Instructions manual / BTP

6

Do not store the machine and battery pack in locations

where the temperature may reach or exceed 50oC

(122oF).

Do not incinerate the battery pack even if it is severely

damaged or completely worn out. The battery pack can

explode in a fire.

Be careful not to drop, shake, or strike the battery.

Do not charge inside a box or container of any kind. The

battery must be placed in a well ventilated are during

charging.

Do not dispose of battery packs into household waste,

fire or water. Battery packs should be collected,

recycled or disposed of in an environmentally-friendly

manner. Call the authorized warranty centers for places

to dispose of damaged or inoperable batteries.

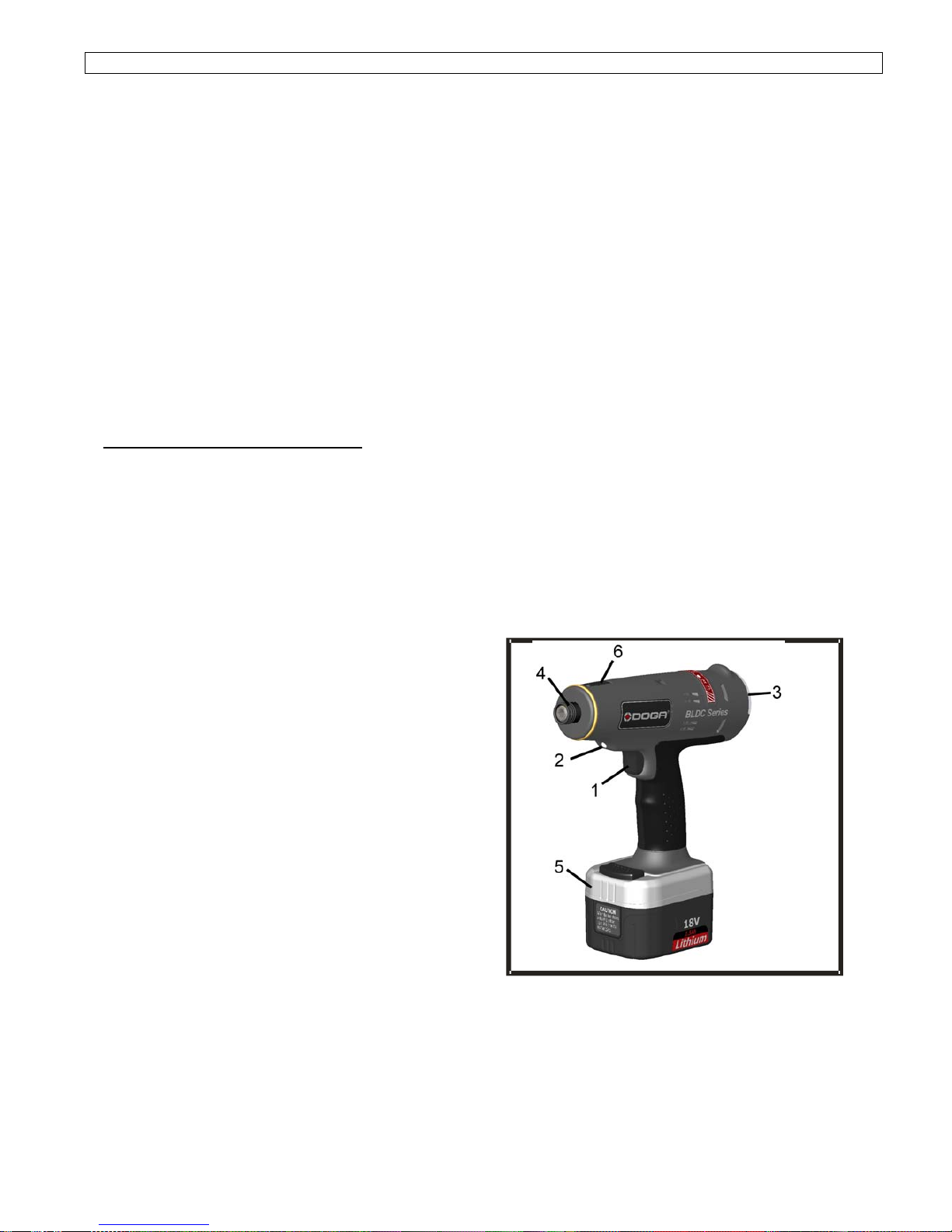

3. FUNCTIONAL DESCRIPTION

This industrial shut off screwdriver is designed for nut

tightening/loosening and screw driving/loosening. It is

not appropriate to use for wood/mild steel drilling.

