SAFEMASTER W Radio controlled safety module UH 6900

0274164 / 13.03.17 en / RV_800 2

Contents

1Important Notes.............................................................................................5

1.1 General safety instructions............................................................................................5

1.2 Disposal.........................................................................................................................5

2Quick guide....................................................................................................6

2.1 Components list.............................................................................................................6

2.2 Configuration at delivery................................................................................................6

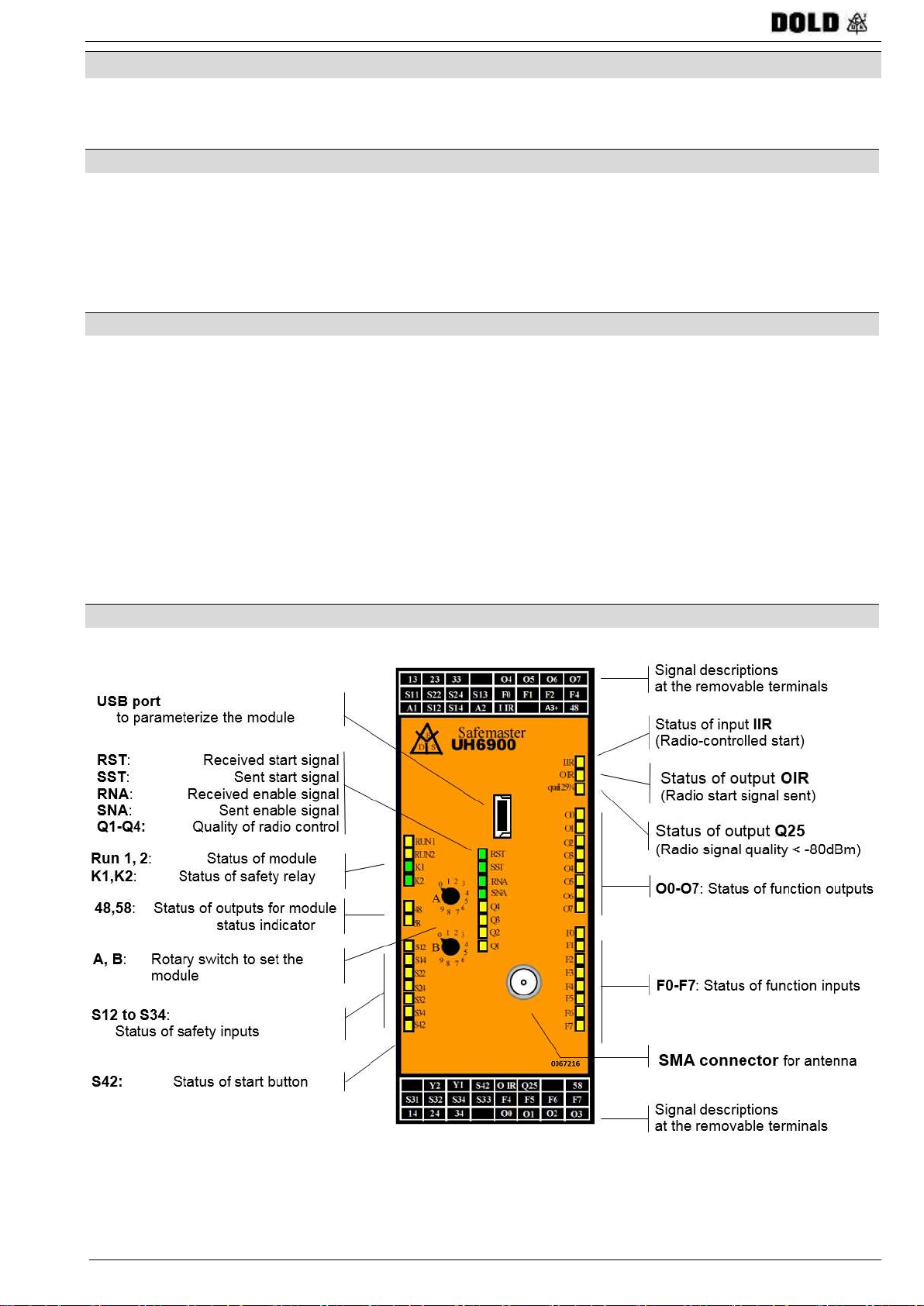

2.3 Front view UH 6900.......................................................................................................6

