60342 07/20 3

INDEX

GENERAL SAFETY RULES..................................................................................................5

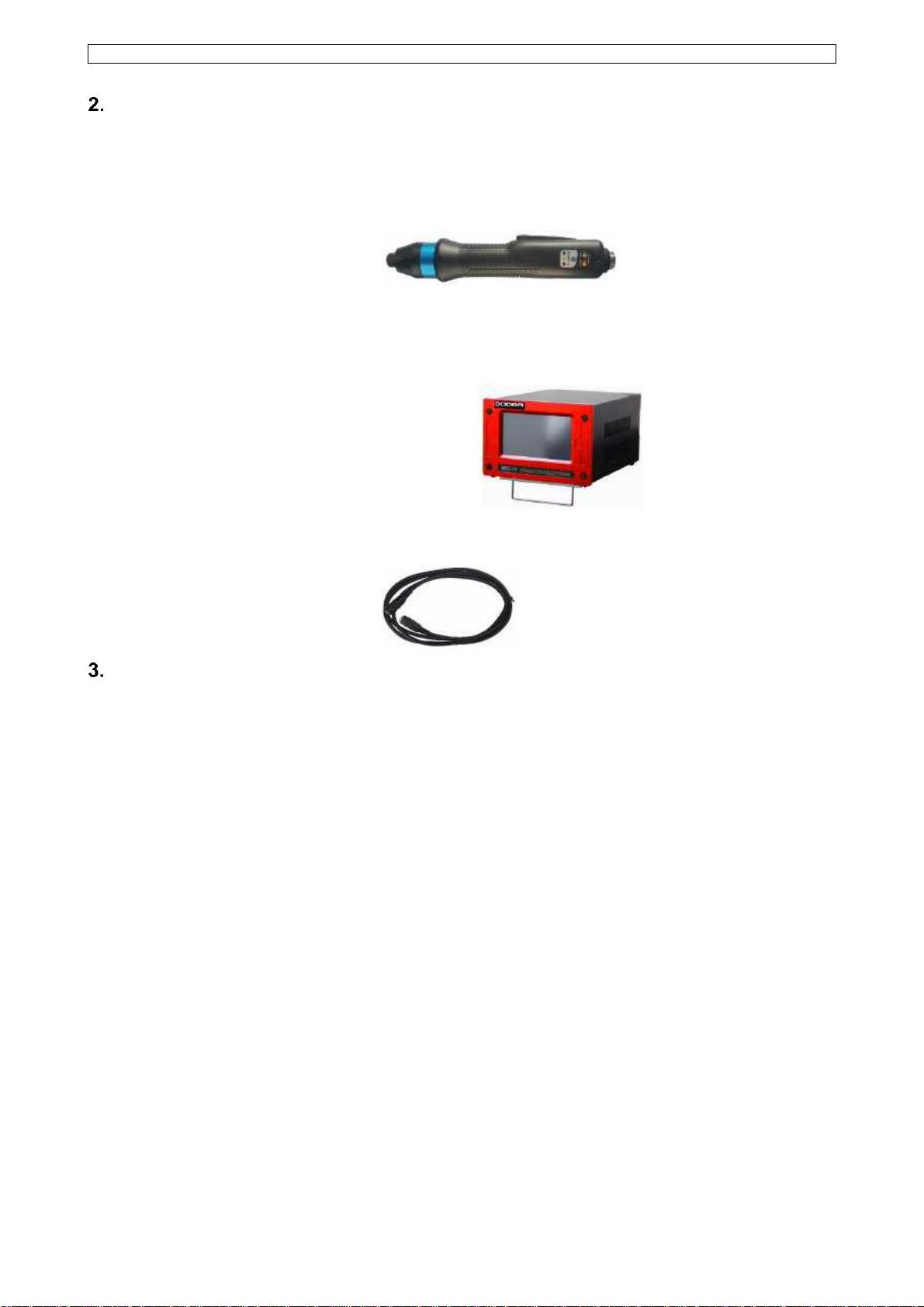

Product..................................................................................................................................7

Main features.........................................................................................................................7