Please refer to the figure on the page to familiarize

yourself with the major components of this tool before

use.

1. Power Switch

Depressing the power switch will energize the LED

light (2) in front and the tool starts to rotate. When

released, power to the motor will cease and the tool

stops to work immediately. But the LED light will

remain for 10 seconds then off.

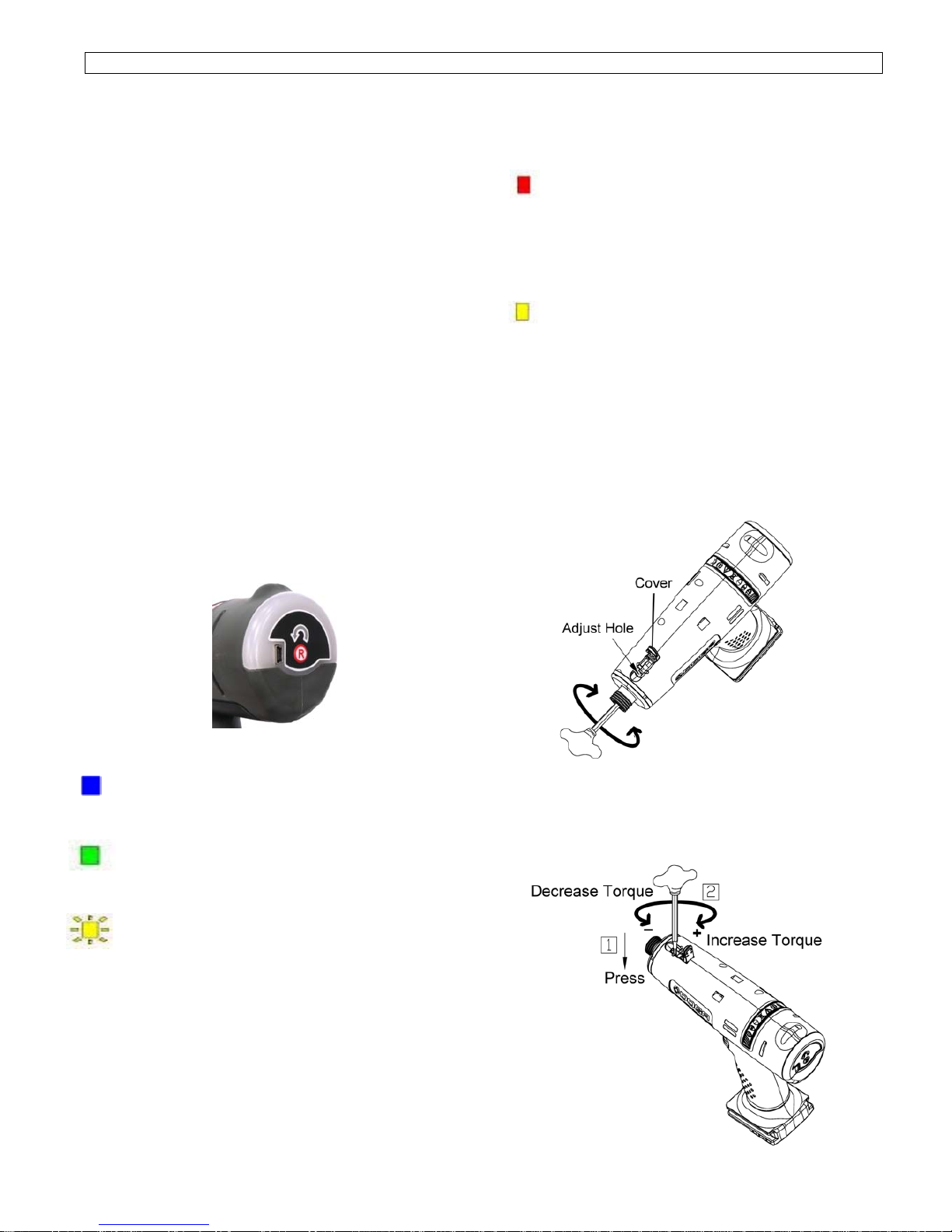

3. Forward/Reverse Button

The tool is always in forward operation unless the

Forward/Reverse button is pressed. When the

button is pressed, the blue LED shows and the

tool will be in reverse operation. To get the tool

back in forward operation, just simply press the

button again and the blue LED would disappear

and the tool is back in forward operation.