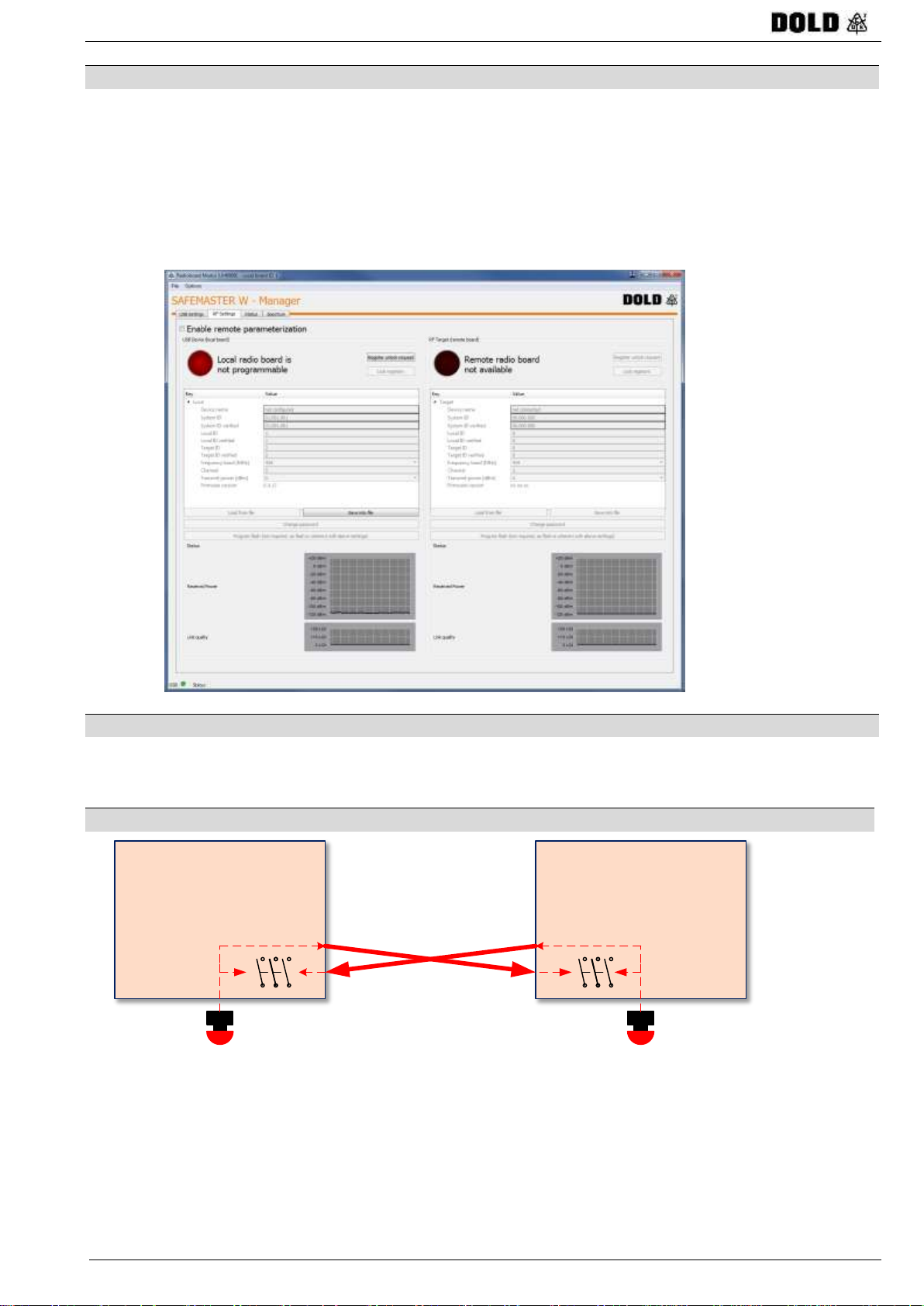

2.4 Installation SAFEMASTER W Manger...........................................................................7

2.5 Main operation modes...................................................................................................7

2.5.1 Full safety operation...............................................................................................7

2.5.2 Cross operation......................................................................................................8

2.5.3 Safety operation with optional radio control............................................................8

2.6 Connections and oprating modes..................................................................................9

2.7 Parameterization .........................................................................................................10

2.7.1 Frequency channel...............................................................................................11

2.7.2 Integrated spectrum analyzer...............................................................................12

2.7.3 Further adjustments .............................................................................................13

2.7.4 Programming........................................................................................................13

2.8 Power on and standby test..........................................................................................14

3Introduction of the system..........................................................................15

3.1 Directives, standards, and certification........................................................................15

3.2 Applications, intended use...........................................................................................15

3.3 Design .........................................................................................................................16

3.4 Functions.....................................................................................................................16

4System description......................................................................................17

4.1 Design and functions of the UH 6900 radio-controlled safety module.........................17

4.1.1 Main features of the UH 6900 radio-controlled safety module..............................17

4.1.2 Inputs and outputs................................................................................................18

4.1.3 Overview UH 6900 radio-controlled safety module; front view.............................18

4.1.4 Detection of safety elements................................................................................18

4.1.5 Start options.........................................................................................................19

4.1.5.1 Manual start and reset........................................................................................19

4.1.5.2 Auto start............................................................................................................19

4.1.5.3 Two-hand............................................................................................................19

4.1.5.4 Start via radio .....................................................................................................19

4.1.6 Semiconductor outputs.........................................................................................20

4.1.7 Assignment of function inputs to semiconductor outputs......................................20

4.1.8 Identity code.........................................................................................................20

4.1.9 Receiver antenna.................................................................................................20

4.1.10 Radio frequency...................................................................................................20

4.1.11 Transmitter power ................................................................................................20

5Installation and connection ........................................................................21

5.1 Important notes on installation and connection............................................................21

5.2 Wiring..........................................................................................................................21

5.3 Protection of power supply ..........................................................................................21

5.4 Positioning of the radio-controlled safety module and the antenna .............................22

5.4.1 Positioning of the radio-controlled safety module.................................................22

5.4.2 Distribution of radio signals ..................................................................................22

5.4.3 Positioning of antenna..........................................................................................22

5.5 Terminal connections of the radio-controlled safety module........................................23

5.6 Connection of safety elements ....................................................................................23

5.7 Installation / removal of the PS / PC terminals.............................................................24

5.8 Minimum and maximum output currents......................................................................24