions could

result in bodily injury.

WARNING: All products over 25 kg (55 lbs)

are noted on the shipping package. Proper

lifting practices are required for these

products.

1. Clean shaft. Slide V-ring seal on shaft with

lip toward bearing (for sizes up to 10 1/2”

bore only.)

2. Slide seal ring on the shaft with largest OD

toward bearing. For sizes larger than 10”

ER ring replaces V-ring and seal ring.

3. Position adapter sleeve on shaft, thread

outboard to approximate location with

respect to required centerline.

4. Coat OD of adapter sleeve with a light oil.

It will facilitate mounting.

5. Measure the internal clearance of the

bearing at the 12 o’clock position before

mounting, then position bearing on the

adapter sleeve. Locate bearing in proper

position on shaft.

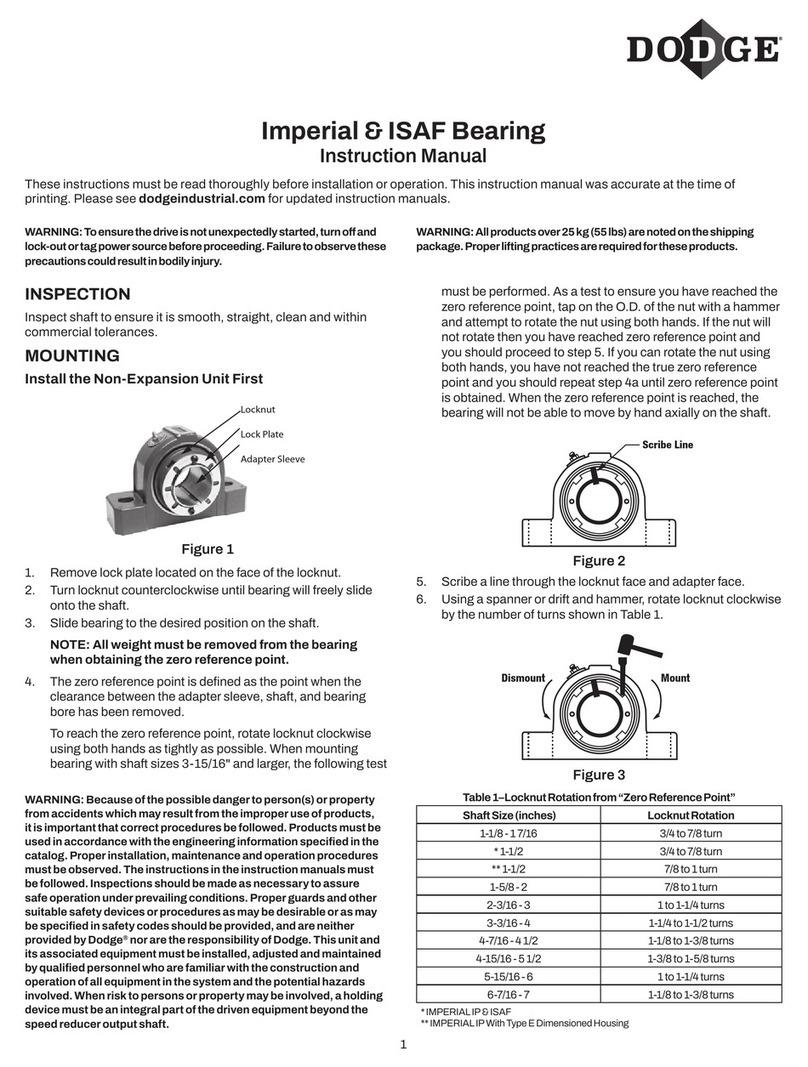

6. Install the lockwasher (8” and smaller

sizes only) on the adapter with inner prong

located in the slot and toward the bearing.

Install locknut, chamfered face toward

bearing.

7. Tighten locknut using a spanner wrench

and hammer or drift pin until clearance

measured in Step 5 is reduced by amount

shown in Table. While tightening, measure

clearance a the 6 o’clock position. During

this step, shaft must be supported so all

weight is off of the bearing.

8. Find a lockwasher tab that aligns with

a locknut slot and bend tab into slot. If

slot is past tab then tighten, not loosen,

locknut to meet a washer tab.

9. Sizes larger than 8” require a lockplate

bolted to the locknut with the inner prong

of the place located in the slot of the

adapter sleeve. If necessary, tighten, not

loosen, locknut to allow prong to t in

adapter slot.

10. Install a second seal ring with large OD

toward locknut*.

11. Slide second V-ring seal onto the shaft,

again making certain lip is toward bearing.

Do not install V-ring seal on seal ring until

housing cap has been set in place and

tightened. For sizes larger than 10” ER ring

replaced V-ring and seal ring.

12. Apply grease to the bearings and seal

rings. The lubricant should be packed

between the rolling elements. Pack the

lower half of the housing one-third (1/3) full

for high speed operation, one-half (1/2) full

for normal speed operation and 100% full

for slow speed operations.

13. Place shaft with bearing into lower half of

housing while carefully guiding the seal

rings into the housing grooves.

14. Bolt lower half of the non-expansion

bearing housing to the base. Move shaft

endwise so that stabilizing ring can be

inserted between the bearing outer ring

and the lower half shoulder on same side

as locknut. Make all other bearings on

the same shaft expansion by centering

in the middle of their housing seat. Bolt

expansion housing to base.

15. Grease the bearing seal grooves in the

housing cap and place over the bearing

after wiping the mating surfaces. The two

dowel pins will align the cap and the lower

housing half.

16. Tighten cap bolts or nuts to values

recommended by bolt manufacturers in

accordance with the bolt grade.

17. Assure that there is seal ring running

clearance then install V-ring seals onto the

seal rings. Make sure V-ring seal lip rides

against face of housing. Cover each V-ring

seal with a heavy coat of grease.

*If auxiliary seals are used, follow appropriate

instruction manual that accompanies auxiliary

seal.