4. Quick Change Holder

This driver accepts only 1/4” (6.35mm) hexagonal

bits. Be sure the bit is fully engaged by the chuck

before operating tool. Otherwise, the bit may fly off

and cause property damage or personal injury.

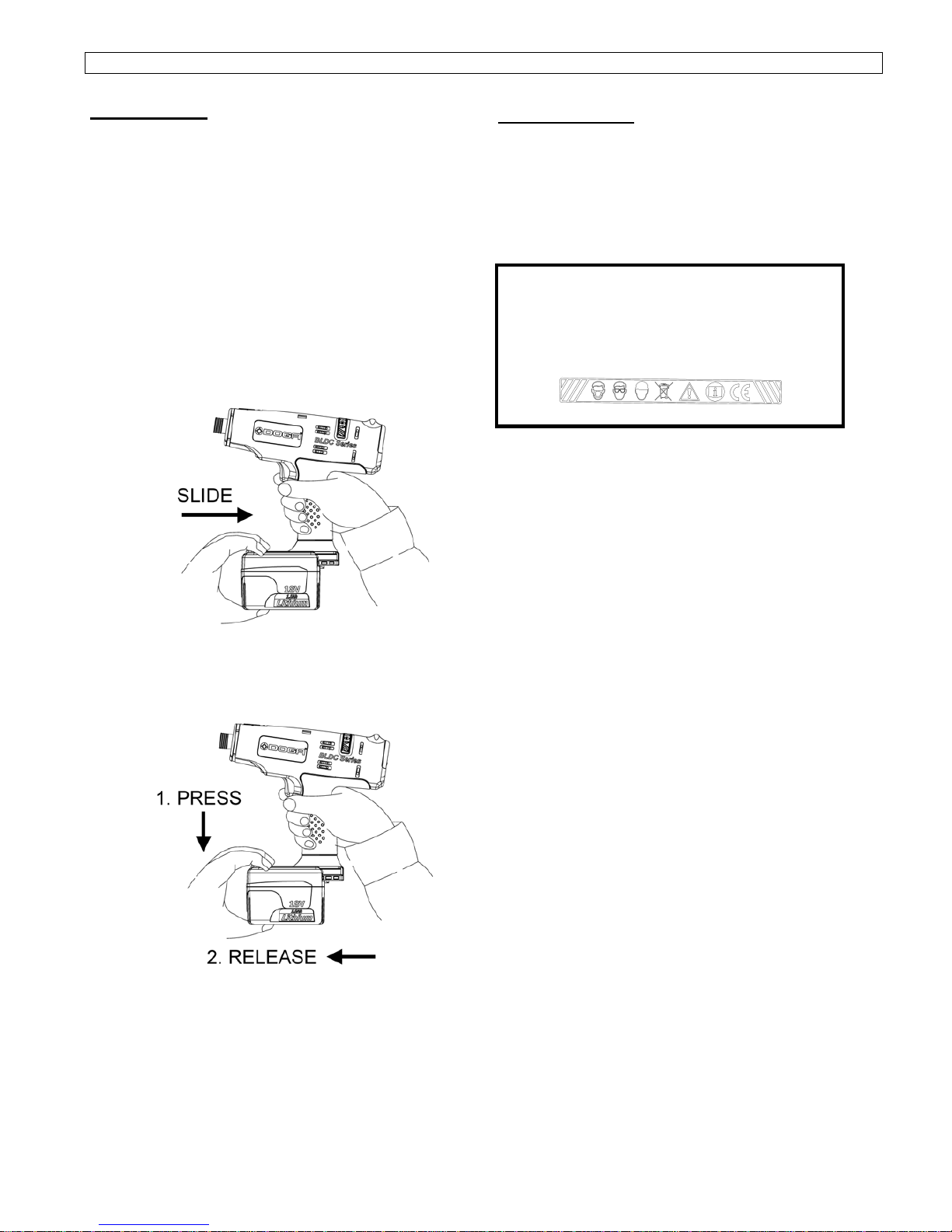

5. Li-ion Battery

This battery provides electrical power to the

motor. Please charge it according to the charging

instruction listed in this manual.

6. Torque Adjustment Cover

Open the torque adjustment cap. Use the torque

adjustment tool to either tighten or loosen the

spring until the desired torque is reached.

WARNING: Use the tool to either tighten or loosen

nuts and screws ONLY in stipulated torque and

voltage ranges.