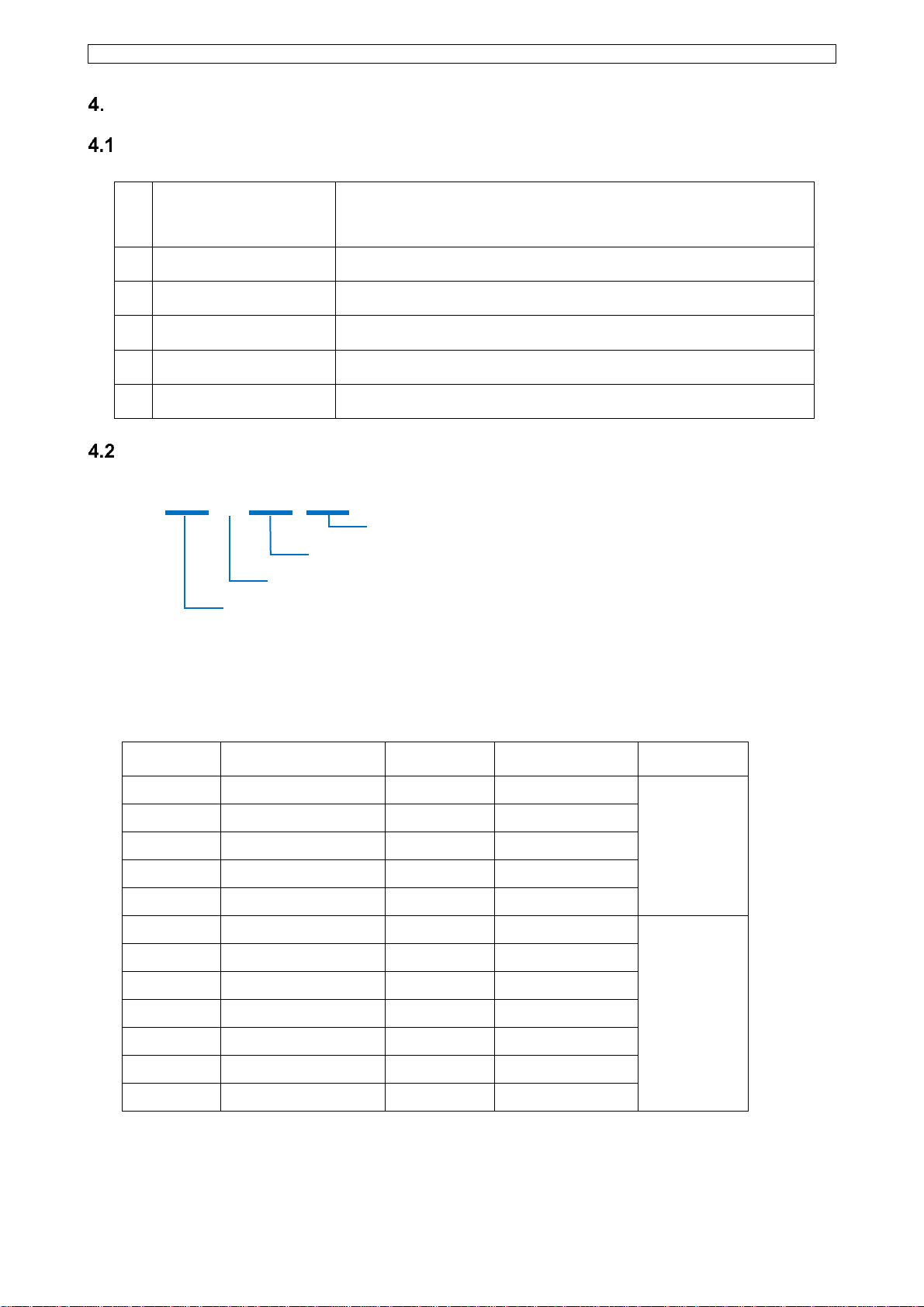

Screwdriver............................................................................................................................8

General specification ......................................................................................................8

Model specification.........................................................................................................8

Auto Speed by torque setting under the each test condition..........................................11

Screwdriver dimension..................................................................................................13

Screwdriver cables...............................................................................................................26

Models..........................................................................................................................26

Installation ....................................................................................................................27

Controller MDC v2 ...............................................................................................................28

Specification.................................................................................................................28

Model specification.......................................................................................................28

Controller dimension.....................................................................................................29

Operation.............................................................................................................................30

Getting started at first power on or after screwdriver change. .......................................30

Operation screen..........................................................................................................32

Rapid view Parameter screens.....................................................................................34

Presets or Model select ................................................................................................36

Parameters...................................................................................................................37

Fastening settings.........................................................................................................38

Advanced functions: .....................................................................................................41

7.7.1 Free reverse rotation before Fastening..................................................................41

7.7.2 Engaging Torque detection....................................................................................42

7.7.3 Angle after torque up .............................................................................................43

7.7.4 Thread tapping ......................................................................................................44

Multi Sequence settings................................................................................................45

Model settings...............................................................................................................46

Screw count settings.....................................................................................................48

Controller settings.........................................................................................................50

I/O settings ...................................................................................................................59

Network settings...........................................................................................................62

Monitoring.....................................................................................................................63

Remote control & Auto customizing..............................................................................65

Remote : Back up / Restore / Power Reset / Factory reset...........................................67

General Settings : Date / Storage / Options..................................................................68

General Settings : Barcode & Barcode Step.................................................................70

General Settings : SD memory card..............................................................................72

Firmware Upgrade...............................................................................................................73